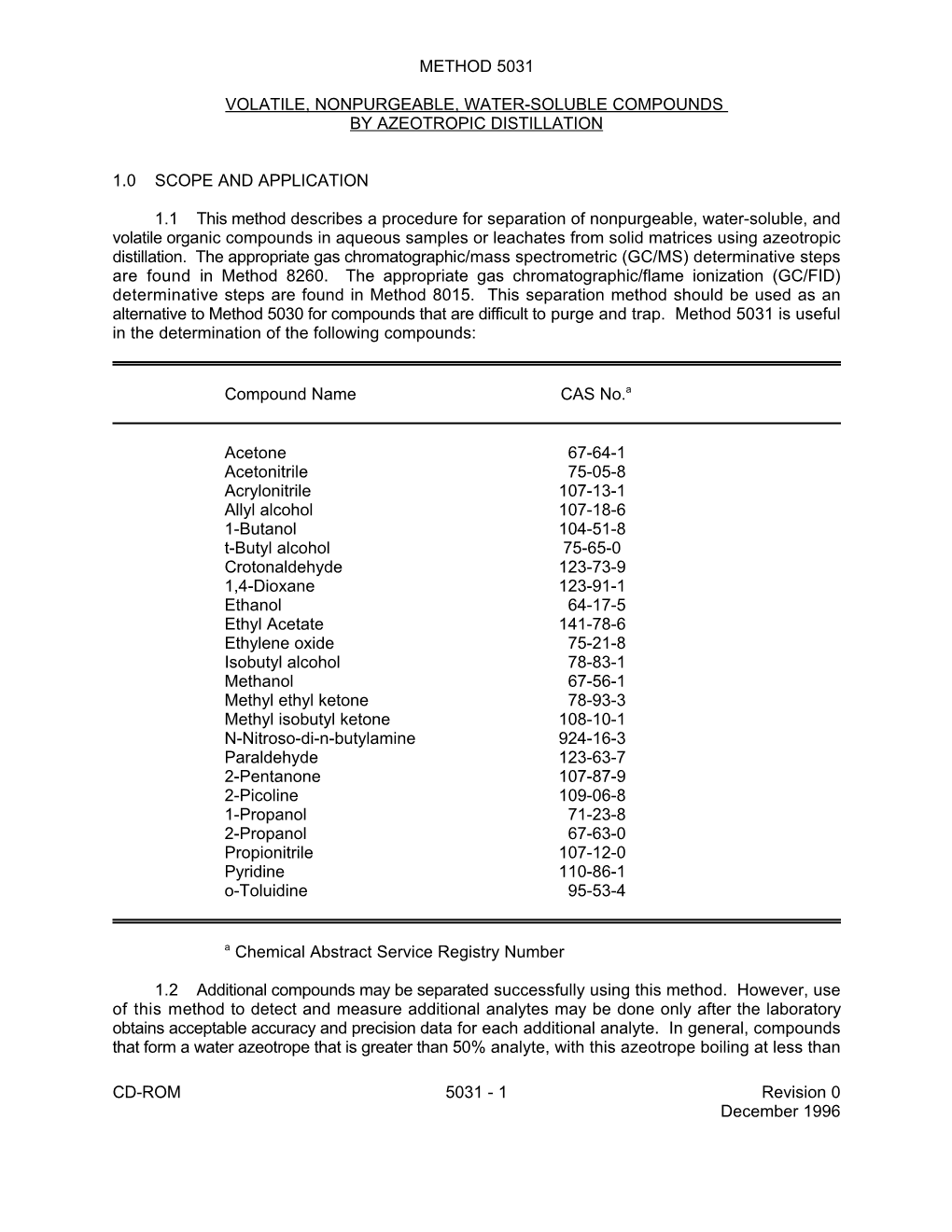

Method 5031: Volatile, Nonpurgeable, Water-Soluble

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Anesthetic Barbiturates in Refractory Status Epilepticus

LE JOURNAL CANADIEN DES SCIENCES NEUROLOGIQUES Anesthetic Barbiturates in Refractory Status Epilepticus G.B. YOUNG, W.T. BLUME, C.F. BOLTON and K.G. WARREN SUMMARY: Two patients with previous INTRODUCTION hours). With intubation and respiratory cerebral damage and seizures and three Generalized status epilepticus is a support an intravenous bolus of 250 mgms. patients with acute inflammatory cerebral medical emergency requiring prompt thiopental was given, followed by 80-120 lesions developed status epilepticus. They mgm/hr. as a continuous infusion for four treatment to prevent cerebral damage days. The seizures stopped promptly. A were unresponsive to standard anticon or death. Rapidly acting anticonvuls vulsants, but anesthetic barbiturates right-sided hemiparesis resolved over the (thiopental and pentobarbital) stopped the ants such as diazepam, phenytoin or next week and he returned home without seizures promptly. paraldehyde are usually effective. additional neurologicaldeficit. Neurology texts, review articles and Case J. A 41 year old woman developed monographs on epilepsy occasionally measles a week prior to the onset of mention anesthesia for resistant cases. delirium and convulsions. Multi-focal RESUME: Deux patients souffrant pre- Anesthetic barbiturates are less com clonic or grand mal seizures continued for alablement de lesion cerebrate et d'epilepsie two days. These were refractory to et trois patients avec lesions cerebrates de monly specified and their effectiveness is not well documented. We present intravenous phenytoin (a loading dose of nature . inflammatoire aigue developpent 1000 mgm intravenously followed by 200 un status epilepticus. Les patients ne five cases successfully treated with mgm every twelve hours), phenobarbital repondent pas a la medication anticon anesthetic barbiturates after conven (200 mgm intravenous bolus and 60 mgm vulsive standard mais I'emploi de barbitur- tional anticonvulsants failed. -

Review of Extractive Distillation. Process Design, Operation

Review of Extractive Distillation. Process design, operation optimization and control Vincent Gerbaud, Ivonne Rodríguez-Donis, Laszlo Hegely, Péter Láng, Ferenc Dénes, Xinqiang You To cite this version: Vincent Gerbaud, Ivonne Rodríguez-Donis, Laszlo Hegely, Péter Láng, Ferenc Dénes, et al.. Review of Extractive Distillation. Process design, operation optimization and control. Chemical Engineering Research and Design, Elsevier, 2019, 141, pp.229-271. 10.1016/j.cherd.2018.09.020. hal-02161920 HAL Id: hal-02161920 https://hal.archives-ouvertes.fr/hal-02161920 Submitted on 21 Jun 2019 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Open Archive Toulouse Archive Ouverte OATAO is an open access repository that collects the work of Toulouse researchers and makes it freely available over the web where possible This is an author’s version published in: http://oatao.univ-toulouse.fr/239894 Official URL: https://doi.org/10.1016/j.cherd.2018.09.020 To cite this version: Gerbaud, Vincent and Rodríguez-Donis, Ivonne and Hegely, Laszlo and Láng, Péter and Dénes, Ferenc and You, Xinqiang Review of Extractive Distillation. Process design, operation optimization and control. (2018) Chemical Engineering Research and Design, 141. -

Hydro-Distillation and Steam Distillation from Aromatic Plants

Hydro-distillation and steam distillation from aromatic plants Sudeep Tandon Scientist Chemical Engineering Division CIMAP, Lucknow HISTORY Written records of herbal distillation are found as early as the first century A.D., and around 1000 A.D., the noted Arab physician and naturalist Ibn Sina also known as Avicenna described the distillation of rose oil from rose petals The ancient Arabian people began to study the chemical properties of essential oils & developed and refined the distillation process Europeans began producing essential oils in the 12th century 1 DISTILLATION ? A process in which a liquid or vapour mixture of two or more substances is separated into its component fractions of desired purity, by the application and removal of heat. In simple terms distillation of aromatic herbs implies vaporizing or liberating the oils from the trichomes / plant cell membranes of the herb in presence of high temperature and moisture and then cooling the vapour mixture to separate out the oil from water. It is the most popular widely used and cost effective method in use today for producing majority of the essential oils throughout the world Distillation is an art and not just a “Chemical" process that is reliant upon many factors for successful quality oil production. BASIC SCIENTIFIC PRINCIPLES INVOLVED IN THE PROCESS To convert any liquid into a vapour we have to apply energy in form of heat called as latent heat of vaporization A liquid always boils at the temperature at which its vapour pressure equals the atmospheric / surrounding pressure For two immiscible liquids the total vapour pressure of the mixture is always equal to the sum of their partial pressures The composition of the mixture will be determined by the concentration of the individual components into its partial pressure As known the boiling point of most essential oil components exceeds that of water and generally lies between 150 – 300oC 2 If a sample of an essential oil having a component ‘A’ having boiling point for example 190oC and the boiling point of the water is 100oC. -

Chloral Hydrate and Paraldehyde As Drugs of Addiction

Sept., 1932J CHLORAL HYDRATE DRUG HABIT : CHOPRA & SINGH CHOPRA 481 certain parts of the Punjab. This is not the outcome of the use of the drug in the treatment Original Articles of insomnia, but is due to entirely different causes. Until a few years ago in that province potable country-made spirits were allowed to CHLORAL HYDRATE AND PARALDE' be sold to retail dealers in bulk and the vendors HYDE AS DRUGS OF ADDICTION bottled the liquor themselves. Some of these ingenious people conceived the idea of diluting R. N. m.d. By CHOPRA, m.a., (Cantab.) the spirit and adding small quantities of chloral I.M.S. LIEUTENANT-COLONEL, hydrate to make up for the loss in its potency and which would result from dilution. The know- GURBAKHSH SINGH CHOPRA, m.b., b.s. ledge that the drug had hypnotic and narcotic was obtained from the (Drug Addiction Inquiry, Indian Research Fund effects undoubtedly Association) medical profession and compounders work- in It was further learnt that Series No. 15 ing dispensaries. the effects chloral hydrate in many Chloral produced by hydrate and paraldehyde belong to resemble those by alcohol, the of ways produced group drugs known as soporifics or especially when the latter is taken in large The chief use of hypnotics. this class of drugs quantities. When the two articles are taken is in the treatment of one insomnia, of the together they act in a manner synergistic to worst evils of modern times from which man- each other and in this way the effect of either kind can suffer. -

Supercritical CO Extraction of Essential Oil from Clove

Supercritical CO2 Extraction of Essential Oil from Clove Bud: Effect of Operation Conditions on the Selective Isolation of Eugenol and Eugenyl Acetate Farshad Yazdani, Morteza Mafi, Fathollah Farhadi, Kourosh Tabar-Heidar, Kioumars Aghapoor, Farshid Mohsenzadeh, and Hossein Reza Darabi Chemistry & Chemical Engineering Research Center of Iran, P.O. Box 14335-186, Teheran, Iran Reprint requests to Dr. H. R. Darabi. E-mail: [email protected] Z. Naturforsch. 60b, 1197 – 1201 (2005); received July 14, 2005 The supercritical fluid extraction (SFE) of clove bud essential oil was studied using CO2 as sol- vent. The effect of operation conditions was analyzed in a series of experiments at temperatures between 325 and 416 K and pressures between 110 and 190 bar. The collected extracts were ana- lyzed and the relative composition of the essential oil was determined. The optimum condition was found in a temperature of 353 K and at a pressure of 190 bar, minimizing the number of extracts to two compounds (eugenol and eugenyl acetate). The extract obtained from clove bud by using su- percritical fluid extraction was compared with the essential oil obtained by steam distillation and microwave-assisted extraction by considering both quantity and quality of the product. The oil yield was higher in steam distillation and microwave oven extraction. In contrast, oil extracted by using SFE contained higher amount of eugenol and eugenyl acetate. Key words: Clove Bud, Eugenol, Extraction Introduction The high pressure is used for processes where to- Identification, extraction and preparation of clove tal extraction of a target compound is desired, since bud oil are gaining interest as its applications are most extractable compounds exhibit their maximum becoming widespread in different sectors like food, solubility in a supercritical solvent at higher pressures. -

INF.20/Rev.1

INF.20/Rev.1 Economic Commission for Europe Inland Transport Committee 17 January 2017 Working Party on the Transport of Dangerous Goods Joint Meeting of Experts on the Regulations annexed to the European Agreement concerning the International Carriage of Dangerous Goods by Inland Waterways (ADN) (ADN Safety Committee) Thirteenth session Geneva, 23 - 27 January 2017 Item 5 (b) of the provisional agenda Proposals for amendments to the Regulations annexed to ADN: other proposals Autonome Schutzsysteme Mitteilung von EBU, ESO und ERSTU Ausgangslage Zur 29. Sitzung des Sicherheitsausschusses sind zahlreiche Dokumente vorgelegt worden, die die Anforderungen an Explosionsgruppen für nicht-elektrische Geräte betreffen. Weil es aus Zeitgründen nicht möglich war, im ADN 2017 Änderungen vorzunehmen, hat sich der Sicherheitsausschuss darauf geeinigt, die Probleme in der ersten Phase durch multilaterale Abkommen zu regeln. Hierfür ist das Binnenschifffahrtsgewerbe dankbar. Allerdings verlangt die multilaterale Vereinbarung ADN / M 018 von denjenigen Schiffen, deren Zulassungszeugnis nach dem 31. Dezember 2018 erneuert werden muss, schon sehr bald Maßnahmen, die gründlicher Vorbereitung bedürfen. Aus diesem Grunde ist es erforderlich, sich mit einigen vom Schifffahrtsgewerbe aufgeworfenen Fragen rechtzeitig zu beschäftigen. Frage Im Protokoll der 29. Sitzung des Sicherheitsausschusses ADN/WP.15/AC.2/60 ist unter Ziffer 44. festgehalten worden, dass die informelle Arbeitsgruppe „Stoffe“ mittlerweile um die Prüfung verschiedener Sachverhalte gebeten worden ist. Wie weit sind diese Prüfungen gediehen ? Nachfrage zum Protokolls der 29. Sitzung Im Protokoll der 29. Sitzung des Sicherheitsausschusses ADN/WP.15/AC.2/60 ist unter Ziffer 44. – zweiter Unterpunkt - festgehalten worden, dass das Gewerbe die Arbeitsgruppe Stoffe mit einschlägigen Informationen versorgen müsse. Diese Formulierung des Protokolls bedarf der Nachfrage. -

Heterogeneous Azeotropic Distillation

PROSIMPLUS APPLICATION EXAMPLE HETEROGENEOUS AZEOTROPIC DISTILLATION EXAMPLE PURPOSE This example illustrates a high purity separation process of an azeotropic mixture (ethanol-water) through heterogeneous azeotropic distillation. This process includes distillation columns. Additionally these rigorous multi- stage separation modules are part of a recycling stream, demonstrating the efficiency of ProSimPlus convergence methods. Specifications are set on output streams in order to insure the required purity. This example illustrates the way to set "non-standard" specifications in the multi-stage separation modules. Three phase calculations (vapor-liquid- liquid) are done with the taken into account of possible liquid phase splitting. ACCESS Free-Internet Restricted to ProSim clients Restricted Confidential CORRESPONDING PROSIMPLUS FILE PSPS_EX_EN-Heterogeneous-Azeotropic-Distillation.pmp3 . Reader is reminded that this use case is only an example and should not be used for other purposes. Although this example is based on actual case it may not be considered as typical nor are the data used always the most accurate available. ProSim shall have no responsibility or liability for damages arising out of or related to the use of the results of calculations based on this example. Copyright © 2009 ProSim, Labège, France - All rights reserved www.prosim.net Heterogeneous azeotropic distillation Version: March, 2009 Page: 2 / 12 TABLE OF CONTENTS 1. PROCESS MODELING 3 1.1. Process description 3 1.2. Process flowsheet 5 1.3. Specifications 6 1.4. Components 6 1.5. Thermodynamic model 7 1.6. Operating conditions 7 1.7. "Hints and Tips" 9 2. RESULTS 9 2.1. Comments on results 9 2.2. Mass and energy balances 10 2.3. -

Distillation Accessscience from McgrawHill Education

6/19/2017 Distillation AccessScience from McGrawHill Education (http://www.accessscience.com/) Distillation Article by: King, C. Judson University of California, Berkeley, California. Last updated: 2014 DOI: https://doi.org/10.1036/10978542.201100 (https://doi.org/10.1036/10978542.201100) Content Hide Simple distillations Fractional distillation Vaporliquid equilibria Distillation pressure Molecular distillation Extractive and azeotropic distillation Enhancing energy efficiency Computational methods Stage efficiency Links to Primary Literature Additional Readings A method for separating homogeneous mixtures based upon equilibration of liquid and vapor phases. Substances that differ in volatility appear in different proportions in vapor and liquid phases at equilibrium with one another. Thus, vaporizing part of a volatile liquid produces vapor and liquid products that differ in composition. This outcome constitutes a separation among the components in the original liquid. Through appropriate configurations of repeated vaporliquid contactings, the degree of separation among components differing in volatility can be increased manyfold. See also: Phase equilibrium (/content/phaseequilibrium/505500) Distillation is by far the most common method of separation in the petroleum, natural gas, and petrochemical industries. Its many applications in other industries include air fractionation, solvent recovery and recycling, separation of light isotopes such as hydrogen and deuterium, and production of alcoholic beverages, flavors, fatty acids, and food oils. Simple distillations The two most elementary forms of distillation are a continuous equilibrium distillation and a simple batch distillation (Fig. 1). http://www.accessscience.com/content/distillation/201100 1/10 6/19/2017 Distillation AccessScience from McGrawHill Education Fig. 1 Simple distillations. (a) Continuous equilibrium distillation. -

124.210 Schedule IV — Substances Included. 1

1 CONTROLLED SUBSTANCES, §124.210 124.210 Schedule IV — substances included. 1. Schedule IV shall consist of the drugs and other substances, by whatever official name, common or usual name, chemical name, or brand name designated, listed in this section. 2. Narcotic drugs. Unless specifically excepted or unless listed in another schedule, any material, compound, mixture, or preparation containing any of the following narcotic drugs, or their salts calculated as the free anhydrous base or alkaloid, in limited quantities as set forth below: a. Not more than one milligram of difenoxin and not less than twenty-five micrograms of atropine sulfate per dosage unit. b. Dextropropoxyphene (alpha-(+)-4-dimethylamino-1,2-diphenyl-3-methyl-2- propionoxybutane). c. 2-[(dimethylamino)methyl]-1-(3-methoxyphenyl)cyclohexanol, its salts, optical and geometric isomers and salts of these isomers (including tramadol). 3. Depressants. Unless specifically excepted or unless listed in another schedule, any material, compound, mixture, or preparation which contains any quantity of the following substances, including its salts, isomers, and salts of isomers whenever the existence of such salts, isomers, and salts of isomers is possible within the specific chemical designation: a. Alprazolam. b. Barbital. c. Bromazepam. d. Camazepam. e. Carisoprodol. f. Chloral betaine. g. Chloral hydrate. h. Chlordiazepoxide. i. Clobazam. j. Clonazepam. k. Clorazepate. l. Clotiazepam. m. Cloxazolam. n. Delorazepam. o. Diazepam. p. Dichloralphenazone. q. Estazolam. r. Ethchlorvynol. s. Ethinamate. t. Ethyl Loflazepate. u. Fludiazepam. v. Flunitrazepam. w. Flurazepam. x. Halazepam. y. Haloxazolam. z. Ketazolam. aa. Loprazolam. ab. Lorazepam. ac. Lormetazepam. ad. Mebutamate. ae. Medazepam. af. Meprobamate. ag. Methohexital. ah. Methylphenobarbital (mephobarbital). -

Tissue Free Water Tritium Separation from Foodstuffs by Azeotropic Distillation

140 SK98K0361 21st RHDJasna podChopkom TISSUE FREE WATER TRITIUM SEPARATION FROM FOODSTUFFS BY AZEOTROPIC DISTILLATION Florentina Constantin, Ariadna Ciubotaru, DecebalPopa Inspectorate of Public Health of Bucharest, Romania 1. INTRODUCTION The actual tritium content in the environment is due to both natural production by cosmic ray interactions in the upper atmosphere and to varying amount of man- made tritium. Tritium, the radioactive isotope of hydrogen, is one of the most important radionuclide released to the environment during the normal operation of a typical nuclear power reactor. Tritiated water constitutes almost the entire radioactivity in liquid waste discharged to the environment from heavy water reactors. Therefore, monitoring tritium in air, precipitation, drinking water and vegetation is necessary for assessing the environmental impact of tritium releases in gaseous and liquid effluents from nuclear plants. The use for agricultural purposes of river water receiving releases of tritium, results in contamination of irrigated crops and then in the contamination of the food chain. ? Tritium is everywhere in living matter, has a long physical half-time (T= 12.26 y) and is known to follow protium pathways in biological material. Tritium in liquid or solid biota samples can not be easily determined quantitatively by any kind of nondestructive analysis because its beta radiation energy (E =18 keV) is so weak that the most part is absorbed in the sample. Therefore, most non-aqueous samples must be treated chemically or physically to be suitable for counting. The choice of preparation method will depend on the type of samples, number and quantities of samples to be processed and availability of measurement equipment. -

The Field Distillation of Peppermint Oil

:__ / C. OREGON COLLLCTlop Improvements in The Field Distillation of Peppermint Oil By A. D. HUGHES Professor of Mechanical Engineering Bulletin No. 31 August 1952 A Cooperative Research Project of the Engineering Experiment Station and the Agricultural Experiment Station. Engineering Experiment Station Oregon State College Corvallis THE Oregon State Engineering Experiment Station was established by act of the Board of Regents of Oregon State College on May 4, 1927. It is the purpose of the Station to serve the state in a manner broadly outlined by the following policy: (1)To stimulate and elevate engineering education by developing the research spirit in faculty and students. (2) To serve the industries,utilities, professional engi- neers, public departments, and engineering teachers by making investigations of interest to them. (3) To publish and distribute by bulletins, circulars, and technical articles in periodicals the results of such studies, sur- veys, tests, investigations, and research as will be of greatest benefit to the people of Oregon, and particularly to the state's industries, utilities, and professional engineers. To make available the results of the investigations con- ducted by the Station three types of publications are issued. These are: (1) Bulletins covering original investigations. (2) Circulars giving compilations of useful data (3) Reprints giving more general distribution to scientific papers or reports previously published elsewhere, as for exam- ple, in the proceedings of professional societies. Single copies of publications are sent free on request to residents of Oregon, to libraries, and to other experiment sta- tions exchanging publications.As long as available, additional copies, or copies to others, are sent at prices covering cost of printing. -

Comparison of Complete Extractive and Azeotropic Distillation Processes for Anhydrous Ethanol Production Using Aspen Plustm Simu

43 A publication of CHEMICAL ENGINEERING TRANSACTIONS VOL. 80, 2020 The Italian Association of Chemical Engineering Online at www.cetjournal.it Guest Editors: Eliseo Maria Ranzi, Rubens Maciel Filho Copyright © 2020, AIDIC Servizi S.r.l. DOI: 10.3303/CET2080008 ISBN 978-88-95608-78-5; ISSN 2283-9216 Comparison of Complete Extractive and Azeotropic Distillation Processes for Anhydrous Ethanol Production using Aspen PlusTM Simulator Nahieh T. Miranda*, Rubens Maciel Filho, Maria Regina Wolf Maciel Laboratory of Optimization, Design, and Advanced Control (LOPCA)/Laboratory of Development of Separation Processes (LDPS), School of Chemical Engineering, University of Campinas, Brazil. [email protected] Performance of the extractive and azeotropic distillation processes using ethylene glycol and cyclohexane as solvents, respectively, for anhydrous ethanol production, were investigated using 02 RadFrac columns each and solvent recycling streams via simulation in Aspen Plus™ Simulator. Both operate at 1 atm, and feed flow -1 rate equals to 100 kmol.h (ethanol – 0.896 and water – 0.104 in mole fractions at the azeotropic point). The NRTL-RK was the model used for extractive and azeotropic distillations. The anhydrous ethanol purity from top of the 1st column of the extractive distillation (22 stages) was 99.50 % (on a mole basis) and water with nd st 99.20 % of purity at the top of the 2 column. On the other hand, in the azeotropic distillation, the 1 column (30 stages) had a bottom product of anhydrous ethanol purity of 99.99 % and water with 99.99 % of purity in the 2nd column, also at the bottom. Both processes produced anhydrous ethanol with a high-grade purity required by the standard norms ASTM D4806, EN 15376, and ANP 36.