COE Control Seminar-11/01-2002- 2

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Duty Hybrid Electric Truck

Cranfield University JONG-KYU PARK MODELLING AND CONTROL OF A LIGHT- DUTY HYBRID ELECTRIC TRUCK School of Engineering MSc by research Thesis Cranfield University SCHOOL OF ENGINEERING MSc by Research THESIS Academic Year 2005-2006 JONG-KYU PARK MODELLING AND CONTROL OF A LIGHT- DUTY HYBRID ELECTRIC TRUCK Supervisor: Professor N.D. Vaughan September 2006 This thesis is submitted in partial fulfilment of the requirements for the degree of MSc by Research © Cranfield University, 2006. All rights reserved. No part of this publication may be reproduced without the written permission of the copyright holder. ABSTRACT This study is concentrated on modelling and developing the controller for the light-duty hybrid electric truck. The hybrid electric vehicle has advantages in fuel economy. However, there have been relatively few studies on commercial HEVs, whilst a considerable number of studies on the hybrid electric system have been conducted in the field of passenger cars. So the current status and the methodologies to develop the LD hybrid electric truck model have been studied through the literature review. The modelling process used in this study is divided into three major stages. The first stage is to determine the structure of the hybrid electric truck and define the hardware. The second is the component modelling using the AMESim simulation tool to develop a forward facing model. In order to complete the component modelling, the information and data were collected from various sources including references and ADVISOR. The third stage is concerned with the controller which was written in Simulink. This was run in a co-simulation with the AMESim vehicle model. -

Joining Forces an Electric Motor/Generator and Batter- Ies

HYBRID TECHNOLOGY Eaton’s parallel electric hybrid system. The vehicle’s diesel engine is coupled with Joining forces an electric motor/generator and batter- ies. It maintains a conventional drive- train architecture, such as Eaton’s Fuller UltraShift automated transmission, while A look at the work being done by OEMs and adding the ability to augment engine component suppliers to bring hydraulic and torque with electrical torque (Eaton photo). electric hybrid technology to on-highway trucks. are an inevitable by-product of burning by Michelle EauClaire hydrocarbon fuel. s a consumer, you can make fuel prices for nearly all of the vehicles used changes to your daily lifestyle in these applications is to improve their Electric and hydraulic Ain order to counteract the efficiency, and the best technology avail- There are two different kinds of effects of the rising fuel prices. Those able to do that today is hybrid technology. hybrids, electric and hydraulic. Electric options, however, don’t suit the obli- A hybrid powertrain system reduces hybrids more easily support other on- gations of commercial vehicle users. fuel consumption by blending the power board electronics and have a high energy Refuse has to be picked up, parcels generated by the internal combustion density — best suited to applications that need to be delivered, and the whole engine with power from other stored have a lot of cruising time because they scope of other services still need to be sources of energy on board. And of course, can support longer engine-off operation. provided, regardless of fuel prices. when you reduce fuel consumption, you Electric power is generated by the die- The only practical response to rising also reduce the polluting emissions that sel engine and through regenerative brak- 40 ■ OEM Off-Highway ■ March 2008 ing, which recovers power which would Glenn R. -

Design and Control Optimization of Hybrid Electric Vehicles: from Two-Wheel-Drive to All-Wheel-Drive Vehicles

Design and Control Optimization of Hybrid Electric Vehicles: from Two-Wheel-Drive to All-Wheel-Drive Vehicles by Ziheng Pan A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy (Mechanical Engineering) in The University of Michigan 2019 Doctoral Committee: Professor Huei Peng, Chair Dr. Tulga Ersal Professor Jessy Grizzle Professor Chinedum Okwudire Dr. Nikhil Ravi Ziheng Pan [email protected] ORCID iD: 0000-0002-9656-0138 © Ziheng Pan 2019 ACKNOWLEDGEMENTS I would like to express my sincerest gratitude to my advisor, Professor Huei Peng. Hi guidance, assistance, patience, encouragement, and continuous support have been of enormous crucial to my studies, research, and career development. Without his support, I would not be able to reach this most amazing journey thus far in my life. I would also like to thank my other committee members, Dr. Tulga Ersal, Professor Jessy Grizzle, Professor Chinedum Okwudire, and Dr. Nikhil Ravi, for their helpful advice and comments. I am indebted to the Department of Mechanical Engineering, the Rackham Graduate School, the US-China Clean Energy Research Center, and Robert Bosch LLC for the financial support for my graduate study. As a proud member of the Vehicle Dynamics Lab, I would like to first express my earnest gratitude to the lab alumni: Chiao-Ting Li, Changsun Ahn, Byung-joo Kim, and Xiaowu zhang, whose patient guidance helped me through my research practice. Great appreciation should go to my colleague in VDL for their help, discussion and all the good times we have had in the office: William Smith, Zhenzhong Jia, Huajie ding, Yalian Yang, Daofei Li, Yugong Luo, Diange Yang, Tianyou Guo, Ding Zhao, Baojin Wang, Steven Karamihas, Yuxiao Chen, Oguz Dagzi, Shaobing Xu, Su-Yang Shieh, Xianan Huang, Geunseob Oh, Nauman Sohani, Songan Zhang, Boqi Li, Xinpeng Wang, Minghan Zhu, and Siyuan Feng. -

A Survey on Through-The-Road Hybrid Electric Vehicles

Review A Survey on Through-the-Road Hybrid Electric Vehicles Gianfranco Rizzo 1 , Shayesteh Naghinajad 2 and Francesco Antonio Tiano 1,* and Matteo Marino 3 1 Department of Industrial Engineering, University of Salerno, 84084 Fisciano, Italy; [email protected] 2 Master Science, University of Tabriz, Tabriz 51368, Iran; [email protected] 3 eProInn S.r.l., 84084 Fisciano, Italy; [email protected] * Correspondence: [email protected] Received: 18 April 2020; Accepted: 21 May 2020; Published: 25 May 2020 Abstract: Hybrid Electric Vehicles (HEVs) can be divided into three categories according to how the two propulsion systems (the thermal and the electric ones) supply the driving torque to the vehicle. When the torque is supplied only by an electric propulsion system, while the heat engine takes care of generating the electricity needed to operate the system, it is called a hybrid-series. Conversely, when both propulsion systems provide torque, the vehicle is identified with parallel hybrid wording. Among the parallel hybrids there is a particular configuration called Through-the-Road (TTR). In this configuration, the two propulsion systems are not mechanically connected to each other, but it is precisely the road that allows hybrid propulsion. This architecture, dating back to the early twentieth century, is still used by several manufacturers and carries with it peculiar configurations and control methods. It is also a configuration that fits well with the transformation of conventional vehicles into a hybrid. The paper presents a survey of the TTR HEV solution, evidencing applications, potentialities and limits. Keywords: hybrid; hybridization; HEV; Through-the-Road; TTR; automotive; state-of-art; sustainable mobility 1. -

The Role of Powertrain Electrification in Achieving Deep Decarbonization

energies Article The Role of Powertrain Electrification in Achieving Deep Decarbonization in Road Freight Transport Juan C. González Palencia 1,* , Van Tuan Nguyen 1, Mikiya Araki 1 and Seiichi Shiga 2 1 Division of Mechanical Science and Technology, Graduate School of Science and Technology, Gunma University, 1-5-1 Tenjincho, Kiryu, Gunma 376-8515, Japan; [email protected] (V.T.N.); [email protected] (M.A.) 2 Division of Mechanical Science and Technology, Graduate School of Science and Technology, Gunma University, 29-1 Honcho, Ota, Gunma 373-0057, Japan; [email protected] * Correspondence: [email protected]; Tel.: +81-277-30-1516 Received: 14 April 2020; Accepted: 10 May 2020; Published: 13 May 2020 Abstract: Decarbonizing road freight transport is difficult due to its reliance on fossil fuel internal combustion engine vehicles (ICEVs). The role of powertrain electrification in achieving deep decarbonization in road freight transport was studied using a vehicle stock turnover model, focusing on Japan. Twelve vehicle types were considered; combining four powertrains, ICEV, hybrid electric vehicle (HEV), battery electric vehicle (BEV) and fuel cell electric vehicle (FCEV); and three vehicle size classes, normal, compact and mini-sized vehicles. A scenario-based approach was used; considering a Base scenario, and three alternative scenarios targeting powertrain electrification. Between 2012 and 2050, tank to wheel CO2 emissions decrease 42.8% in the Base scenario, due to the reduction of vehicle stock, the improvement of vehicle fuel consumption and the adoption of HEVs. Diffusion of FCEVs in normal vehicles and BEVs in compact and mini-sized vehicles achieves the largest tank to wheel CO2 emissions reductions, up to 44.6% compared with the 2050 baseline value. -

Zero-Emission Medium- and Heavy-Duty Truck Technology, Markets, and Policy Assessments for California

UC Office of the President ITS reports Title Zero-Emission Medium- and Heavy-duty Truck Technology, Markets, and Policy Assessments for California Permalink https://escholarship.org/uc/item/7n68r0q8 Authors Burke, Andrew, PhD Miller, Marshall, PhD Publication Date 2020 DOI 10.7922/G23776ZB eScholarship.org Powered by the California Digital Library University of California Zero-Emission Medium- and Heavy- duty Truck Technology, Markets, and Policy Assessments for California A Research Report from the University of California Institute of Transportation Studies Andrew Burke, Research Engineer, Institute of Transportation Studies, University of California, Davis Marshall Miller, Senior Development Engineer, Institute of Transportation Studies, University of California, Davis January 2020 REPORT No.: UC-ITS-2018-30 | DOI:10.7922/G23776ZB Technical Report Documentation Page 1. Report No. 2. Government Accession No. 3. Recipient’s Catalog No. UC-ITS-2018-30 N/A N/A 4. Title and Subtitle 5. Report Date Zero-Emission Medium- and Heavy-duty Truck Technology, Markets, and Policy January 2020 Assessments for California 6. Performing Organization Code ITS-Davis 7. Author(s) 8. Performing Organization Report No. Andrew Burke, PhD https://orcid.org/0000-0002-4245-0056 UCD-ITS-RR-20-07 Marshall Miller, PhD https://orcid.org/0000-0002-9105-3188 9. Performing Organization Name and Address 10. Work Unit No. Institute of Transportation Studies, Davis N/A 1605 Tilia Street 11. Contract or Grant No. Davis, CA 95616 UC-ITS-2018-30 12. Sponsoring Agency Name and Address 13. Type of Report and Period Covered The University of California Institute of Transportation Studies Final Report (January 2018 – December www.ucits.org 2018) 14. -

LOW CARBON PATHWAYS Concawe DEEP DIVE on HEAVY-DUTY TRANSPORTATION SECTOR

Revised final meeting presentation Prepared for LOW CARBON PATHWAYS Concawe DEEP DIVE ON HEAVY-DUTY TRANSPORTATION SECTOR Aachen, 28th of June 2019 FEV Consulting GmbH © by FEV – all rights reserved. Confidential – no passing on to third parties Agenda Executive summary Framework and long-term scenarios for HD on-road transportation Technology options towards 2050 Future pathways towards clean on-road transportation Reduced GHG emissions with holistic technology strategies CO2 abatement costs for selected reference trucks TCO performance of underlying reference trucks Life-cycle analysis for HD trucks FEV Consulting, March 28th 2019 © by FEV – all rights reserved. Confidential – no passing on to third parties | 2 Executive summary CO2 emission reduction of heavy-duty trucks by 80% requires serious actions of authorities, operators, OEMs and energy companies EXECUTIVE SUMMARY FEV’s analysis of low carbon pathways in the EU transportation sector shows that CO2 reduction targets of 80% and above (vs. 1990) can be achieved; high efforts of regulatory bodies, logistics companies, OEMs, energy producers and providers are required Authorities should involve all key stakeholders and (jointly) define long-term boundary conditions driving infrastructural investments and technology decisions (e.g. well-to-wheel vs. tank-to-wheel; CO2 based taxation; standards for e-fuel / blends) Logistics companies, operators and technology providers should enable efficient solutions of transportation resulting in increased utilization of trucks; a holistic approach is the baseline to counteract implications of growing freight demand throughout 2050 OEMs should develop and implement efficient glider and powertrain technologies: aerodynamics, weight and rolling resistance reduction and automation on glider side; efficient ICEs (incl. -

Analysis of Class 8 Hybrid-Electric Truck Technologies Using Diesel, LNG, Electricity, and Hydrogen, As the Fuel for Various Applications

EVS27 Barcelona, Spain, November 17-20, 2013 Analysis of Class 8 Hybrid-Electric Truck Technologies Using Diesel, LNG, Electricity, and Hydrogen, as the Fuel for Various Applications Hengbing Zhao, Andrew Burke, Lin Zhu Institute of Transportation Studies, University of California, Davis California 95616 USA Abstract Class 8 trucks using various powertrains and alternative fuel options have been analysed to determine their fuel economy, greenhouse gas emissions, and economic attractiveness at the present time (2013) and in the future. This was done by modelling the vehicles and simulating their operation on day, short haul, and long haul driving cycles. The economic attractive was determined by calculating the differential vehicle cost of each powertrain option and the corresponding breakeven alternative fuel price needed to recover the additional cost in a specified payback period with a fixed discount rate. The baseline vehicle was a diesel engine truck of the same weight and road load using $4/gallon diesel fuel. The use of some of the powertrains resulted in an energy saving and others resulted in higher energy consumption, but compared to the conventional Class 8 diesel trucks, conventional LNG-CI trucks, LNG-SI and LNG-CI hybrids, battery electric trucks, and fuel cell trucks can reduce CO2 emission by 24-39% over the day drive cycle and 12-29% over the short haul and the long haul drive cycles. The breakeven fuel price was calculated for all the powertrain/fuel options. The economic results indicate that at “today’s” differential vehicle costs, none of the alternative powertrains/fuels are economically attractive except for the LNG-CI engine in the long-haul application (VMT=150,000 miles) for which the DGE cost is $2.98/DGE and the LNG cost is $1.70/LNG gallon. -

Fedex Express Gasoline Hybrid Electric Delivery Truck Evaluation: 12-Month Report

FedEx Express Gasoline Hybrid Electric Delivery Truck Evaluation: 12-Month Report R. Barnitt NREL is a national laboratory of the U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, operated by the Alliance for Sustainable Energy, LLC. Technical Report NREL/TP-5400-48896 January 2011 Contract No. DE-AC36-08GO28308 FedEx Express Gasoline Hybrid Electric Delivery Truck Evaluation: 12-Month Report R. Barnitt Prepared under Task No. FC08.3000 NREL is a national laboratory of the U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, operated by the Alliance for Sustainable Energy, LLC. National Renewable Energy Laboratory Technical Report 1617 Cole Boulevard NREL/TP-5400-48896 Golden, Colorado 80401 January 2011 303-275-3000 • www.nrel.gov Contract No. DE-AC36-08GO28308 NOTICE This report was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or any agency thereof. Available electronically at http://www.osti.gov/bridge Available for a processing fee to U.S. -

CARB Heavy-Duty Low Nox Omnibus Rulemaking Public Workshop

MarchCARB 2019 Heavy-Duty Low NOx Omnibus Rulemaking Public Workshop September 26, 2019 Naveen Berry, Assistant DEO, Office of Technology Advancement 20 min increments Cancer Risk Assessment – Diesel Exhaust 2005 2012 NOx Reductions Needed 250 Heavy-Duty Diesel Trucks 200 Off-Road Mobile 45-55% Equipment Ocean Going Vessels Tons/day 150 2023 Locomotives Cars/Light-Duty Trucks/SUVs NOx Tons/Day NOx 100 Aircraft 2032 RECLAIM Commercial Manufacturing Harbor Craft and Industrial Residential Fuel 50 Combustion Service and Medium-Duty Buses Commercial Trucks Recreational Boats Other 0 4 2018 Annual Enforcement Report, June 2019 IHS/Polk Data - CA Heavy Duty Trucks (Aggregate) 3500 3000 These trucks will be replaced mostly with 2010+ trucks that subject high low load emissions!!! 2500 2000 1500 1000 500 0 In-Use Emissions Still Need to be Addressed2 • Modification to CARB proposed HDIUT and new LLC will help address high in-use emissions from low load/idle operation • But timing? UCR Source: CARB White Paper Source: Johnson et al (2015, 2018, 2019), “Ultra-Low NOx Near- Zero Natural Gas Vehicle Evaluation“, Final Reports to SCAQMD Current Proposal Not Stringent Enough for 2023 Goal 2023 ozone attainment? Source: CARB White Paper Natural Gas Nero Zero Technology Proven Successful Past and on-going • HD: CWI 9-liter (L9N) and 12-liter (ISX12N) certified at 0.02g-NOx/bhp-hr − Commercialized in Class 7-8 trucks, including heavy duty trucks and buses • Medium Duty: CNG and LPG conversions certified to 0.02 g-NOx/bhp-hr (Additional engine certifications -

Control System Development for an Advanced-Technology Medium-Duty Hybrid Electric Truck

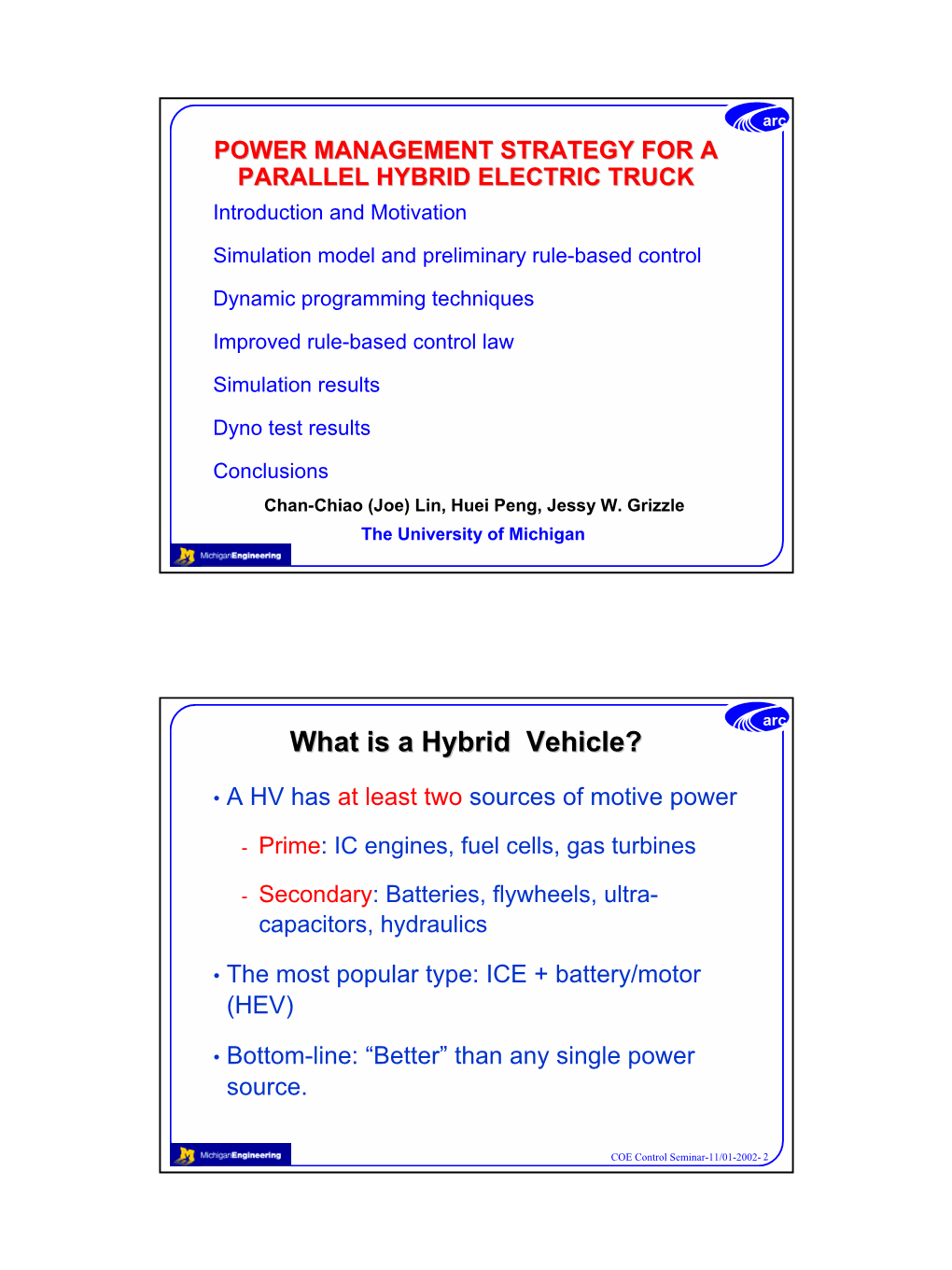

International Truck & Bus Meeting & Exhibition, Fort Worth, TX, November 2003. 2003-01-3369 Control System Development for an Advanced-Technology Medium-Duty Hybrid Electric Truck Chan-Chiao Lin, Huei Peng and Jessy W. Grizzle University of Michigan Jason Liu and Matt Busdiecker Eaton Corporation Copyright © 2003 SAE International ABSTRACT traction motor, Lithium-Ion batteries, an automatic clutch, and an automated manual transmission system. The power management control system development The motor is directly linked between the output of the and vehicle test results for a medium-duty hybrid electric master clutch and the input to the transmission. This truck are reported in this paper. The design procedure architecture provides the regenerative braking during adopted is a model-based approach, and is based on deceleration and allows efficient motor assist and the dynamic programming technique. A vehicle model is recharge operations by the engine. first developed, and the optimal control actions to maximize fuel economy are then obtained by the The control of hybrid powertrains is more complicated dynamic programming method. A near-optimal control than the control of ICE-only powertrain. First, one needs strategy is subsequently extracted and implemented to determine the optimal operating mode among five using a rapid-prototyping control development system, possible modes (motor only, engine only, power assist, which provides a convenient environment to adjust the recharge, and regenerative). Furthermore, when the control algorithms and accommodate various I/O power assist mode or the recharge mode is selected, the configurations. Dynamometer-testing results confirm engine power, motor power and transmission gear ratio that the proposed algorithm helps the prototype hybrid need to be selected to achieve optimal fuel economy, truck to achieve a 45% fuel economy improvement on emissions reduction, charge balance, and drivability. -

Review and Analysis of Potential Safety Impacts of and Regulatory

DOT HS 812 159 June 2015 Review and Analysis of Potential Safety Impacts of and Regulatory Barriers to Fuel Efficiency Technologies and Alternative Fuels In Medium- and Heavy-Duty Vehicles DISCLAIMER This publication is distributed by the U.S. Department of Transportation, National Highway Traffic Safety Administration, in the interest of information exchange. The opinions, findings, and conclusions expressed in this publication are those of the authors and not necessarily those of the Department of Transportation or the National Highway Traffic Safety Administration. The content is not intended to be used for determination of federal grant programs. The United States Government assumes no liability for its contents or use thereof. If trade or manufacturers’ names or products are mentioned, it is because they are considered essential to the object of the publication and should not be construed as an endorsement. The United States Government does not endorse products or manufacturers. Suggested APA Format Citation: Brecher, A., Epstein, A. K., & Breck, A. (2015, June). Review and analysis of potential safety impacts of and regulatory barriers to fuel efficiency technologies and alternative fuels in medium- and heavy-duty vehicles. (Report No. DOT HS 812 159). Washington, DC: National Highway Traffic Safety Administration. TECHNICAL REPORT DOCUMENTATION PAGE 1. Report No. 2. Government Accession No. 3. Recipient's Catalog No. DOT HS 812 159 4. Title and Subtitle 5. Report Date Review and Analysis of Potential Safety Impacts of and Regulatory June 2015 Barriers to Fuel Efficiency Technologies and Alternative Fuels in 6. Performing Organization Code Medium- and Heavy-Duty Vehicles 7. Author(s) 8.