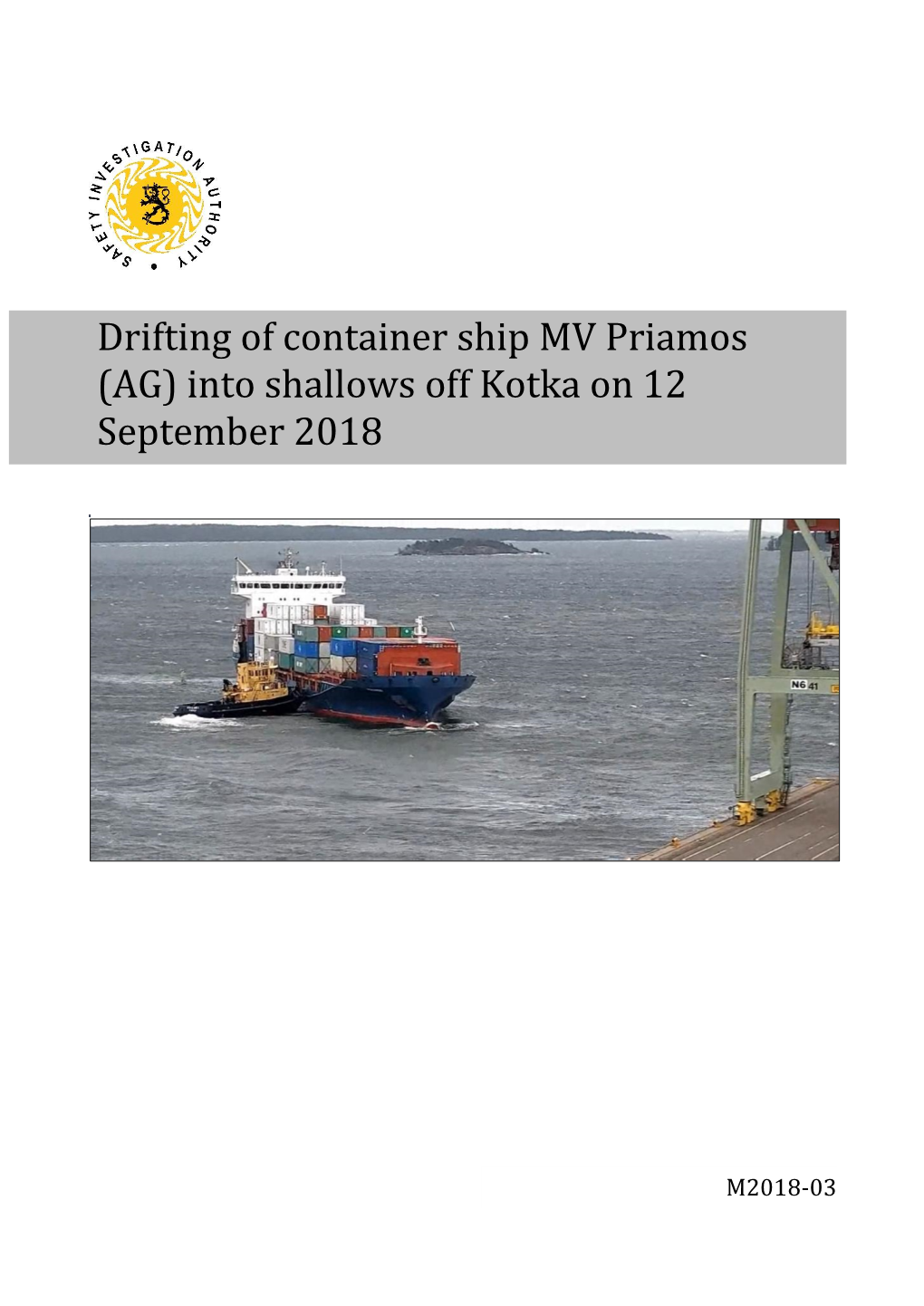

Drifting of Container Ship MV Priamos (AG) Into Shallows Off Kotka on 12 September 2018

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Distortion and Faults Detection in Shipboard AC/DC Power Distribution System

Faculty of Civil and Industrial Engineering Dottorato di Ricerca in Ingegneria dei Materiali e delle Nanotecnologie (EMNE) XXXI CICLO Distortion and faults detection in shipboard AC/DC power distribution system Tutor: Candidate: Prof. Regina Lamedica Ing. Alessandro Ruvio Reviewers: Prof. Massimo Ceraolo Prof. Giorgio Sulligoi Summary Acronyms ........................................................................................................................................... 5 Introduction ........................................................................................................................................ 7 Chapter I: Overview of Electrical Maritime Systems ...................................................................... 10 1.1 Electrical Propulsion System in Ships ................................................................................... 10 1.2 Electric Propulsion – Historical overview.............................................................................. 12 1.3 Naval Classification ............................................................................................................... 14 1.3.1 Field of use ...................................................................................................................... 14 1.3.2 On-Board Power .............................................................................................................. 16 1.4 Electrical Generation On Board ............................................................................................ -

Deliverable D2.2 New Models Library, Used for Innovative Ship

Grant Agreement No266082 Start date: 01/05/2011 – Duration: 55 months Coordinator: UNEW, Prof. A.P. ROSKILLY Deliverable D2.2 New Models Library, used for Innovative Ship Design WP2 “Energy Balance Analyse” Hans van Vugt Walter van der Pennen Author(s): Tom Bradley Jonathan Heslop Lisa Smeaton Reviewer(s): Tony Roskilly Identifier: D2.2_INOMANSHIP_M31_V1 Dissemination level: PU Contractual date: 30th November 2013 Actual date: 6th December 2013 Number of pages: 127 Summary This document presents the work of Task 2.3, the modelling of all energy relevant components. Deliverable D2.2 discusses in detail the development of models for simulation the state-of-the-art energy technologies and necessary ship systems to evaluate the potential the implementation of the appropriate technologies on-board a reference cargo ship. The models shall be incorporated in the simulation tool libraries for use in other tasks and work packages to evaluate and demonstrate the different potential of the new energy systems’ configurations, which will be developed as part of this project. This report provides the arithmetic methods used to create a selection of the novel energy technologies, as described in detail in Deliverable D3.1, needed to develop and evaluate the new on-board electrical systems’ configurations and power management strategies to be later developed as part of this project. In addition, this report discuss further the modelling of the reference ship’s components and global modelling environment, which are expanded with code necessary to have an overview of all the information that is needed for work in subsequent work packages. Approved by Coordinator Date: 6/12/2013 Dissemination Levels PU Public PP Restricted to other programme participants (including the Commission Services). -

Naval Accidents 1945-1988, Neptune Papers No. 3

-- Neptune Papers -- Neptune Paper No. 3: Naval Accidents 1945 - 1988 by William M. Arkin and Joshua Handler Greenpeace/Institute for Policy Studies Washington, D.C. June 1989 Neptune Paper No. 3: Naval Accidents 1945-1988 Table of Contents Introduction ................................................................................................................................... 1 Overview ........................................................................................................................................ 2 Nuclear Weapons Accidents......................................................................................................... 3 Nuclear Reactor Accidents ........................................................................................................... 7 Submarine Accidents .................................................................................................................... 9 Dangers of Routine Naval Operations....................................................................................... 12 Chronology of Naval Accidents: 1945 - 1988........................................................................... 16 Appendix A: Sources and Acknowledgements........................................................................ 73 Appendix B: U.S. Ship Type Abbreviations ............................................................................ 76 Table 1: Number of Ships by Type Involved in Accidents, 1945 - 1988................................ 78 Table 2: Naval Accidents by Type -

POPE MARINE Inc. Naval Architects / Marine Surveyors / Appraisers

POPE MARINE Inc. Naval Architects / Marine Surveyors / Appraisers 1015 Central Avenue , Suite 211 Telephone : (504) 415-3083 Metairie, LA 70001 Fax : (504) 779-1610 Email : [email protected] HULL - MACHINERY – APPRAISALS MEMBERS: SOCIETY OF ACCREDITED MARINE SURVEYORS SOCIETY OF NAVAL ARCHITECTS AND MARINE ENGINEERS REF # 16-038b MAY 14th, 2016 This is to certify that at the request of Mr. John Hewitt, of Global Energy Development PLC., the undersigned marine surveyor attended the: ”MYSTIC VIKING” (Owner : Everest Hill Marine Ltd.) the vessel was surveyed while at afloat at Hope Services Dock, Dulac, Louisiana on May 11-12 2016, for the purpose of conducting a general “Condition Survey” in order to determine the vessel’s overall condition and physical characteristics. GENERAL PARTICULARS OF THE VESSEL The DP vessel, Mystic Viking was built in 1983 as a supply vessel and converted to a Diving Offshore Construction Vessel. Mystic Viking has been classed by DNV with the following Notations 1A1 ICE-C Supply Vessel HELDK E0 DYNPOS-AUTR (1993) which is an IMCA DP2 class equivalent. Vessel Name : MYSTIC VIKING Previous Name : Bergen Viking (2001), Veslik Viking (1996), Highland Challenger (1990), Offshore Challenger (1989), Balder Challenger (1988), Owners : Everest Hill Marine Ltd. Call Sign : C6HC5 Flag Sate : Bahamas I.M.O. No. : 8209377 Class : DNV-GL Class Notation : A1, Supply Vessel, DYNPOS(AUTR), E0, HELDK, Ice (C) Class ID No. : 18155 Port of Registry : Nassau Built : 1983 / Marystown Shipyard Ltd., Newfoundland , Canada Converted -

Heavy Weather Damage to the Anthem of the Seas

THE COMMONWEALTH OF THE BAHAMAS ANTHEM OF THE SEAS IMO Number: 9656101 Official Number: 7000686 Report of the marine safety investigation into a heavy weather incident on 7th & 8th February 2016 Anthem of the Seas – Marine Safety Investigation Report The Bahamas conducts marine safety or other investigations on ships flying the flag of the Commonwealth of the Bahamas in accordance with the obligations set forth in International Conventions to which The Bahamas is a Party. In accordance with the IMO Casualty Investigation Code, mandated by the International Convention for the Safety of Life at Sea (SOLAS) Regulation XI-1/6, investigations have the objective of preventing marine casualties and marine incidents in the future and do not seek to apportion blame or determine liability. It should be noted that the Bahamas Merchant Shipping Act, Para 170 (2) requires officers of a ship involved in an accident to answer an Inspector’s questions fully and truly. If the contents of a report were subsequently submitted as evidence in court proceedings relating to an accident this could offend the principle that a person cannot be required to give evidence against themselves. The Bahamas Maritime Authority makes this report available to any interested individuals, organizations, agencies or States on the strict understanding that it will not be used as evidence in any legal proceedings anywhere in the world. You must re-use it accurately and not in a misleading context. Any material used must contain the title of the source publication. Date of Issue: 19th February 2020 Bahamas Maritime Authority 120 Old Broad Street LONDON EC2N 1AR United Kingdom THE BAHAMAS MARITIME AUTHORITY Anthem of the Seas – Marine Safety Investigation Report CONTENTS 1. -

Vintersjöfartsforskning

STYRELSEN FÖR VINTERSJÖFARTSFORSKNING WINTER NAVIGATION RESEARCH BOARD Research Report No 57 Risto Jalonen, Kaj Riska, Samuli Hänninen A PRELIMINARY RISK ANALYSIS OF WINTER NAVIGATION IN THE BALTIC SEA Sjöfartsverket Sjöfartsverket Finland Sverige Finnish Maritime Administration Swedish Maritime Administration ISBN 951-49-2098-8 Edita Prima Oy, Helsinki, 2005 FOREWORD In its report no 57, the Winter Navigation Research Board presents the study to assess the risk involved with winter navigation in the Baltic Sea. The study was carried out by Mr. Risto Jalonen, professor Kaj Riska and Mr. Samuli Hänninen from the Technical University of Helsinki. This information can be used in the development of rules and recommendations for the safety of winter navigation in the Baltic Sea area. The Winter Navigation Research Board warmly thanks Mr. Risto Jalonen, Mr. Samuli Hänninen and professor Kaj Riska for this report, and the Ministry of Transport and Communications for financing the work. Helsinki February 2005 Markku Mylly A PRELIMINARY RISK ANALYSIS OF WINTER NAVIGATION IN THE BALTIC SEA Risto Jalonen, Kaj Riska & Samuli Hänninen HELSINKI UNIVERSITY OF TECHNOLOGY Ship Laboratory Espoo, December 2004 PREFACE The purpose of this risk analysis is to assess the risk involved with winter navigation on the Baltic Sea. The basis for this work was laid in the second meeting of HELCOM’s Ice Expert Working Group in Helsinki, 17-18 June, 2003. This risk analysis is carried out in the period of autumn 2003 – winter 2004 by the Helsinki University of Technology as commissioned by the Finnish Ministry of Transport and Communications and the Finnish Maritime Administration. -

Hydrex Magazine 205 0505001-Hydrex Mag 106.Qxd 17/12/13 09:38 Pagina 1

Hydrex magazine 205_0505001-Hydrex Mag 106.qxd 17/12/13 09:38 Pagina 1 Magazine Number 205 Underwater stern tube seal repair in Trinidad saves time and money........................................ 4 Hydrex performs a wide range of propeller operations, keeping ships out of drydock .............. 7 How Hydrex revolutionized underwater bow thruster operations.............................................. 11 Hydrex magazine 205_0505001-Hydrex Mag 106.qxd 17/12/13 09:38 Pagina 2 www.hydrex.be Hydrex magazine 205_0505001-Hydrex Mag 106.qxd 17/12/13 09:38 Pagina 3 The magazine ends with an inter- Table of contents Editorial view with Hydrex Production Exe- cutive, Dave Bleyenberg. He talks about the history of underwater bow thruster operations and the benefits this kind of repairs bring for ship owners. We hope you enjoy reading this issue of our magazine as much as we have enjoyed producing it. Please contact us if you have questions or Underwater stern tube seal comments about the magazine or if repair in Trinidad saves time you need our assistance with one or and money 4-6 more of your vessels. In the end that is still our main goal: to help you keep your ship sailing safely, economically and on schedule. n this magazine you can read Iabout a range of on-site oper- ations carried out by Hydrex Best regards, diver/technicians around the world. These operations were all performed with the same purpose in mind: to keep the customer’s Hydrex performs a wide range of vessel out of drydock and allow Hydrex founder propeller operations, keeping ships out of drydock 7-10 him to keep his ship on schedule. -

Ship Energy Efficiency Technologies − Now and the Future

NOL CH OG E Y T • • R E E C S N E E Ship energy efficiency technologies − now and the A I 306 R VTT TECHNOLOGY C C future S H • S H N 3 0 6 I G O I H S L I I V G • H S T S hip energy efficiency techn olo gies −... Ship energy efficiency ISBN 978-951-38-8567-0 (Soft back ed.) technologies − now and ISBN 978-951-38-8566-3 (URL: http://www.vttresearch.com/impact/publications) ISSN-L 2242-1211 the future ISSN 2242-1211 (Print) ISSN 2242-122X (Online) http://urn.fi/URN:ISBN:978-951-38-8566-3 Zou Guangrong (Editor) VTT TECHNOLOGY 306 Ship energy efficiency technologies − now and the future Zou Guangrong (Editor) VTT Technical Research Centre of Finland Ltd ISBN 978-951-38-8567-0 (Soft back ed.) ISBN 978-951-38-8566-3 (URL: http://www.vttresearch.com/impact/publications) VTT Technology 306 ISSN-L 2242-1211 ISSN 2242-1211 (Print) ISSN 2242-122X (Online) http://urn.fi/URN:ISBN:978-951-38-8566-3 Copyright © VTT 2017 JULKAISIJA – UTGIVARE – PUBLISHER Teknologian tutkimuskeskus VTT Oy PL 1000 (Tekniikantie 4 A, Espoo) 02044 VTT Puh. 020 722 111, faksi 020 722 7001 Teknologiska forskningscentralen VTT Ab PB 1000 (Teknikvägen 4 A, Esbo) FI-02044 VTT Tfn +358 20 722 111, telefax +358 20 722 7001 VTT Technical Research Centre of Finland Ltd P.O. Box 1000 (Tekniikantie 4 A, Espoo) FI-02044 VTT, Finland Tel. +358 20 722 111, fax +358 20 722 7001 Juvenes Print, Tampere 2017 Preface Given the great opportunity in Tekes1 Arctic Seas Programme (2014–2017), we were able to form a joint R&D consortium (Ship Energy Efficiency Technologies – SET) to demonstrate a Finnish approach to systematically modelling onboard energy systems of different ship types and to evaluating and optimizing the practical performances of various energy efficiency technologies and solutions, using ship energy flow simulation methods, and to improving the energy efficiency of different ship types under real operating conditions. -

Global Ice Ridge Ramming Loads Based on Full Scale Data and Specific

Global ice ridge ramming loads based on full scale data and specific energy ap- proach Job Kramers echnische Universiteit Delft T GLOBAL ICE RIDGE RAMMING LOADS BASED ON FULL SCALE DATA AND SPECIFIC ENERGY APPROACH by Job Kramers in partial fulfillment of the requirements for the degree of Master of Science in Offshore and Dredging Engineering at the Delft University of Technology, to be defended publicly on November 25th, 2016 at 14:30. Sponsor: Sustainable Arctic Marine and Coastal Technology (SAMCoT) Research Centre Student number: 4011120 Date: ?, 2016 Supervisor: Prof. S. Løset NTNU Prof. dr. ir. A. V. Metrikine TU Delft M. A. van den Berg TU Delft Thesis committee: Prof. dr. ir. A. Metrikine TU Delf Prof. S. Løset NTNU An electronic version of this thesis is available at http://repository.tudelft.nl/. ABSTRACT This thesis analyses the loads that occurred during an ice ridge ramming experiment with the icebreaker Oden. Sea ice ridges are formed due to breaking and deformation of the ice cover. Wind, current, thermal expansion and Coriolis forces induce compression and shear forces onto level ice which can break the ice into rubble. The blocks of ice rubble are pushed together, forming a wall of broken ice in hydrostatic equilib- rium. This wall of broken ice forced up by pressure is defined as an ice ridge. In general ice ridges are long, nonsymmetrical, curvilinear features with a wide variability of sizes and shapes. In Arctic regions, sea ice ridges are often used to calculate the design load in the absence of icebergs. Ice ridges also play a major role in icebreaker efficiency, since an icebreaker might need several ‘rams’ to break through an ice ridge. -

A History of Icebreaking Ships Jones, S

NRC Publications Archive Archives des publications du CNRC A history of icebreaking ships Jones, S. J. This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur. Publisher’s version / Version de l'éditeur: Journal of Ocean Technology, 3, 1, pp. 54-74, 2008-03-01 NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=dcc15ce0-198b-4d20-92d2-5e0e1a7bc201 https://publications-cnrc.canada.ca/fra/voir/objet/?id=dcc15ce0-198b-4d20-92d2-5e0e1a7bc201 Access and use of this website and the material on it are subject to the Terms and Conditions set forth at https://nrc-publications.canada.ca/eng/copyright READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site https://publications-cnrc.canada.ca/fra/droits LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB. Questions? Contact the NRC Publications Archive team at [email protected]. If you wish to email the authors directly, please see the first page of the publication for their contact information. Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. -

Hydrex Magazine 188 0505001-Hydrex Mag 106.Qxd 31/05/12 14:47 Pagina 1

Hydrex Magazine 188_0505001-Hydrex Mag 106.qxd 31/05/12 14:47 Pagina 1 Number 188 Permanent on-site insert repair in South-Korea keeps ship out of drydock ............................... 3 Underwater propeller blade straightening in the British Indian Ocean Territory...................... 5 Underwater removal and reinstallation of bow thruster on container vessel.............................. 7 Underwater stern tube seal repairs in Algeciras and Le Havre .................................................. 12 Hydrex Magazine 188_0505001-Hydrex Mag 106.qxd 31/05/12 14:47 Pagina 2 Contents Page 3 - 4 Permanent on-site insert repair in South-Korea keeps ship out of drydock Page 5 - 6 Underwater propeller blade straightening in the British Indian Ocean Territory Page 7 - 10 Underwater removal and reinstallation of bow thruster on container vessel Page 12 - 14 Underwater stern tube seal repairs in Algeciras and Le Havre KEEPING SHIPS IN BUSINESS ISO 9001 certified Underwater services and technology approved by: ©musicman KEEPING SHIPS IN BUSINESS Fully equipped for a worldwide fast response 2 Hydrex Magazine 188_0505001-Hydrex Mag 106.qxd 31/05/12 14:47 Pagina 3 Permanent on-site insert repair in South-Korea keeps ship out of drydock n May, Hydrex diver/techni- Icians carried out a permanent insert repair on a 224-meter bulk- er at anchor in Busan, South Korea. The vessel was being sold and the repair needed to be carried out before the sale could be finalized. The tight working window available was however no problem for the team. Like all Hydrex divers they are trained to perform a wide range of operations within the shortest possible time frame and this without compromising the high standards Hydrex is known for. -

Part C Machinery, Systems and Fire Protection

Rules for the Classification of Inland Waterway Ships and for Conformity to Directive 2006/87/EC Effective from 1 January 2016 Part C Machinery, Systems and Fire Protection Emirates Classification Society (Tasneef) Phone (+971) 2 692 2333 Aldar HQ 19th Floor, Fax (+971) 2 445 433 Al Raha Beach, Abu Dhabi, UAE P.O. Box. 111155 Abu Dhabi, United Arab Emirates [email protected] GENERAL CONDITIONS Definitions: “Administration” means the Government of the State whose flag the Ship is entitled to fly or under whose authority the Ship is authorized to operate in the specific case. “IACS” means the International Association of Classification Societies. “Interested Party” means the party, other than the Society, having an interest in or responsibility for the Ship, product, plant or system subject to classification or certification (such as the owner of the Ship and his representatives, the ship builder, the engine builder or the supplier of parts to be tested) who requests the Services or on whose behalf the Services are requested. “Owner” means the registered owner, the ship owner, the manager or any other party with the responsibility, legally or contractually, to keep the ship seaworthy or in service, having particular regard to the provisions relating to the maintenance of class laid down in Part A, Chapter 2 of the Rules for the Classification of Ships or in the corresponding rules indicated in the specific Rules. "Rules" in these General Conditions means the documents below issued by the Society: (i) Rules for the Classification of Ships or other special units; (ii) Complementary Rules containing the requirements for product, plant, system and other certification or containing the requirements for the assignment of additional class notations; (iii) Rules for the application of statutory rules, containing the rules to perform the duties delegated by Administrations; (iv) Guides to carry out particular activities connected with Services; (v) Any other technical document, as for example rule variations or interpretations.