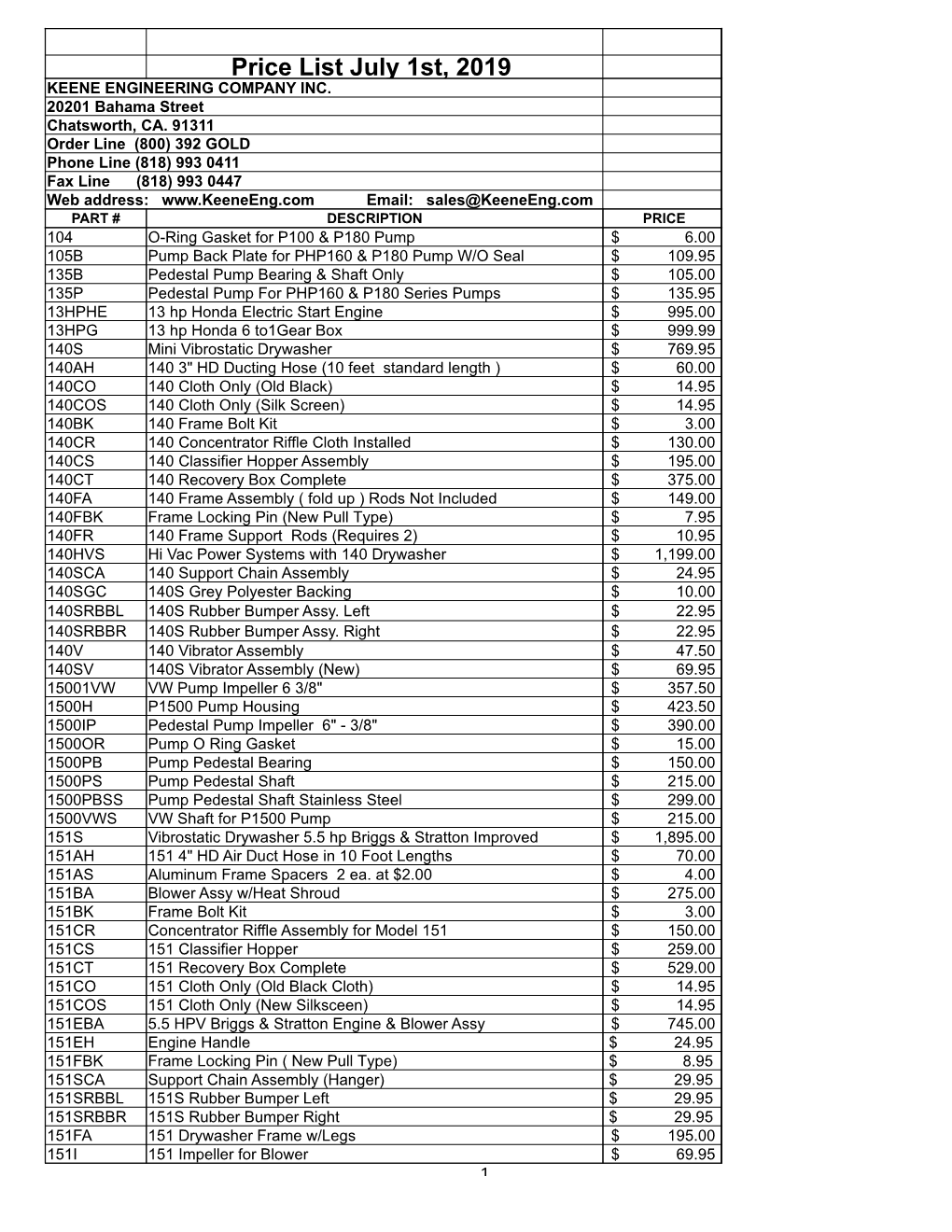

Price List July 1St, 2019 KEENE ENGINEERING COMPANY INC

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

From Base Metals and Back – Isamills and Their Advantages in African Base Metal Operations

The Southern African Institute of Mining and Metallurgy Base Metals Conference 2013 H. de Waal, K. Barns, and J. Monama From base metals and back – IsaMills and their advantages in African base metal operations H. de Waal, K. Barns, and J. Monama Xstrata IsaMill™ technology was developed from Netzsch Feinmahltechnik GmbH stirred milling technology in the early 1990s to bring about a step change in grinding efficiency that was required to make Xstrata’s fine-grained lead/zinc orebodies economic to process. From small-scale machines suited to ultrafine grinding, the IsaMill™ has developed into technology that is able to treat much larger tonnages, in coarser applications, while still achieving high energy efficiency, suited for coarser more standard regrind and mainstream grinding applications. The unique design of the IsaMillTM, combining high power intensity and effective internal classification, achieves high energy efficiency and tight product distribution which can be effectively scaled from laboratory scale to full-sized models. The use of fine ceramic media also leads to significant benefits in downstream flotation and leaching operations. These benefits are key drivers for the adoption of the technology into processing a diverse range of minerals worldwide, and offer major opportunities for power reduction and improved metallurgy for the African base metal operations. Keywords: IsaMill, regrind, energy efficiency, inert grinding. Introduction The development of the IsaMillTM, by MIM (now GlencoreXstrata) and Netzsch Feinmahltechnik GmbH, was initiated to enable the development of the fine-grained ore deposits at Mt Isa and McArthur River in Northern Australia. To liberate the valuable minerals and so produce a saleable concentrate this ultrafine-grained ore needed to be ground to a P80 of 7 μm. -

Some Problems and Potentials of the Study of Cupellation

Some problems and potentials of the study of cupellation remains: the case of post-medieval Montbéliard, France Marcos Martinon-Torres, Nicolas Thomas, Thilo Rehren, Aude Mongiatti To cite this version: Marcos Martinon-Torres, Nicolas Thomas, Thilo Rehren, Aude Mongiatti. Some problems and po- tentials of the study of cupellation remains: the case of post-medieval Montbéliard, France. Archeo- sciences, revue d’Archéométrie, G.M.P.C.A./Presses universitaires de Rennes, 2008, pp.59-70. halshs- 00599974 HAL Id: halshs-00599974 https://halshs.archives-ouvertes.fr/halshs-00599974 Submitted on 19 Jun 2011 HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non, lished or not. The documents may come from émanant des établissements d’enseignement et de teaching and research institutions in France or recherche français ou étrangers, des laboratoires abroad, or from public or private research centers. publics ou privés. Some problems and potentials of the study of cupellation remains: the case of early modern Montbéliard, France Problèmes et perspectives à partir de l’étude des vestiges archéologiques issus de la coupellation : l’exemple du site de Montbéliard (France) Marcos Martinón-Torres*, Nicolas Thomas**, Thilo Rehren*, and Aude Mongiatti* Abstract: Bone-ash cupels are increasingly identified in medieval and later archaeological contexts related to the refining of noble metals in alchemy, assaying, jewellery or coin minting. These small finds may provide information on metal refining activities, the technical knowledge of different craftspeople, and the versatility of laboratory practices, which often differed from the standard protocols recorded in metallurgical treatises. -

The Gold Panning Booklet

GoldPanning A Guide to recreational goldpanning on the Kenai Peninsula, Chugach National Forest, Alaska GoldPANNING A guide to recreational gold panning on the Kenai Peninsula, Chugach National Forest, Alaska Written by Carol Huber Chugach national Forest, anchorage, alaska & Joseph Kurtak Bureau of Land Management, anchorage, alaska Technical assistance by nathan Rathbun Bureau of Land Management, anchorage, alaska (formerly with the U.S. Bureau of Mines) graphic design and editing by David L. allen & Charles Lindemuth Chugach national Forest, anchorage, alaska graphic art by Kathy Sarns Chugach national Forest, anchorage, alaska Contents Welcome . 2 gold – Significance and Use . 3 Kenai Peninsula Mining – a History . 5 Mining Right & guidelines . 7 geology of the northern Kenai Peninsula . 9 Equipment you will need . 10 For your safety . 10 Where to look for gold . 12 How to pan . 13 Kenai Peninsula gold panning areas . 16 map1: Panning sites on the Kenai Peninsula . 17 Bertha Creek panning area . 18 map 2: Bertha Creek . 19 Six Mile Creek panning area . 20 map 3: Sixmile Creek . 21 Resurrection Creek panning area . 22 map 4: Resurrection Creek . 23 Crescent Creek panning area . 24 map 5: Crescent Creek . 25 How much gold have you found? . 26 A glossary of mining terms . 27 Further Reading… . 28 More information… . 29 Welcome Striking it rich! Finding the mother lode! ‘Tis the stuff of miners’ dreams. Unlike professional gold seekers, recreational gold pan- ners benefit mostly from the adventure. The entire family can share in the fun of prospecting and gold panning. in this booklet, we explain basic gold panning techniques, how to find gold, discuss mining rights and guidelines, and identify areas available for recreational panning on the Chugach national Forest portion of alaska’s Kenai Peninsula. -

Heart of Gold Lesson Plan Year 7

Heart of Gold Lesson Plan Year 7 Lesson 1 Separation of Gold Curriculum Links: (ACSSU112) / Year 7 / Science / Science Understanding / Chemical Sciences (ACSSU222) / Year 7 / Science / Science Understanding / Earth and Space Sciences (ACSHE119) / Year 7 / Science / Science as a Human Endeavour / Nature and Development of Science (ACSHE121) / Year 7 / Science / Science as a Human Endeavour / Use and Influence of Science Background Information: It is actually quite unusual to find large nuggets of gold and most gold prospectors actually need to separate gold out from lots of other material. Depending on where the gold is found, this may be done by panning or through dry blowing. Each of these methods relies on the property of density. As gold has a very high density compared to the rock, soil and sediments it is contained in, it can be separated out by exploiting this property as it will fall to the bottom of mixtures that are allowed to settle out. The process of panning is used when small pieces of gold are found in creeks and rivers. It involves using a large shallow dish (pan) to scoop out some of the sediments in the riverbed and a small amount of water. You use a swirling motion with the pan tipped away from you and allow small amounts of the sediments and water to spill over the edge of the pan. When you have only a small amount of the sediments remaining in the pan, you will be able to see any gold particles that remain at the bottom of the pan. During the West Australian gold rush, most of the gold was being found in dry areas and water was a scarce commodity. -

Fine Tuning Your GOLD BUDDY Drywasher. Drywashers Are an Excellent Tool to Recover Gold from Dry Material

Drywasher Components Hopper: This is where you place the raw material. A classifier screen separates the material by size allow- ing the smaller material to enter the hopper and discarding the material that is too large to pass through the machine. Angle Adjustment: Changes the angle of the Recovery Box by adjusting the chain length. Flow Gate: This is a slide gate that controls the size of Recovery Box: This is the the opening at the bottom of lower box that is pressurized the hopper which regulates by the blower and collects how fast the material in the values in the riffle system. hopper enters the recovery box. Rear Leg: Frame: This is the steel structure that holds the components in place. For illustration purposes we are calling the leg where the fine material exits the drywasher the “Front Leg” and the leg where the larger material falls off the drywasher Front Leg: the “Rear Leg”. Setting up the Hopper / Frame Step 1: Your drywasher may have slightly different frame components than the illustration but the easiest way to as- semble a drywasher is usually to place the Hopper on the ground upside down. The upper part of the front and rear legs are at- tached to the hopper and need to be lifted so that the point where they intersect can be bolted together making the frame rigid. Step 2: Attach the bottom portions of the legs and secure them with the hardware provided. The bottom portions are differ- ent widths so you cannot get them mixed up. Step 3: Flip the assembled unit right side up and it should look like this. -

S Ndlovu (PDF)

Extraction of Gold Then, Now and the Future Prof Sehliselo Ndlovu DST/NRF SARChI: Hydrometallurgy and Sustainable Development University of the Witwatersrand, Johannesburg Building a Robust Minerals Industry 3 – 4 July 2017, Cresta Lodge, Harare University of the Witwatersrand Johannesburg Founded Oct. 1896: School of Mines Approx. 37 000 Students 5 Faculties, 33 Schools, 3610 Courses >160 000 Degrees Conferred since 1922 55% Female Students 10 National Centres of Excellence Home to the Bidvest Football Club( Current PSL league Champions) Evolution in Gold Processing Past Technologies • Amalgamation • Panning Current Technologies • Cyanide leaching • Processing of Emerging and Future refractory ores Technologies • Bio-oxidation • Ionic liquids • Alternative leaching • Ultrasonic leaching reagents • Corn starch?? Past Technologies Used in Ancient Times History of gold extends back at least 6,000 years. Egypt and Mesopotamia around 4000 BC. Gravity Separation: Gold Panning Gold concentrated by washing lighter river sands with water Leaves dense gold particles Alternative- wash gold-bearing sand and gravel over a woollen fleece Traps heavier gold dust that would sink into the wool fibres. Advantages • Simplicity Disadvantages • Labour intensive Gravity Separation: Sluicing • Water is channelled to flow through a sluice-box. • Sluice-box is essentially a man-made channel with riffles (barriers) at the bottom. • Riffles create dead-zones in the water current which allows gold to drop out of suspension. Sluicing and panning results in the direct recovery of small gold nuggets and flakes. Gold Parting: Salt Cementation Process • Invented to remove Ag from Au-Ag mixtures around 6th century BC. Mix: argentiferous gold foil, common salt, brick dust or burnt clay and urine in a sealed container. -

Principles of Extractive Metallurgy Lectures Note

PRINCIPLES OF EXTRACTIVE METALLURGY B.TECH, 3RD SEMESTER LECTURES NOTE BY SAGAR NAYAK DR. KALI CHARAN SABAT DEPARTMENT OF METALLURGICAL AND MATERIALS ENGINEERING PARALA MAHARAJA ENGINEERING COLLEGE, BERHAMPUR DISCLAIMER This document does not claim any originality and cannot be used as a substitute for prescribed textbooks. The information presented here is merely a collection by the author for their respective teaching assignments as an additional tool for the teaching-learning process. Various sources as mentioned at the reference of the document as well as freely available material from internet were consulted for preparing this document. The ownership of the information lies with the respective author or institutions. Further, this document is not intended to be used for commercial purpose and the faculty is not accountable for any issues, legal or otherwise, arising out of use of this document. The committee faculty members make no representations or warranties with respect to the accuracy or completeness of the contents of this document and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. BPUT SYLLABUS PRINCIPLES OF EXTRACTIVE METALLURGY (3-1-0) MODULE I (14 HOURS) Unit processes in Pyro metallurgy: Calcination and roasting, sintering, smelting, converting, reduction, smelting-reduction, Metallothermic and hydrogen reduction; distillation and other physical and chemical refining methods: Fire refining, Zone refining, Liquation and Cupellation. Small problems related to pyro metallurgy. MODULE II (14 HOURS) Unit processes in Hydrometallurgy: Leaching practice: In situ leaching, Dump and heap leaching, Percolation leaching, Agitation leaching, Purification of leach liquor, Kinetics of Leaching; Bio- leaching: Recovery of metals from Leach liquor by Solvent Extraction, Ion exchange , Precipitation and Cementation process. -

Chapter 11: Beneficiation

CHAPTER 11 Beneficiation – Comminution Sponsored by: SPONSOR PROFILE Through pioneering the introduction of modern process • project controls and reporting plants and associated technologies to remote and logistically • contract management challenging locations, Lycopodium Minerals Pty Ltd has • procurement and logistics management developed a successful track record in developing and • inspection and expediting commissioning major resource projects worldwide. • quality assurance/quality control Since its establishment in 1992, Lycopodium has become a • financial evaluations leading international engineering and project management • client representation. consultancy, with an enviable reputation for providing Engineering technically innovative and cost-effective engineering solutions. They are focused on the evaluation and development of projects • Conceptual through to detailed design in the fields of minerals processing, materials handling and • across all disciplines: earthworks, civil infrastructure. • structural, mechanical, piping • electrical, instrumentation, control Lycopodium Minerals has undertaken studies and projects across a broad range of commodities including gold (free, • systems, automation and infrastructure. gravity, refractory, preg robbing), base metals (concentrators, Process hydrometallurgy), iron ore, uranium, rare earths and industrial minerals. Their resume of projects reflects diversity in not • Metallurgical test work design only commodity, but client background, technology, scale of • management and interpretation -

Table of Contents

Table of Contents Preface ........................................... xi Chapter 1. Physical Extraction Operations .................... 1 1.1. Solid-solid and solid-fluid separation operations .............. 1 1.1.1. Flotation ................................... 1 1.1.2. Settling under gravity ........................... 3 1.1.3. Centrifugation ................................ 3 1.1.4. Filtration ................................... 4 1.2. Separation operations of the components of a fluid phase ........ 5 1.2.1. Condensation ................................ 5 1.2.2. Vacuum distillation ............................. 5 1.2.3. Liquation ................................... 6 1.2.4. Distillation .................................. 8 1.2.5. Extractive distillation ........................... 11 1.3. Bibliography ................................... 12 Chapter 2. Hydrometallurgical Operations .................... 15 2.1. Leaching and precipitation operations .................... 15 2.1.1. Leaching and precipitation reactors ................... 15 2.1.2. Continuous stirred tank reactor (CSTR) ................ 18 2.1.3. Models of leaching and precipitation operations ........... 20 2.1.4. Particle-size distribution (PSD) functions ............... 21 2.2. Reactor models based on particle residence time distribution functions ........................................ 24 2.2.1. Performance equations for a single CSTR ............... 24 2.2.2. Performance equations for multistage CSTRs ............. 28 2.3. Reactor models based on the population balance -

Public Comments

Revised Willamette Mercury TMDL and Water Quality Management Plan Public Comments Watershed Management 700 NE Multnomah St. Suite 600 Portland, OR 97232 Phone: 503-229-5696 800-452-4011 www.oregon.gov/DEQ DEQ is a leader in restoring, maintaining and enhancing the quality of Oregon’s air, land and water. State of Oregon Department of Environmental Quality 1 This report prepared by: Oregon Department of Environmental Quality 700 NE Multnomah Street, Suite 600 Portland, OR 97232 1-800-452-4011 www.oregon.gov/deq Contact: Kevin Brannan Alex Liverman Andrea Matzke Priscilla Woolverton 503-229-6629 503-229-5080 503-229-5350 541-687-7347 DEQ can provide documents in an alternate format or in a language other than English upon request. Call DEQ at 800-452-4011 or email [email protected]. Table of Contents Introduction ................................................................................................................................................. 1 Comments .................................................................................................................................................... 1 1. Steven Wright, Texas ................................................................................................................... 1 2. Craig & Linda Olson, Oregon ...................................................................................................... 1 3. Tom Quintal, Oregon .................................................................................................................... 6 4. Craig -

The Pharaohs' Gold: Ancient Egyptian Metallurgy

THE PHARAOHS' GOLD: ANCIENT EGYPTIAN METALLURGY TI n an age when mining is conducted on an lode country increased in size and scale, the clam industrial scale through the use of explosives, or for more efficient means of processing ores huge draglines, and enormous ore-carriers, there grew ever more strident and in response to this is a tendency to forget that mining was, and is, an demand milling processes grew increasingly activity involving the concerted efforts of human sophisticated. Greever notes that California's beings. In his depiction of mining activities in hardrock miners first relied on arrastras and California's nineteenth-century gold fields, Chilean mills to reduce their ores. When these William S. Greever in The Bonanza West: The Story devices failed to provide satisfactory returns of the Western Mining Frontier, 1848-1900 calls to California's argonauts then began to employ mind the human factor involved in the extraction stamp mills to process their gold ores.3 of ore from beneath the earth's surface: The processes underlying the operation of a stamp mill had changed little in the centuries [T)he deepest shafts in California leading up to the California gold rush.4 Greever quartz mining went down ... about compares the basic function of a stamp to that of a three hundred feet; often a deposit was pharmacist's mortar and pestle. In its simplest worked by a tunnel into a hillside or application, a stamp was dropped repeatedly on a even an open cut. The men used hand piece of metallic ore until the ore was reduced to drills, sledges, and a little black pow powder. -

Sand, Gravel, and Crushed Stone On-The-Job Training Modules

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB TRAINING MODULES Module 17 - “Primary Crushing Operation” UNITED STATES DEPARTMENT OF LABOR ELAINE L. CHAO SECRETARY MINE SAFETY AND HEALTH ADMINISTRATION DAVE D. LAURISKI ASSISTANT SECRETARY Originally Published AUGUST 2000 INSTRUCTION GUIDE SERIES MSHA IG 40 MODULE NUMBER 17 OF INSTRUCTION GUIDE NUMBER 40 ON-THE-JOB TRAINING FOR THE SAND, GRAVEL, AND CRUSHED STONE INDUSTRY PRIMARY CRUSHING OPERATION This module describes basic job steps, potential hazards and accidents, and recommended safe job procedures for primary crushing operations. This job is normally done by the crusher operator, but may be done by other occupations. Crusher operators must protect themselves, and other people in the area, from accidents and injuries resulting from operation of the crusher and associated equipment. There are several different types of primary crushers, however, there are many similarities in the job clxii procedures followed by crusher operators. Crushing is the first step in converting shot rock into usable products. Essentially, crushing is no more than taking large rocks and reducing them to small pieces. Crushing is sometimes continued until only fines remain. At some operations, all the crushing is accomplished in one step, by a primary crusher. At other operations, crushing is done in two or three steps, with a primary crusher that is followed by a secondary crusher, and sometimes a tertiary crusher. Raw material, of various sizes, is brought to the primary crusher by rear-dump haul units, or carried by a wheel front-end loader. Primary crushing reduces this run-of-mine rock to a more manageable size.