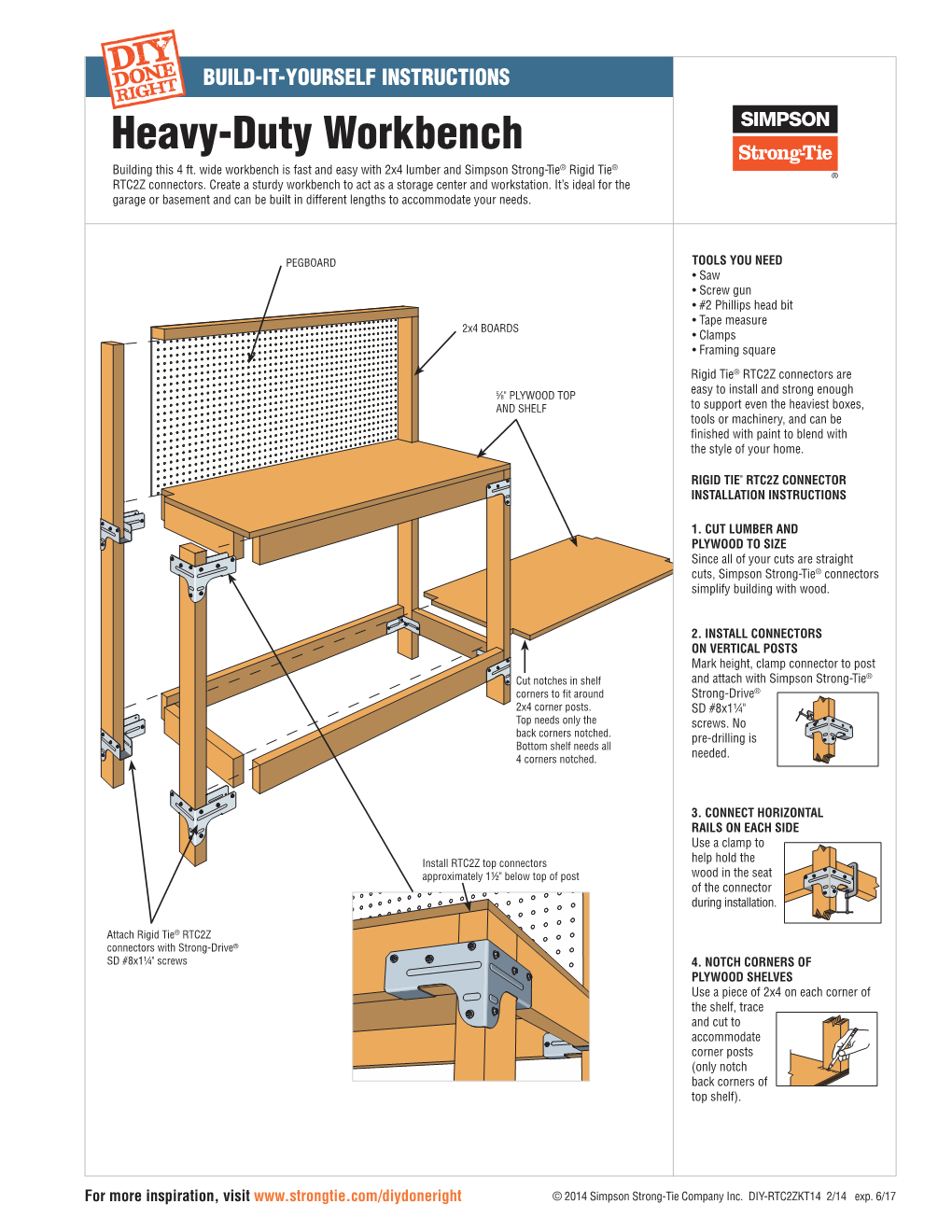

Heavy-Duty Workbench Building This 4 Ft

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

IO-INCH DIRECT DRIVE BAND SA W CAUTION: Read GENERAL and ,, Assembly ADDITIONAL SAFETY INSTRUCTIONS • Operating Carefully , Repair Parts

SAVE THIS MANUAL FOR FUTURE REFERENCE _ARS owners manual MODEL NO. 113.244512 Serial Number Model and serial number may be found at the right-hand side of the frame. You should record both model and serial number in a safe place for future use. IO-INCH DIRECT DRIVE BAND SA W CAUTION: Read GENERAL and ,, assembly ADDITIONAL SAFETY INSTRUCTIONS • operating carefully , repair parts Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A. Part No. 69188 FULL ONE YEAR WARRANTY ON CRAFTSMAN BAND SAW If within one year from the date of purchase, this Craftsman Band Saw fails due to a defect in material or workmanship, Sears will repair it, free of charge. ,WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS USED IN THE UNITED STATES. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state, SEARS, ROEBUCK AND CO.. 698/731A, Sears Tower, Chicago. IL 60684 general safety instructions for power tools 1. KNOW YOUR POWER TOOL Z87.1) at all times. Everyday eyeglasses only Read and understand the owner's manual and have impact resistant lenses, they are NOT labels affixed to the toot. Learn its application safety glasses. Also, use face or dust mask if and limitations as well as'the specific potential cutting operation is dusty, and ear protectors hazards peculiar to this toot, (plugs or muffs) during extended periods of 2. GROUND ALL TOOLS operation. -

60" Workbench

Owner’s Manual & Safety Instructions Save This Manual Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance and cleaning procedures. Write the product’s serial number in the back of the manual near the assembly diagram (or month and year of purchase if product has no number). Keep this manual and the receipt in a safe and dry place for future reference. ITEM 69054 60" Workbench Visit our website at: http://www.harborfreight.com Email our technical support at: [email protected] When unpacking, make sure that the product is intact and undamaged. If any parts are missing or broken, please call 1-800-444-3353 as soon as possible. Copyright© 2012 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork contained herein may be reproduced in Read this material before using this product. any shape or form without the express written consent of Harbor Freight Tools. Failure to do so can result in serious injury. Diagrams within this manual may not be drawn proportionally. Due to continuing SAVE THIS MANUAL. improvements, actual product may differ slightly from the product described herein. Tools required for assembly and service may not be included. Table of Contents Safety ......................................................... 2 Parts List and Diagram .............................. 10 Specifications ............................................. 3 Warranty .................................................... 12 Setup .......................................................... 3 SA F ET Y WARNING SYMBOLS AND DEFINITIONS This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. Indicates a hazardous situation which, if not avoided, will result in death or serious injury. -

Paul Sellers' Workbench Measurements and Cutting

PAUL SELLERS’ WORKBENCH MEASUREMENTS AND CUTTING LIST PAUL SELLERS’ WORKBENCH MEASUREMENTS AND CUTTING LIST NOTE When putting together the cutting list for my workbench, I worked in imperial, the system with which I am most comfortable. I was not happy, however, to then provide direct conversions to metric because to be accurate and ensure an exact fit this would involve providing measurements in fractions of millimetres. When I do work in metric I find it more comfortable to work with rounded numbers, therefore I have created two slightly different sets of measurements. This means that in places the imperial measurement given is not a direct conversion of the metric measurement given. Therefore, I suggest you choose one or other of the systems and follow it throughout. © 2017 – Paul Sellers v2 PAUL SELLERS’ WORKBENCH MEASUREMENTS AND CUTTING LIST WOOD QTY DESCRIPTION SIZE (IMPERIAL) SIZE (METRIC) (THICK X WIDE X LONG) (THICK X WIDE X LONG) 4 Leg 2 ¾” x 3 ¾” x 34 ⅜” 70 x 95 x 875mm 1 Benchtop 2 ⅜” x 12” x 66” 65 x 300 x 1680mm 2 Apron 1 ⅝” x 11 ½” x 66” 40 x 290 x 1680mm 1 Wellboard 1” x 12 ½” x 66” 25 x 320 x 1680mm 4 Rail 1 ½” x 6” x 26” 40 x 150 x 654mm 2 Bearer 1 ¼” x 3 ¾” x 25” 30 x 95 x 630mm 4 Wedge ⅝” x 1 ½” x 9” 16 x 40 x 228mm 4 Wedge retainer ⅝” x 1 ½” x 4” 16 x 40 x 100mm HARDWARE QTY DESCRIPTION SIZE (IMPERIAL) SIZE (METRIC) 1 Vise 9” 225mm Dome head bolts (including nuts and washers) for 4 ⅜” x 5” 10 x 130mm bolting legs to aprons 2 Lag screws (with washers) for underside of vise ½” x 2 ½” 12 x 65mm 2 Lag screws for face -

Brembana Kosmos

brembana kosmos jet 5 axes saw jet machine STONE CMS is part of SCM Group, a technological world leader in processing a wide CMS SpA manufactures machinery and systems for the machining of composite range of materials: wood, plastic, glass, stone, metal and composites. The materials, carbon fibre, aluminium, light alloys, plastic, glass, stone and metals. It was Group companies, operating throughout the world, are reliable partners of established in 1969 by Mr Pietro Aceti with the aim of offering customized and state- brembana kosmos jet leading manufacturing industries in various market sectors, including the of-the-art solutions, based on the in-depth understanding of the customer’s production furniture, construction, automotive, aerospace, ship-building and plastic needs. Significant technological innovations, originating from substantial investments processing industries. SCM Group coordinates, supports and develops a in research and development and take-overs of premium companies, have enabled system of industrial excellence in 3 large highly specialized production constant growth in the various sectors of reference. centres employing more than 4,000 workers and operating in all 5 continents. SCM Group: the most advanced skills and know-how in the fields of industrial machinery and components. APPLICATIONS 4-5 BREMBANA KOSMOS JET TECHNOLOGICAL BENEFITS 6-7 ACCESSORIES 8-13 OPTIONAL 14-15 SOFTWARE 16-17 CMS Stone Technology realizes avant-garde solutions for the working of marble, natural stones and composite stones. Under OVERALL DIMENSIONS & TECHNICAL DATA the brand name Brembana Macchine, CMS Stone Technology was in the 80’s the first manufacturer of a stone machining 18-19 centre, thanks to an idea of its founder Mr Pietro Aceti. -

Snap on On-Site Power Generation Tool Kit Price $ 3095 Sales Tax $185.70 Total $3280.70 Student Name Student ID Email

Pennsylvania College of Technology Snap On On-Site Power Generation 1650 Pry bar, 16" 211FY Socket Set, Shallow, 12-Pt 3/8 Drive, (11 pc)(1/4" to 7/8") 211SFSY Socket Set, Deep, 6-Pt 3/8 drive, (11 pcs.) (1/4" to 7/8") 212SFSMY Socket Set, Metric, Deep, 6-Pt (12 pcs.) 3/8 drive (8 to 9 mm) 313SMYA Socket Set, Metric, Deep, 12-Pt (13 pcs.) 1/2 drive (12-24 mm) 313SWMYA Socket Set, Metric, Shallow, 12-Pt (13 pcs.) 1/2 drive (12-24 mm) 313SYA Socket Set, Deep, 12-Pt (13 pcs.) 1/2 drive (3/8" to 1 1/8") 317MPC General Set, Standard Shallow, 12-Pt (17 pcs.) 1/2 drive (3/8" to 1 1/8") AWP120 Adjustable Joint, Straight Serrated Jaws, 12 3/4" BP24B Hammer, Ball Peen, 24 oz. MAGM2A03H Flashlight ( was ECF2B discontinued) OEX709B Set, Wrench, Combination, 12-Pt (9 pcs. in tray) (3/8" to 7/8") OEXM710B Set, Wrench, Combination, Metric, 12-Pt (10 pcs. in tray) (10-19 mm) SHDX60R Set Screwdriver, Combination, Instinct Hard Handle, Red 6 pcs. QD3R250 Torque Wrench, Adj. Click-type, Fixed-Ratchet PPC710BK Punch and Chisel Set, 11 pc. (Center/Pin/Starter) FXK11 Extension, Knurled, Friction Ball, 11" 3/8 Drive PPB1226A Punch, Drift, Bronze, 13/16" point, 12 FXK3 Extension, Knurled, Friction Ball, 3" GLASS1BK Glasses, Safety, Clear Lens/Black Frames HBFE24 Hammer, Dead Blow, Soft Grip, 24 oz. OEX30B 15/16" Standard Combination Wrench OEX32B 1" Standard Combination Wrench OEX36B 1 1/8" Standard Combination Wrench OEX40B 1 1/4" Standard Combination Wrench OEXM80B 8mm Metric Combination Wrench PK23A Scraper PL300CF Set, Cutters/Pliers, 3 pcs. -

DP101 Manual

OPERATOR’S MANUAL 10 in. (254 mm) DRILL PRESS MODEL DP101 THANK YOU FOR BUYING A RYOBI BENCH TOP DRILL PRESS. Your new Drill Press has been engineered and manufactured to Ryobi's high standards for dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance. CAUTION: Carefully read through this entire operator's manual before using your new machine. Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your machine properly and only for what it is intended, you will enjoy years of safe, reliable service. Please fill out and return the Warranty Registration Card so we can be of future service to you. Thank you again for buying Ryobi tools. SAVE THIS MANUAL FOR FUTURE REFERENCE 1 TABLE OF CONTENTS Rules for Safe Operation....................................................................................................................................................... 3 Specific Safety Rules for Drill Presses .................................................................................................................................. 5 Electrical.................................................................................................................................................................................6 Glossary of Terms ..................................................................................................................................................................7 Features .................................................................................................................................................................................8 -

Introduction and Analysis of the Ultrahigh Pressure Water Jet Cutting Multifunctional Application

2017 WJTA-IMCA Conference and Expo October 25-27, 2017 ● New Orleans, Louisiana Paper INTRODUCTION AND ANALYSIS OF THE ULTRAHIGH PRESSURE WATER JET CUTTING MULTIFUCTIONAL APPLICATION Xue Shengxiong, Chen Zhengwen, Han Caihong, Ren Qile Hefei General Machinery Research Institute Hefei, Anhui, China Chen Bo Nanjing Dadi Water Limited by Share Ltd. Nanjing, Jiangsu, China Wu Ziquan All-Powerful Inc Shenyang, Liaoning, China Li Yuefeng Hua Zhen Mechanical Equipment Co. Ltd Guangzhou, Guangdong, China ABSTRACT The aerospace industry bring a new development for ultrahigh pressure water jet cutting technology, such as large scale curved composite components cutting process engineering application, large scale impeller rough cutting, special precise cutting, composite materials to milling, drill, polishing and so on. As National Advanced Technology Support Project of China for an opportunity, the author developed 500MPa ultrahigh pressure water cutting equipment for super large composite wing and a multifunction water jetting CNC center. This paper introduce the ultrahigh pressure water jet multifunctional technical features about these two equipments involved, and combine with the foreign development situation. The technical modules, parameter matching technology, process method and experiment result are analyzed to realizing the highly-difficult water jet cutting, milling and other applications. Organized and Sponsored by WJTA-IMCA 1. MARKET REQUIREMENT OF HIGH END ULTRAHIGH PRESSURE WATER CUTTING In China, technology and equipment development of ultrahigh pressure water cutting have been a full twenty years. The first water cutting machine developed by author is 250MPa of pressure, 2.5L/min of flow. And the current main water cutting products which use ultrahigh pressure intensifier or reciprocating pump are 400MPa of pressure, 3L/min of flow [1]. -

Flowpath User's Guide

FlowPATH User’s Guide M-320 Version 6.02 FLOWMASTER® FlowPATH User's Guide Due to continuing product improvement, the information contained in this document is subject to change without notice. Flow International Corporation shall not be held liable for technical or editorial omissions made herein, nor for any incidental or consequential damage resulting from the use of this material. This document contains information protected by copyright. The software described in this document is furnished under a license agreement. The software may be used or copied only in accordance with the terms of the license agreement. No part of this document shall be reproduced or transmitted in any manner without prior written consent from Flow International Corporation. DISCLAIMER All technical data and information provided in this software is done as a service to customers of Flow In- ternational Corporation (“Flow”) and consumers of our products. All names, designs, and model numbers of products are trademarks of their respective manufacturers. Specifications of products are subject to change without notice or obligation. Manufacturers may also change or discontinue models of their prod- ucts without notice or obligation. While Flow endeavors to provide accurate information and descriptions of products, accuracy and completeness cannot be guaranteed. Flow is not responsible for, nor does it have any liability for any incomplete information, inaccurate CAD files, mistakes or typographical errors, including liability for incidental, consequential, or special damages. All products should be inspected and measured promptly upon delivery and certainly before any improvements or alterations are done in antici- pation of or preparation for installation. Flow assumes no liability for the use of such information or for any damages incurred through its use or application. -

Ultrahd 2-Door Rolling Workbench

ASSEMBLY INSTRUCTIONS UltraHD® 2-Door Rolling Workbench (Model No. 20262, 20142, 20152) Granite Graphite Red 77 in. W x 20 in. D x 37.5 in. H (1.95 m W x 50.8 cm D x 95.2 cm H) Reference page 15 for special care and maintenance of stainless steel SC200304 #8 #41 #1 #11 Small #27-B Drawers #40 #12-B #4 #24 #27 #26 #9 #12 #2 Medium Drawer #57 #13 #23 #6 #5 #42 #15 #13-B Large Drawer #20-A #18 #20-B #19 #3 #17 1 2 Small Drawer #26-2 #15 #26-1 Medium Drawer #12-5 #12-2 #12-1 #15 Large Drawer #13-4 #13-2 #13-1 #15 3 PARTS LIST Please check the parts carefully according to the parts list. If you are missing any parts, please contact our customer service department (please see page 15.) (#1) LEFT SIDE PANEL x 1 PC (#2) RIGHT SIDE PANEL x 1PC (#3) FRONT FRAME x 1 PC (#4) BACK FRAME x 1 PC (#5) BASE PANEL x 1 PC (#6) SHELF x 1 PC (#8) SOLID HARDWOOD TOP x 1 PC (#9) PUSH BAR x 2 PCS 34 PARTS LIST Please check the parts carefully according to the parts list. If you are missing any parts, please contact our customer service department (please see page 15.) (#11) LEFT SIDE SLIDER SUPPORT x 1PC (#12-1) MEDIUM-SIZE DRAWER FRONT x 1 PC (#12-2) MEDIUM-SIZE DRAWER BOTTOM PANEL x 1 PC (#12-5) MEDIUM-SIZE DRAWER BACK PANEL x 1 PC (#12-B) WHEEL WITH BRAKE x 2 PCS (#13-B) WHEEL W/O BRAKE x 2 PCS (#13-1) LARGE DRAWER FRONT PANEL x 1 PC (#13-2) LARGE DRAWER BOTTOM PANEL x 1 PC 5 PARTS LIST Please check the parts carefully according to the parts list. -

Klamp Traktm

Logo on white, gray or any lighter shade when printing color Logo on Pantone 2945 or any darker shade when printing color TM Logo on white or light shade when Klampprinting grayscale Trak Instructions ITEM# KKS1020 - Klamp TrakTM Logo on black or Getting Started dark shade when There are three main methods for installing Klamp Trak™printing in grayscaleyour workshop. In all three methods, your goal will be to construct an opening with the same (or slightly larger) dimensions as the Klamp Trak™, directly below your intended work surface. This will allow the trak to sit flush-with or slightly below the main surface, keeping your work surface clear of obstacles. Klamp Trak™ dimensions can be found in the diagram on page 5 of this instruction manual.. Below are the three methods to choose from. Depending on how you intend to use your Klamp Trak™, determine the best choice for your specific situation. 1. Rout into edge of workbench (page 1) 2. Add a 3/4” surface to the top of your workbench (page 2) 3. Place between two staggered pieces of 3/4” plywood (page 3) Page 1 Klamp TrakTM Instructions • Rout into edge of workbench. Good for adding fast-clamping capabilities to the edge of your current workbench. 1. Place the trak above the spot on the bench where you would like it to position it. Trace around the trak with a pencil. 2. Place your router on top of the Klamp Trak™ and drop the flat-tip bit to the table’s surface. This will make your routing depth equal to the height of the trak. -

Catalog Insert

PRODUCT CATALOG Vol.12 KOMELON Corporation The world’s most vertically integrated measuring tape manufacturer. From our raw material manufacturing plant to global marketing and distribution, KOMELON handles it all with the most advanced and innovative KOMELON Corporation R & D technology. This assures our customers the highest quality products available. For over 50 years, Komelon has manufactured a full line of quality measuring tools with dedication and a passion for craftsmanship while supplying markets throughout the world. Komelon Corporation - Korea, Since 1963 KOMELON Steel This is the corporate headquarters housing all product design, engineering and research & development. This facility also manufactures the Meter-Man Measuring wheel line. Komelon Steel Corporation - Korea, Since 1995 Komelon manufacturers its own steel strip material for all blades and springs used in tape measure production. This ensures the highest quality tape KOMELON China measures on the market. Komelon China, Since 2002 This state-of-the art measuring tool manufacturing facility, located in Qingdao, China was recently built to better serve Komelon’s rapidly growing wordwide sales. KOMELON USA Division Komelon USA Division, Since 1997 This sales and distribution center for North America warehouses high inventory levels to ensure fast shipments and superior customer service. Komelon SAW - Korea, Since 2012 Komelon Saw manufacturing facility located in Daegu, S.Korea is an industry leading manufacturer of high end pruning saws KOMELON Saw - Korea Contents -

Laying Instructions

1 2 3 4 5 AREA OF USE SUBSTRATES INSTALLATION FIRST USE MAINTENANCE Residential use, temperature-regulated interior room + 8 < T < + 35°C. Loose laying is allowed as long as the ambient temperature is regulated and the floor temperature doesn’t exceed 60°C This floor covering cannot be laid on verandas. IMPORTANT: The information in this document is valid from: 01/06/2021 and is subject to change without notice. In the face of continuous technical improvements, before starting any work, our customers should check with us that this document is still in force. RESIDENTIAL FLOORING 1 2 3 4 5 AREA OF USE SUBSTRATES INSTALLATION FIRST USE MAINTENANCE 1. GENERAL The flooring must be laid on a flat, clean, sound, dry and solid The moisture content must not exceed 7% with a carbide substrate. moisture test. < 5 mm < 1 mm < 13/64" < 3/64" The flatness tolerance must be < 5 mm under a 2 meters The substrate must not have any uneven areas > 1 mm every straight edge. 20 cm. 2. RECOMMANDATIONS BY SUBSTRATE TYPE Substrate Conditions If joint < 5 mm width < 2 mm depth. Otherwise, apply a grouting product or levelling Ceramic Tiles compound to eliminate irregularities. Concrete Floor, Painted Concrete, Levelling Concrete, Substrate moisture content < 7%. liquid cement-based screed If necessary, apply a levelling compound to eliminate any surface irregularities. Anhydrite Substrate moisture content < 0,5 %. Compact Vinyl Removal mandatory. If necessary, apply a levelling compound to eliminate any Acoustic Vinyl , Carpet , Laminate surface irregularities. If not glued and nailed onto spaced battens. If glued, removal mandatory.