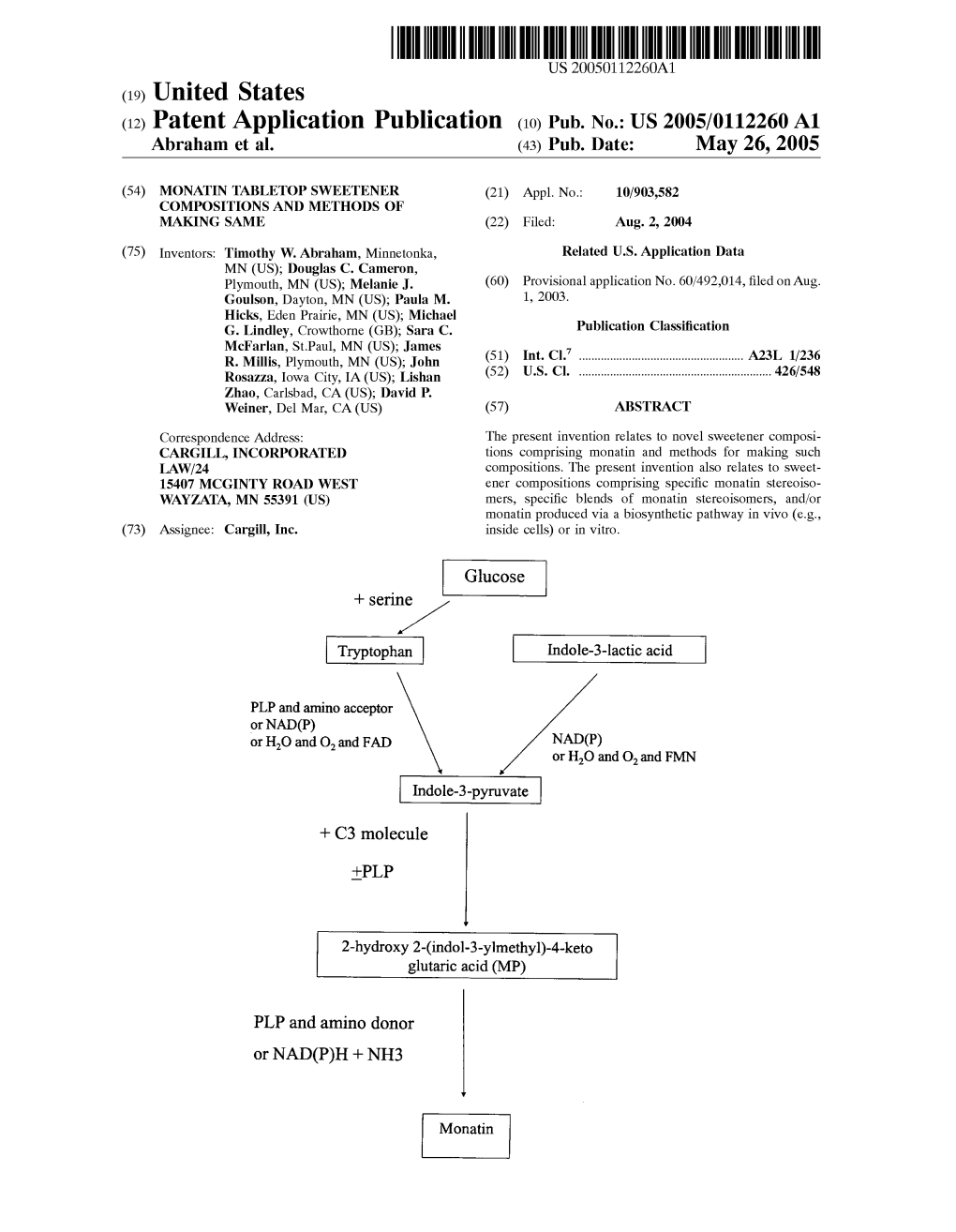

(12) Patent Application Publication (10) Pub. No.: US 2005/0112260 A1 Abraham Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Page Numbers in Bold Indicate Main Discus- Sion of Topic. Page Numbers

168397_P489-520.qxd7.0:34 Index 6-2-04 26p 2010.4.5 10:03 AM Page 489 source of, 109, 109f pairing with thymine, 396f, 397, 398f in tricarboxylic acid cycle, 109–111, 109f Adenine arabinoside (vidarabine, araA), 409 Acetyl CoA-ACP acetyltransferase, 184 Adenine phosphoribosyltransferase (APRT), Index Acetyl CoA carboxylase, 183, 185f, 190 296, 296f in absorptive/fed state, 324 Adenosine deaminase (ADA), 299 allosteric activation of, 183–184, 184f deficiency of, 298, 300f, 301–302 allosteric inactivation of, 183, 184f gene therapy for, 485, 486f dephosphorylation of, 184 Adenosine diphosphate (ADP) in fasting, 330 in ATP synthesis, 73, 77–78, 78f Page numbers in bold indicate main discus- hormonal regulation of, 184, 184f isocitrate dehydrogenase activation by, sion of topic. Page numbers followed by f long-term regulation of, 184 112 denote figures. “See” cross-references direct phosphorylation of, 183–184 transport of, to inner mitochondrial short-term regulation of, 183–184, 184f membrane, 79 the reader to the synonymous term. “See Acetyl CoA carboxylase-2 (ACC2), 191 in tricarboxylic acid cycle regulation, 114, also” cross-references direct the reader to N4-Acetylcytosine, 292f 114f related topics. [Note: Positional and configura- N-Acetyl-D-glucosamine, 142 in urea cycle, 255–256 N-Acetylgalactosamine (GalNAc), 160, 168 ribosylation, 95 tional designations in chemical names (for N-Acetylglucosamindase deficiency, 164f Adenosine monophosphate (AMP; also called example, “3-“, “α”, “N-“, “D-“) are ignored in N-Acetylglucosamine (GlcNAc), -

Review Article

REVIEW ARTICLE COLLAGEN METABOLISM COLLAGEN METABOLISM Types of Collagen 228 Structure of Collagen Molecules 230 Synthesis and Processing of Procollagen Polypeptides 232 Transcription and Translation 233 Posttranslational Modifications 233 Extracellular Processing of Procollagen and Collagen Fibrillogenesis 240 Functions of Collagen in Connective rissue 243 Collagen Degradation 245 Regulation of the Metabolism of Collagen 246 Heritable Diseases of Collagen 247 Recessive Dermatosparaxis 248 Recessive Forms of EDS 251 EDS VI 251 EDS VII 252 EDS V 252 Lysyl Oxidase Deficiency in the Mouse 253 X-Linked Cutis Laxa 253 Menke's Kinky Hair Syndrome 253 Homocystinuria 254 EDS IV 254 Dominant Forms of EDS 254 Dominant Collagen Packing Defect I 255 Dominant and Recessive Forms of Osteogenesis Imperfecta 258 Dominant and Recessive Forms of Cutis Laxa 258 The Marfan Syndrome 259 Acquired Diseases and Repair Processes Affecting Collagen 259 Acquired Changes in the Types of Collagen Synthesis 260 Acquired Changes in Amounts of Collagen Synthesized 263 Acquired Changes in Hydroxylation of Proline and Lysine 264 Acquired Changes in Collagen Cross-Links 265 Acquired Defects in Collagen Degradation 267 Conclusion 267 Bibliography 267 Collagen Metabolism A Comparison of Diseases of Collagen and Diseases Affecting Collagen Ronald R. Minor, VMD, PhD COLLAGEN CONSTITUTES approximately one third of the body's total protein, and changes in synthesis and/or degradation of colla- gen occur in nearly every disease process. There are also a number of newly described specific diseases of collagen in both man and domestic animals. Thus, an understanding of the synthesis, deposition, and turnover of collagen is important for the pathologist, the clinician, and the basic scientist alike. -

Tryptophan Catabolism During Sporulation in Bacillus Cereus. Chandan Prasad Louisiana State University and Agricultural & Mechanical College

Louisiana State University LSU Digital Commons LSU Historical Dissertations and Theses Graduate School 1970 Tryptophan Catabolism During Sporulation in Bacillus Cereus. Chandan Prasad Louisiana State University and Agricultural & Mechanical College Follow this and additional works at: https://digitalcommons.lsu.edu/gradschool_disstheses Recommended Citation Prasad, Chandan, "Tryptophan Catabolism During Sporulation in Bacillus Cereus." (1970). LSU Historical Dissertations and Theses. 1804. https://digitalcommons.lsu.edu/gradschool_disstheses/1804 This Dissertation is brought to you for free and open access by the Graduate School at LSU Digital Commons. It has been accepted for inclusion in LSU Historical Dissertations and Theses by an authorized administrator of LSU Digital Commons. For more information, please contact [email protected]. 71 - 34-36 PRASAD, Chandan, 1942- TRYPTOPHAN CATABOLISM DURING SPORULATION IN BACILLUS CEREUS. The Louisiana State University and Agricultural and Mechanical College, Ph.D., 1970 Microbiology University Microfilms, Inc., Ann Arbor, Michigan THIS DISSERTATION HAS BEEN MICROFILMED EXACTLY AS RECEIVED Tryptophan Catabolism During Sporulation in Bacillus cereus A Dissertation Submitted to the Graduate Faculty of the Louisiana State University and Agricultural and Mechanical College in partial fulfillment of the requirements for the degree of Doctor of Philosophy in The Department of Microbiology by Chandan Prasad B. Sc. (Hons.) U. P. Agricultural University, India, 1964 M. Sc. U. P. Agricultural University, India, 1966 May, 1970 ACKNOWLEDGME NTS The author wishes to express his appreciation to the staff and faculty members of the Department of Microbiology, who in their own ways contri buted to the progress of this work. It is with great pleasure that acknowledgment is made to Dr. -

Clostridium Sporogenes

(R)-Indolelactyl-CoA dehydratase, the key enzyme of tryptophan reduction to indolepropionate in Clostridium sporogenes Dissertation zur Erlangung des Doktorgrades der Naturwissenschaften (Dr. rer. Nat.) dem Fachbereich Biologie der Philipps-Universität Marburg vorgelegt von Diplom-Chemikerin Huan Li aus JiLin VR. China Marburg/Lahn, 2014 Die Untersuchungen zur vorliegenden Arbeit wurden von September 2010 bis Dezember 2013 im Max-Planck-Institut für terrestrische Mikrobiologie, Marburg und im Laboratorium für Mikrobiologie, Fachbereich Biologie, der Philipps-Universität Marburg (Hochschulkennziffer: 1180) unter der Leitung von Prof. Dr. Wolfgang Buckel durchgeführt. Vom Fachbereich Biologie der Philipps-Universität Marburg als Dissertation am angenommen. Erstgutachter: Prof. Dr. Wolfgang Buckel Zweitgutachter: Prof. Dr. Johann Heider Tag der mündlichen Prüfung am: Für den gläubigen Menschen steht Gott am Anfang, für den Wissenschaftler am Ende aller seiner Überlegungen. Max Planck 献给最亲爱的爸爸妈妈 Index Zusammenfassung 1 Summary 2 Introduction 3 1. The role of gastrointestinal microbiota metabolites ........................................................... 3 2. Fermentation of amino acids and Stickland-reaction ......................................................... 5 3. Clostridium sporogenes ........................................................................................................... 7 4. 2-Hydroxyacyl-CoA dehydratases and the unusual radical H2O-elimination ................. 9 5. Family Ш CoA-transferases ............................................................................................... -

Tryptophan Catabolism by Lactobacillus Spp. : Biochemistry and Implications on Flavor Development in Reduced-Fat Cheddar Cheese

Utah State University DigitalCommons@USU All Graduate Theses and Dissertations Graduate Studies 5-1998 Tryptophan Catabolism by Lactobacillus spp. : Biochemistry and Implications on Flavor Development in Reduced-Fat Cheddar Cheese Sanjay Gummalla Utah State University Follow this and additional works at: https://digitalcommons.usu.edu/etd Part of the Food Chemistry Commons, Food Microbiology Commons, and the Food Processing Commons Recommended Citation Gummalla, Sanjay, "Tryptophan Catabolism by Lactobacillus spp. : Biochemistry and Implications on Flavor Development in Reduced-Fat Cheddar Cheese" (1998). All Graduate Theses and Dissertations. 5454. https://digitalcommons.usu.edu/etd/5454 This Thesis is brought to you for free and open access by the Graduate Studies at DigitalCommons@USU. It has been accepted for inclusion in All Graduate Theses and Dissertations by an authorized administrator of DigitalCommons@USU. For more information, please contact [email protected]. TRYPTOPHAN CATABOLISM BY LACTOBACILLUS SPP.: BIOCHEMISTRY AND IMPLICATIONS ON FLAVOR DEVELOPMENT IN REDUCED-FAT CHEDDAR CHEESE by Sanjay Gummalla A thesis submitted in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE m Nutrition and Food Sciences Approved: UTAH STATE UNIVERSITY Logan, Utah 1998 11 Copyright © Sanjay Gummalla 1998 All Rights Reserved w ABSTRACT Tryptophan Catabolism by Lactobacillus spp. : Biochemistry and Implications on Flavor Development in Reduced-Fat Cheddar Cheese by Sanjay Gummalla, Master of Science Utah State University, 1998 Major Professor: Dr. Jeffery R. Broadbent Department: Nutrition and Food Sciences Amino acids derived from the degradation of casein in cheese serve as precursors for the generation of key flavor compounds. Microbial degradation of tryptophan (Trp) is thought to promote formation of aromatic compounds that impart putrid fecal or unclean flavors in cheese, but pathways for their production have not been established. -

Mice Carrying a Human GLUD2 Gene Recapitulate Aspects of Human Transcriptome and Metabolome Development

Mice carrying a human GLUD2 gene recapitulate aspects of human transcriptome and metabolome development Qian Lia,b,1, Song Guoa,1, Xi Jianga, Jaroslaw Brykc,2, Ronald Naumannd, Wolfgang Enardc,3, Masaru Tomitae, Masahiro Sugimotoe, Philipp Khaitovicha,c,f,4, and Svante Pääboc,4 aChinese Academy of Sciences Key Laboratory of Computational Biology, Chinese Academy of Sciences-Max Planck Partner Institute for Computational Biology, Shanghai Institutes for Biological Sciences, Chinese Academy of Sciences, 200031 Shanghai, China; bUniversity of Chinese Academy of Sciences, 100049 Beijing, China; cMax Planck Institute for Evolutionary Anthropology, 04103 Leipzig, Germany; dMax Planck Institute of Molecular Cell Biology and Genetics, D-01307 Dresden, Germany; eInstitute for Advanced Biosciences, Keio University, 997-0035 Tsuruoka, Yamagata, Japan; and fSkolkovo Institute for Science and Technology, 143025 Skolkovo, Russia Edited by Joshua M. Akey, University of Washington, Seattle, WA, and accepted by the Editorial Board April 1, 2016 (received for review September 28, 2015) Whereas all mammals have one glutamate dehydrogenase gene metabolic flux from glucose and glutamine to lipids by way of the (GLUD1), humans and apes carry an additional gene (GLUD2), TCA cycle (12). which encodes an enzyme with distinct biochemical properties. To investigate the physiological role the GLUD2 gene may We inserted a bacterial artificial chromosome containing the human play in human and ape brains, we generated mice transgenic for GLUD2. GLUD2 gene into mice and analyzed the resulting changes in the a genomic region containing human We compared effects transcriptome and metabolome during postnatal brain development. on gene expression and metabolism during postnatal development Effects were most pronounced early postnatally, and predominantly of the frontal cortex of the brain in these mice and their wild-type genes involved in neuronal development were affected. -

Combined Network Analysis and Machine Learning Allows the Prediction of Metabolic Pathways from Tomato Metabolomics Data

ARTICLE https://doi.org/10.1038/s42003-019-0440-4 OPEN Combined network analysis and machine learning allows the prediction of metabolic pathways from tomato metabolomics data David Toubiana 1, Rami Puzis 2, Lingling Wen3, Noga Sikron3, Assylay Kurmanbayeva3, 1234567890():,; Aigerim Soltabayeva3, Maria del Mar Rubio Wilhelmi1, Nir Sade3,4, Aaron Fait3, Moshe Sagi3, Eduardo Blumwald 1 & Yuval Elovici2 The identification and understanding of metabolic pathways is a key aspect in crop improvement and drug design. The common approach for their detection is based on gene annotation and ontology. Correlation-based network analysis, where metabolites are arran- ged into network formation, is used as a complentary tool. Here, we demonstrate the detection of metabolic pathways based on correlation-based network analysis combined with machine-learning techniques. Metabolites of known tomato pathways, non-tomato pathways, and random sets of metabolites were mapped as subgraphs onto metabolite correlation networks of the tomato pericarp. Network features were computed for each subgraph, generating a machine-learning model. The model predicted the presence of the β-alanine- degradation-I, tryptophan-degradation-VII-via-indole-3-pyruvate (yet unknown to plants), the β-alanine-biosynthesis-III, and the melibiose-degradation pathway, although melibiose was not part of the networks. In vivo assays validated the presence of the melibiose- degradation pathway. For the remaining pathways only some of the genes encoding reg- ulatory enzymes were detected. 1 Department of Plant Sciences, University of California, Davis, CA, USA. 2 Telekom Innovation Labs, Department of Software and Information Systems Engineering, Ben-Gurion University of the Negev, Beer Sheva, Israel. -

Organic Chemistry to Biochemistry

page 1 Metabolisn1 Review: Step by Step from Organic Chemistry to Biochemistry Overview: This handout contains a review of the fundamental parts of organic chemistry needed for metabolism. Dr. Richard Feinman Department of Biochemistry Room 7-20, BSB (718) 270-2252 [email protected] STEP-BY-STEP: ORGANIC CHEMISTRY TO NUTRITION AND METABOLISM page 2 CHAPTER O. INTRODUCTION Where we're going. The big picture in nutrition and metabolism is shown in a block diagram or "black box" diagram. A black box approach shows inputs and outputs to a process that may not be understood. It is favored by engineers who are the group that are most uncomfortable with the idea that they don't know anything at all. The black box approach can frequently give ----c02 you some insight because it organizes whatever you do know. For example: ENERGY CELL MA TERIA L 1. Even though the block diagram is very simple, just looking at the inputs and outputs gives us some useful information. il The diagram says animals obtain energy by the oxidation of food to CO2 and water. Although you knew this before, the diagram highlights the fact that understanding biochemistry probably involves understanding oxidation-reduction reactions. 2. The diagram also indicates what might not be obvious: a major part of the energy obtained from oxidation of food is used to make new cell material. Although we think of organisms using energy for locomotion or to do physical work, in fact, most of the energy used is chemical energy. 3. Inside the black boxes in the diagram contain are the (organic) chemical reactions that convert food into energy and cell material. -

Elastin and the Lung

Thorax: first published as 10.1136/thx.41.8.577 on 1 August 1986. Downloaded from Thorax 1986;41:577-585 Review article Elastin and the lung It is essential that the framework of all multicellular most prominently displayed in newly synthesised or organisms should include some materials with high juvenile elastin, is a glycoprotein that stains with ura- tensile strength and rigidity, such as bone and col- nyl acetate and leads, which appears as small fibrils lagen, to maintain shape and mechanical rigidity. In 10-12 nm in diameter concentrated around the addition, there is a requirement for a component with periphery of the amorphous elastin. The microfibrils intrinsic elasticity that can stretch and undergo elastic are chemically and morphologically quite distinct recoil when required. This property is supplied by an from the amorphous elastin. There is some evidence unusual fibrous protein, which over 150 years ago was to suggest that the microfibrils are secreted into the given the name elastin. extracellular matrix before elastin synthesis and func- Elastin fibres are present in virtually all vertebrate tion as a nucleation site for future elastin deposition. tissues, although it is only within a few, such as ar- For more details on every aspect of the microfibrils, teries, some ligaments, and the lung, that elastin com- readers are referred to other articles.24 prises an appreciable percentage of the total protein. The purification of elastin depends predominantly The ligamentum nuchae of grazing animals and the on its remarkable insolubility, even under harsh, aorta of most vertebrates contain over 50% elastin on denaturing conditions. -

Characterization of Two Aromatic Amino Acid Aminotransferases and Production of Indoleacetic Acid in Azospirillum Strains

Soil Biol. Biochem.Vol. 26, No. 1, pp. 51-63, 1994 Pergamon Copyright 0 1994 Elsevier Science Ltd Printed in Great Britain. All rights reserved 0038-0717/94$6.00 + 0.00 CHARACTERIZATION OF TWO AROMATIC AMINO ACID AMINOTRANSFERASES AND PRODUCTION OF INDOLEACETIC ACID IN AZOSPIRILLUM STRAINS B. E. BACA, L. SOTO-URZUA, Y. G. XOCHIHUA-CORONAand A. CUERVO-GARCIA Department0 de Investigaciones Microbiologicas, Instituto de Ciencias, Universidad Autonoma de Puebla, Apartado Postal 1622, 72000 Puebla Pue, Mexico (Accepted 30 May 1993) Sunnnary-Experiments were made to quantify indole-3-acetic acid (IAA) excreted by different wild type strains of Azospirilhun spp. The microorganisms produce IAA, during the late stationary growth phase and show a significant increase in IAA production when tryptophan is present in the medium. Under these conditions with the A. brusilense strain UAP 14, we observed two aromatic amino acid aminotransferases. Their enzymatic activity and electrophoretic mobility under non-denaturating conditions were character- ized using cell-free extracts. Biochemical studies showed that these two enzymes can be distinguished by their electrophoretic mobilities. These enzymes are constitutively produced and they are not repressed by tyrosine or by tyrosine plus phenlylalanine. INTRODUCTION described in Pseudomonas savastanoi and Agrobac- terium tumefaciens. In Azospirillum this process is Soil bacteria of the genus Azospirillum live in associ- poorly understood. Hartman et al. (1983) and Zim- ation with the root zones of grasses and other plants, mer et al. (1988) identified indole-3-pyruvic acid among which are the economically-important culti- (IPyA), indole-3-acetaldehyde, and IAA as the sub- vated plants maize, wheat, barley, rye, oat and rice. -

Pharmaceutical Preparation for Preventing and Treating Progressive Myopia

(19) TZZ¥_Z¥ T (11) EP 3 103 446 A2 (12) EUROPEAN PATENT APPLICATION published in accordance with Art. 153(4) EPC (43) Date of publication: (51) Int Cl.: 14.12.2016 Bulletin 2016/50 A61K 31/13 (2006.01) A61K 9/08 (2006.01) A61P 27/10 (2006.01) (21) Application number: 14872234.1 (86) International application number: (22) Date of filing: 16.12.2014 PCT/RU2014/000949 (87) International publication number: WO 2015/094019 (25.06.2015 Gazette 2015/25) (84) Designated Contracting States: • Korigodskiy, Aleksandr Robertovich AL AT BE BG CH CY CZ DE DK EE ES FI FR GB Moscow 107113 (RU) GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR (72) Inventors: Designated Extension States: • Zakharov, Ivan Dmitrievich BA ME Moscow 109125 (RU) • Korigodskiy, Aleksandr Robertovich (30) Priority: 17.12.2013 RU 2013155972 Moscow 107113 (RU) (71) Applicants: (74) Representative: Chas. Hude A/S • Zakharov, Ivan Dmitrievich H.C. Andersens Boulevard 33 Moscow 109125 (RU) 1780 Copenhagen V (DK) (54) PHARMACEUTICAL PREPARATION FOR PREVENTING AND TREATING PROGRESSIVE MYOPIA (57) The invention relates to medicine, and more par- during the treatment of progressive myopia. These aims ticularly to opthalmology, and is intended for strengthen- are achieved through the creation and use of a pharma- ing the sclera for the purposes of preventing and treating ceutical preparation in the form of an instillable aqueous progressive myopia. The invention is directed toward solution or an eye gel or a medicated eye film containing strengthening the sclera in the case of progressive my- an effective amount of an amine with functional groups opia, reducing the time taken to strengthen the sclera, in the form of a salt or a part of a transition metal complex and preventing damaging, toxic and inflammatory effects compound or a combination thereof. -

O O2 Enzymes Available from Sigma Enzymes Available from Sigma

COO 2.7.1.15 Ribokinase OXIDOREDUCTASES CONH2 COO 2.7.1.16 Ribulokinase 1.1.1.1 Alcohol dehydrogenase BLOOD GROUP + O O + O O 1.1.1.3 Homoserine dehydrogenase HYALURONIC ACID DERMATAN ALGINATES O-ANTIGENS STARCH GLYCOGEN CH COO N COO 2.7.1.17 Xylulokinase P GLYCOPROTEINS SUBSTANCES 2 OH N + COO 1.1.1.8 Glycerol-3-phosphate dehydrogenase Ribose -O - P - O - P - O- Adenosine(P) Ribose - O - P - O - P - O -Adenosine NICOTINATE 2.7.1.19 Phosphoribulokinase GANGLIOSIDES PEPTIDO- CH OH CH OH N 1 + COO 1.1.1.9 D-Xylulose reductase 2 2 NH .2.1 2.7.1.24 Dephospho-CoA kinase O CHITIN CHONDROITIN PECTIN INULIN CELLULOSE O O NH O O O O Ribose- P 2.4 N N RP 1.1.1.10 l-Xylulose reductase MUCINS GLYCAN 6.3.5.1 2.7.7.18 2.7.1.25 Adenylylsulfate kinase CH2OH HO Indoleacetate Indoxyl + 1.1.1.14 l-Iditol dehydrogenase L O O O Desamino-NAD Nicotinate- Quinolinate- A 2.7.1.28 Triokinase O O 1.1.1.132 HO (Auxin) NAD(P) 6.3.1.5 2.4.2.19 1.1.1.19 Glucuronate reductase CHOH - 2.4.1.68 CH3 OH OH OH nucleotide 2.7.1.30 Glycerol kinase Y - COO nucleotide 2.7.1.31 Glycerate kinase 1.1.1.21 Aldehyde reductase AcNH CHOH COO 6.3.2.7-10 2.4.1.69 O 1.2.3.7 2.4.2.19 R OPPT OH OH + 1.1.1.22 UDPglucose dehydrogenase 2.4.99.7 HO O OPPU HO 2.7.1.32 Choline kinase S CH2OH 6.3.2.13 OH OPPU CH HO CH2CH(NH3)COO HO CH CH NH HO CH2CH2NHCOCH3 CH O CH CH NHCOCH COO 1.1.1.23 Histidinol dehydrogenase OPC 2.4.1.17 3 2.4.1.29 CH CHO 2 2 2 3 2 2 3 O 2.7.1.33 Pantothenate kinase CH3CH NHAC OH OH OH LACTOSE 2 COO 1.1.1.25 Shikimate dehydrogenase A HO HO OPPG CH OH 2.7.1.34 Pantetheine kinase UDP- TDP-Rhamnose 2 NH NH NH NH N M 2.7.1.36 Mevalonate kinase 1.1.1.27 Lactate dehydrogenase HO COO- GDP- 2.4.1.21 O NH NH 4.1.1.28 2.3.1.5 2.1.1.4 1.1.1.29 Glycerate dehydrogenase C UDP-N-Ac-Muramate Iduronate OH 2.4.1.1 2.4.1.11 HO 5-Hydroxy- 5-Hydroxytryptamine N-Acetyl-serotonin N-Acetyl-5-O-methyl-serotonin Quinolinate 2.7.1.39 Homoserine kinase Mannuronate CH3 etc.