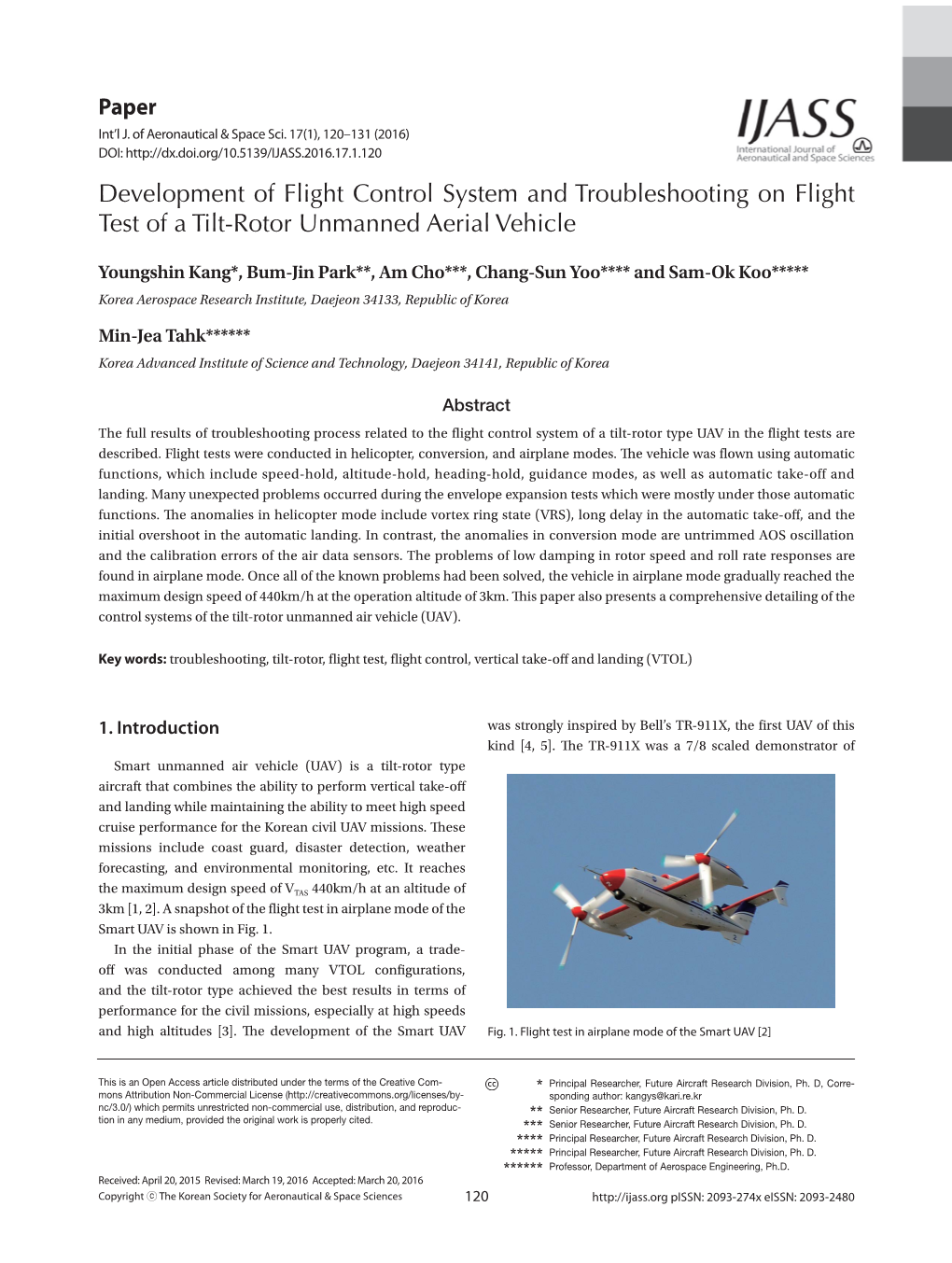

Development of Flight Control System and Troubleshooting on Flight Test of a Tilt-Rotor Unmanned Aerial Vehicle

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Aircraft Flight Manual

AIRCRAFT FLIGHT MANUAL 770-00048 | REVISION A | 03.23.2016 REVISION HISTORY REVISION DATE DESCRIPTION A March 2016 Initial Release ALTA 8 AIRCRAFT FLIGHT MANUAL PART NUMBER: 770-00048 CONTENTS 2 Revision History 3 Contents 6 ALTA 8 OVERVIEW 7 Disclaimer and Warning 9 Limitation of Liability 11 Introduction 12 Symbols, Abbreviations and Terminology 15 Dimensions 17 Included Items 18 Specifications 22 Limitations 24 System Diagrams 28 ALTA Mobile App 28 Additional Required Components (not included) 29 SETTING UP ALTA 8 30 Unfolding/Folding ALTA 8 33 Radio Installation 38 Radio Mapping 43 Configuring for MōVIs 45 Isolator Cartridges 46 Battery Installation 51 Compass Calibration 54 Propellers 56 First Person View (FPV) 63 Tuning ALTA 8 66 ALTA 8 Flight Parameters 69 Resetting ALTA 8 WiFi Password 70 OPERATING ALTA 8 71 Flight Controller Modes 74 Home Switch | AIRCRAFT FLIGHT MANUAL 3 75 Disarm Safety Switch 76 Status Light 78 Alarms 79 Orientation Lights 80 ALTA App Monitor 81 Data Logging 82 NORMAL PROCEDURES 83 Unpacking and Setup 84 Before Starting 86 Before Takeoff 88 After Every Flight 90 After Last Flight 91 EMERGENCY PROCEDURES 92 Emergency Guidance 93 Status Light Warning Indicator Illuminates 94 Pilot Disorientation 95 Unexpected Flight Controller Behavior 96 Battery Exhaustion 97 Loss of Radio Control Signal 98 Loss of FPV Signal 99 PERFORMANCE 100 Weight / Endurance Performance Data 101 Allowable Gross Weight Gross Weight 102 MAINTAINING ALTA 8 103 General Information and Techniques 104 Maintenance Items 108 Firmware Update Process 109 Motor Alignment 112 Guidelines Following an Accident | AIRCRAFT FLIGHT MANUAL 4 113 TROUBLESHOOTING 116 APPENDIX 117 Appendix A. -

Development and Flight Test Experiences with a Flight-Crucial Digital Control System

NASA Technical Paper 2857 1 1988 Development and Flight Test Experiences With a Flight-Crucial Digital Control System Dale A. Mackall Ames Research Center Dryden Flight Research Facility Edwards, Calgornia I National Aeronautics I and Space Administration I Scientific and Technical Information Division I CONTENTS Page ~ SUMMARY ................................... 1 I 1 INTRODUCTION . 1 2 NOMENCLATURE . 2 3 SYSTEM SPECIFICATION . 5 3.1 Control Laws and Handling Qualities ................. 5 3.2 Reliability and Fault Tolerance ................... 5 4 DESIGN .................................. 6 4.1 System Architecture and Fault Tolerance ............... 6 4.1.1 Digital flight control system architecture .......... 6 4.1.2 Digital flight control system computer hardware ........ 8 4.1.3 Avionics interface ...................... 8 4.1.4 Pilot interface ........................ 9 4.1.5 Actuator interface ...................... 10 4.1.6 Electrical system interface .................. 11 4.1.7 Selector monitor and failure manager ............. 12 4.1.8 Built-in test and memory mode ................. 14 4.2 ControlLaws ............................. 15 4.2.1 Control law development process ................ 15 4.2.2 Control law design ...................... 15 4.3 Digital Flight Control System Software ................ 17 4.3.1 Software development process ................. 18 4.3.2 Software design ........................ 19 5 SYSTEM-SOFTWARE QUALIFICATION AND DESIGN ITERATIONS ............ 19 5.1 Schedule ............................... 20 5.2 Software Verification ........................ 21 5.2.1 Verification test plan .................... 21 5.2.2 Verification support equipment . ................ 22 5.2.3 Verification tests ...................... 22 5.2.4 Reverifying the design iterations ............... 24 5.3 System Validation .......................... 24 5.3.1 Validation test plan . ............... 24 5.3.2 Support equipment ....................... 25 5.3.3 Validation tests ....................... 25 5.3.4 Revalidation of designs ................... -

Fly-By-Wire - Wikipedia, the Free Encyclopedia 11-8-20 下午5:33 Fly-By-Wire from Wikipedia, the Free Encyclopedia

Fly-by-wire - Wikipedia, the free encyclopedia 11-8-20 下午5:33 Fly-by-wire From Wikipedia, the free encyclopedia Fly-by-wire (FBW) is a system that replaces the Fly-by-wire conventional manual flight controls of an aircraft with an electronic interface. The movements of flight controls are converted to electronic signals transmitted by wires (hence the fly-by-wire term), and flight control computers determine how to move the actuators at each control surface to provide the ordered response. The fly-by-wire system also allows automatic signals sent by the aircraft's computers to perform functions without the pilot's input, as in systems that automatically help stabilize the aircraft.[1] Contents Green colored flight control wiring of a test aircraft 1 Development 1.1 Basic operation 1.1.1 Command 1.1.2 Automatic Stability Systems 1.2 Safety and redundancy 1.3 Weight saving 1.4 History 2 Analog systems 3 Digital systems 3.1 Applications 3.2 Legislation 3.3 Redundancy 3.4 Airbus/Boeing 4 Engine digital control 5 Further developments 5.1 Fly-by-optics 5.2 Power-by-wire 5.3 Fly-by-wireless 5.4 Intelligent Flight Control System 6 See also 7 References 8 External links Development http://en.wikipedia.org/wiki/Fly-by-wire Page 1 of 9 Fly-by-wire - Wikipedia, the free encyclopedia 11-8-20 下午5:33 Mechanical and hydro-mechanical flight control systems are relatively heavy and require careful routing of flight control cables through the aircraft by systems of pulleys, cranks, tension cables and hydraulic pipes. -

Development of F/A-18 Spin Departure Demonstration Procedure with Departure Resistant Flight Control Computer Version 10.7

University of Tennessee, Knoxville TRACE: Tennessee Research and Creative Exchange Masters Theses Graduate School 12-2004 Development of F/A-18 Spin Departure Demonstration Procedure with Departure Resistant Flight Control Computer Version 10.7 David J. Park University of Tennessee - Knoxville Follow this and additional works at: https://trace.tennessee.edu/utk_gradthes Part of the Aerospace Engineering Commons Recommended Citation Park, David J., "Development of F/A-18 Spin Departure Demonstration Procedure with Departure Resistant Flight Control Computer Version 10.7. " Master's Thesis, University of Tennessee, 2004. https://trace.tennessee.edu/utk_gradthes/2312 This Thesis is brought to you for free and open access by the Graduate School at TRACE: Tennessee Research and Creative Exchange. It has been accepted for inclusion in Masters Theses by an authorized administrator of TRACE: Tennessee Research and Creative Exchange. For more information, please contact [email protected]. To the Graduate Council: I am submitting herewith a thesis written by David J. Park entitled "Development of F/A-18 Spin Departure Demonstration Procedure with Departure Resistant Flight Control Computer Version 10.7." I have examined the final electronic copy of this thesis for form and content and recommend that it be accepted in partial fulfillment of the equirr ements for the degree of Master of Science, with a major in Aviation Systems. Robert. B. Richards, Major Professor We have read this thesis and recommend its acceptance: Charles T. N. Paludan, Richard J. Ranaudo Accepted for the Council: Carolyn R. Hodges Vice Provost and Dean of the Graduate School (Original signatures are on file with official studentecor r ds.) To the Graduate Council: I am submitting herewith a thesis written by David J. -

Fly-By-Wire: Getting Started on the Right Foot and Staying There…

Fly-by-Wire: Getting started on the right foot and staying there… Imagine yourself getting into the cockpit of an aircraft, finishing your preflight checks, and taxiing out to the runway ready for takeoff. You begin the takeoff roll and start to rotate. As you lift off, you discover your side stick controller is not responding correctly to your commands. Panic sets in, and you feel that you’ve lost total control of the aircraft. Thanks to quick action from your second in command, he takes over and stabilizes the aircraft so that you both can plan to return to the airport under reversionary mode. This situation could have been a catastrophe. This happened in August of 2001. A Lufthansa Airbus A320 came within less than two feet and a few seconds of crashing during takeoff on a planned flight from Frankfurt to Paris. Preliminary reports indicated that maintenance was performed on the captain’s sidestick controller immediately before the incident. This had inadvertently created a situation in which control inputs were reversed. The case reveals that at least two "filters," or safety defenses, were breached, leading to a near-crash shortly after rotation at Frankfurt’s Runway 18. Quick action by the first officer prevented a catastrophe. Lufthansa Technik personnel found a damaged pin on one segment of the four connector segments (with 140 pins on each) at the "rack side," as it were, of the avionics mount. This incident prompted an article to be published in the 2003 November-December issue of the Flight Safety Mechanics Bulletin. The report detailed all that transpired during the maintenance and subsequent release of the aircraft. -

Radio Altimeter Industry Coalition Coalition Overview David Silver, Aerospace Industries Association

Radio Altimeter Industry Coalition Coalition Overview David Silver, Aerospace Industries Association 7/1/2021 2 Background • The aviation industry, working through a multi-stakeholder group formed after open, public invitation by RTCA, conducted a study to determine interference threshold to radio altimeters • The study found that 5G systems operating in the 3.7-3.98 GHz band will cause harmful interference altimeter systems operating in the 4.2- 4.4 GHz band – and in some cases far exceed interference thresholds • Harmful interference has the serious potential to impact public and aviation safety, create delays in aircraft operations, and prevent operations responding to emergency situations 7/1/2021 3 Goals and Way Forward • To ensure the safety of the public and aviation community, government, manufacturers, and operators must work together to: • Further refine the full scope of the interference threat • Determine operational environments affected • Identify technical solutions that will resolve interference issues • Develop future standards • Government needs to bring the telecom and aviation industries to the table to refine understanding of the extent of the problem and collaboratively develop mitigations to address the changing spectrum environment near-, mid-, and long- term. 7/1/2021 4 Coalition Tech-Ops Presentation John Shea, Helicopter Association International Sai Kalyanaraman, Ph.D., Collins Aerospace 7/1/2021 5 What is a Radar Altimeter? • Radar altimeters are the only device on the aircraft that can directly measure the distance between the aircraft and the ground and only operate in 4200-4400 MHz • Operate when the aircraft is on the surface to over 2500’ above ground Radar Altimeter Antennas Radar Altimeter Antennas Photo credit: Honeywell Photo credit: ALPA 7/1/2021 6 How Does a Radar Altimeter Work? 1. -

Flight Control Systems Development and Flight Test Exp(6Rience With

NASA Technical Paper 2822 June 1988 Flight Control Systems Development and Flight Test Exp(6rienceWith the HiMAT Research Vehicles Robert W. Kernpel and Michael R. &ark (bAS1-Ik-282.k) kllGtllI CChlECl SYSTEHS N89-15929 LEVELCCMEkS AND FLlGHl 'XES2 ELEEBlEhCE kIlH ItE iliMA? KESkAICt VEHICLES (bASB) U8 p CSCL OlC Unclas 81/08 016S7tl NASA NASA Tech nica I Paper 2822 1988 Flight Control Systems Development and Flight - Test Experience With the HiMAT Research Vehicles Robert W. Kempel and Michael R. Earls Ames Research Center Dryden Flight Research Facility Edwarcls, Calfornia National Aeronautics and Space Administration Scientific and Technical Information Division CONTENTS SUMMARY 1 INTRODUCTION 1 NOMENCLATURE 1 Letter and Mathematical Symbols ................................... 1 Abbreviations ............................................... 2 HiMAT VEHICLE DESCRIPTION AND OPERATIONAL PROCEDURE 2 HiMAT SYSTEMS DESCRIPTIONS 3 Systems Overview ............................................ 3 Ground Systems ............................................. 4 Downlink Receiving Station .................................... 4 V-77 Computer ........................................... 4 Pilot’s and Flight Test Engineer’s Station ............................ 4 Control Law. Maneuver. and Navigation Computers ...................... 4 Uplink Encoder ........................................... 5 Airborne Systems ............................................. 5 Uplink Receivers-Diversity Combiner-Decoders ......................... 5 Airborne Computers ....................................... -

Aircraft Flight Manual

AIRCRAFT FLIGHT MANUAL 770-00042 | REVISION D | 01.16.2017 REVISION HISTORY REVISION DATE DESCRIPTION A July 2015 Initial Release B August 2015 Revised section order. Added Allowable Gross Weight table. C October 2015 Revised for clarity. Added Disarm Safety function and WiFi password reset information. Revised default tuning values to reflect SYNAPSE version 3.4. D January 2017 Added discussion of features available in SYNAPSE version 4.0.4. Added Kinematic Position Mode. Added Orbit Mode. Updated Alarm Light scenarios. Added procedure to disable ceiling and range limits. Updated Autoland descent rate. Updated default settings, switch functions, and data logging fields. General updates and typographical fixes. Revised name to ALTA 6. Added additional maintenance items, motor alignment process, additional troubleshooting information. Fixed errata. ALTA 6 AIRCRAFT FLIGHT MANUAL DOCUMENT NUMBER: 770-00042 CONTENTS 2 Revision History 3 Table of Contents 6 ALTA 6 OVERVIEW 7 Disclaimer and Warning 9 Limitation of Liability 10 Introduction 11 Symbols, Abbreviations, and Terminology 14 Dimensions 16 Included Items 17 Specifications 21 Limitations 23 System Diagrams 27 ALTA Mobile App 28 Additional Required Components (not included) 29 SETTING UP ALTA 6 30 Unfolding/Folding ALTA 6 33 Radio Installation 38 Radio Channel Mapping 44 Configuring for MōVI 46 Isolator Cartridges 47 Battery Installation 52 Compass Calibration 55 Propellers 57 First Person View (FPV) 64 Tuning ALTA 6 68 ALTA 6 Flight Parameters 72 Resetting ALTA 6 WiFi Password 73 OPERATING -

Fly-By-Wire Augmented Manual Control - Basic Design Considerations

FLY-BY-WIRE AUGMENTED MANUAL CONTROL - BASIC DESIGN CONSIDERATIONS Dominik Niedermeier∗ , Anthony A. Lambregts∗∗ ∗Deutsches Zentrum für Luft- und Raumfahrt e.V., ∗∗Federal Aviation Administration [email protected]; [email protected] Keywords: Fly-by-Wire, Manual augmented control, C∗ control algorithm, C∗U control algorithm Abstract manufacturer allowing reduced training re- quirements After the introduction of Fly-by-Wire (FBW) flight control in the late eighties, several thousands of com- • Weight and maintenance effort reduction by re- mercial FBW aircraft are in service today. Look- placing mechanical components (e.g. pulleys, ing back, it can be concluded that FBW has brought cables) an impressive improvement to handling qualities and • Introduction of flight envelope protection func- flight safety. However, after the long time of experi- tions for enhanced safety ence with the first generations of FBW aircraft, open questions and issues with respect to the design and • Introduction of maneuver/gust load alleviation the operation of FBW have been revealed. The main functions objective of this paper is to discuss those issues and to • Optimization of aerodynamic performance (e.g. point out further research needs in this field. The char- drag reduction by aft-shifted center of gravity) acteristics of manual augmented pitch control algo- rithms implemented in commercial FBW aircraft are Manufacturer Current Models No. of deliveries discussed in detail. Subsequently the paper describes Boeing B777 1003 particular features of Airbus and Boeing FBW control B787 8 systems that are not directly related to the chosen con- Airbus A318/319/320/321 5022 trol algorithm. Open questions and resulting research A330/340 1225 needs with special focus on recent incidents and acci- A380 71 Embraer E-170/190 802 dents are discussed. -

Pilot Performance, Workload, and Situation Awareness During Lunar Landing Mode Transitions

JOURNAL OF SPACECRAFT AND ROCKETS Pilot Performance, Workload, and Situation Awareness During Lunar Landing Mode Transitions Christopher J. Hainley, Jr.∗ Massachusetts Institute of Technology, Cambridge, Massachusetts 02139 Kevin R. Duda† Charles Stark Draper Laboratory, Inc., Cambridge, Massachusetts 02139 and Charles M. Oman‡ and Alan Natapoff§ Massachusetts Institute of Technology, Cambridge, Massachusetts 02139 DOI: 10.2514/1.A32267 Aircraft and spacecraft pilots frequently change their level of supervisory control between full autopilot and other modes, providing varying levels of manual control. Therefore, multimodal systems must transition “gracefully,” meaning without unsafe decreases in flight performance or unacceptable changes in workload or situation awareness. Thirteen subjects flew a fixed base simulation of the NASA Constellation Program Altair lunar lander that transitioned from full autopilot to one of three flight-director-guided rate-command attitude hold manual control modes. After training, each subject flew 24 approaches, half of which included a landing point redesignation at the time of the mode transition requiring the pilot to null additional guidance errors. Bedford subjective workload and two-choice embedded secondary task response times were used to quantify temporal changes in mental workload. Situation awareness transients were detected by analysis of a tertiary task, verbal callouts of altitude, fuel, and terrain hazards. Graceful transitions were particularly difficult because Altair’s large inertia made the plant dynamics relatively sluggish. Transitions to manual control increased subjective and objective workloads and decreased callout accuracy in proportion to the number of flight control axes being manually commanded. I. Introduction Automation design heuristics [4], theories of supervisory control – ANY large transport aircraft and spacecraft, such as the [5], and level-of-automation (LOA) taxonomies [6 8] were initially M Apollo Lunar Landing Module and the U.S. -

Flight Envelope Protection for Automatic and Augmented Manual Control

Proceedings of the EuroGNC 2013, 2nd CEAS Specialist Conference on FrAT3.5 Guidance, Navigation & Control, Delft University of Technology, Delft, The Netherlands, April 10-12, 2013 Flight Envelope Protection for Automatic and Augmented Manual Control Antonius A. Lambregts* Abstract Loss of Control (LOC) is currently the largest contributing category of catastrophic airplane accidents. A large percentage of the LOC accidents involve general aviation airplanes. The FAA is therefore has sponsored research to develop certification requirements for add-on envelope protection functions. This paper briefly discusses some of the LOC accidents and the deficiencies existing in many of the current GA and Transport airplane guidance and control systems that can lead to LOC. Next the paper discusses Envelope Protection (EP) design requirements, as well as functional, safety and performance objectives and design guidelines. Various approaches to designing envelope protection functions are discussed for airplanes under automatic or augmented manual Fly by Wire (FBW) control, to prevent stall, overspeed, excessive pitch and roll attitudes and excessive Normal Load Factor (NLF). Examples of simulation time history of what can be achieved are included. 1 Introduction In spite of the large strides made in recent years to improve flight safety, Loss of Control (LOC) continues to be the largest contributing cause of accidents and incidents. Loss of Control can occur during airplane operations under automatic and under manual control, on airplanes with conventional control systems, or FBW control systems. LOC accidents and incidents can be attributed to many causes, including pilot error, airplane upsets, design malfunctions, design deficiency. LOC accidents and incidents can be further classified by main types: airplane stall during manual speed control o pilot mishandling (e.g. -

Powerplant Trainers Avionics & Instruments

Train for Tomorrow...TODAY s uct . od p Pr r g o in C in ra n T i e a c Powerplant Trainers r n a T n o e r t in e a M Aircraft Systems Trainers A ft a r c r i A Avionics & Instruments Trainers Computer Based Training Courseware Catalog 0113 Introduction AeroTrain Corp. has gone through an evolutionary Besides supplying training aids, AeroTrain Corp. also process from a modest start in 1995 as a dba (doing offers consulting services for the development of Federal business as) company named ‘Systems Solutions’ to Aviation Administration (FAA) Part 147 and European a Michigan-incorporated company in April 2001 as Aviation Safety Agency (EASA) part 147 approved ‘Avitek Engineering Corporation’. The company name curricula for aircraft maintenance training schools. We was changed to the current name ‘AeroTrain Corp.’ have recently begun offering our consultation services in 2006 to show our total focus on aircraft training to universities for the establishment of undergraduate products. degree programs in Aerospace Engineering, and in Avionics Engineering. With a customer base spread in 23 countries, AeroTrain is your one-stop source for aircraft maintenance We look forward to expanding our customer base training equipment needs. We have sound expertise in and are continuously striving to improve our product developing standard and customized training-aids for quality and capabilities, to ensure on-time deliveries, aircraft systems training. and to provide excellent after sales support. Our expertise includes design and development of training-aids for avionics, aircraft engines, aircraft systems, instruments, and electrical systems relevant to aircraft maintenance training.