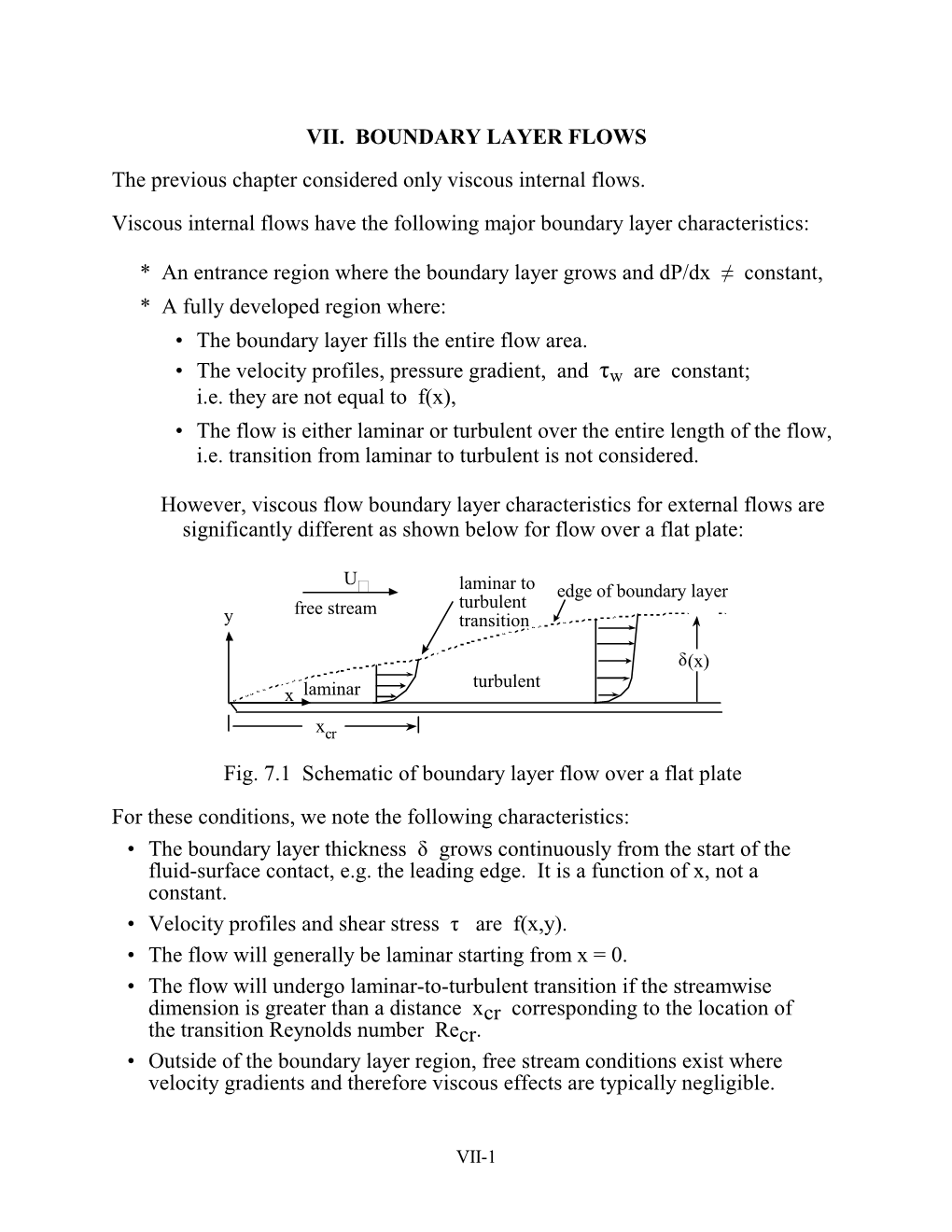

VII. BOUNDARY LAYER FLOWS the Previous Chapter Considered Only Viscous Internal Flows. Viscous Internal Flows Have the Followin

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Glossary Physics (I-Introduction)

1 Glossary Physics (I-introduction) - Efficiency: The percent of the work put into a machine that is converted into useful work output; = work done / energy used [-]. = eta In machines: The work output of any machine cannot exceed the work input (<=100%); in an ideal machine, where no energy is transformed into heat: work(input) = work(output), =100%. Energy: The property of a system that enables it to do work. Conservation o. E.: Energy cannot be created or destroyed; it may be transformed from one form into another, but the total amount of energy never changes. Equilibrium: The state of an object when not acted upon by a net force or net torque; an object in equilibrium may be at rest or moving at uniform velocity - not accelerating. Mechanical E.: The state of an object or system of objects for which any impressed forces cancels to zero and no acceleration occurs. Dynamic E.: Object is moving without experiencing acceleration. Static E.: Object is at rest.F Force: The influence that can cause an object to be accelerated or retarded; is always in the direction of the net force, hence a vector quantity; the four elementary forces are: Electromagnetic F.: Is an attraction or repulsion G, gravit. const.6.672E-11[Nm2/kg2] between electric charges: d, distance [m] 2 2 2 2 F = 1/(40) (q1q2/d ) [(CC/m )(Nm /C )] = [N] m,M, mass [kg] Gravitational F.: Is a mutual attraction between all masses: q, charge [As] [C] 2 2 2 2 F = GmM/d [Nm /kg kg 1/m ] = [N] 0, dielectric constant Strong F.: (nuclear force) Acts within the nuclei of atoms: 8.854E-12 [C2/Nm2] [F/m] 2 2 2 2 2 F = 1/(40) (e /d ) [(CC/m )(Nm /C )] = [N] , 3.14 [-] Weak F.: Manifests itself in special reactions among elementary e, 1.60210 E-19 [As] [C] particles, such as the reaction that occur in radioactive decay. -

Brief History of the Early Development of Theoretical and Experimental Fluid Dynamics

Brief History of the Early Development of Theoretical and Experimental Fluid Dynamics John D. Anderson Jr. Aeronautics Division, National Air and Space Museum, Smithsonian Institution, Washington, DC, USA 1 INTRODUCTION 1 Introduction 1 2 Early Greek Science: Aristotle and Archimedes 2 As you read these words, there are millions of modern engi- neering devices in operation that depend in part, or in total, 3 DA Vinci’s Fluid Dynamics 2 on the understanding of fluid dynamics – airplanes in flight, 4 The Velocity-Squared Law 3 ships at sea, automobiles on the road, mechanical biomedi- 5 Newton and the Sine-Squared Law 5 cal devices, and so on. In the modern world, we sometimes take these devices for granted. However, it is important to 6 Daniel Bernoulli and the Pressure-Velocity pause for a moment and realize that each of these machines Concept 7 is a miracle in modern engineering fluid dynamics wherein 7 Henri Pitot and the Invention of the Pitot Tube 9 many diverse fundamental laws of nature are harnessed and 8 The High Noon of Eighteenth Century Fluid combined in a useful fashion so as to produce a safe, efficient, Dynamics – Leonhard Euler and the Governing and effective machine. Indeed, the sight of an airplane flying Equations of Inviscid Fluid Motion 10 overhead typifies the laws of aerodynamics in action, and it 9 Inclusion of Friction in Theoretical Fluid is easy to forget that just two centuries ago, these laws were Dynamics: the Works of Navier and Stokes 11 so mysterious, unknown or misunderstood as to preclude a flying machine from even lifting off the ground; let alone 10 Osborne Reynolds: Understanding Turbulent successfully flying through the air. -

1 Fluid Flow Outline Fundamentals of Rheology

Fluid Flow Outline • Fundamentals and applications of rheology • Shear stress and shear rate • Viscosity and types of viscometers • Rheological classification of fluids • Apparent viscosity • Effect of temperature on viscosity • Reynolds number and types of flow • Flow in a pipe • Volumetric and mass flow rate • Friction factor (in straight pipe), friction coefficient (for fittings, expansion, contraction), pressure drop, energy loss • Pumping requirements (overcoming friction, potential energy, kinetic energy, pressure energy differences) 2 Fundamentals of Rheology • Rheology is the science of deformation and flow – The forces involved could be tensile, compressive, shear or bulk (uniform external pressure) • Food rheology is the material science of food – This can involve fluid or semi-solid foods • A rheometer is used to determine rheological properties (how a material flows under different conditions) – Viscometers are a sub-set of rheometers 3 1 Applications of Rheology • Process engineering calculations – Pumping requirements, extrusion, mixing, heat transfer, homogenization, spray coating • Determination of ingredient functionality – Consistency, stickiness etc. • Quality control of ingredients or final product – By measurement of viscosity, compressive strength etc. • Determination of shelf life – By determining changes in texture • Correlations to sensory tests – Mouthfeel 4 Stress and Strain • Stress: Force per unit area (Units: N/m2 or Pa) • Strain: (Change in dimension)/(Original dimension) (Units: None) • Strain rate: Rate -

Introduction to the CFD Module

INTRODUCTION TO CFD Module Introduction to the CFD Module © 1998–2018 COMSOL Protected by patents listed on www.comsol.com/patents, and U.S. Patents 7,519,518; 7,596,474; 7,623,991; 8,457,932; 8,954,302; 9,098,106; 9,146,652; 9,323,503; 9,372,673; and 9,454,625. Patents pending. This Documentation and the Programs described herein are furnished under the COMSOL Software License Agreement (www.comsol.com/comsol-license-agreement) and may be used or copied only under the terms of the license agreement. COMSOL, the COMSOL logo, COMSOL Multiphysics, COMSOL Desktop, COMSOL Server, and LiveLink are either registered trademarks or trademarks of COMSOL AB. All other trademarks are the property of their respective owners, and COMSOL AB and its subsidiaries and products are not affiliated with, endorsed by, sponsored by, or supported by those trademark owners. For a list of such trademark owners, see www.comsol.com/trademarks. Version: COMSOL 5.4 Contact Information Visit the Contact COMSOL page at www.comsol.com/contact to submit general inquiries, contact Technical Support, or search for an address and phone number. You can also visit the Worldwide Sales Offices page at www.comsol.com/contact/offices for address and contact information. If you need to contact Support, an online request form is located at the COMSOL Access page at www.comsol.com/support/case. Other useful links include: • Support Center: www.comsol.com/support • Product Download: www.comsol.com/product-download • Product Updates: www.comsol.com/support/updates •COMSOL Blog: www.comsol.com/blogs • Discussion Forum: www.comsol.com/community •Events: www.comsol.com/events • COMSOL Video Gallery: www.comsol.com/video • Support Knowledge Base: www.comsol.com/support/knowledgebase Part number: CM021302 Contents Introduction . -

In Classical Fluid Dynamics, a Boundary Layer Is the Layer I

Atm S 547 Boundary Layer Meteorology Bretherton Lecture 1 Scope of Boundary Layer (BL) Meteorology (Garratt, Ch. 1) In classical fluid dynamics, a boundary layer is the layer in a nearly inviscid fluid next to a surface in which frictional drag associated with that surface is significant (term introduced by Prandtl, 1905). Such boundary layers can be laminar or turbulent, and are often only mm thick. In atmospheric science, a similar definition is useful. The atmospheric boundary layer (ABL, sometimes called P[lanetary] BL) is the layer of fluid directly above the Earth’s surface in which significant fluxes of momentum, heat and/or moisture are carried by turbulent motions whose horizontal and vertical scales are on the order of the boundary layer depth, and whose circulation timescale is a few hours or less (Garratt, p. 1). A similar definition works for the ocean. The complexity of this definition is due to several complications compared to classical aerodynamics. i) Surface heat exchange can lead to thermal convection ii) Moisture and effects on convection iii) Earth’s rotation iv) Complex surface characteristics and topography. BL is assumed to encompass surface-driven dry convection. Most workers (but not all) include shallow cumulus in BL, but deep precipitating cumuli are usually excluded from scope of BLM due to longer time for most air to recirculate back from clouds into contact with surface. Air-surface exchange BLM also traditionally includes the study of fluxes of heat, moisture and momentum between the atmosphere and the underlying surface, and how to characterize surfaces so as to predict these fluxes (roughness, thermal and moisture fluxes, radiative characteristics). -

Chapter 5 Frictional Boundary Layers

Chapter 5 Frictional boundary layers 5.1 The Ekman layer problem over a solid surface In this chapter we will take up the important question of the role of friction, especially in the case when the friction is relatively small (and we will have to find an objective measure of what we mean by small). As we noted in the last chapter, the no-slip boundary condition has to be satisfied no matter how small friction is but ignoring friction lowers the spatial order of the Navier Stokes equations and makes the satisfaction of the boundary condition impossible. What is the resolution of this fundamental perplexity? At the same time, the examination of this basic fluid mechanical question allows us to investigate a physical phenomenon of great importance to both meteorology and oceanography, the frictional boundary layer in a rotating fluid, called the Ekman Layer. The historical background of this development is very interesting, partly because of the fascinating people involved. Ekman (1874-1954) was a student of the great Norwegian meteorologist, Vilhelm Bjerknes, (himself the father of Jacques Bjerknes who did so much to understand the nature of the Southern Oscillation). Vilhelm Bjerknes, who was the first to seriously attempt to formulate meteorology as a problem in fluid mechanics, was a student of his own father Christian Bjerknes, the physicist who in turn worked with Hertz who was the first to demonstrate the correctness of Maxwell’s formulation of electrodynamics. So, we are part of a joined sequence of scientists going back to the great days of classical physics. -

Hydraulics Manual Glossary G - 3

Glossary G - 1 GLOSSARY OF HIGHWAY-RELATED DRAINAGE TERMS (Reprinted from the 1999 edition of the American Association of State Highway and Transportation Officials Model Drainage Manual) G.1 Introduction This Glossary is divided into three parts: · Introduction, · Glossary, and · References. It is not intended that all the terms in this Glossary be rigorously accurate or complete. Realistically, this is impossible. Depending on the circumstance, a particular term may have several meanings; this can never change. The primary purpose of this Glossary is to define the terms found in the Highway Drainage Guidelines and Model Drainage Manual in a manner that makes them easier to interpret and understand. A lesser purpose is to provide a compendium of terms that will be useful for both the novice as well as the more experienced hydraulics engineer. This Glossary may also help those who are unfamiliar with highway drainage design to become more understanding and appreciative of this complex science as well as facilitate communication between the highway hydraulics engineer and others. Where readily available, the source of a definition has been referenced. For clarity or format purposes, cited definitions may have some additional verbiage contained in double brackets [ ]. Conversely, three “dots” (...) are used to indicate where some parts of a cited definition were eliminated. Also, as might be expected, different sources were found to use different hyphenation and terminology practices for the same words. Insignificant changes in this regard were made to some cited references and elsewhere to gain uniformity for the terms contained in this Glossary: as an example, “groundwater” vice “ground-water” or “ground water,” and “cross section area” vice “cross-sectional area.” Cited definitions were taken primarily from two sources: W.B. -

The Atmospheric Boundary Layer (ABL Or PBL)

The Atmospheric Boundary Layer (ABL or PBL) • The layer of fluid directly above the Earth’s surface in which significant fluxes of momentum, heat and/or moisture are carried by turbulent motions whose horizontal and vertical scales are on the order of the boundary layer depth, and whose circulation timescale is a few hours or less (Garratt, p. 1). A similar definition works for the ocean. • The complexity of this definition is due to several complications compared to classical aerodynamics: i) Surface heat exchange can lead to thermal convection ii) Moisture and effects on convection iii) Earth’s rotation iv) Complex surface characteristics and topography. Atm S 547 Lecture 1, Slide 1 Sublayers of the atmospheric boundary layer Atm S 547 Lecture 1, Slide 2 Applications and Relevance of BLM i) Climate simulation and NWP ii) Air Pollution and Urban Meteorology iii) Agricultural meteorology iv) Aviation v) Remote Sensing vi) Military Atm S 547 Lecture 1, Slide 3 History of Boundary-Layer Meteorology 1900 – 1910 Development of laminar boundary layer theory for aerodynamics, starting with a seminal paper of Prandtl (1904). Ekman (1905,1906) develops his theory of laminar Ekman layer. 1910 – 1940 Taylor develops basic methods for examining and understanding turbulent mixing Mixing length theory, eddy diffusivity - von Karman, Prandtl, Lettau 1940 – 1950 Kolmogorov (1941) similarity theory of turbulence 1950 – 1960 Buoyancy effects on surface layer (Monin and Obuhkov, 1954). Early field experiments (e. g. Great Plains Expt. of 1953) capable of accurate direct turbulent flux measurements 1960 – 1970 The Golden Age of BLM. Accurate observations of a variety of boundary layer types, including convective, stable and trade- cumulus. -

Sediment Transport & Fluid Flow

Sediment Transport & Fluid Flow • Downslope transport • Fluid Flow – Viscosity – Types of fluid flow – Laminar vs. Turbulent – Eddy Viscosity – Reynolds number – Boundary Layer • Grain Settling • Particle Transport Loss of intergrain cohesion caused by saturation of pores… before… …after 1 Different kinds of mass movements, variable velocity (and other factors) From weathering to deposition: sorting and modification of clastic particles 2 Effects of transport on rounding, sorting How are particles transported by fluids? What are the key parameters? 3 Flow regimes in a stream Fluid Flow • Fundamental Physical Properties of Fluids – Density (ρ) – Viscosity (µ) Control the ability of a fluid to erode & transport particles • Viscosity - resistance to flow, or deform under shear stress. – Air - low – Water - low – Ice- high ∆µ with ∆ T, or by mixing other materials 4 Shear Deformation Shear stress (τ) is the shearing force per unit area • generated at the boundary between two moving fluids • function of the extent to which the slower moving fluid retards motion of the faster moving fluid (i.e., viscosity) Fluid Viscosity and Flow • Dynamic viscosity(µ) - the resistance of a substance (water) to ∆ shape during flow (shear stress) ! µ = du/dy where, dy τ = shear stress (dynes/cm2) du/dy = velocity gradient (rate of deformation) • Kinematic viscosity(v) =µ/ρ 5 Behaviour of Fluids Viscous Increased fluidity Types of Fluids Water - flow properties function of sediment concentrations • Newtonian Fluids - no strength, no ∆ in viscosity as shear rate ∆’s (e.g., -

Introduction

VERIFYING CONSISTENCY OF EFFECTIVE-VISCOSITY AND PRESSURE- LOSS DATA FOR DESIGNING FOAM PROPORTIONING SYSTEMS Bogdan Z. Dlugogorski1, Ted H. Schaefer1,2 and Eric M. Kennedy1 1Process Safety and Environment Protection Research Group School of Engineering The University of Newcastle Callaghan, NSW 2308, AUSTRALIA Phone: +61 2 4921 6176, Fax: +61 2 4921 6920 Email: [email protected] 23M Specialty Materials Laboratory Dunheved Circuit, St Marys, NSW 2760, AUSTRALIA ABSTRACT Aspirating and compressed-air foam systems often incorporate proportioners designed to draw sufficient rate of foam concentrate into the flowing stream of water. The selection of proportioner’s piping follows from the engineering correlations linking the pressure loss with the flow rate of a concentrate, for specified temperature (usually 20 oC) and pipe size. Unfortunately, reports exist that such correlations may be inaccurate, resulting in the design of underperforming suppression systems. To illustrate the problem, we introduce two correlations, sourced from industry and developed for the same foam concentrate, that describe effective viscosity (μeff) and pressure loss as functions of flow rate and pipe diameter. We then present a methodology to verify the internal consistency of each data set. This methodology includes replotting the curves of the effective viscosity vs the nominal shear rate at the wall (32Q/(πD3)) and also replotting the pressure loss in terms of the stress rate at the wall (τw) vs the nominal shear rate at the wall. In the laminar regime, for time-independent fluids with no slip at the wall (which is the behaviour displayed by foam concentrates), consistent data sets are 3 3 characterised by a single curve of μeff vs 32Q/(πD ), and a single curve of τw vs 32Q/(πD ) in the laminar regime. -

Boundary Layers

1 I-campus project School-wide Program on Fluid Mechanics Modules on High Reynolds Number Flows K. P. Burr, T. R. Akylas & C. C. Mei CHAPTER TWO TWO-DIMENSIONAL LAMINAR BOUNDARY LAYERS 1 Introduction. When a viscous fluid flows along a fixed impermeable wall, or past the rigid surface of an immersed body, an essential condition is that the velocity at any point on the wall or other fixed surface is zero. The extent to which this condition modifies the general character of the flow depends upon the value of the viscosity. If the body is of streamlined shape and if the viscosity is small without being negligible, the modifying effect appears to be confined within narrow regions adjacent to the solid surfaces; these are called boundary layers. Within such layers the fluid velocity changes rapidly from zero to its main-stream value, and this may imply a steep gradient of shearing stress; as a consequence, not all the viscous terms in the equation of motion will be negligible, even though the viscosity, which they contain as a factor, is itself very small. A more precise criterion for the existence of a well-defined laminar boundary layer is that the Reynolds number should be large, though not so large as to imply a breakdown of the laminar flow. 2 Boundary Layer Governing Equations. In developing a mathematical theory of boundary layers, the first step is to show the existence, as the Reynolds number R tends to infinity, or the kinematic viscosity ν tends to zero, of a limiting form of the equations of motion, different from that obtained by putting ν = 0 in the first place. -

Tubular Flow with Laminar Flow (CHE 512) M.P. Dudukovic Chemical Reaction Engineering Laboratory (CREL), Washington University, St

Tubular Flow with Laminar Flow (CHE 512) M.P. Dudukovic Chemical Reaction Engineering Laboratory (CREL), Washington University, St. Louis, MO 4. TUBULAR REACTORS WITH LAMINAR FLOW Tubular reactors in which homogeneous reactions are conducted can be empty or packed conduits of various cross-sectional shape. Pipes, i.e tubular vessels of cylindrical shape, dominate. The flow can be turbulent or laminar. The questions arise as to how to interpret the performance of tubular reactors and how to measure their departure from plug flow behavior. We will start by considering a cylindrical pipe with fully developed laminar flow. For a Newtonian fluid the velocity profile is given by r 2 u = 2u 1 (1) R u where u = max is the mean velocity. By making a balance on species A, which may be a 2 reactant or a tracer, we arrive at the following equation: 2C C D C C D A u A + r A r = A (2) z2 z r r r A t For an exercise this equation should be derived by making a balance on an annular cylindrical region of length z , inner radius r and outer radius r. We should render this equation dimensionless by defining: z r t C = ; = ; = ;c = A L R t C Ao where L is the pipe length of interest, R is the pipe radius, t = L/u is the mean residence time, C is some reference concentration. Let us assume an n-th order rate form. Ao The above equation (2) now reads: 2 D c c D L 1 c n1 c 212 + kC t c n = (2a) 2 () A0 u L u R R We define: u L L2 / D characteristic diffusion time() axial Pe = = = (3) a D L / u process time() characteristic convection time = axial Peclet number.