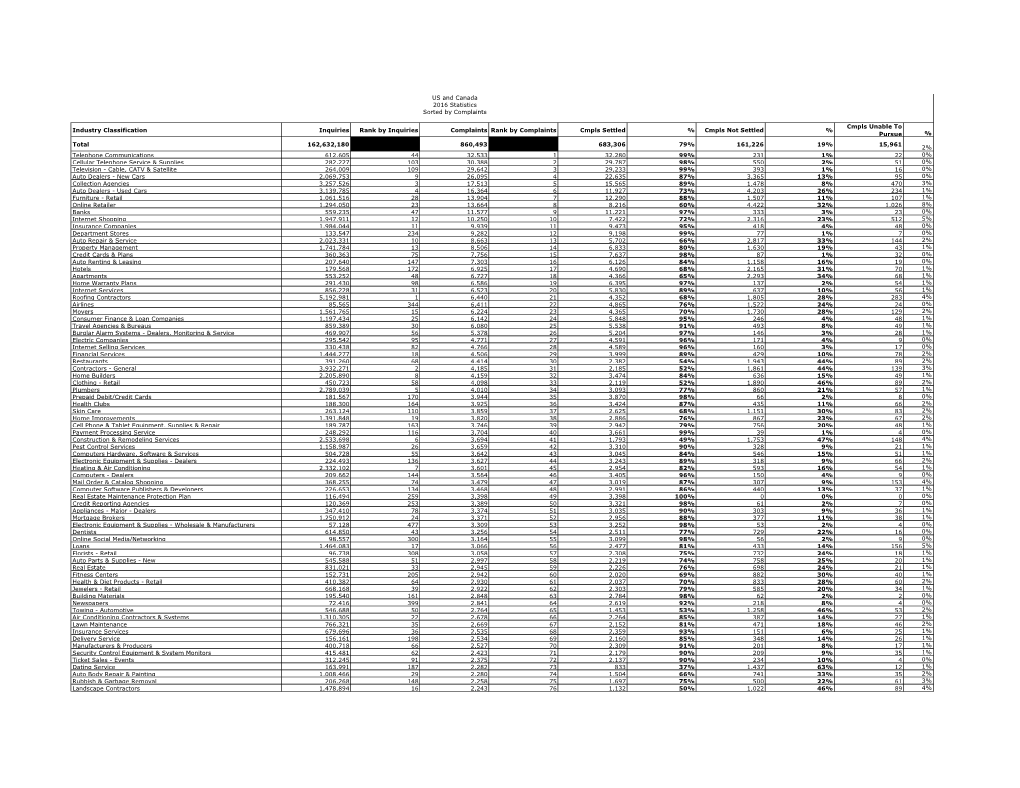

U.S. and Canada Complaint Statistics

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Complex Multi-System Integration Problems Associated with Titanium Metalworking and Manufacture: System of Systems Aproach—Part I

metals Article Complex Multi-System Integration Problems Associated with Titanium Metalworking and Manufacture: System of Systems Aproach—Part I Adam Stroud 1 and Atila Ertas 2,* 1 Ellwood Texas Forge, Houston, TX 77045, USA; [email protected] 2 Department of Mechanical Engineering, Texas Tech University, Lubbock, TX 79409, USA * Correspondence: [email protected]; Tel.: +1-(806)-834-57788 Received: 11 January 2019; Accepted: 26 March 2019; Published: 9 April 2019 Abstract: Titanium has an excellent combination of properties that make it an attractive material for use in aerospace applications. The one area in which titanium is not aligned with customer needs is affordability. Components made from titanium are many times more expensive than those manufactured from other alloys. The supply chain of an extruded product is no exception. A breakthrough in extrusion cost reduction would enable wider adoption of titanium in many structural member applications. In an effort to accomplish any breakthrough in titanium component costs, the entire supply chain for manufacturing should be evaluated simultaneously. Due to the complex interaction of the many facets of the systems in a manufacturing supply chain, it is inferred that the supply chain in its entirety must be the focus of the design activity in order to be successful. Design improvements on a single facet of manufacture may have little to no effect on the manufacture of the component. If the improvement has a detrimental impact on another system in the supply chain, overall performance may be lowered. The use of a system of systems’ (SoS) design approach was used due to its capability to address complex multi-system integration problems associated with titanium metalworking and manufacture. -

Materials Resources

Woods Sat 9am – 6pm, Sun 9am – 5pm (303) 290 – 0007 Austin Hardwoods Wood, tools, hardware, plans, books http://www.austinhardwoods.com/ 975 W. Mississippi Avenue Collector’s Specialty Woods Denver, CO 80223 http://www.cswoods.com/ M – F 7:30am – 5pm, Sat 7:30am – 1pm Warehouse and Showroom (303) 733 – 1292 4355 Monaco St. Unit A Denver, CO 80216 Wood stock and sheet, Molding, Veneer M – F 8am – 5pm (303) 355 - 0302 Frank Paxton Lumber Company Woodyard, Kiln Drying Facility, Woodshop, http://www.paxtonwood.com/ Showroom 4837 Jackson Street 8055 County Road 570 Denver, CO 80216 Gardner , CO 81040 Office 7:30am – 5pm, Warehouse 8am - 4:30pm Open by Appointment Only Woodcrafter’s Store M - F 8 am – 5pm, Sat 8am – 800 – 746 – 2413 12pm Lumber, Table tops (raw), thick wood, burl, (303) 399 – 6810, (303) 399 – 6047 matched wood, blocks, table bases Wood Stock and sheet Centennial Woods B&B Rare Woods http://www.centennialwoods.com/ http://www.wood-veneers.com/ Wyoming 871 Brickyard Circle Unit C4 (307) 760 – 8037, (307) 742 – 3672 Golden, CO 80403 Doors, flooring, furniture, siding M –F 9am – 4pm (303) 986 - 2585 Klingspor’s Woodworking Shop http://www.woodworkingshop.com/ Rockler Woodworking and Hardware North Carolina http://www.Rockler.com/ Tools, Hardware, Finishing Supplies 2553 S Colorado Blvd Ste 108 Denver, CO 80222 Lee Valley Tools M – F 9am – 7pm, Sat 9am – 6pm, http://www.leevalley.com Sun 11am – 4pm Canada (303) 782 – 0588 Woodworking, tools, gardening tools Limited wood stock, Woodworking tools, plans, finishing supplies, and hardware Metals Tool King, LLC Altitude Steel http://www.toolking.com/ http://www.altitudesteel.com/ th 11111 West 6 Avenue Unit D 1401 Umatilla St. -

Development of Non-Conventional Casting Processes

D 2014 DEVELOPMENT OF NON-CONVENTIONAL CASTING PROCESSES RUI JORGE DE LEMOS NETO TESE DE DOUTORAMENTO DOUTORAMENTO EM ENGENHARIA MECÂNICA FACULDADE DE ENGENHARIA DA UNIVERSIDADE DO PORTO © Rui Neto, 2014 ii | P a g e Acknowledgments There were many people and entities who scientifically, financially and emotionally contributed to the realization of this thesis. It is therefore with great pleasure that I express my sincere gratitude to them. To my late father, wood patternmaker for 49 years, who taught me the foundry fundaments and life values, namely that work is the basis of the life. To Professor Ana Reis, Assistant Professor at the Faculty of Engineering of Porto who is a big friend and was the main driving force and the first responsible for the presentation of this thesis To Professors Jorge Lino, Associate Professor at the Faculty of Engineering of Porto University, and Professor Teresa Duarte, Assistant Professor at the Faculty of Engineering, for the motivation and tireless support. I also thank the confidence that always placed in my work, but above all, I thank the friendship always demonstrated. To Professor Antonio Torres Marques, Full Professor at the Faculty of Engineering of Porto, the numerous attempts, often frustrated, immovable and constantly renewed to take this work forward. To Professor António Barbedo de Magalhães, Professor Emeritus already retired, my true master and great friend, the tireless attempts to get me to take this work forward and the unshakable confidence that for 34 years always placed in me. To all my students, especially the ones who intervened in these teamwork the kindness with which they heard me, and especially what they taught me. -

Essentially Unprotected

University of Tennessee Law Legal Scholarship Repository: A Service of the Joel A. Katz Library UTK Law Faculty Publications 3-2021 Essentially Unprotected Sherley Cruz Follow this and additional works at: https://ir.law.utk.edu/utklaw_facpubs Part of the Law Commons Research Paper #406 April 2021 Essentially Unprotected Sherley E. Cruz Tulane Law Review (Forthcoming) This paper may be downloaded without charge from the Social Science Research Network Electronic library at http://ssrn.com/abstract=3798730 Learn more about the University of Tennessee College of Law: law.utk.edu Preprint not peer reviewed This preprint research paper has not been peer reviewed. Electronic copy available at: https://ssrn.com/abstract=3798730 ESSENTIALLY UNPROTECTED Sherley E. Cruz* TABLE OF CONTENTS ABSTRACT ....................................................................................................... 3 INTRODUCTION................................................................................................ 3 I. THE STORY OF SAUL SANCHEZ ................................................................. 9 II. WHO ARE THE MEAT PROCESSING WORKERS? ....................................... 19 A. The Power of Narratives and Counter-Narratives ............................ 19 B. The COVID-19 Pandemic Hits the United States ............................ 20 C. Who are the Individuals Working the Meat Processing Lines? ....... 23 i. Today’s Meatpacking Workers are Mostly People of Color Living in Low-Wage Jobs ..................................... 24 D. Choosing -

Jobs & Wages: the Tourism Industry Dilemma

Jobs & Wages: The Tourism Industry Dilemma Prepared by: Neal A. Christensen Norma P. Nickerson Institute for Tourism and Recreation Research The University of Montana Missoula, MT 59812 Research Note 22 December, 1995 1 Jobs & Wages: TheTourism Industry Dilemma Many people in Montana believe the pursuit of tourism as an economic development strategy is not wise. Tourism is perceived as producing minimum wage ‘hamburger flipper’ jobs rather than decent ‘living wage’ jobs like those in the mining, timber and other basic industries. Even nationally, the concerns about tourism and the economy center around low wages, little career opportunity, and seasonal and part-time jobs that leave workers under-employed (Barrett, 1987). As recently as the October 1995 White House Conference on Travel and Tourism, the number one stated goal was to demonstrate the economic power of the travel and tourism industry. Within this goal, two objectives related directly to the perception of tourism’s economic impact and the perception of tourism career opportunities. Objective number one stated: Articulate the economic significance of the industry to economic, social and political segments that will result in greater awareness of travel and tourism as a generator of quality jobs, tax revenues for federal, state and local governments, and the number one service export in our national economy. Objective number three stated: Increase awareness of travel and tourism’s contribution to job creation and enhance career and employment opportunities and worker skills through improved public and private sector coordination of education training initiatives. But what is the tourism industry? Much of the difficulty describing tourism wages comes from the lack of a standard industrial classification (SIC) for the jobs. -

Chemical Etching Electroforming Laser Cutting Printed Glass & Film SMT Stencils

Chemical etching electroforming Laser Cutting Printed glass & film SMT Stencils Our Philosophy Thin Metal Parts (TMP) has clear industry leadership in the following areas: • The most complete line of HIGH PERFORMANCE thin metal parts: Electroformed, Laser-Cut and Chem-Milled • Continued TECHNOLOGY LEADERSHIP in the industry...with significant and on-going R&D • An ISO 9001:2008 QUALITY certified company with complete process controls and analytical laboratory. • Highly-trained and dedicated people to provide true APPLICATIONS SUPPORT • A culture of COMMITMENT TO CUSTOMERS with continued investment in people, facilities, equipment and systems to support our commitment to be THE INDUSTRY’S BEST VALUE. We encourage you to closely compare TMP’s products and services to any other supplier. We are confident that TMP delivers the BEST TRUE VALUE. 4733 Centennial Blvd., Colorado Springs, CO 80919 (719) 268-8300 • [email protected] • www.thinmetalparts.com History of Thin Metal Parts 1985 Specialty Parts, a product line of Photo Stencil, was started to address the precision parts needs of the Photo Stencil circuit board manufacturing customers using photo-chemical milling process. 1990 Parts began to be manufactured using the laser cutting process. 1997 Became the first parts manufacturer to become ISO 9001 certified (now ISO 9001:2008). 1999 Began using the electroforming process to manufacture precision metal parts. 2002 Introduced multi-layer and 3D electroforming 2002 The Specialty Products Division became the Thin Metal Parts Company to better focus efforts on thin metal parts development. 2004 Significant efforts began to target new industries in addition to electronics. 2007 Thin Metal Parts acquired industry leading photo-plotting equipment, increasing quality and capability. -

Washington, Friday, December 27, 1946

f 9 REGISTE VOLUME 11 '9 3 4 ^ NUMBER 251 * Í/A/ITEO % Washington, Friday, December 27, 1946 i The President ations under the Civil Service Rules and CONTENTS authorized the adoption of special regu THE PRESIDENT lations during the transitional period, see EXECUTIVE ORDER 9815 Executive Order 9815, supra. Executive Order: Pa8e Civil Service Commission, direc Amending Section 7 of Executive Order tion to resume operations No. 9691 of February 4,1946, Entitled under Civil Service rules “Directing the Civil Service Com TITLE 6—AGRICULTURAL CREDIT and authorizing adoption of mission To R esume Operations U nder Chapter II—Production and Marketing special regulations during the Civil Service Rules, and Au transitional period; amend Administration (Commodity Credit) thorizing the Adoption of Special ment_______________________ 14661 Regulations D uring the T ransitional P art 245—I r ish P otatoes Period” - . * REGULATIONS AND NOTICES SUBPART— 1947 ACREAGE GOALS By virtue of the authority vested in A griculture D epartment. See also me by the Civil Service Act of January GENERAL Sec. Commodity Credit Corpora 16, 1883 (22 Stat. 403), and section 1753 245.68 Applicability of §§ 245.68 to 245.85, tion; Dairy Industry Bureau. of the Revised Statutes, and in the in inclusive. Fruits and vegetables, fresh, and terest of the internal management of 245.69 Definitions. other products; U. S. stand the Government, the proviso of section 7 245.70 Extent of calculations and rule of ards ________________________ 14665 fractions. of Executive Order No. 9691 of February Import authorizations for sugar 2^5.71 Instructions and forms. 4, 1946, is hereby amended to read as syrups and related items, is follows: NATIONAL AND STATE ACREAGE GOALS AND COUNTY suance; statement of policy. -

COVID19 Janitor Project Time & Motion Study Proposal

COVID19 Janitor Project Time & Motion Study Proposal Presented by: Melissa Afterman MS-HFE, CPE & Meg Honan MS, PT, CPE March 4, 2021 1 Agenda • UC Ergonomics team • What is a Time & Motion Study • Research questions • Study design/outcomes • Methods: data collection devices/exposures measured • Sample results • Estimated timeline and costs • Discussion 2 Our Team Onsite consulting Data collection, processing, analysis & interpretation Supervising associate consultants Main point of contact for consulting projects Melissa Afterman Senior Consultant Post doctoral fellows Study design, data collection, analysis & Meg Honan Assist with data collection interpretation Senior Consultant & processing Associate consultants Dr. Carisa Harris Graduate Students Lab Director Assist with video digitization Advisor to the study Alan Barr Senior Lab Engineer Undergraduates Dr. Fadi Fathalluh Director Agriculture Safety and Manage instrumentation Health Program (UC Davis) Assist with data processing 3 COEH faculty on Janitor’s Project: Protecting Workers and Communities from Occupational and Environmental Health Hazards through Teaching Research and Service 4 Time & Motion Study with Human Factors Framework Human Factors Health & Safety & Health Time Motion Study • To complete • Tasks • Objective, tasks • Sitting vs. data driven • Varies with Standing vs. • Accurate and worker Walking reliable experience • Not and height observational Human Performance Human Ergonomics 5 Study questions • What are the tasks per square foot (density) while cleaning/disinfecting the 5 typical workspaces? • What are the task durations (rate) while cleaning/disinfecting these 5 typical workspaces? • What are the durations, frequency and magnitudes of physical exposures* while cleaning/disinfecting these 5 typical workspaces? • What is the physiological workload** and risk of lumbar spine disorder while cleaning then disinfecting the 5 typical workspaces. -

US BBB 2013 Statistics Sorted by Industry

US BBB 2013 Statistics Sorted by Industry Rank by Industry Classification Inquiries Rank by Inquiries Complaints Cmpls Settled % Cmpls Not Settled % Cmpls Unable to Pursue % Complaints Totals 123,188,182 885,845 689,601 78% 172,802 20% 23,442 2.65% Abrasives 3,573 1,971 7 2,480 2 29% 5 71% 0 0.00% Absorbents 273 3,895 0 3,965 0 0% 0 0% 0 0.00% Abstracters 2,291 2,320 8 2,400 0 0% 4 50% 4 50.00% Access Control Systems 700 3,271 4 2,821 2 50% 1 25% 1 25.00% Accident Reconstruction Service 1,903 2,472 5 2,696 3 60% 2 40% 0 0.00% Accordions 310 3,819 1 3,547 1 100% 0 0% 0 0.00% Accountants 93,768 237 165 611 97 59% 67 41% 1 0.61% Accountants - Certified Public 248,689 86 207 514 145 70% 59 29% 3 1.45% Accounting - Forensic 2,341 2,305 3 2,998 0 0% 3 100% 0 0.00% Accounting & Bookkeeping Machines 1,735 2,542 4 2,821 3 75% 1 25% 0 0.00% Accounting Services 40,233 496 109 788 69 63% 33 30% 7 6.42% Accumulators 2,148 2,372 15 1,962 7 47% 8 53% 0 0.00% Acid Proof Equipment & Materials 91 4,412 0 3,965 0 0% 0 0% 0 0.00% Acids 279 3,875 1 3,547 1 100% 0 0% 0 0.00% Acoustical Ceiling Removal 307 3,825 1 3,547 0 0% 1 100% 0 0.00% Acoustical Consultants 3,235 2,061 2 3,218 1 50% 1 50% 0 0.00% Acoustical Materials 1,584 2,624 0 3,965 0 0% 0 0% 0 0.00% Acting & Voice Over Training 645 3,327 1 3,547 1 100% 0 0% 0 0.00% Actuaries 659 3,313 0 3,965 0 0% 0 0% 0 0.00% Acupressure 386 3,679 2 3,218 0 0% 0 0% 2 100.00% Acupuncturists 12,337 1,097 14 1,995 11 79% 3 21% 0 0.00% Ad Word Sponsorship 16 4,848 0 3,965 0 0% 0 0% 0 0.00% Addressing Machines & Supplies -

Chemical Machining and Milling

CHEMICAL MACHINING AND MILLING Introduction Chemical machining (CM) is the controlled dissolution of workpiece material (etching) by means of a strong chemical reagent (etchant). In CM material is removed from selected areas of workpiece by immersing it in a chemical reagents or etchants; such as acids and alkaline solutions. Material is removed by microscopic electrochemical cell action, as occurs in corrosion or chemical dissolution of a metal. This controlled chemical dissolution will simultaneously etch all exposed surfaces even though the penetration rates of the material removal may be only 0.0025–0.1 mm/min. The basic process takes many forms: chemical milling of pockets, contours, overall metal removal, chemical blanking for etching through thin sheets; photochemical machining (pcm) for etching by using of photosensitive resists in microelectronics; chemical or electrochemical polishing where weak chemical reagents are used (sometimes with remote electric assist) for polishing or deburring and chemical jet machining where a single chemically active jet is used. A schematic of chemical machining process is shown in Figure 6. Figure 6: (a) Schematic of chemical machining process (b) Stages in producing a profiled cavity by chemical machining (Kalpakjain & Schmid) Chemical milling In chemical milling, shallow cavities are produced on plates, sheets, forgings and extrusions. The two key materials used in chemical milling process are etchant and maskant. Etchants are acid or alkaline solutions maintained within controlled ranges of chemical composition and temperature. Maskants are specially designed elastomeric products that are hand strippable and chemically resistant to the harsh etchants. Steps in chemical milling Residual stress relieving: If the part to be machined has residual stresses from the previous processing, these stresses first should be relieved in order to prevent warping after chemical milling. -

Variables Affecting the Chemical Machining of Stainless Steel 420 Dr

ISSN: 2277-3754 ISO 9001:2008 Certified International Journal of Engineering and Innovative Technology (IJEIT) Volume 3, Issue 6, December 2013 Variables Affecting the Chemical Machining of Stainless Steel 420 Dr. Haydar A. H. Al-Ethari, Dr. Kadhim Finteel Alsultani, Nasreen Dakhil F. Abstract— Chemical machining has a considerable value in unique characteristics, it should be approached with the idea the solution of machining problems that are constantly arising that this industrial tool can do jobs not practical or possible due to introduction of new materials and requirement for high with any other metal working methods (Langworthy M., surface finish and dimensional accuracy, complicated shape and 1994). It has a considerable value in the solution of special size which cannot be achieved by the conventional machining processes. The present work is aimed at studying the problems that are constantly arising as the result of the effect of machining temperature, machining time, and previous introduction of new materials. cold working on the metal removal rate and the surface finish of All the common metals including aluminum, copper, zinc, chemically machined samples of stainless steel 420 using a steel, lead, and nickel can be chemically machined. Many mixture of acids (H2O + HCl + HNO3 + HF + HCOOH) as an exotic metals such as titanium, molybdenum, and zirconium, etchant. Alloy samples of (44.5×44.5×3mm) dimensions and cold as well as nonmetallic materials including glass, ceramics, rolled alloy samples with the same dimensions were chemically machined. Four machining temperatures (45, 50, 55, and 58oC) and some plastics, can also be used with the process for each of which five machining times (2, 4, 6, 8, and 10min) (Blak.JT, DeGarmo, 2007). -

Machining of Aluminum and Aluminum Alloys / 763

ASM Handbook, Volume 16: Machining Copyright © 1989 ASM International® ASM Handbook Committee, p 761-804 All rights reserved. DOI: 10.1361/asmhba0002184 www.asminternational.org MachJning of Aluminum and AlumJnum Alloys ALUMINUM ALLOYS can be ma- -r.. _ . lul Tools with small rake angles can normally chined rapidly and economically. Because be used with little danger of burring the part ," ,' ,,'7.,','_ ' , '~: £,~ " ~ ! f / "' " of their complex metallurgical structure, or of developing buildup on the cutting their machining characteristics are superior ,, A edges of tools. Alloys having silicon as the to those of pure aluminum. major alloying element require tools with The microconstituents present in alumi- larger rake angles, and they are more eco- num alloys have important effects on ma- nomically machined at lower speeds and chining characteristics. Nonabrasive con- feeds. stituents have a beneficial effect, and ,o IIR Wrought Alloys. Most wrought alumi- insoluble abrasive constituents exert a det- num alloys have excellent machining char- rimental effect on tool life and surface qual- acteristics; several are well suited to multi- ity. Constituents that are insoluble but soft B pie-operation machining. A thorough and nonabrasive are beneficial because they e,,{' , understanding of tool designs and machin- assist in chip breakage; such constituents s,~ ,.t ing practices is essential for full utilization are purposely added in formulating high- of the free-machining qualities of aluminum strength free-cutting alloys for processing in alloys. high-speed automatic bar and chucking ma- Strain-hardenable alloys (including chines. " ~ ~p /"~ commercially pure aluminum) contain no In general, the softer ailoys~and, to a alloying elements that would render them lesser extent, some of the harder al- c • o c hardenable by solution heat treatment and ,p loys--are likely to form a built-up edge on precipitation, but they can be strengthened the cutting lip of the tool.