Toxic and Highly Toxic Gases

Total Page:16

File Type:pdf, Size:1020Kb

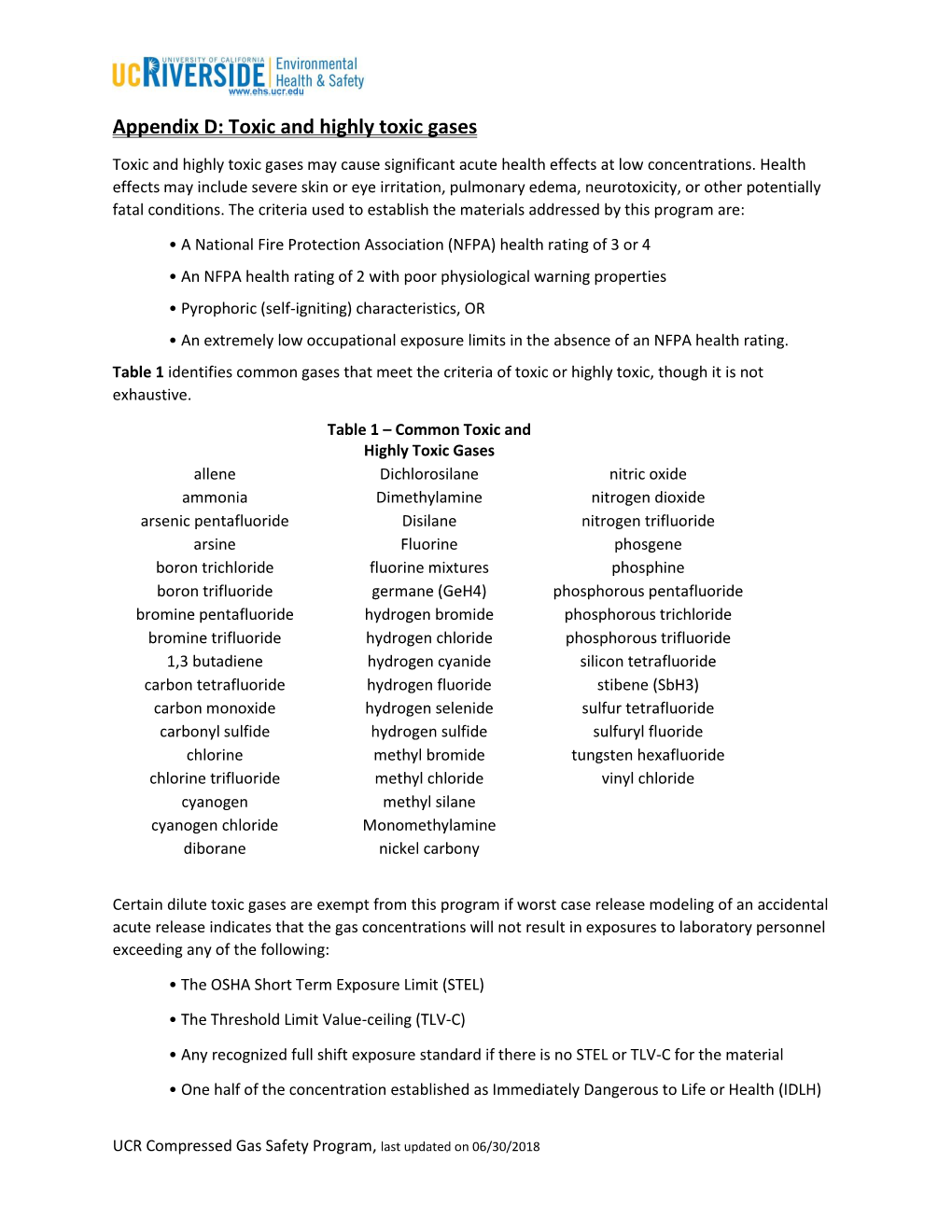

Load more

Recommended publications

-

Nitrogen Trifluoride Hazard Summary Identification

Common Name: NITROGEN TRIFLUORIDE CAS Number: 7783-54-2 RTK Substance number: 1380 DOT Number: UN 2451 Date: March 2001 ------------------------------------------------------------------------- ------------------------------------------------------------------------- HAZARD SUMMARY * Nitrogen Trifluoride can affect you when breathed in. * Exposure to hazardous substances should be routinely * Contact may irritate the skin and eyes. evaluated. This may include collecting personal and area * High levels can interfere with the ability of the blood to air samples. You can obtain copies of sampling results carry Oxygen causing headache, fatigue, dizziness, and a from your employer. You have a legal right to this blue color to the skin and lips (methemoglobinemia). information under OSHA 1910.1020. Higher levels can cause trouble breathing, collapse and * If you think you are experiencing any work-related health even death. problems, see a doctor trained to recognize occupational * Repeated high exposure can cause weakness, muscle diseases. Take this Fact Sheet with you. twitching, seizures and convulsions. * Nitrogen Trifluoride may damage the liver and kidneys. WORKPLACE EXPOSURE LIMITS * Repeated high exposure can cause deposits of Fluorides in OSHA: The legal airborne permissible exposure limit the bones and teeth, a condition called "Fluorosis." This (PEL) is 10 ppm averaged over an 8-hour can cause pain, disability and mottling of the teeth. workshift. * The above health effects do NOT occur at the level of Fluoride used in water for preventing cavities in teeth. NIOSH: The recommended airborne exposure limit is 10 ppm averaged over a 10-hour workshift. IDENTIFICATION Nitrogen Trifluoride is a colorless gas with a moldy odor. It ACGIH: The recommended airborne exposure limit is is used as a Fluorine source in the electronics industry and in 10 ppm averaged over an 8-hour workshift. -

NF3, the Greenhouse Gas Missing from Kyoto Michael J

GEOPHYSICAL RESEARCH LETTERS, VOL. 35, L12810, doi:10.1029/2008GL034542, 2008 NF3, the greenhouse gas missing from Kyoto Michael J. Prather1 and Juno Hsu1 Received 5 May 2008; accepted 27 May 2008; published 26 June 2008. [1] Nitrogen trifluoride (NF3) can be called the missing chemical industry are following: Kanto Denka produces greenhouse gas: It is a synthetic chemical produced in 1,000 tons per yr; DuPont is setting up a manufacturing industrial quantities; it is not included in the Kyoto basket of facility in China; Formosa Plastics and Mitsui Chemicals greenhouse gases or in national reporting under the United are expanding production. Data on total production is not Nations Framework Convention on Climate Change freely available, but based on press releases and industry (UNFCCC); and there are no observations documenting its data, we estimate 2008 production to be about 4,000 tons, atmospheric abundance. Current publications report a long with a likely range of ±25%. Planned expansion could lifetime of 740 yr and a global warming potential (GWP), double this by 2010. which in the Kyoto basket is second only to SF6.Were- [3] The published global warming potentials (GWP) of examine the atmospheric chemistry of NF3 and calculate a NF3 are 12,300, 17,200 and 20,700 for time horizons of shorter lifetime of 550 yr, but still far beyond any societal 20, 100, and 500 years, respectively [Forster et al., 2007]. time frames. With 2008 production equivalent to 67 million The increasing GWP with time horizon reflects the longer metric tons of CO2,NF3 has a potential greenhouse impact atmospheric residence time of NF3 compared with that of larger than that of the industrialized nations’ emissions of CO2. -

Nitrogen Trifluoride

Nitrogen trifluoride (CAS No: 7783-54-2) Health-based Reassessment of Administrative Occupational Exposure Limits Committee on Updating of Occupational Exposure Limits, a committee of the Health Council of the Netherlands No. 2000/15OSH/125, The Hague, June 8, 2004 Preferred citation: Health Council of the Netherlands: Committee on Updating of Occupational Exposure Limits. Nitrogen trifluoride; Health-based Reassessment of Administrative Occupational Exposure Limits. The Hague: Health Council of the Netherlands, 2004; 2000/15OSH/125. all rights reserved 1 Introduction The present document contains the assessment of the health hazard of nitrogen trifluoride by the Committee on Updating of Occupational Exposure Limits, a committee of the Health Council of the Netherlands. The first draft of this document was prepared by MA Maclaine Pont, M.Sc. (Wageningen University and Research Centre, Wageningen, the Netherlands). In November 1999, literature was searched in the databases Toxline, Medline, and Chemical Abstracts, starting from 1981, 1966, and 1937, respectively, and using the following key words: nitrogen trifluoride, nitrogen fluoride (NF3), and 7783-54-2. In February 2001, the President of the Health Council released a draft of the document for public review. No comments were received. An additional search in Toxline and Medline in January 2004 did not result in information changing the committee’s conclusions. 2Identity name : nitrogen trifluoride synonyms : nitrogen fluoride; trifluoroamine; trifluoroammonia; perfluoroammonia molecular formula : NF3 CAS number : 7783-54-2 3 Physical and chemical properties molecular weight : 71.0 boiling point : -129oC melting point : -208.5oC flash point : - vapour pressure : at 20°C: >100 kPa solubility in water : very slightly soluble log Poctanol/water : -1.60 conversion factors : at 20°C, 101.3 kPa: 1 mg/m3 = 0.34 ppm 1 ppm = 2.96 mg/m3 Data from ACG91, NLM04, http://esc.syrres.com. -

Cleaning Gas Mixture for an Apparatus and Cleaning Method

Europäisches Patentamt *EP001529854A1* (19) European Patent Office Office européen des brevets (11) EP 1 529 854 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: (51) Int Cl.7: C23C 16/44, H01L 21/00 11.05.2005 Bulletin 2005/19 (21) Application number: 04256591.1 (22) Date of filing: 26.10.2004 (84) Designated Contracting States: (72) Inventors: AT BE BG CH CY CZ DE DK EE ES FI FR GB GR • Isaki, Ryuichiro, HU IE IT LI LU MC NL PL PT RO SE SI SK TR Taiyo Nippon Sanso Corporation Designated Extension States: Shinagawa-ku, Tokyo (JP) AL HR LT LV MK • Shinriki, Manabu, Taiyo Nippon Sanso Corporation (30) Priority: 04.11.2003 JP 2003374160 Shinagawa-ku, Tokyo (JP) (71) Applicant: Taiyo Nippon Sanso Corporation (74) Representative: Smyth, Gyles Darren Shinagawa-ku, Tokyo (JP) Marks & Clerk 90 Long Acre London WC2E 9RA (GB) (54) Cleaning gas mixture for an apparatus and cleaning method (57) A cleaning gas improves the etching reaction and an integer from 1 to 3, y is an integer from 1 to 12, rate of cleaning gas including a fluorocarbon gas, and and z is selected from 0 and 1 and oxygen gas, to which increases the cleaning effect. And the cleaning method is added at least one selected from the group of nitrogen uses the cleaning gas. A mixed gas of a fluorocarbon trifluoride, fluorine, nitrous oxide, nitrogen, and rare gas- gas represented by the general formula of CvHxFyOz, es up to 10% by volume based on the total gas volume. wherein v is an integer from 1 to 5, x is selected from 0 EP 1 529 854 A1 Printed by Jouve, 75001 PARIS (FR) 1 EP 1 529 854 A1 2 Description ciency since these are raw materials for producing fluor- ocarbon type resins such as TEFLON (trademark), and BACKGROUND OF THE INVENTION are used in significantly large amounts in the chemical industry. -

1. Hydrogen Forms Compounds with Most Non-Metallic Elements and with Some Metals

PMT 1. Hydrogen forms compounds with most non-metallic elements and with some metals. (a) Calculate the empirical formula of the compound used in the manufacture of artificial rubber which has the following composition by mass. Hydrogen 11.1% Carbon 88.9% (3) (b) The boiling temperatures of hydrogen chloride and hydrogen iodide are: Hydrogen chloride ±85ºC Hydrogen iodide ±35ºC Explain why hydrogen iodide has a higher boiling temperature than hydrogen chloride. ............................................................................................................................. ... ............................................................................................................................. ... ............................................................................................................................. ... (2) (c) Draw and explain the shapes of: (i) the PH3 molecule; .......................................................... ............................................................ ...................................................................................................................... (2) 1 PMT ± (ii) the AlH4 ion. ...................................................................................................................... ...................................................................................................................... (2) 3 (d) Calculate the number of molecules in 8.0 cm of gaseous phosphine, PH3, at room temperature and pressure. (The molar volume of -

Synthetic Greenhouse Gases

Synthetic Greenhouse Gases How are they different to What are ‘synthetic greenhouse gases’? ‘greenhouse gases’? Synthetic greenhouse gases are man made Greenhouse gases are naturally occurring. chemicals. They are commonly used in They include carbon dioxide (CO2), methane refrigeration and air conditioning, fire (CH4) and nitrous oxide (N2O). Synthetic extinguishing, foam production and in greenhouse gases are man made chemicals medical aerosols. When they are released, and generally have a much higher global synthetic greenhouse gases trap heat in warming potential than naturally occurring the atmosphere. greenhouse gases. What is global warming potential? Global warming potential (GWP) is a measure of how much heat a greenhouse gas traps in the atmosphere over a specific time compared to a similar mass of carbon dioxide (CO2). CO2, with a global warming potential of 1, is used as the base figure for measuring global warming potential. The higher the global warming potential number, the more heat a gas traps. The most common synthetic greenhouse gas in Australia is HFC-134a, which is mostly used in refrigerators and air conditioners. It has a global warming potential of 1430; this means the release of one tonne of HFC-134a is equivalent to releasing 1430 tonnes of CO2 into the atmosphere. Which synthetic greenhouse gases does 22,800 Australia regulate? SF6 the global warming potential of sulfur hexafluoride (SF6) • hydrofluorocarbons (HFCs) • perfluorocarbons (PFCs) • sulfur hexafluoride (SF6) Synthetic • nitrogen trifluoride (NF3) greenhouse gases account for around 2% of all greenhouse gas emissions in Australia How do we use synthetic greenhouse gases? They are man made chemicals with a wide variety of uses. -

Heat of Formation of Nitrogen Trifluoride

4j*m *" ARREN i' NATIONAL BUREAU OF STANDARDS REPORT 6363 HEAT OF FORMATION OF NITROGEN TRIFLUORIDE by Sidney Marantz, Charles F* Coyle, and George T. Armstrong Order No. IPR NOrd 03168 Technical Report to U.S. Navy Bureau of Ordnance <NBS> U. S. DEPARTMENT OF COMMERCE NATIONAL BUREAU OF STANDARDS THE NATIONAL BUREAU OF STANDARDS Functions find Activities The functions of the National Bureau of Standards are set forth in the Act of Congress, March 3, 1901, as amended hy Congress in Public Paw 619, 1950. These include the development and maintenance of the national standards of measurement and the provision of means and methods for making measurements consistent with these standards; the determination of physical constants and properties of materials; the development of methods and instruments for testing materials, devices, and structures; advisory services to Government Agencies on scientific and technical problems; invention and development of devices to serve special needs of the Government; and the development of standard practices, codes, and specifications. The work includes basic and applied research, development, engineering, instrumentation, testing, evaluation, calibration services, and various consultation and information services. A major portion of the Bureau’s work is performed for other Government Agencies, particularly the Department of Defense and the Atomic Energy Commission. The scope'of activities is suggested by the listing of divisions and sections on the inside of the back cover. Reports and Publications The results of the Bureau’s work take the form of either actual equipment and devices or published papers and reports. Reports are issued to the sponsoring agency of a particular project or program. -

Safety Data Sheet Nitrogen Trifluoride

Safety Data Sheet Nitrogen Trifluoride Section 1: Product and Company Identification Middlesex Gases & Technologies 292 Second Street P.O. Box 490249 Everett, MA 02149 (617) 387-5050 (800) 649-6704 Fax (617) 387-3537 http://www.middlesexgases.com/ Product Code: Nitrogen Trifluoride Section 2: Hazards Identification Warning Hazard Classification: Gases Under Pressure Hazard Statements: Contains gas under pressure; may explode if heated Precautionary Statements Storage: Protect from sunlight. Store in well-ventilated place. Section 3: Composition/Information on Ingredients CAS # 7783-54-2 Middlesex Gases & Technologies page 1 of 4 Generated by the SDS Manager from AsteRisk, LLC. All Rights Reserved Generated: 06/01/2015 Chemical Chemical Trade Names Substance Family Nitrogen Trifluoride inorganic halide Nitrogen fluoride, trifluoroamine, trifluoroammonia, Perfluoroammonia; NF3; UN 2451; N,N,N- Trifluoroamine Section 4: First Aid Measures Skin Contact Eye Contact Ingestion Inhalation Note to Physicians Flush skin with plenty of water for 15 Flush eyes with plenty of Not likely Remove victim to fresh air. Provide Consider minutes. Remove contaminated clothing water for 15 minutes. Get route of artificial respiration if breathing is oxygen. and shoes, wash before reuse. Get medical attention exposure. difficult. Consider oxygen. Contact medical attention immediately. immediately. medical personnel immediately. Section 5: Fire Fighting Measures Suitable Extinguishing Media Products of Protection of Firefighters Combustion Non-flammable. Use extinguishing media suitable for Non-flammable § Wear self-contained breathing apparatus. surrounding fire. Section 6: Accidental Release Measures Personal Precautions Environmental Precautions Methods for Containment Isolate area. Contact emergency personnel. Eliminate ignition Avoid contact with soil, waterways, drains Shut off flow if possible sources if it is safe to do so. -

Nitrogen Trifluoride DOT I.D

AGA GAS, INC. (216) 642-6600 6055 ROCKSIDE WOODS BLVD P.O. BOX 94737 CLEVELAND, OH 44101-4737 PRODUCT NAME CAS # 7783-54-2 Nitrogen Trifluoride DOT I.D. No.: TRADE NAME AND SYNONYMS UN 2451 Nitrogen trifluoride (D.O.T.) DOT Hazard Class: Division 2.2 CHEMICAL NAME AND SYNONYMS Nitrogen Trifluoride Formula NF3 ISSUE DATES AND REVISIONS Chemical Family: Inorganic Flouride Revised January 1995 HEALTH HAZARD DATA TIME WEIGHTED AVERAGE EXPOSURE LIMIT TWA = 10 Molar PPM (ACGIH 1994-1995). OSHA 1993 PEL (8 Hr. TWA) = 10 Molar PPM. SYMPTOMS OF EXPOSURE Symptoms include headache, weakness, dizziness, confusion and other manifestations associated with a reduced oxygen supply in the blood. No hazard from skin contact has been recognized. TOXICOLOGICAL PROPERTIES Inhalation: Monkey LC50:10,000 ppm (1%) The toxicity of nitrogen trifluoride is related to its capacity to form methemoglobin, a modified form of hemoglobin incapable of transporting oxygen, and its ability to destroy red blood cells (hemolysis). Upon cessation of exposure, methemoglobin spontaneously reverts to hemoglobin. However, at high levels of conversion, therapeutic intervention may be indicated (oxygen, methylene blue, exchange transfusion). The occurence of hemolysis requires careful monitoring for degree of anemia and the potential for impaired kidney function. No hazard from skin contact is recognized. (Continued on Page 4) RECOMMENDED FIRST AID TREATMENT PROMPT MEDICAL ATTENTION IS MANDATORY IN ALL CASES OF OVEREXPOSURE TO NITROGEN TRIFLUORIDE. RESCUE PERSONNEL SHOULD BE EQUIPPED WITH SELF-CONTAINED BREATHING APPARATUS. An individual exposed to nitrogen trifluoride should be removed from the contaminated area as quickly as possible. If there is evidence of chemical cyanosis, administer oxygen. -

Chemical Names and CAS Numbers Final

Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number C3H8O 1‐propanol C4H7BrO2 2‐bromobutyric acid 80‐58‐0 GeH3COOH 2‐germaacetic acid C4H10 2‐methylpropane 75‐28‐5 C3H8O 2‐propanol 67‐63‐0 C6H10O3 4‐acetylbutyric acid 448671 C4H7BrO2 4‐bromobutyric acid 2623‐87‐2 CH3CHO acetaldehyde CH3CONH2 acetamide C8H9NO2 acetaminophen 103‐90‐2 − C2H3O2 acetate ion − CH3COO acetate ion C2H4O2 acetic acid 64‐19‐7 CH3COOH acetic acid (CH3)2CO acetone CH3COCl acetyl chloride C2H2 acetylene 74‐86‐2 HCCH acetylene C9H8O4 acetylsalicylic acid 50‐78‐2 H2C(CH)CN acrylonitrile C3H7NO2 Ala C3H7NO2 alanine 56‐41‐7 NaAlSi3O3 albite AlSb aluminium antimonide 25152‐52‐7 AlAs aluminium arsenide 22831‐42‐1 AlBO2 aluminium borate 61279‐70‐7 AlBO aluminium boron oxide 12041‐48‐4 AlBr3 aluminium bromide 7727‐15‐3 AlBr3•6H2O aluminium bromide hexahydrate 2149397 AlCl4Cs aluminium caesium tetrachloride 17992‐03‐9 AlCl3 aluminium chloride (anhydrous) 7446‐70‐0 AlCl3•6H2O aluminium chloride hexahydrate 7784‐13‐6 AlClO aluminium chloride oxide 13596‐11‐7 AlB2 aluminium diboride 12041‐50‐8 AlF2 aluminium difluoride 13569‐23‐8 AlF2O aluminium difluoride oxide 38344‐66‐0 AlB12 aluminium dodecaboride 12041‐54‐2 Al2F6 aluminium fluoride 17949‐86‐9 AlF3 aluminium fluoride 7784‐18‐1 Al(CHO2)3 aluminium formate 7360‐53‐4 1 of 75 Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number Al(OH)3 aluminium hydroxide 21645‐51‐2 Al2I6 aluminium iodide 18898‐35‐6 AlI3 aluminium iodide 7784‐23‐8 AlBr aluminium monobromide 22359‐97‐3 AlCl aluminium monochloride -

Safety Data Sheet

SAFETY DATA SHEET Nonflammable Gas Mixture: Carbon Dioxide / Carbon Monoxide / Methane / Nitrogen / Nitrogen Trifluoride / Tetrafluoromethane / Silicon Tetrafluoride / Sulfur Hexafluoride Section 1. Identification GHS product identifier : Nonflammable Gas Mixture: Carbon Dioxide / Carbon Monoxide / Methane / Nitrogen / Nitrogen Trifluoride / Tetrafluoromethane / Silicon Tetrafluoride / Sulfur Hexafluoride Other means of : Not available. identification Product use : Synthetic/Analytical chemistry. SDS # : 022149 Supplier's details : Airgas USA, LLC and its affiliates 259 North Radnor-Chester Road Suite 100 Radnor, PA 19087-5283 1-610-687-5253 24-hour telephone : 1-866-734-3438 Section 2. Hazards identification OSHA/HCS status : This material is considered hazardous by the OSHA Hazard Communication Standard (29 CFR 1910.1200). Classification of the : GASES UNDER PRESSURE - Compressed gas substance or mixture GHS label elements Hazard pictograms : Signal word : Warning Hazard statements : Contains gas under pressure; may explode if heated. May displace oxygen and cause rapid suffocation. Precautionary statements General : Read and follow all Safety Data Sheets (SDS’S) before use. Read label before use. Keep out of reach of children. If medical advice is needed, have product container or label at hand. Close valve after each use and when empty. Use equipment rated for cylinder pressure. Do not open valve until connected to equipment prepared for use. Use a back flow preventative device in the piping. Use only equipment of compatible materials of construction. Prevention : Not applicable. Response : Not applicable. Storage : Protect from sunlight. Store in a well-ventilated place. Disposal : Not applicable. Hazards not otherwise : In addition to any other important health or physical hazards, this product may displace classified oxygen and cause rapid suffocation. -

Nitrogen Trifluoride (NF3 ): Production and Purification

Journal content Nitrogen trifluoride (NF3): Production and purification T. Fiodorova, S. Igoumnov, V. Kornilov 1. Introduction NF3 is a toxic gas, inert under normal conditions , odorless in the absence of admixtures. At an elevated temperature it is a strong oxidizer comparable with fluorine. General constants: Boiling point, oC -129 (1), -129.1 (2) Melting point,oC -206.8 (1), -208.5 (2) Liquid density,g/cm3 - 1.533 (1) Evaporation heat, cal/mol- 2769 (1) Melting heat, cal/mol - 95.1 (1) Due to easy handling at room temperature, NF3 has advantages compared with fluorine and is used as a stable fluorinating agent and has a wide application in high-energy chemical lasers, at dry etching in production of semiconductors, as a filling gas in lamps to prolong their durability and increase brightness, as a detergent gas in CVD apparatuses ( chemical gas- phase precipitation) (3,4,77). 2. Methods of NF3 production o For the first time, NF3 was produced by O.Ruff et al. in 1928 by electrolysis of melt anhydrous NH4* HF at 125 C, voltage of 7-9 V, current of 10 A in a copper electrolytic cell on a carbon anode (5). This method was assumed as a basis for modern technologies to produce NF3, the second industrial method is direct fluorination of ammonia. Paper (6) presents a review based on publications right up to 1984 including data on methods of NF3 production, purification, reactions with elements, organic and inorganic compounds and also its molecular properties, spectra, thermodynamic constants etc. That is why the present review considers only publications from 1983 y.