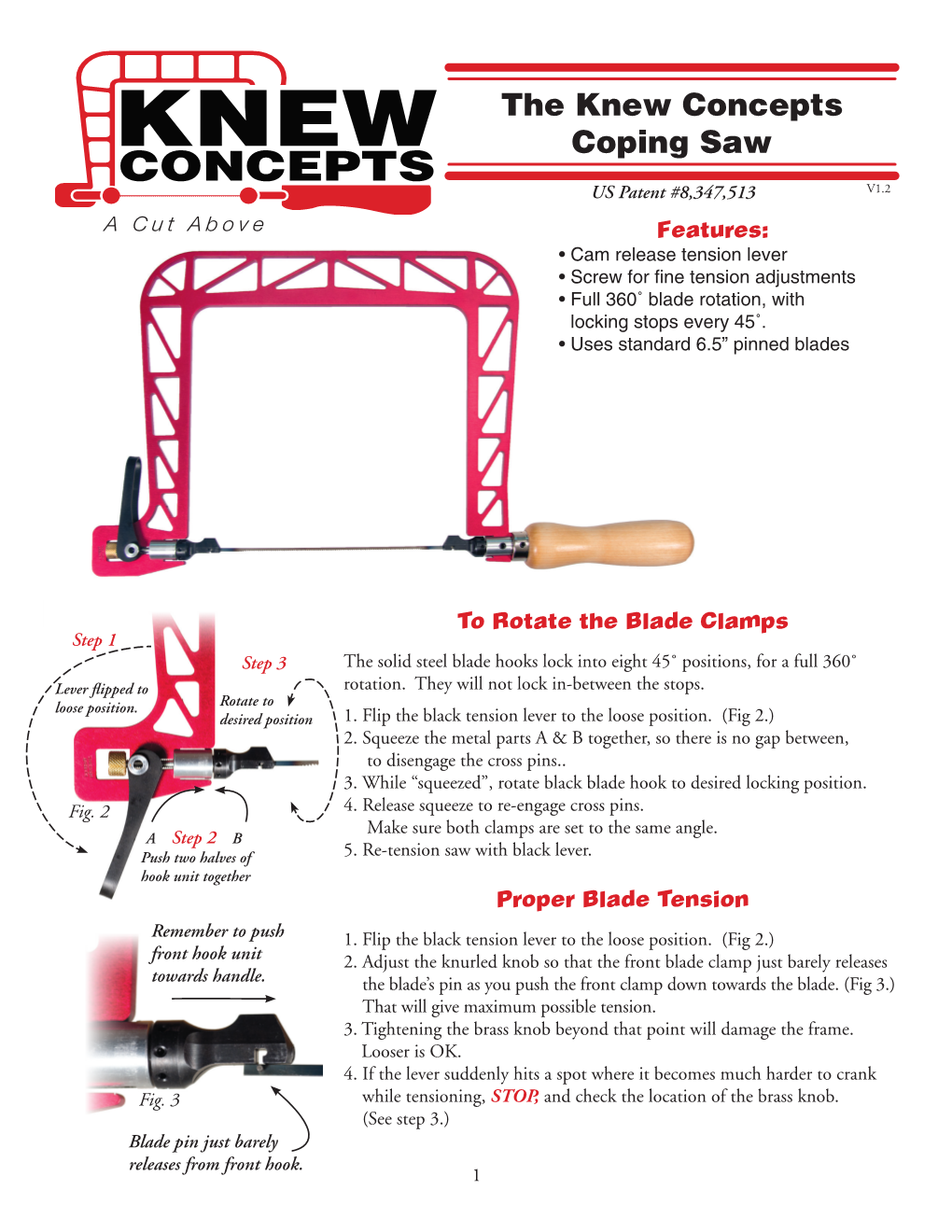

The Knew Concepts Coping Saw

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Hand Saws Hand Saws Have Evolved to fill Many Niches and Cutting Styles

Source: https://www.garagetooladvisor.com/hand-tools/different-types-of-saws-and-their-uses/ Hand Saws Hand saws have evolved to fill many niches and cutting styles. Some saws are general purpose tools, such as the traditional hand saw, while others were designed for specific applications, such as the keyhole saw. No tool collection is complete without at least one of each of these, while practical craftsmen may only purchase the tools which fit their individual usage patterns, such as framing or trim. Back Saw A back saw is a relatively short saw with a narrow blade that is reinforced along the upper edge, giving it the name. Back saws are commonly used with miter boxes and in other applications which require a consistently fine, straight cut. Back saws may also be called miter saws or tenon saws, depending on saw design, intended use, and region. Bow Saw Another type of crosscut saw, the bow saw is more at home outdoors than inside. It uses a relatively long blade with numerous crosscut teeth designed to remove material while pushing and pulling. Bow saws are used for trimming trees, pruning, and cutting logs, but may be used for other rough cuts as well. Coping Saw With a thin, narrow blade, the coping saw is ideal for trim work, scrolling, and any other cutting which requires precision and intricate cuts. Coping saws can be used to cut a wide variety of materials, and can be found in the toolkits of everyone from carpenters and plumbers to toy and furniture makers. Crosscut Saw Designed specifically for rough cutting wood, a crosscut saw has a comparatively thick blade, with large, beveled teeth. -

Build a Plane That Cuts Smooth and Crisp Raised Panels With, Against Or Across the Grain – the Magic Is in the Spring and Skew

Fixed-width PanelBY WILLARD Raiser ANDERSON Build a plane that cuts smooth and crisp raised panels with, against or across the grain – the magic is in the spring and skew. anel-raising planes are used Mass., from 1790 to 1823 (Smith may to shape the raised panels in have apprenticed with Joseph Fuller doors, paneling and lids. The who was one of the most prolific of the profile has a fillet that defines early planemakers), and another similar Pthe field of the panel, a sloped bevel example that has no maker’s mark. to act as a frame for the field and a flat Both are single-iron planes with tongue that fits into the groove of the almost identical dimensions, profiles door or lid frame. and handles. They differ only in the I’ve studied panel-raising planes spring angles (the tilt of the plane off made circa the late 18th and early 19th vertical) and skew of the iron (which centuries, including one made by Aaron creates a slicing cut across the grain to Smith, who was active in Rehoboth, reduce tear-out). The bed angle of the Smith plane is 46º, and the iron is skewed at 32º. Combined, these improve the quality of cut without changing the tool’s cutting angle – which is what happens if you skew Gauges & guides. It’s best to make each of these gauges before you start your plane build. In the long run, they save you time and keep you on track. Shaping tools. The tools required to build this plane are few, but a couple of them – the firmer chisel and floats – are modified to fit this design. -

Common Saw Types

Common Saw Types “Basic” Handsaw This is the most recognizable and the simplest to operate of all of saws. It works on wood of all types but is best for “soft” woods. Can be used for all types of cuts. Hack Saw This type of handsaw features a fine-toothed replaceable blade on a C-frame. Commonly used for cutting metals and plastics. Japanese Saws A saw type with a thinner blade with crosscut teeth on one side and rip teeth on the other. These saws are more often found in a fine woodworking or furniture making situation. Coping Saw Popular with artists, this simple but useful cutting tool consists of a thin replaceable blade in a C-shaped frame that uses interchangeable blades for both metal and wood. It can cut tight radiuses but perhaps its most useful feature is the ability to remove the blade and thread it through a drilled hole to cut inside profiles. Jigsaw/Reciprocating Saw If you’ve ever needed to cut a custom shape out of a sheet of plywood or even plastic, this is a great saw. If a perfectly straight line is what you need, then leave this tool on the shelf. Even in the hands of a skilled operator the blade will drift easily. Circular Saw This saw is the standard for making cross and rip cuts. If you van only have one powered saw, this is the one. When it is paired with a saw guide it can make surprisingly accurate cuts. Table Saw Ripping and beveling are the things the table saw does best. -

Special Ty Fluids

Tel: 201-518-8461 / Fax: 201-596-3427 TAR OOL UPPLY / RAND OOL UPPLY S T S G T S 650 Huyler St / So. Hackensack, NJ 07606 USA MACHINIST JACK “LITTLE GIANT” SERIES 508: JACK SCREWS STARRETT SERIES 190, 191: • Base is made of heavy cast steel. • Adjustable screw and tilting swivel head. For leveling work on planer beds, • Range: 3-4”/75-100mm upright drills and setting up machinery. • Approximately 1”/25mm adjustment The versatility of this tool is greatly • 1000 lb. lifting capacity. increased by the number of • For use on various machine tools or attachments available. wherever leveling is necessary. Ability to lift 1,000 lbs. or more. • • 20-pitch screws for fine adjustments. Order No. 5080001 • Can be used on uneven and round surfaces. Price Catalog EDP No. Order No. Description Price HEAVY DUTY SET INCLUDES: Range 2-1/4” - 3-3/8” • Jack, extension bases & attachments. • Range: 2-1/4 - 3-3/8”mm / 75-100mm S190 50680 Set Complete with all Attachments Order No. 5080150 Range 1-1/2” - 2-1/4” Price S191 50687 Set Complete with all Attachments HEAVY DUTY “INDUSTRIAL” We also distribute See page 725 BENCH GRINDERS BALDOR grinders. SERIES 508: See our website or inquire. for grinders. SPECIALTY FLUIDS SPECIALTY • Pre-lubricated and enclosed ball Model No. BG6 BG8 BG10 bearings ensure smooth operation Wheel Size 6” x 3/4” x 1/2” 8” x 3/4” x 5/8” 10” x 1” x 1” under full load. • Complete with eye shields, spark Motor / 1/3 HP, 1PH 3/4 HP, 1PH 1-1/2 HP,1 PH shields, adjustable tool rests, fine & Electricals 110V 110V 110V coarse wheels. -

How Scroll Saw Blades Are Made There Are Three Ways We Manufacture Scroll Saw Blades

lson has been a leading manufacturer of scroll saw blades for more than 80 years, offering a full Oline of superior quality blades to satisfy almost every scrolling application. Olson blades are for use with scroll/jig saw machines sold by Delta, DeWalt, Dremel, Skil, Rockwell, Pro-Tech, Powermatic, RB Industries, Hegner, Sakura, Shopsmith, Excalibur, Rexon, Ryobi, Sears Craftsman, and Makita. (virtually all domestic and imported scroll saws). They can also be used in hand held fret and jewelers saw frames. The Olson Saw Co. has introduced many innovative blades, including: PGT® (Precision Ground Tooth) Scroll Saw Blades in skip and new double tooth styles with reverse teeth are simply the finest scroll saw blades there are! Considered among experts as “the best blade available”, PGT® blades are made with an exclusive grinding process that forms teeth in hardened steel. The blades are double ground to ensure that every edge of the tooth (face, tip, and gullet) is as sharp as possible. Crown Tooth™ Blades are a recent edition to the line. They have a unique tooth design that cuts on both the up and down stroke. Because of this two-way cutting action, Crown Tooth blades allow for cutting with more control while leaving a smooth, splinter-free finish. Also, they can be turned over for cutting with a fresh set of teeth. They are also excellent for cutting many kinds of plastics. Reverse Skip Tooth Blades with special reverse teeth on the lower end of the blade for a smooth, splinter-free finish on the bottom surface. Olson is continually improving and expanding its blade selection. -

SOUTHERN AFRICA HAND TOOLS & STORAGE 2015 TOOLSTHAT BUILDTHE WORLD Since 1843, STANLEY® Has Been Proudly Offering Quality and Innovative Tool Solutions

SOUTHERN AFRICA HAND TOOLS & STORAGE 2015 TOOLSTHAT BUILDTHE WORLD Since 1843, STANLEY® has been proudly offering quality and innovative tool solutions. For over a century, we have built a legacy by producing some of the most well known hand tools and storage products in the world, all to help you build a legacy of your own. We are committed to bringing you durable and quality tools that are inventive and distinct. With superior quality, constant innovation and rigorous operational improvements, STANLEY® defines excellence and is trusted by professionals around the globe. In 2013, STANLEY® embraced a new brand logo and identity, modernising one of the most recognizable brands in the world. The new brand identity exemplifies STANLEY’s 170-year reputation for innovation, merit and performance. With the evolution of the brand logo, we are proud to offer you even more cutting- edge products for all your job site needs. It is time to experience the power of innovation! THE HISTORY OF STANLEY® TOOLS 1863 1911 1936 1954 1980 Stanley introduced hammers Stanley began manufacturing Stanley manufactured its Time Magazine published a cover story titled The Stanley Works was presented the to their line-up. chisels and vises. first utility knife. “Do-It-Yourself – The New Million Dollar American Eagle Award from the American Hobby”. Stanley was ideally positioned to Supply & Machinery Manufacturers’ benefit from this trend and quickly Associ., Inc. for its “unusual across-the- 1843 1870 1921 developed products for this new market. board quality”. The Stanley Works was Stanley began manufacturing A new logo is introduced to founded in New Britain, screwdrivers and hand planes. -

How to Cut and Install Moulding

How to Cut and Install Moulding Start with the Right Tools for the Job Some of the tools needed are: • Safety glasses • Power miter saw – We recommend using carbide saw blade with 80 teeth or more. Left and Right hand positioning – the side of the trim you • Miter box and hand are cutting is as important as its position on the saw table. saw – They have The positions are illustrated above. limited angle adjustment (not recommended for Vertical Position Miters crown). Use this technique for cutting • Coping saw – Only baseboard, chair rail, quarter needed if you choose round, and splice miters. the coping technique Inside corners - A left hand to install the moulding. inside corner is shown in the • Angle gage – To create the correct miter, you must photo. determine the wall corner angle. Step 1 - To accomplish this, place • Glue – To adhere the miter joints (we strongly the trim on the saw table in the recommend gluing all joints). left hand vertical position and • Hammer & nails or a pneumatic nail gun. rotate the angle gage “clock • Other tools may include a tape measure, pencil, wise” to 45°, or the desired angle C-clamp, putty and caulk. setting, and make the cut. Step 2 - To cut the mating piece simply rotate the table angle Determine the Amount of gage to the opposite 45° or desired angle, and place the Moulding to Buy next piece of trim on the saw table in the right hand verti - You must decide where the cal position and cut the trim. mouldings are to be used and measure the distances. -

Chisels BEVEL •Edged Chisels Are Slightly Undercut

Chisels BEVEL •Edged chisels are slightly undercut. •Easy to push into corners. •They are normally used for finishing dovetail joints. FIRMER •Have a blade with a rectangular cross- section. •They are stronger and can be used for tougher/heavier work. PARING •A longer, thinner chisel which can be pushed into long joints such as housing joints. •It is used for cleaning up the joint and to make it an accurate fit. Hand Tool Basics Identification and Use Chisel Safe Always clamp wood down Never hold wood in your hands Use as many clamps as needed to prevent wood from moving Work with the grain when ever possible Keep both hands behind the chisel Use a rubber mallet only on chisels with metal tabs Keep your tool sharp Hand saws Crosscut Saw The crosscut saw has teeth that is specially designed to cut horizontally through wood. All western saws cut on the push stroke • Saw length: 21 to 27 inches • Teeth size: 8 to 12 per inch • The teeth of the crosscut saw cuts wood at a right angle toward the direction of the wood grain. Rip Cut Saw Used for cutting with the grain of the wood. The blades are pitched between 85 to 90 degrees. This type of saw is specially designed to make what is called a "rip cut." • Saw length: 23 to 27 inches • Teeth size: 5 ½ to 7 per inch Back Saw Saws that have smaller teeth; Length are shorter the typical saws. Have a metal backing rib to stabilize the blade. • Saw length: 7 to 15 inches • Teeth size: Varies per inch Dovetail saw, tenon saw and the miter saw. -

Super Clip User Guide

Super Clip Contents of Kit • Block of pine wood approximately 9" x 1-7/8" x 1-3/4" • Clip spring The finished Tools and Materials Super Clip. You Will Need • Try square • Planer • Backsaw or coping saw Learning • Awl Objective • Brace and auger bit • Vise By making the Super Clip, you will learn the fun- • 150-grit sandpaper damentals of woodworking and the uses of basic • 220-grit sandpaper or emery cloth hand tools. • Paint, stain, or varnish The Process • Paint, stain, or varnish brush • Primer, if paint is used as a finish These are the steps you will use to change a • Clean, soft rags block of wood into a Super Clip. • Eye protectors Step 1 Cut and plane the wood. • Carbon paper Step 2 Make and trace the clip pattern. • 4/0 steel wool Step 3 Drill the holes. • Light polishing oil Step 4 Cut the notches. • Pencil Step 5 Cut out and sand the clip. Step 6 Apply the finish. Step 7 Attach the spring. Safety First Safety is an important part of every job. Working with hand tools can be dangerous. It is impor- tant to respect the sharp edges and points of woodworking tools and to wear eye protectors when cutting, drilling, and chiseling. Always think safety. Measuring Tools A steel rule is used to measure short Carpenter’s Square distances and can also be used as a straightedge to test or draw straight lines. Tape measures and folding rules are best for measuring longer distances. Try squares, combination squares, and carpen- ter’s squares are instruments used by carpenters for laying off right angles and for testing wheth- Tape Measure er work is square. -

The Wonderful World of Wood Woodworking Tools Attention Awl

The Wonderful World of Wood Woodworking Tools Wood Science Unit I contains information about Scratch Awl a group of tools and some equipment you should have Now that you are doing more exact and accurate for your use. This unit contains information about work than before, you may need a scratch awl for more tools. You may want to add some of them to your marking. It gives a very clean, sharp, distinct line for tool set. accurate cutting. It can be used to make a center point Steel Tape and Folding Rule in wood for drilling. In this unit, you will be making bigger things than before. Therefore, you may desire a steel tape rule or a folding rule. Both are available in similar price ranges. For your use, consider the lower cost range and either the steel tape rule or folding rule as suggested by your leader. Attention Awl Users The steel tape rule is available in many lengths: 6, An awl is sharp-pointed like an ice pick. It is used 8, 10, and 12-foot lengths. The 6-foot length probably is for marking lines or piercing small holes in wood. Because of its sharpness, it must be handled adequate for your use. carefully at all times so it won’t pierce your skin. Folding rules are available with either standard inside reading or outside reading. The numbers on the inside-reading rule begin on the inside face. Thus the markings are close to the work when the rule lies on the work with the unfolded portion up. -

31974 WW Cutting Circles TG

Woodworking: The Art and the Craft METHODSMETHODS OFOF CUTTINGCUTTING CIRCLESCIRCLES ANDAND CURVESCURVES TEACHER’S GUIDE INTRODUCTION This Teacher’s Guide provides information to help you get the most out of Methods of Cutting Circles and Curves. The contents of this guide will allow you to prepare your stu- dents before using the program and present follow-up activities to reinforce the program’s key learning points. Part of Woodworking: The Art and the Craft video series, Methods of Cutting Circles and Curves explains and illustrates how to properly make accurate drawings to use as a guide and how to use several types of saws when cutting circles and curves. While the program includes information about the tools and safety requirements of the task, the focus of the program is to provide specific information centered on how to cut curves and circles. LEARNING OBJECTIVES After viewing the program, students will be able to: ■ Demonstrate making an accurate drawing using a compass, circle template, or French curve. ■ Demonstrate transferring a design onto wood. ■ Describe the uses of a band saw, a scroll saw, a saber saw, a router, and a coping saw. ■ Describe how to make different cuts using a saw. ■ Describe how to making a coped joint. ■ Demonstrate using a coping saw to make an interior cut. ■ Demonstrate the safety rules for using power equipment. EDUCATIONAL STANDARDS National Standards This program correlates with the following competency standards from the National Center for Construction Education & Research. The content has been aligned with the fol- lowing educational standards and benchmarks from this organization. -

Door Trim and Baseboards Tools and Materials Needed: 1

70 - Door Trim and Baseboards Tools and Materials Needed: 1. Trim nails guns loaded with 2 inch finish nails. Uses the small hoses with small fittings. 2. 6ft and 2 ft levels 3. Trim miter saw 4. Coping saw 5. Angle finder (adjustable square) 6. ¼ inch reveal trim gauge (homemade blocks of wood) Most Common Mistakes: 1. Poorly fitting miter joint 2. Inconsistent reveal around door casing 3. Trim interferes with electrical boxes Roles Teams of 2 work well. One person adjusts the door trim or floorboard while another nails. On long baseboards, a 2nd person holding the far end of the tape results in better measurements. Door Trim Installation Before this step, drywall was hung taped and textured and interior doors where installed. The walls may or may not have been painted – either way is acceptable. 1. Verify that there is sufficient space for door trim between the doors and any neighboring room corner and electric box (including electric trim plate). Rarely, some mistake is made in this area. If problems are found, consult the supervisor. 2. Mark a ¼ inch reveal on the top and both sides of the door casing using the homemade trim gauge. 3. Measure from the subfloor to the top mark made in step 2. Subtract ¼ inch so that the side molding is elevated off the floor by ¼ inch. 4. Measure from side to side marks made in step 1. This is the size of the short end of the miter cuts for the top door trim. 5. Mark door trim to match the measurements in step 2.