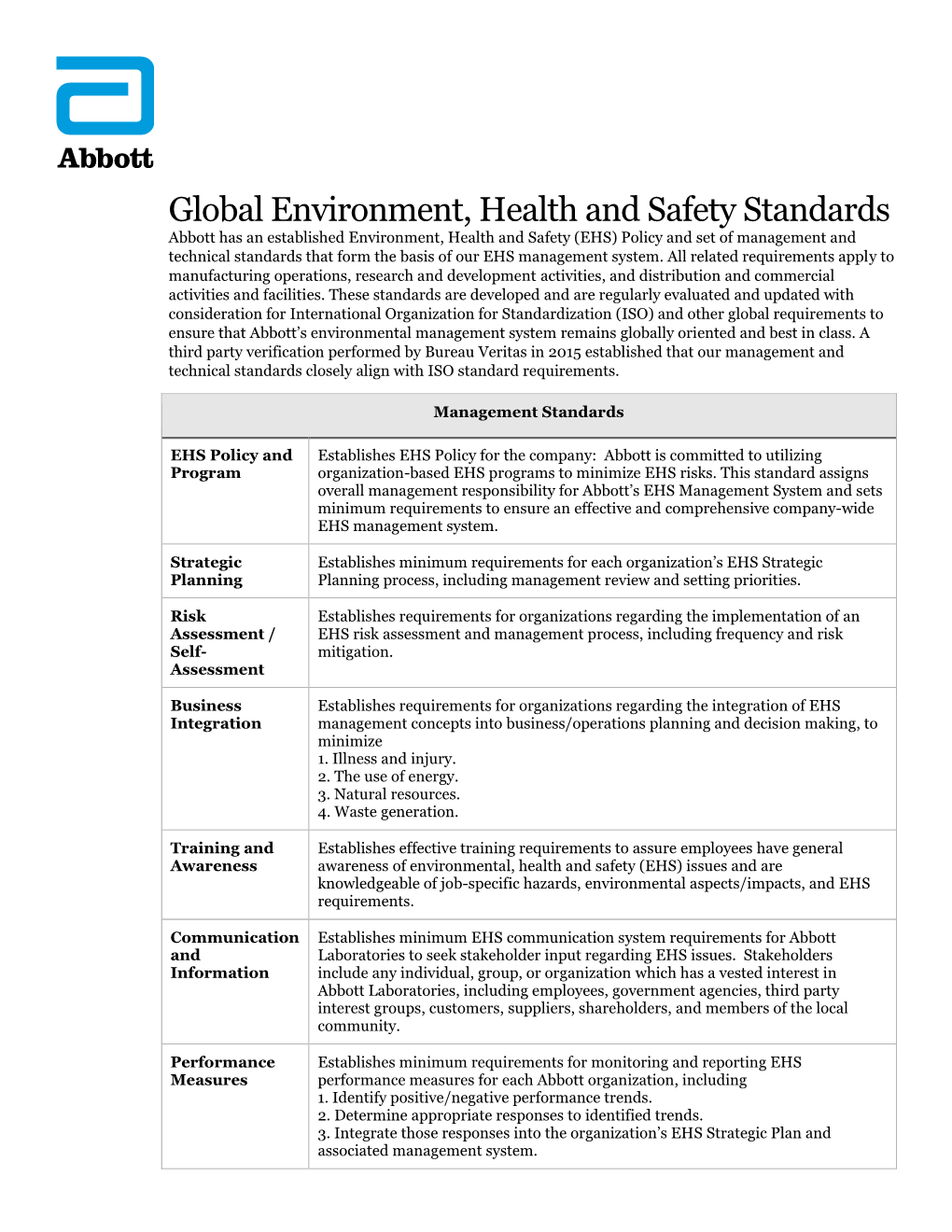

EHS Technical Standards

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Rational Use of Personal Protective Equipment for Coronavirus Disease (COVID-19) and Considerations During Severe Shortages Interim Guidance 6 April 2020

Rational use of personal protective equipment for coronavirus disease (COVID-19) and considerations during severe shortages Interim guidance 6 April 2020 Background • avoiding touching your eyes, nose, and mouth; • practicing respiratory hygiene by coughing or This document summarizes WHO’s recommendations for the sneezing into a bent elbow or tissue and then rational use of personal protective equipment (PPE) in health immediately disposing of the tissue; care and home care settings, as well as during the handling of • wearing a medical mask if you have respiratory cargo; it also assesses the current disruption of the global symptoms and performing hand hygiene after supply chain and considerations for decision making during disposing of the mask; severe shortages of PPE. • routine cleaning and disinfection of environmental and other frequently touched surfaces. This document does not include recommendations for members of the general community. See here: for more In health care settings, the main infection prevention and information about WHO advice of use of masks in the general control (IPC) strategies to prevent or limit COVID-19 community. transmission include the following:2 In this context, PPE includes gloves, medical/surgical face 1. ensuring triage, early recognition, and source control masks - hereafter referred as “medical masks”, goggles, face (isolating suspected and confirmed COVID-19 shield, and gowns, as well as items for specific procedures- patients); 3 filtering facepiece respirators (i.e. N95 or FFP2 or 2. applying standard precautions for all patients and FFP3 standard or equivalent) - hereafter referred to as including diligent hand hygiene; “respirators" - and aprons. This document is intended for 3. -

Occupational Hygiene Report Writing

BACK TO BASICS PEER REVIEWED Occupational hygiene report writing Peter-John “Jakes” ABSTRACT Jacobs Occupational hygiene reports record occupational hygiene exposure assessments. Although their (MPH Occ. Hygiene) Cas Badenhorst (PhD purpose and format can vary, they must provide adequate information for managing occupational Occ. Hygiene) risks and so ensure the health and safety of employees. This article describes how to write a good occupational hygiene report, specifi cally with respect to the minimum content and style. Corresponding author: E-mail: jakes.jacobs2@ Key words: occupational hygiene report, content, standards sasol.com INTRODUCTION When the target audience is the senior management of an The fi ndings of occupational hygiene exposure assessments organisation, the report needs to be concise and prefer- are recorded in occupational hygiene reports. The purpose ably no longer than one page with the technical and other of these reports can vary, for example providing commu- information contained in an appendix. A popularly recounted nication to management, employees, health and safety anecdote is that the average reading ability of a company’s representatives, engineers, etc. regarding occupational chief executive offi cer is equitable to that of a 14-year-old, the hazards present in the workplace, addressing emergencies reason being that they are burdened with massive amounts and, importantly, provide practical exposure control advice of data that must be digested on a daily basis. This report and, are critical in managing occupational risks.1 Although can typically be a summary of fi ndings as described in the several formats for the reports exist, they should all serve detailed occupational hygiene report. -

Occupational Exposure to Heat and Hot Environments

Criteria for a Recommended Standard Occupational Exposure to Heat and Hot Environments DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for Disease Control and Prevention National Institute for Occupational Safety and Health Cover photo by Thinkstock© Criteria for a Recommended Standard Occupational Exposure to Heat and Hot Environments Revised Criteria 2016 Brenda Jacklitsch, MS; W. Jon Williams, PhD; Kristin Musolin, DO, MS; Aitor Coca, PhD; Jung-Hyun Kim, PhD; Nina Turner, PhD DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for Disease Control and Prevention National Institute for Occupational Safety and Health This document is in the public domain and may be freely copied or reprinted. Disclaimer Mention of any company or product does not constitute endorsement by the National Institute for Occupational Safety and Health (NIOSH). In addition, citations of websites external to NIOSH do not constitute NIOSH endorsement of the sponsoring organizations or their programs or products. Furthermore, NIOSH is not responsible for the content of these websites. Ordering Information This document is in the public domain and may be freely copied or reprinted. To receive NIOSH documents or other information about occupational safety and health topics, contact NIOSH at Telephone: 1-800-CDC-INFO (1-800-232-4636) TTY: 1-888-232-6348 E-mail: [email protected] or visit the NIOSH website at www.cdc.gov/niosh. For a monthly update on news at NIOSH, subscribe to NIOSH eNews by visiting www.cdc.gov/ niosh/eNews. Suggested Citation NIOSH [2016]. NIOSH criteria for a recommended standard: occupational exposure to heat and hot environments. By Jacklitsch B, Williams WJ, Musolin K, Coca A, Kim J-H, Turner N. -

Guide to OH&S Certifications & Designations

THIRD EDITION Guide to OH&S Certifications & Designations A Resource for Safety Practitioners, Employers, and those considering a Career in Occupational Health & Safety COHSPRAC CRST This guide is produced by the Canadian Society of Safety Engineering CSSE Guide to OH&S Certifications & Designations 1 A Guide for Employers and OH&S Practitioners This document has been prepared by Canadian Society of Safety Engineering (CSSE) in the pursuit of CSSE’s mission, vision and goals. All rights reserved. Permission to photocopy or download for individual use is granted. Further reproduction in any manner, including posting to a website, is prohibited without prior written permission of the publisher. Permission may be obtained by contacting the CSSE at [email protected]. © Canadian Society of Safety Engineering 468 Queen Street East, Suite LL-02 Toronto, Ontario M5A 1T7 Tel.: 416-646-1600 www.csse.org Third Edition September 2018 CSSE Guide to OH&S Certifications & Designations 2 A Guide for Employers and OH&S Practitioners PURPOSE OF THE GUIDE The Guide is intended to serve as a resource to employers when hiring a health and safety practitioner. It also provides guidance to future OH&S practitioners on the type of education, experience, and other qualifications being sought by employers. Information on both Canadian and International safety certifications and designations is provided, along with suggested competencies and qualifications for OH&S positions from entry to executive level. An interview guide is included to provide employers with suggested -

Management of Occupational Exposure Limits: a Guide for Mine Ventilation Engineers

Management of Occupational Exposure Limits: A Guide for Mine Ventilation Engineers Derrick J. (Rick) Brake1,2(&) 1 Mine Ventilation Australia, Brisbane, QLD, Australia [email protected] 2 Monash University, Melbourne, VIC, Australia Abstract. Many underground mines do not have a qualified or dedicated occupational (industrial) hygienist on site, or even available as a resource. Many mine ventilation engineers do not even consider occupational exposure moni- toring to be relevant to their role as an engineer. In many cases where occu- pational exposure monitoring is conducted, the mine ventilation engineer is not informed about the results of the monitoring, or if he is, cannot interpret cor- rectly what these results mean. This bunker mentality separating occupational hygiene and ventilation engineering reduces the range of tools available to the ventilation engineer to actively adjust or tune the ventilation system to keep the underground environment healthy, or as healthy as it could otherwise be. This paper sets out the principles and practices that the mine ventilation engineer needs to know to be able to understand how to interpret occupational hygiene monitoring results, and the implications for the mine primary and secondary ventilation systems. Keywords: Occupational Á Industrial Á Hygiene Á Monitoring Underground Á Ventilation 1 Introduction In most countries, occupational (or industrial) hygiene is managed by professional hygienists—quite a different field of specialty to engineers; mine ventilation engineers have only been peripherally involved if at all. The exception is probably South Africa where the role of ventilation engineers now tends to encompass at least basic occu- pational hygiene management. There are arguments for and against combining the roles of hygienist and engineer, but the dual-role system has not been adopted elsewhere to date. -

Occupational Health Hazards: Employer, Employee, and Labour Union Concerns

International Journal of Environmental Research and Public Health Review Occupational Health Hazards: Employer, Employee, and Labour Union Concerns Oscar Rikhotso 1,* , Thabiso John Morodi 1 and Daniel Masilu Masekameni 2 1 Department of Environmental Health, Tshwane University of Technology, Private Bag X680, Pretoria 0001, South Africa; [email protected] 2 Occupational Health Division, School of Public Health, University of Witwatersrand, Parktown 2193, South Africa; [email protected] * Correspondence: [email protected]; Tel.: +27-123-824-923 Abstract: This review paper examines the extent of employer, worker, and labour union concerns to occupational health hazard exposure, as a function of previously reported and investigated com- plaints. Consequently, an online literature search was conducted, encompassing publicly available reports resulting from investigations, regulatory inspection, and enforcement activities conducted by relevant government structures from South Africa, the United Kingdom, and the United States. Of the three countries’ government structures, the United States’ exposure investigative activities con- ducted by the National Institute for Occupational Safety and Health returned literature search results aligned to the study design, in the form of health hazard evaluation reports reposited on its online database. The main initiators of investigated exposure cases were employers, workers, and unions at 86% of the analysed health hazard evaluation reports conducted between 2000 and 2020. In the synthesised literature, concerns to exposure from chemical and physical hazards were substantiated by occupational hygiene measurement outcomes confirming excessive exposures above regulated Citation: Rikhotso, O.; Morodi, T.J.; health and safety standards in general. Recommendations to abate the confirmed excessive exposures Masekameni, D.M. -

Part 18 Personal Protective Equipment Highlights

Occupational Health and Safety Code 2009 Part 18 Explanation Guide Part 18 Personal Protective Equipment Highlights • Section 229 recognizes that the face piece of a full face piece respirator can provide eye protection. • Section 232 requires workers to wear flame resistant outerwear if they could be exposed to a flash fire or electrical equipment flashover. • Section 233 provides several options in protective footwear. Footwear requirements are based on the hazards feet may be exposed to. External safety toecaps are permitted as an alternative to protective footwear when a medical condition prevents a worker from wearing normal protective footwear. Footwear approved to ASTM Standard F2413 is now acceptable for use in Alberta. • Section 234 recognizes both Canadian Standards Association (CSA) and American National Standards Institute (ANSI) standards for protective headwear. • Section 235 requires employers to ensure that a worker riding a bicycle or using in-line skates or a similar means of transport wears an approved cycling helmet. • Section 246 requires employers to ensure that respiratory protective equipment must be approved by the National Institute for Occupational Safety and Health (NIOSH) or by another organization that sets standards and tests equipment, and is approved by a Director of Occupational Hygiene. Directors of occupational hygiene are staff members of Alberta Human Resources and Employment appointed by the Minister under Section 5 of the OHS Act. • Section 247 requires that employers select respiratory protective equipment in accordance with CSA Standard Z94.4-02, Selection, Use and Care of Respirators. • Section 250 requires that employers test respiratory protective equipment for fit, according to CSA Standard Z94.4-02, Selection, Use and Care of Respirators, or a method approved by a Director of Occupational Hygiene. -

Guidelines for Statistical Analysis of Occupational Exposure Data

GUIDELINES FOR STATISTICAL ANALYSIS OF OCCUPATIONAL EXPOSURE DATA FINAL by IT Environmental Programs, Inc. 11499 Chester Road Cincinnati, Ohio 45246-0100 and ICF Kaiser Incorporated 9300 Lee Highway Fairfax, Virginia 22031-1207 Contract No. 68-D2-0064 Work Assignment No. 006 for OFFICE OF POLLUTION PREVENTION AND TOXICS U.S. ENVIRONMENTAL PROTECTION AGENCY 401 M STREET, S.W. WASHINGTON, D.C. 20460 August 1994 DISCLAIMER This report was developed as an in-house working document and the procedures and methods presented are subject to change. Any policy issues discussed in the document have not been subjected to agency review and do not necessarily reflect official agency policy. Mention of trade names or products does not constitute endorsement or recommendation for use. i CONTENTS FIGURES.......................................................... v TABLES........................................................... vi ACKNOWLEDGMENT................................................vii INTRODUCTION.................................................... 1 A. Types of Occupational Exposure Monitoring Data ...................... 1 B. Types of Occupational Exposure Assessments ........................ 2 C. Variability in Occupational Exposure Data ........................... 3 D. Organization of This Report .................................... 4 STEP 1: IDENTIFY USER NEEDS........................................ 9 STEP 2: COLLECT DATA............................................. 15 A. Obtaining Data From NIOSH ................................... 15 -

Safety Data Sheet

G-Biosciences, St Louis, MO, USA | 1-800-628-7730 | 1-314-991-6034 | [email protected] A Geno Technology, Inc. (USA) brand name Safety Data Sheet Cat. # DG098 CHAPS, 5% filtered solution Size: 100ml think proteins! think G-Biosciences! www.GBiosciences.com CHAPS 5% Solution (Filtered) Safety Data Sheet according to Regulation (EC) No. 1907/2006 (REACH) with its amendment Regulation (EU) 2015/830 Revision date: 5/11/2017 Version: 1.1 SECTION 1: Identification of the substance/mixture and of the company/undertaking 1.1. Product identifier Product form : Mixture Product name : CHAPS 5% Solution (Filtered) Product code : 258C Product group : Blend 1.2. Relevant identified uses of the substance or mixture and uses advised against 1.2.1. Relevant identified uses Main use category : Research purposes 1.2.2. Uses advised against No additional information available 1.3. Details of the supplier of the safety data sheet Geno Technology, Inc./ G-Biosciences 9800 Page Avenue 63132-1429 Saint Louis - United States T 800-628-7730 - F 314-991-1504 [email protected] - www.GBiosciences.com 1.4. Emergency telephone number Emergency number : Chemtrec 1-800-424-9300 (USA/Canada), +1-703-527-3887 (Intl) SECTION 2: Hazards identification 2.1. Classification of the substance or mixture Classification according to Regulation (EC) No. 1272/2008 [CLP] Mixtures/Substances: SDS EU 2015: According to Regulation (EU) 2015/830 (REACH Annex II) Not classified Adverse physicochemical, human health and environmental effects To our knowledge, this product does not present any particular risk, provided it is handled in accordance with good occupational hygiene and safety practice. -

STUDENT MANUAL Basic Principles in Occupational Hygiene

STUDENT MANUAL Basic Principles in Occupational Hygiene July 2019 This course is offered by the Occupational Hygiene Training Association and available free of charge though the OHTA website ohtatraining.org. Copyright information This student manual is provided under the Creative Commons Attribution - NoDerivs licence agreement. It can only be reproduced in its entirety without change, unless with the prior written permission of OHTA. Occupational Hygiene Training Association, 5/6 Melbourne Business Court Millennium Way, Pride Park, Derby, DE24 8LZ Email: [email protected] TABLE OF CONTENTS ACKNOWLEDGEMENTS i 1 INTRODUCTION 1 1.1 HISTORY 3 1.2 THE IMPORTANCE OF OCCUPATIONAL HYGIENE 6 2 HUMAN PHYSIOLOGY AND INDUSTRIAL DISEASES 8 2.1 SKIN 8 2.1.1 Dermatitis 9 2.1.2 Physical damage 10 2.1.3 Biological agents 10 2.1.4 Cancer 11 2.1.5 Other effects 11 2.2 MUSCULOSKELETAL SYSTEM 11 2.3 NERVOUS SYSTEM 12 2.4 ENDOCRINE SYSTEM 14 2.5 THE CIRCULATORY SYSTEM 15 2.5.1 The blood 17 2.6 RESPIRATORY SYSTEM 18 2.7 THE GASTROINTESTINAL TRACT 21 2.8 THE LIVER 22 2.9 URINARY SYSTEM 23 2.10 THE EYE 23 3 FUNDAMENTALS OF TOXICOLOGY 25 3.1 INTRODUCTION 25 3.2 TERMS 25 3.3 BASIC CONCEPTS 26 3.3.1 Physical form 27 3.3.2 Dose 27 3.3.3 Route of entry / absorption 28 3.3.4 Metabolism 29 3.3.5 Excretion 29 3.3.6 Response to toxins 30 3.4 STAGES OF TOXICOLOGICAL EVALUATION 30 3.4.1 What adverse effects can a chemical cause? 30 3.4.2 Are the effects seen in animals relevant to man? 31 3.5 SAFETY DATA SHEETS 31 4 EXAMPLES OF HAZARDOUS SUBSTANCES / PROCESSES 33 -

Personal Protective Equipment (PPE) Hazard Assessment Certificate Instructions

Personal Protective Equipment (PPE) Hazard Assessment Certificate Instructions Based on the hierarchy of controls, PPE is a last resort. Personal protective equipment alone should not be relied upon to provide protection against hazards but should be used in conjunction with engineering controls, administrative controls, and procedural controls. This document addresses eye, face, head, hand, foot, torso, respiratory, noise, and fall protection. It will serve as the Personal Protective Equipment (PPE) Certification document required to satisfy the federal requirements of the Occupational Safety and Health Administration (OSHA) Standard, 29 CFR 1910.132 Subpart I‐ Personal Protective Equipment. General Guidelines The PPE Hazard Assessment can be conducted for an area, a job category or for an individual by selecting and filling in the appropriate box. The assigned evaluator shall include their name, department/division being assessed, and the date. Completed assessments must be accessible to employees and inspectors and updated when needed. PPE HAZARD ASSESSMENT INSTRUCTIONS STEP 1: INFORM AFFECTED EMPLOYEES OF THE PROCESS: Affected employees from each work area that is being assessed should be involved in the process. Discuss the reasons for the survey and the procedures being used for the assessment. Review the job procedures, potential hazards and the PPE currently in use. Step 2: Review data: Reports of work‐related injuries or illnesses, near‐miss events and reported safety concerns are sources of data that can provide helpful information for assessing hazards. Step 3: Conduct a walk‐through survey: The purpose of the survey is to identify sources of hazards to employees. Observe the following: layout of the workplace, location of the employees, work operations, hazards and places where PPE is currently used including the device and reason for use. -

Occupational Hygiene Sampling and Exposure Limits by Rachel Pinto (Mhsc, CIH), Occupational Hygienist, University of Guelph

Occupational Hygiene Sampling and Exposure Limits For Veterinary Practices Disclaimer The following material has been prepared for the information of members of the Ontario Veterinary Medical Association as a guideline only relating to various safety issues encountered at a veterinary practice. In all cases, it is the responsibility of individual veterinarians to ensure that their practices and standards comply with all applicable federal, provincial, and municipal by-laws, regulations, and legislation. Nothing contained in this guide suggests or implies complete or proper training or certification of veterinarians or their staff as might be required by legislation. © Ontario Veterinary Medical Association 2019 1 Occupational Hygiene Sampling and Exposure Limits By Rachel Pinto (MHSc, CIH), Occupational Hygienist, University of Guelph What is occupational hygiene? Occupational hygiene, often also referred to as industrial hygiene, is an aspect of health and safety dedicated to the anticipation, recognition, evaluation and control of workplace hazards, to prevent the onset of occupational disease. Workplace hazards may be physical (e.g., noise, radiation), chemical (e.g., anesthetics, chemotherapy drugs, disinfectants, formalin), biological (e.g., zoonotic agents) or ergonomic agents (e.g., lifting patients). Anticipating and recognizing hazards involves reviewing workplace tasks, processes and equipment to identify hazards and stressors that may be present in the workplace. Evaluating workplace hazards involves assessing the degree of risk the hazard poses to the health and safety of workers and often includes taking measurements or conducting occupational hygiene sampling. Prevention and control of exposure involves eliminating hazards or substituting work processes or tasks with less hazardous options, or implementing engineered solutions (e.g., local exhaust ventilation), administrative controls (e.g., warning signs, standard operating procedures), or the use of personal protective equipment (e.g., respirators, gloves).