Preparation of Papers for AIAA Journals

Total Page:16

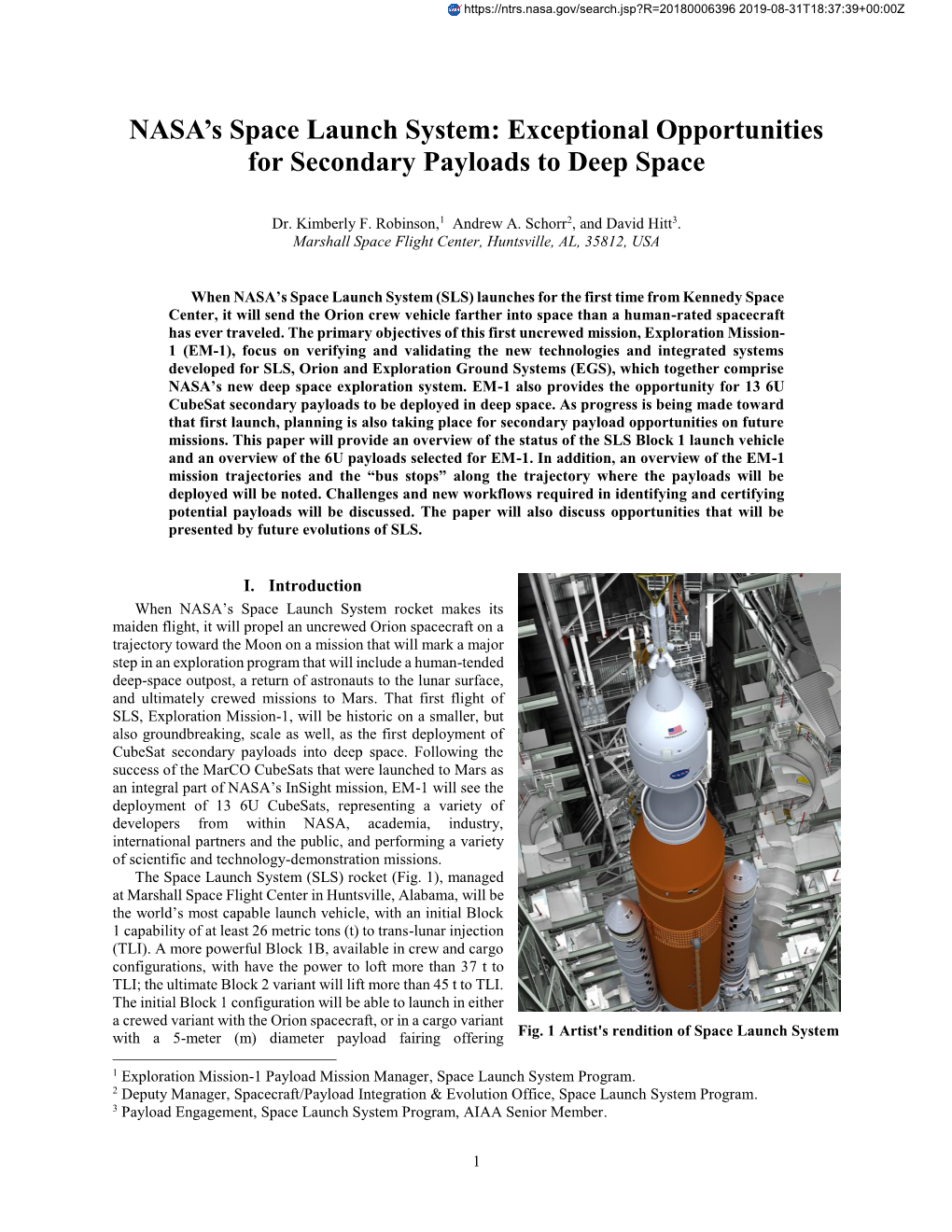

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Cubesat Mission to Study Solar Particles (Cusp) Walt Downing IEEE Life Senior Member Aerospace and Electronic Systems Society President (2020-2021)

The CubeSat Mission to Study Solar Particles (CuSP) Walt Downing IEEE Life Senior Member Aerospace and Electronic Systems Society President (2020-2021) Acknowledgements – National Aeronautics and Space Administration (NASA) and CuSP Principal Investigator, Dr. Mihir Desai, Southwest Research Institute (SwRI) Feature Articles in SYSTEMS Magazine Three-part special series on Artemis I CubeSats - April 2019 (CuSP, IceCube, ArgoMoon, EQUULEUS/OMOTENASHI, & DSN) ▸ - September 2019 (CisLunar Explorers, OMOTENASHI & Iris Transponder) - March 2020 (BioSentinnel, Near-Earth Asteroid Scout, EQUULEUS, Lunar Flashlight, Lunar Polar Hydrogen Mapper, & Δ-Differential One-Way Range) Available in the AESS Resource Center https://resourcecenter.aess.ieee.org/ ▸Free for AESS members ▸ What are CubeSats? A class of small research spacecraft Built to standard dimensions (Units or “U”) ▸ - 1U = 10 cm x 10 cm x 11 cm (Roughly “cube-shaped”) ▸ - Modular: 1U, 2U, 3U, 6U or 12U in size - Weigh less than 1.33 kg per U NASA's CubeSats are dispensed from a deployer such as a Poly-Picosatellite Orbital Deployer (P-POD) ▸NASA’s CubeSat Launch initiative (CSLI) provides opportunities for small satellite payloads to fly on rockets ▸planned for upcoming launches. These CubeSats are flown as secondary payloads on previously planned missions. https://www.nasa.gov/directorates/heo/home/CubeSats_initiative What is CuSP? NASA Science Mission Directorate sponsored Heliospheric Science Mission selected in June 2015 to be launched on Artemis I. ▸ https://www.nasa.gov/feature/goddard/2016/heliophys ics-cubesat-to-launch-on-nasa-s-sls Support space weather research by determining proton radiation levels during solar energetic particle events and identifying suprathermal properties that could help ▸ predict geomagnetic storms. -

Solar Sail Propulsion for Deep Space Exploration

Solar Sail Propulsion for Deep Space Exploration Les Johnson NASA George C. Marshall Space Flight Center NASA Image We tend to think of space as being big and empty… NASA Image Space Is NOT Empty. We can use the environments of space to our advantage NASA Image Solar Sails Derive Propulsion By Reflecting Photons Solar sails use photon “pressure” or force on thin, lightweight, reflective sheets to produce thrust. 4 NASA Image Real Solar Sails Are Not “Ideal” Billowed Quadrant Diffuse Reflection 4 Thrust Vector Components 4 Solar Sail Trajectory Control Solar Radiation Pressure allows inward or outward Spiral Original orbit Sail Force Force Sail Shrinking orbit Expanding orbit Solar Sails Experience VERY Small Forces NASA Image 8 Solar Sail Missions Flown Image courtesy of Univ. Surrey NASA Image Image courtesy of JAXA Image courtesy of The Planetary Society NanoSail-D (2010) IKAROS (2010) LightSail-1 & 2 CanX-7 (2016) InflateSail (2017) NASA JAXA (2015/2019) Canada EU/Univ. of Surrey The Planetary Society Earth Orbit Interplanetary Earth Orbit Earth Orbit Deployment Only Full Flight Earth Orbit Deployment Only Deployment Only Deployment / Flight 3U CubeSat 315 kg Smallsat 3U CubeSat 3U CubeSat 10 m2 196 m2 3U CubeSat <10 m2 10 m2 32 m2 9 Planned Solar Sail Missions NASA Image NASA Image NASA Image Near Earth Asteroid Scout Advanced Composite Solar Solar Cruiser (2025) NASA (2021) NASA Sail System (TBD) NASA Interplanetary Interplanetary Earth Orbit Full Flight Full Flight Full Flight 100 kg spacecraft 6U CubeSat 12U CubeSat 1653 m2 86 -

Cornell University

Advanced CubeSat Technologies for Affordable Deep Space Science and Exploration Missions Ground Tournaments, the Moon, and Beyond Jim Cockrell Cube Quest Challenge Administrator iCubeSat - 30 May 2017 • What is Cube Quest? – Why a Cube Quest? – Rules and Prize Structure • Today’s Status Get your CubeSat to the moon, work the best – GT4 Competitors survive the longest win big prizes! – Emerging Technologies • Next Steps – GT4 winners – In-space Competition 30 May 2017 CubeQuest Challenge - iCubeSat 2 • SmallSats/CubeSats > conventional spacecraft – easier to launch – lower in cost • Unique missions with ensembles – planetary seismographs – array of Mars weather stations – distributed, correlated measurements – redundancy at the system level; robust system of systems – nodes for antenna arrays or telescope arrays – Augments traditional probes 30 May 2017 CubeQuest Challenge - iCubeSat 3 To-date, CubeSats don’t venture beyond LEO: Limitation SoA Deep Space Missions Need Limited comm range Low-gain dipoles or patches high gain directional antennas mainly used needed Limited comm data Low power, amateur band High-power, high frequency, wide rate transmitters mainly used bandwidth transmitters needed Lacking radiation COTS, low-cost parts used; more Radiation shielding, fault detection, tolerance benign environment of LEO fault tolerance Lacking in-space Not demonstrated (except solar High thrust, high ISP needed; propulsion sails); chemical fuel/pressurized chemical, electrical, solar containers prohibited Depend on Earth- Passive magnetorquers -

Bradley County Gets

T U E S D A Y 161st YEAR • NO. 178 NOVEMBER 24, 2015 CLEVELAND, TN 16 PAGES • 50¢ Bradley County gets ‘AA’ rating by S&P By BRIAN GRAVES Davis said the rating came after “a “Standard and Poor’s rationale for the “They also expressed recognition of flexibility” with an available fund bal- Banner Staff Writer very grueling conference call” with the awarding of this ‘AA’ rating took into strong budgetary performance with an ance in fiscal 2014 of 16 percent of agencies in New York, as well as account many aspects of today’s finan- operating surplus in the general fund,” operating expenditures, a strong debt Bradley County has been assigned an Cumberland Securities financial advi- cial facts,” Davis said. “They explained he said. and contingent liability profile and an “AA” rating by Standard and Poor’s rat- sors. that even in what is considered a weak The mayor has been an avid propo- estimated 71.4 percent of debt sched- ing service. “They did reissue the ‘AA’ rating,” economy there are many aspects that nent for maintaining a good fund bal- uled to be retired in 10 years. Mayor D. Gary Davis announced the Davis said, recalling the county origi- lead to their favorable rating and out- ance and added during his Monday Standard and Poor’s also shows a rating at Monday’s Commission work nally obtained that rating a few years look.” comments, “Those things are very “stable outlook” of the county’s debt session, which contained very little ago. Davis said the assessment included a important.” and contingent liabilities that “is business for commissioners to discuss “We were at A-, then AA-, and then we finding of “strong management with Davis said the assessment showed expected to remain strong even in light during the holiday week. -

List of Private Spaceflight Companies - Wikipedia

6/18/2020 List of private spaceflight companies - Wikipedia List of private spaceflight companies This page is a list of non-governmental (privately owned) entities that currently offer—or are planning to offer—equipment and services geared towards spaceflight, both robotic and human. List of abbreviations used in this article Contents Commercial astronauts LEO: Low Earth orbit GTO: Geostationary transfer Manufacturers of space vehicles orbit Cargo transport vehicles VTOL: Vertical take-off and Crew transport vehicles landing Orbital SSTO: Single-stage-to-orbit Suborbital TSTO: Two-stage-to-orbit Launch vehicle manufacturers SSTSO: Single-stage-to-sub- Landers, rovers and orbiters orbit Research craft and tech demonstrators Propulsion manufacturers Satellite launchers Space-based economy Space manufacturing Space mining Space stations Space settlement Spacecraft component developers and manufacturers Spaceliner companies See also References External links Commercial astronauts Association of Spaceflight Professionals[1][2] — Astronaut training, applied research and development, payload testing and integration, mission planning and operations support (Christopher Altman, Soyeon Yi)[1][3] Manufacturers of space vehicles Cargo transport vehicles Dry Launch Return Company Launch Length Payload Diameter Generated Automated Spacecraft mass mass Payload (kg) payload S name system (m) volume (m3) (m) power (W) docking (kg) (kg) (kg) 10.0 (pressurized), 3,310 plus 14 2,500 Falcon 9 pressurized or (unpressurized), Dragon 6.1 4,200[4] 10,200 capsule -

Space Launch System Program March 1, 2018

https://ntrs.nasa.gov/search.jsp?R=20180003498 2019-08-31T15:55:45+00:00Z National Aeronautics and Space Administration 5 . 4 . 3 .SPACE . 2 . 1 . LAUNCH SYSTEM CubeSats - To The Moon & Beyond Scott Spearing CubeSat Subject Matter Expert Space Launch System Program March 1, 2018 www.nasa.gov/sls www.nasa.gov/sls SLS BLOCK 1 EXPLORATION MISSION-1 (EM-1) Forward Ring Launch Abort System Secondary Payloads Electrical Panels Cabling Orion Avionics Box (2 places) Interim Cryogenic Propulsion Stage Launch Vehicle Stage Adapter OSA Diaphragm Core Stage Secondary Payload Brackets (13) Boosters Isogrid Barrel Panels Access Cover Aft Ring (2 places) Orion Stage Adapter (OSA) www.nasa.gov/sls 0418 EM-1 OSA SECONDARY PAYLOAD ACCOMMODATIONS Secondary Payload Avionics Box Cabling 6U CubeSat Payload 6U CubeSat Secondary Payload Dispenser Brackets (13) (PSC) Secondary Payload Mounting Bracket LEGEND: SLS Provided PD Provided www.nasa.gov/sls 0418 EM-1 SYSTEM DESCRIPTION AND PURPOSE Expand and fully utilize the SLS capabilities for exploration purposes without causing harm or inconvenience to SLS or its primary payload. • Thirteen (max capability 17) 6U payload locations • 6U volume/mass is the current standard OSA (14 kg payload mass) Diaphragm • Payloads will be “powered off” from turnover through Orion separation and ~Ø156” (13’) payload deployment • Payload Deployment System Avionics Unit; payload deployment will begin with pre-loaded OSA ~21° sequence following Orion separation and ~22° ICPS disposal burn • Payload requirements captured in Interface -

Smallsats Supporting Deep Space Human Exploration

National Aeronautics and Space Administration SmallSats supporting Deep Space Human Exploration August 06, 2018 Andres Martinez, Program Executive, Advanced Exploration Systems, HEOMD, NASA HQ Background about me… 2 National Advisory Committee for Aeronautics 3 National Aeronautics and Space Administration 4 NASA 5 Small Spacecraft Technology Program 6 NASA’S DEEP SPACE EXPLORATION SYSTEM The Orion spacecraft and Space Launch System rocket, launching from a modernized Kennedy spaceport is foundational to extending human presence deeper into the solar system. 7 EM-1 Secondary Payloads 13 CUBESATS SELECTED TO FLY ON EM-1 INTERIM • Lunar Flashlight CRYOGENIC • Near Earth Asteroid Scout PROPULSION STAGE • Bio Sentinel • LunaH-MAP • CuSP • Lunar IceCube • LunIR • EQUULEUS (JAXA) • OMOTENASHI (JAXA) • ArgoMoon (ESA) • STMD Centennial Challenge Winners: CU-E3, CisLunar Explorers, & Team Miles HEOMD/AES Deep Space SmallSats: SLS EM-1 Secondary Payloads Lunar IceCube Lunar Flashlight NEA Scout LunIR AES SmallSat Missions selected to contribute to key Human Exploration Strategic Knowledge Gaps and to Advance Key Technologies BioSentinel 10 HEOMD/AES Deep Space SmallSats: Deep Space Station 17 (DSS-17) LRO Demonstrations: • Routinely Tracking LRO at S-band • Intermediate Frequency (IF) Systems and DSN Downlink Equipment (DCD, MarCO Demonstrations: DTT) Verified • Downlink Using X-Band Feed and DSN Equipment • LRO Telemetry Blocks Sent Directly • Downlink Using X-Band Feed and MarCO Receiver System Expands DSN capabilities by utilizing from DSS-17 to JPL DSOC over the • OMSPA Using X-Band Feed and Custom SDR-based NASA Mission Backbone- verifying Multiple Receiver System non-NASA assets to provide DSS-17 Signal Path communication and navigation services FirstFirst OMSPA OMSPA Demonstration Demonstration to small spacecraft missions to the withwith a a CubeSat CubeSat Moon and inner solar system. -

National Center for Atmospheric Research 2018 Annual Report

2018 NCAR Annual Report National Center for Atmospheric Research 2018 Annual Report 2018 NCAR ANNUAL REPORT TABLE OF CONTENTS 2018 NCAR Annual Report A Message from the Interim NCAR Director New Approach to Geoengineering Simulations is Significant Step Forward North American storm Clusters Could Produce 80 Percent More Rain US Gains in Air Quality are Slowing Down Scientists Fly into the Heart of Smoke Plume The Climate Secrets of Southern Clouds New Model Reveals Origins of the Sun's Seasons NCAR-Based Climate Model Gets a Significant Upgrade The Entire Atmosphere in a Single Model Groundbreaking Data Set Gives Unprecedented Look at Future Weather New Climate Forecasts for Watershed - and the Water Sector NCAR 2018 Metrics & Publications A MESSAGE FROM THE INTERIM NCAR DIRECTOR The National Center for Atmospheric Research (NCAR) is one of the world’s premier scientific institutions. With a strong focus on the atmospheric and related sciences we have an internationally recognized staff and research program dedicated to advancing knowledge, providing community- based resources, and building human capacity. In this Annual Report, and in the accompanying Laboratory Reports, I invite you to learn more about NCAR, see how we are collaborating internally and with the worldwide research community to drive advances in our understanding of fundamental processes in our atmosphere and how the atmosphere interacts with, and is influenced by, other components of the Sun-Earth system. This progress is being driven, in part, by new technologies and their effective utilization at NCAR, including: advanced observing facilities for field studies and the Sun, powerful high-performance computing capabilities, valuable research data sets that describe the state of the Sun- Earth system, and widely used state-of-the-science community models that are providing improved capabilities for predictions of weather (including catastrophic events), air quality, hydrology, climate variability and change, and space weather. -

From Ground Tournaments to Lunar and Deep Space Derby

NASA’s CubeQuest Challenge – From Ground Tournaments to Lunar and Deep Space Derby Liz Hyde1 Millennium Engineering and Integration, Moffett Field, CA, 94035 and Jim Cockrell2 NASA Ames Research Center, Moffett Field, CA, 94035 The First Flight of NASA’s Space Launch System will feature 13 CubeSats that will launch into cis-lunar space. Three of these CubeSats are winners of the CubeQuest Challenge, part of NASA’s Space Technology Mission Directorate (STMD) Centennial Challenge Program. In order to qualify for launch on EM-1, the winning teams needed to win a series of Ground Tournaments, periodically held since 2015. The final Ground Tournament, GT-4, was held in May 2017, and resulted in the Top 3 selection for the EM-1 launch opportunity. The Challenge now proceeds to the in-space Derbies, where teams must build and test their spacecraft before launch on EM-1. Once in space, they will compete for a variety of Communications and Propulsion-based challenges. This is the first Centennial Challenge to compete in space and is a springboard for future in-space Challenges. In addition, the technologies gained from this challenge will also propel development of deep space CubeSats. Nomenclature ARC = Ames Research Center BCT = Blue Canyon Technologies CDR = Critical Design Review ConOps = Concept of Operations COTS = Commercial Off-The-Shelf CU-E3 = University of Colorado Earth Escape Explorer DSN = Deep Space Network EDU = Engineering Development Unit EM-1 = Exploration Mission 1 GRC = Glenn Research Center GT = Ground Tournament Isp = Specific Impulse LEO = Low-Earth Orbit MCR = Mission Concept Review mN = milinewtons MSFC = Marshall Space Flight Center PDR = Preliminary Design Review RACP = Resilient Affordable CubeSat Processor SAR = System Acceptance Review SDR = Software Defined Radio SLS = Space Launch System SRR = System Requirements Review 1 Mechanical Engineer, MEI, MS 213-6, Moffett Field, CA, AIAA Member. -

A 6U Cubesat for Lunar Orbit and Beyond

A 6U CubeSat for Lunar Orbit and Beyond Presenter: Kathleen Morse, Ph.D. Founder of Yosemite Space, LLC and Member of Team Miles, [email protected] Team Miles POC: Wes Faler, Owner of Fluid & Reason, LLC and Team Lead for Miles, [email protected] Miles Mission and NASA Cube Quest • NASA Cube Quest is a Centennial Challenge to build flight-qualified, 6U satellites capable of advanced communication and propulsion near and beyond the moon • Miles to compete in Lunar Derby • Team Miles accomplishments to date: • Won first position in ground tournament 1 • Finished in top 5 in ground tournament 2 • Miles qualifies as 1 of 6 teams eligible for EM1 launch • EM1 launch scheduled for 2018 13th Annual CubeSat Developer's Workshop Summary of Miles Mission Time Action 0s Deployment from SLS >30s CDH on, internal checks 10 to 30 min. Deploy solar panels, RF transmission remaining subsystems on >40 min. Attitude Stabilization >1Hr.40min. Calculate and execute trans-lunar to 8 days insertion plan Mission autonomy enabled by: • Customs mission s/w 60 days Lunar Derby, NASA DSN confirms orbit • Open source trajectory prediction s/w > 60 days to Calculate and execute storage orbit • RACP performance and reliability 75 days (Earth- Mars orbit) >75 days Execute kill sequence and powers down. 13th Annual CubeSat Developer's Workshop Summary of Miles Bus 14 ConstantQ 4 Sun Sensors Thrusters: SSBV Iodine Plasma 10 Solar Panels propulsion Clyde Space Miles Spacecraft Specs > 1.1mN/W 0.5U for 4 thrusters 3 EPS Boards Size 6U GOM Space Fluid & Reason, -

Nasa's Space Launch System: Deep

https://ntrs.nasa.gov/search.jsp?R=20180005407 2020-02-21T02:27:56+00:00Z NASA’S SPACE LAUNCH SYSTEM: DEEP-SPACE OPPORTUNITIES FOR SMALLSATS 4S Symposium Kimberly Robinson, Ph.D. Payloads Manager Carole McLemore, Ph.D. Secondary Payloads Integration Manager Space Launch System Program May 29, 2018 0496 0496 NASA’S EXPLORATION PLANS 0496 SLS – ENABLING HUMAN EXPLORATION EXPLORATION CLASS: DEEP SPACE CAPABILITIES • Five times more volume than any contemporary heavy lift vehicle VOLUME Orion 8m fairing • Only vehicle that can carry the Orion and a co- with with large manifested payload to the Moon Science aperture Missions telescope • Block 1: Can launch 60% more mass than any contemporary launch vehicle MASS • Block 2: Mars-enabling capability of greater than Contemporary SLS Block 1 SLS Block 2 Heavy Lift Exploration Exploration 45 metric tons to Trans Lunar Injection Class Class • Reduce transit times by half or greater to the outer DEPARTURE solar system ENERGY 0496 SLS BLOCK 1 CONFIGURATION FOR EM-1 Launch Abort System (LAS) Crew Module (CM) Service Module (SM) Encapsulated Service Module (ESM) Panels Spacecraft Adapter Orion Stage Adapter Orion Spacecraft Lockheed Martin 5 Segment Solid Rocket Boosters (2) Orbital ATK Interim Cryogenic Propulsion Stage (ICPS) Boeing/United Launch Alliance Launch Vehicle Stage Adapter Teledyne Brown Engineering Core Stage & Avionics Boeing RS-25 Engines (4) Aerojet Rocketdyne 0496 SOLID ROCKET BOOSTERS 0496 ENGINES 0496 CORE STAGE 0496 IN-SPACE STAGE AND ADAPTERS 0496 EXPLORATION MISSION-1 FULL SYSTEMS -

Nasa's Space Launch System: Deep-Space Opportunities

https://ntrs.nasa.gov/search.jsp?R=20180005407 2019-08-31T14:51:15+00:00Z NASA’S SPACE LAUNCH SYSTEM: DEEP-SPACE OPPORTUNITIES FOR SMALLSATS 4S Symposium Kimberly Robinson, Ph.D. Payloads Manager Carole McLemore, Ph.D. Secondary Payloads Integration Manager Space Launch System Program May 29, 2018 0496 0496 NASA’S EXPLORATION PLANS 0496 SLS – ENABLING HUMAN EXPLORATION EXPLORATION CLASS: DEEP SPACE CAPABILITIES • Five times more volume than any contemporary heavy lift vehicle VOLUME Orion 8m fairing • Only vehicle that can carry the Orion and a co- with with large manifested payload to the Moon Science aperture Missions telescope • Block 1: Can launch 60% more mass than any contemporary launch vehicle MASS • Block 2: Mars-enabling capability of greater than Contemporary SLS Block 1 SLS Block 2 Heavy Lift Exploration Exploration 45 metric tons to Trans Lunar Injection Class Class • Reduce transit times by half or greater to the outer DEPARTURE solar system ENERGY 0496 SLS BLOCK 1 CONFIGURATION FOR EM-1 Launch Abort System (LAS) Crew Module (CM) Service Module (SM) Encapsulated Service Module (ESM) Panels Spacecraft Adapter Orion Stage Adapter Orion Spacecraft Lockheed Martin 5 Segment Solid Rocket Boosters (2) Orbital ATK Interim Cryogenic Propulsion Stage (ICPS) Boeing/United Launch Alliance Launch Vehicle Stage Adapter Teledyne Brown Engineering Core Stage & Avionics Boeing RS-25 Engines (4) Aerojet Rocketdyne 0496 SOLID ROCKET BOOSTERS 0496 ENGINES 0496 CORE STAGE 0496 IN-SPACE STAGE AND ADAPTERS 0496 EXPLORATION MISSION-1 FULL SYSTEMS