The 156-Tonne

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

PDF Version June/July 2016

IDWEST FLYER M AGAZINE JUNE/JULY 2016 Published For & By The Midwest Aviation Community Since 1978 midwestflyer.com Finding a fi x for TFRs Just about anyone who has planned a fl ight in or near a major metro area has had to worry about temporary fl ight restrictions (TFRs) at one time or another. Scrolling through dozens, even hundreds, of NOTAMs to identify TFRs that are relevant to your fl ight can be daunting. The sheer number can make it easy to miss something. But when you have access to good graphics, you can instantly see if a TFR will a ect your fl ight. Unfortunately, graphics aren’t available for every TFR. And when graphics are unavailable or are inaccurate, the number of violations goes way up. That’s why AOPA will be helping to lead an e ort to improve TFR graphics, from how the information is delivered to how it is depicted. Back in 2015, we started asking questions about the scope and extent of problems we were seeing with TFRs that either had no graphics or, maybe worse, showed incorrect graphics. After uncovering recurring issues, we asked the FAA to provide an authoritative online source of TFR information, provide TFR information in a consistent format so that automated systems used by third-party vendors can translate it into accurate graphics, and work to make the text of TFR NOTAMs more user friendly for pilots. This April, the FAA responded by formally tasking the RTCA Tactical Operations Committee to address the issues we raised and report back with recommendations within six months. -

Aviation Maintenance Alerts

ADVISORY CIRCULAR 43-16A AVIATION MAINTENANCE ALERTS ALERT JULY NUMBER 2006 336 CONTENTS AIRPLANES BEECH ........................................................................................................................................1 CESSNA ......................................................................................................................................3 ENGINES LYCOMING................................................................................................................................3 CONTINENTAL .........................................................................................................................4 PRATT & WHITNEY .................................................................................................................4 ROLLS ROYCE ..........................................................................................................................6 PROPELLERS MC CAULEY ..............................................................................................................................8 ACCESSORIES ELECT. WIRE.............................................................................................................................9 ELECTROSYSTEMS................................................................................................................10 KELLY AEROSPACE ..............................................................................................................10 LAMAR TECHNOLOGY.........................................................................................................11 -

The Last Word in Airfields a Special History Study Ofcrissy Field Presidio Ofsan Francisco, California

The Last Word in Airfields A Special History Study ofCrissy Field Presidio ofSan Francisco, California by Stephen A. Haller Park Historian Golden Gate National Recreation Area San Francisco National Park Service 1994 Table ofContents Management Summary ................................III Site History .......................................... 1 Project Background .................................... .IV Chapter 1: In the beginning .............................. 1 Historical Context . .................................... .IV Chapter 2: An Airfield is Established, 1919-1922 ............. 11 Site History Summary ...................................V Chapter 3: Early Operations, 1922-1924 ...................29 Study Boundaries ..................................... .IX Chapter 4: Of Races and Runways, 1924-1934. ............. 51 Methodology and Scope . ..................................X Chapter 5: Winding Down, 1935-1940 ....................79 Administrative Context. .................................x Chapter 6: War and Post-War, 1941-1993 ...................S9 Summary ofFindings ....................................X Significance and Integrity Assessment .................. 103 Recommendations .................................... 10S Acknowledgements ................................... 112 Bibliography ........................................ 114 Appendices A Commanding Officers, Crissy Field ...................... 116 B Types of Aircraft at Crissy Field ......................... IIS C Roster of Fourth Army Intelligence School. ............... -

Flight Safety Magazine Jul-Aug 2003

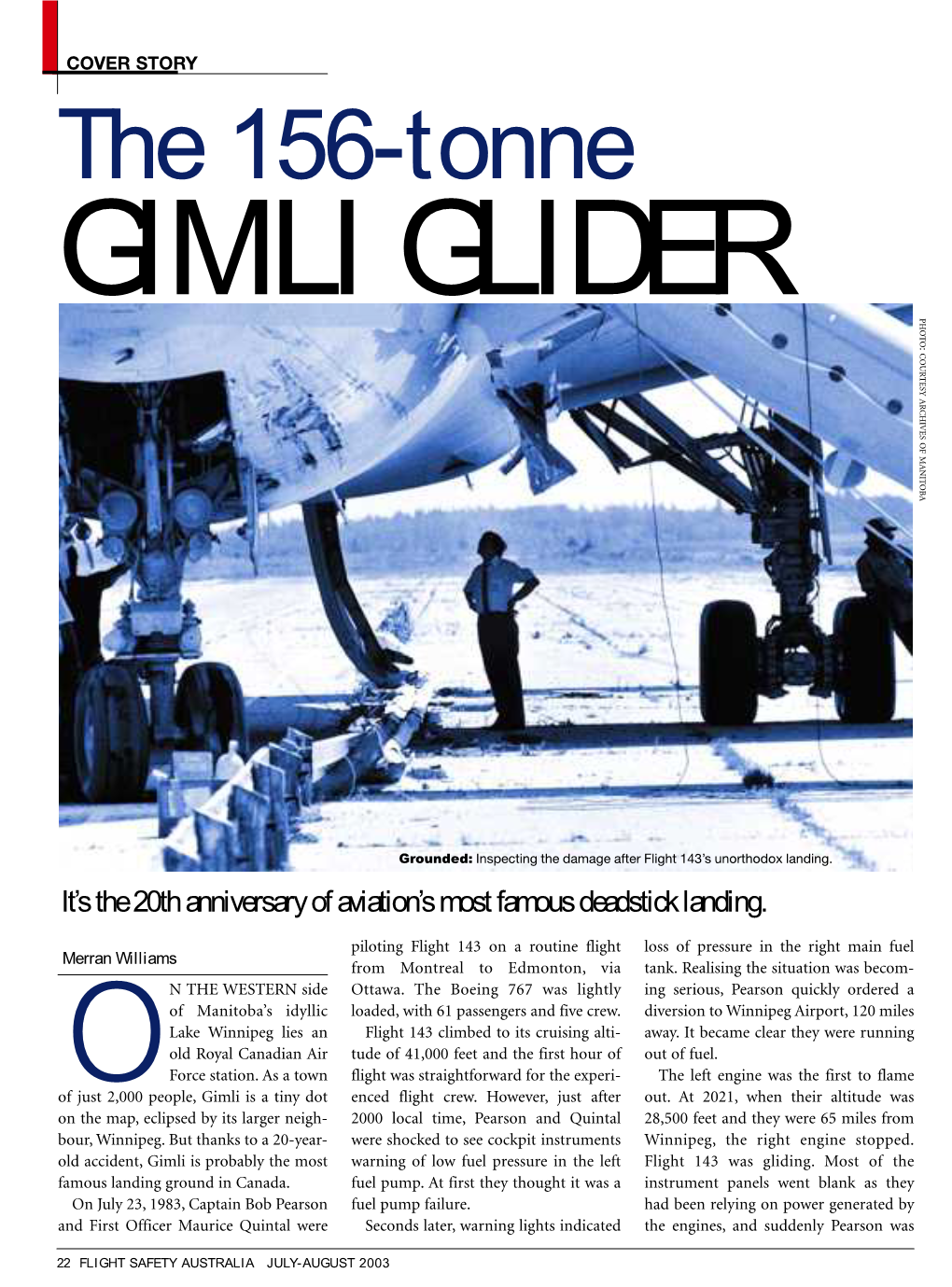

COVER STORY The 156-tonne GIMLI GLIDER PHOTO : COURTESY ARCHIVES OF MANITOBA Grounded: Inspecting the damage after Flight 143’s unorthodox landing. It’s the 20th anniversary of aviation’s most famous deadstick landing. piloting Flight 143 on a routine flight loss of pressure in the right main fuel Merran Williams from Montreal to Edmonton, via tank. Realising the situation was becom- N THE WESTERN side Ottawa. The Boeing 767 was lightly ing serious, Pearson quickly ordered a of Manitoba’s idyllic loaded, with 61 passengers and five crew. diversion to Winnipeg Airport, 120 miles Lake Winnipeg lies an Flight 143 climbed to its cruising alti- away. It became clear they were running old Royal Canadian Air tude of 41,000 feet and the first hour of out of fuel. Force station. As a town flight was straightforward for the experi- The left engine was the first to flame ofO just 2,000 people, Gimli is a tiny dot enced flight crew. However, just after out. At 2021, when their altitude was on the map, eclipsed by its larger neigh- 2000 local time, Pearson and Quintal 28,500 feet and they were 65 miles from bour, Winnipeg. But thanks to a 20-year- were shocked to see cockpit instruments Winnipeg, the right engine stopped. old accident, Gimli is probably the most warning of low fuel pressure in the left Flight 143 was gliding. Most of the famous landing ground in Canada. fuel pump. At first they thought it was a instrument panels went blank as they On July 23, 1983, Captain Bob Pearson fuel pump failure. -

Some Special Aircraft

Journal of Aircraft and Spacecraft Technology Review Some Special Aircraft 1Relly Victoria Petrescu, 2Raffaella Aversa, 3Bilal Akash, 4Juan Corchado, 2Antonio Apicella and 1Florian Ion Tiberiu Petrescu 1ARoTMM-IFToMM, Bucharest Polytechnic University, Bucharest, (CE), Romania 2Advanced Material Lab, Department of Architecture and Industrial Design, Second University of Naples, 81031 Aversa (CE), Italy 3Dean of School of Graduate Studies and Research, American University of Ras Al Khaimah, UAE 4University of Salamanca, Spain Article history Abstract: In this study, the authors want to present a few more distinct Received: 10-07-2017 aircraft from a constructive and functional point of view. Their role has Revised: 10-08-2017 often been determined by the need to achieve or fulfill certain more or less Accepted: 18-08-2017 strategic objectives. Such ships will also be built in the future more and more often in order to be able to respond to all new flight requirements and Corresponding Author: to meet, under optimal conditions, the new and increasingly demanding Florian Ion Tiberiu Petrescu ARoTMM-IFToMM, Bucharest requirements. Many of the new special aircraft have been built so far to Polytechnic University, achieve special tasks, or at the request of the defense ministry in some Bucharest, (CE), Romania highly developed countries, even with the United States of America. The E-mail: [email protected] PA-23 was the first twin-engine design from Piper and was developed from a proposed "Twin Stinson" design inherited when Piper bought the Stinson Division of the Consolidated Vultee Aircraft Corporation. The prototype PA-23 was a four-seater low-wing all-metal monoplane with a twin tail, powered by a two 125 hp Lycoming O-290-D piston engines the prototype first flew 2 March 1952. -

Aerosafety World March 2012

AeroSafety WORLD MAINTENANCE FATIGUE Awareness training needed MANAGING ANOMALIES Cockpit cooperation essential VISUALIZING SAFETY Turning data into pictures DISORIENTATION, POOR CRM TOXIC CAPTAINS Cockpit unhappy, unsafe SPIRAL DIVE THE JOURNAL OF FLIGHT SAFETY FOUNDATION MARCH 2012 ESEXECUTIVE’SXMEECUTIVE’ MESSAGESSAGE Value Proposition n the last issue, I wrote about some of the high Look for the new membership structure to be points of what we are doing at Flight Safety unveiled about October, and please think about Foundation. This month, I am going to go a your budget in order to join for 2013. You are go- little deeper into our operations and how we ing to hear me say this many times: If you have to Iare able to function. First off, the support of our choose one safety resource to keep you in touch members is very valuable, and if you are one, we with what is taking place in the industry, Flight thank you! If you aren’t, then you should be. The Safety Foundation is the one. largest amount of our operating budget comes The other area that I would like to draw your from members’ support. The technical projects, attention to is our outreach activities. Outreach research, advocacy, safety communication and keeps our members and the aviation/aerospace shaping of safety culture and policy come from the industry informed on current hot topics such as support you provide through your membership. lessons learned from an incident or accident, and As a matter of fact, 47 percent of the Founda- on the long-range issues that need our attention. -

Developing the U-2

C00190094 Approved for Release: 2013/06/25 Chapter 2 39 Developing the U-2 THE ESTABliSHMENT OF THE U-2 PROJECT On 26 November 1954, the day after Thanksgiving, Allen Dulles called his special assistant, Richard Bissell, into his offiae to tell him that President Eisenhower had just approved a very secret program and that Dulles wanted Bissell to take charge of it. Saying it was too ?ecret for him to explain, Dulles gave Bissell a packet of documents and told him he could keep it for several days to acquaint himself with the project. Bissell had long known of the proposal to build a high-altitude reconnaissance aircraft, but only in the most general terms. Now he learned in detail about the project that proposed send- aircraft over the Soviet Union. Late on the morning of 2 December 1954, Dulles told Bissell to go to the Pentagon on the following day to represent the Agency at an organizational meeting the 1 project. Before leaving, Bissell asked Dulles which was to run the project The DCI replied that had been then asked who was the "That wasn't even July C00190094 Approved for Release: 2013/06/25 sat down with a group of key Air Force officials that included Trevor Gardner and Lt. Gen. Donald L. Putt. The participants spent very lit tle time delineating Air Force and Agency re sponsibilities in the pro ject, taking for granted that the ClA would handle the security matters. Much of the discussion centered on methods for diverting Air Force materiel to the program, particularly the Pratt & Whitney 157 engines, because a separate contract for the engines might jeop ardize the project's security. -

HEIGHT VELOCITY CURVE for GYROPLANES - by Greg Gremminger

HEIGHT VELOCITY CURVE for GYROPLANES - By Greg Gremminger This article is an update to the original article on the H/V curves also apply to gyroplanes – they have “Deadman’s subject we had published in Rotorcraft several years ago. The Zones” also! All rotorcraft require a sufficient amount of rotor subject is an important safety issue for gyroplane fliers to RPM and airspeed to be able to raise the nose and make a safe understand and respect. Recent events suggest reasons to review “deadstick” landing. If the engine is not available to provide some this subject again. But, importantly also, this article is to point out of this landing energy, the rotorcraft – including gyroplane – has additional significant and possibly inadequately understood only its potential energies of height and velocity to use up for the “aggravating conditions” within the Height Velocity (H/V) curve required energy for a safe landing. Height is a form of energy – that gyro pilots should understand and appreciate. “potential” energy because you can convert height above the “Deadman’s Zone!” - is an ominously descriptive term ground into landing energy of rotor RPM and airspeed. Airspeed for the Height Velocity curve for rotorcraft. Helicopter pilots are is also a form of potential energy, and if there isn’t enough airspeed drilled on this issue and the limitations it presents for helicopter for a safe landing, the pilot needs to increase airspeed by trading operations. Most people think that helicopters can go straight up some height for additional velocity, or applying engine power. from the ground and straight down to a landing. -

Aeronautical Decision Making: Experience, Training and Behaviour

Aeronautical decision making: Experience, training and behaviour Richard Batt A thesis submitted for the degree of Doctor of Philosophy at the University of Otago, Dunedin, New Zealand. 1 November 2005 Richard Batt 6 Bishop Place, Melba ACT 2615, Australia. [email protected] [email protected] [email protected] to Lincoln i Abstract Decision making is fundamental to all aspects of flying operations. The results that flow from poor aeronautical decision making can be both swift and devastating. The work of this thesis uses data from a variety of sources to investigate the following aspects of aeronautical decision making; • accident and incident case histories and pilot decision making • case-based versus rule-based pilot decision training • pilot behaviours in the face of adverse weather The first part of thesis uses survey data to gain a better understanding of the role of accident and incident case histories in aviation safety and training. Anecdotal evidence suggests that exposure to case-based information can leave a lasting impression on a pilot and significantly influence their flying behaviour. To investigate this aspect more formally, information was obtained from a survey of 138 pilots. A questionnaire was then distributed to pilots worldwide and responses were received from 409 pilots, from all areas of aviation. The combined experience of pilots who responded was over 700,000 hours flying time. The second part of the thesis uses experimental data to compare the effectiveness of aviation safety training using case-based material or rule- based material. Two experiments were carried out, based on the two areas that account for the majority of fatal general aviation accidents: flight into adverse weather and low flying. -

The Last Word in Airfields: a Special History Study of Crissy Field, Presidio of San Francisco

The Last Word in Airfields A Special History Study ofCri ssy Field Presidio ofSan Francisco, California The Last Word in Airfields A Special History Study ofCrissy Field Presidio ofSan Francisco, California by Stephen A. Haller Park Historian Golden Gate National Recreation Area San Francisco National Park Service 1994 Table ofContents Management Summary ................................III Site History .......................................... 1 Project Background .................................... .IV Chapter 1: In the beginning .............................. 1 Historical Context ..................................... .IV Chapter 2: An Airfield is Established, 1919-1922 ............. 11 Site History Summary ...................................V Chapter 3: Early Operations, 1922-1924 ...................29 Study Boundaries ..................................... .IX Chapter 4: Of Races and Runways, 1924-1934............... 51 Methodology and Scope ...................................X Chapter 5: Winding Down, 1935-1940 ....................79 Administrative Context. ................................ .X Chapter 6: War and Post-War, 1941-1993 ...................89 Summary ofFindings ................................... .X Significance and Integrity Assessment .................. 103 Recommendations .................................... 108 Acknowledgements ................................... 112 Bibliography ........................................ 114 Appendices A Commanding Officers, Crissy Field ...................... 116 B Types of Aircraft -

VAM Club Rules Revision a 07112015

VOLUNTEER AEROMODELERS VOLUNTEER AMA Charter # 1572 AEROMODELERS Club Organization and Rules Established and Adopted: July 11, 2015 CLUB ORGANIZATION AND RULES VOLUNTEER AMA Charter No. 1572 R/C Model Aircraft AEROMODELERS Adopted July 11, 2015 Club of Knoxville, TN Revision Level A VOLUNTEER Table of Contents AEROMODELERS Membership ...................................................................................................................... 3 Meetings .......................................................................................................................... 3 Club Grounds .................................................................................................................... 3 Safety .............................................................................................................................. 3 Club Safety Rules ........................................................................................................... 3 Frequency Control .......................................................................................................... 5 Pilot Proficiency ............................................................................................................. 5 Aircraft Flight Worthiness ................................................................................................ 6 APPENDIX ........................................................................................................................ 8 AMA Introductory Pilot Program ...................................................................................... -

Taxiway Takeoff Pilots Were Distracted by a ‘Sudden Surge in Cockpit Workload’ During Line-Up

ONRECORD Taxiway Takeoff Pilots were distracted by a ‘sudden surge in cockpit workload’ during line-up. BY MARK LACAGNINA The following information provides an aware- responsibility for taxiing solely to pilots-in- ness of problems that might be avoided in the command and “did not provide a sufficiently future. The information is based on final reports robust process for the verification of the de- by official investigative authorities on aircraft parture runway before commencement of the accidents and incidents. takeoff roll.” The passenger terminal is on the east JETS side of the Hong Kong airport and between parallel east-west runways, both 3,800 m Controller Called for Abort (12,467 ft) long and 60 m (197 ft) wide. Airbus A340-300. No damage. No injuries. The south runway was closed for scheduled he flight crew had been instructed by air traf- maintenance, and the A340 flight crew was fic control (ATC) to expedite their departure told to taxi to Runway 07L for their departure Tand were completing a variety of tasks when to Helsinki, Finland. Visual meteorological they inadvertently turned onto a parallel taxiway conditions (VMC) prevailed, with 10 km (6 and began a rolling takeoff. The A340 was ac- mi) visibility. The report did not specify the celerating through 75 kt when the air movements number of people aboard the A340. controller told the crew to stop. The pilots re- The aircraft was about 1,400 m (4,593 ft) jected the takeoff and, after waiting for the brakes from the end of the outer parallel taxiway, to cool, departed without further incident.