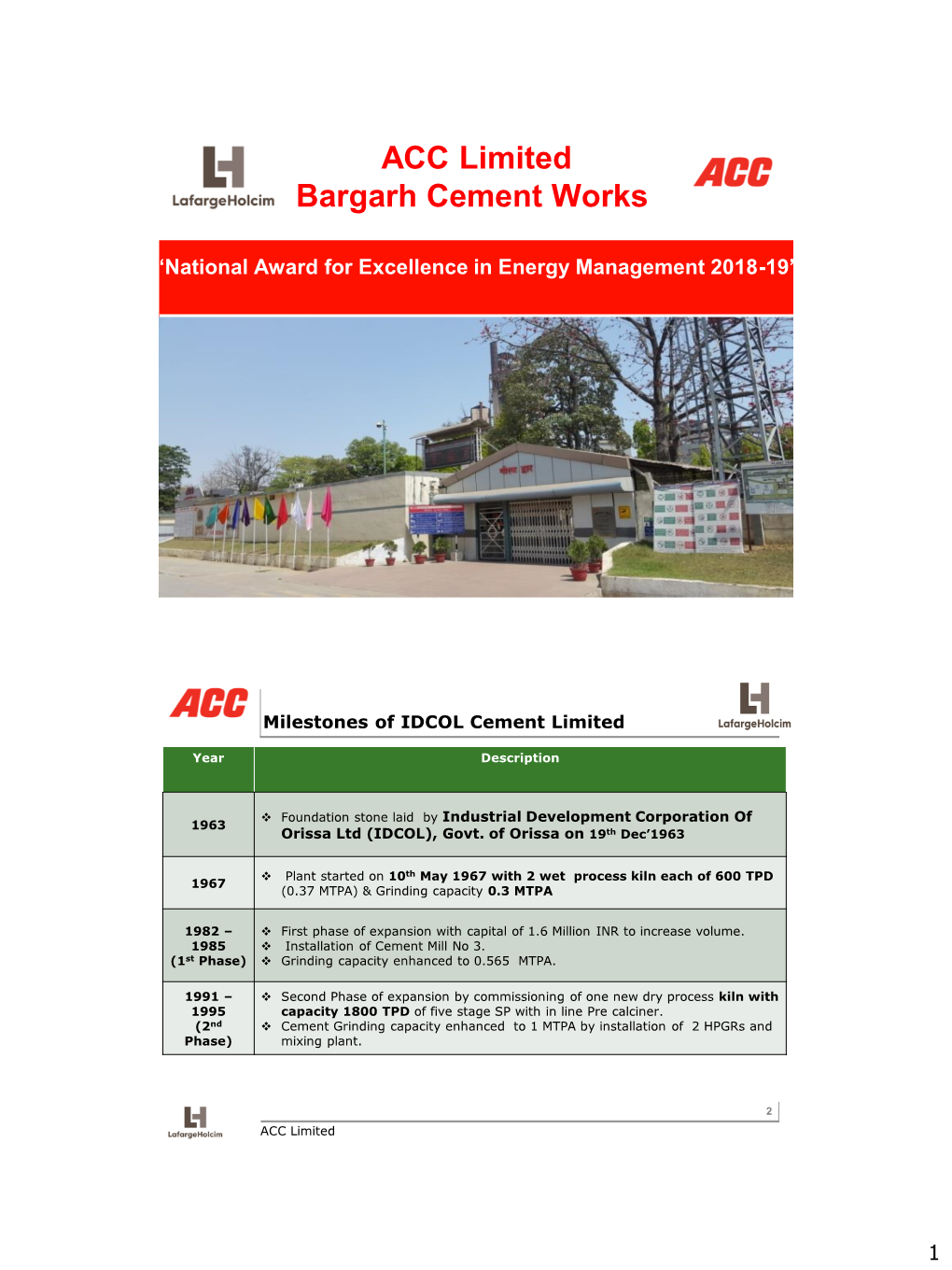

ACC Limited, Bargarh Cement Works

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Pre - Feasibility Report

BHAVYA CEMENTS LIMITED TANGEDA VILLAGE, DACHEPALLY MANDAL, GUNTUR DISTRICT, ANDHRA PRADESH Pre - Feasibility Report Submitted by: Bhavya Cements Ltd., IInd Bhavyas Spoorthi Bhavan, Plot No. A1, Film Nagar, Jubilee Hills, Hyderabad – 500 003. Phone: 040-23558384 Fax: 040-23558393. Email: - [email protected] Submitted to MINISTRY OF ENVIRONMENT, FOREST AND CLIMATE CHANGE GOVERNMENT OF INDIA INDIRA PARYAVARAN BHAWAN, JOR BAGH ROAD, ALIGANJ, NEW DELHI Pre-Feasibility Report Bhavya Cements Limited, Pre – Feasibility Report Bhavya Cements Limited, Tangeda Village, Dachepalli Mandal, Guntur District, Andhra Pradesh. 1 Executive Summary M/s. Bhavya Cements Ltd obtained Environmental Clearance for integrated Cement Plant of 4.0 Million TPA (Phase I : 4200 TPD and Phase II: 7700 TPD) Capacity, 15 MW captive power plant and Captive mining of Limestone at Thangeda Village, Dachepalle Mandal, Guntur Dist, Andhra Pradesh from Ministry of Environment, Forest and Climate Change (MoEFCC) vide letter no. F. No. J- 11011/1186/2007-IA II (I), dt. 22.09.2008, and secured extension of EC validity by letter dt.03.03.2016. The existing project for 3000 TPD of Clinker production and 4200 TPD of cement production is in operation. The consent to operate was obtained from AP Pollution Control Board vide letter no. APPCB/VJA/GTR/205/HO/CFO/2018, dt. 06.06.2018 valid till 31.08.2023. It is now proposed to modernize the Phase I project to enhance clinker manufacturing capacity by 1200 TPD to achieve 4200 TPD, and cement manufacturing capacity by 1680 TPD to achieve a total capacity of 5880 TPD. The modernization mainly entails increasing operational hours of limestone crusher, raw mill coal mill, and enhancing capacity of Cooler ESP transformer field and modernization of kiln. -

Facility DEC ID: 4192600001 PERMIT Under the Environmental

Facility DEC ID: 4192600001 PERMIT Under the Environmental Conservation Law (ECL) IDENTIFICATION INFORMATION Permit Type: Air Title V Facility Permit ID: 4-1926-00001/00110 Mod 0 Effective Date: 10/18/2001 Expiration Date: 10/18/2006 Mod 1 Effective Date: 10/03/2003 Expiration Date: 10/18/2006 Permit Issued To: GLENS FALLS LEHIGH CEMENT CO INC 313 WARREN ST PO BOX 440 GLENS FALLS, NY 12801-0440 Contact: RICHARD MOSS GLENS FALLS LEHIGH CEMENT CO INC 313 WARREN STREET PO BOX 440 GLENS FALLS, NY 12801-0440 Facility: GLENS FALLS LEHIGH CEMENT COMPANY 120 ALPHA ROAD, OFF ROUTE 9W CEMENTON, NY 12415 Description: By acceptance of this permit, the permittee agrees that the permit is contingent upon strict compliance with the ECL, all applicable regulations, the General Conditions specified and any Special Conditions included as part of this permit. Permit Administrator: STEVE G SCHASSLER 1150 NORTH WESTCOTT RD SCHENECTADY, NY 12306-2014 Authorized Signature: _________________________________ Date: ___ / ___ / _____ Mod 1/FINAL Facility DEC ID: 4192600001 Notification of Other State Permittee Obligations Item A: Permittee Accepts Legal Responsibility and Agrees to Indemnification The permittee expressly agrees to indemnify and hold harmless the Department of Environmental Conservation of the State of New York, its representatives, employees, and agents ("DEC") for all claims, suits, actions, and damages, to the extent attributable to the permittee's acts or omissions in connection with the permittee's undertaking of activities in connection with, or operation and maintenance of, the facility or facilities authorized by the permit whether in compliance or not in compliance with the terms and conditions of the permit. -

Download 7.98 MB

Project Number: 52041-002 August 2021 Integrated High Impact Innovation in Sustainable Energy Technology Prefeasibility Analysis for Carbon Capture, Utilization and Storage (Subproject 2) Prepared by BCS Baliga, Ramesh Bhujade, Subhamoy Kar, Guido Magneschi, V Karthi Velan, Dewika Wattal, and Jun Zhang For ADB Energy Sector Group This the Government cannot be held liable for its contents. Project Number: 52041-002 Integrated High Impact Innovation in Sustainable Energy Technology - Prefeasibility Analysis for Carbon Capture, Utilization and Storage (Subproject 2) Prefeasibility Study on Carbon Capture and Utilization in Cement Industry of India August 2021 1 ABBREVIATIONS AND NOTES ABBREVIATIONS ADB Asian Development Bank CCS Carbon Capture and Storage CCU Carbon Capture and Utilization CCUS Carbon Capture Utilization and Storage CAPEX Capital expenditure CIF Cost, Insurance and Freight CO2 Carbon dioxide CSI Cement Sustainability Initiative CUP CO2 Utilization Plant DAC Direct air capture DBL Dalmia Bharat Limited DCBL Dalmia Cement (Bharat) Limited EA Executing Agency EOR Enhanced oil Recovery EGR Enhanced gas Recovery ECBM Enhanced coal bed methane FOB Free on Board FY Financial Year H2 Hydrogen IA Implementing Agency INDC Intended Nationally Determined Contributions IRR Internal Rate of Return MCA Multi Criteria Analysis MIRR Modified Internal Rate of Return MTPA Million Tonnes Per Annum NPV Net Present Value OPEX Operating expenditure SPV Special Purpose Vehicle 2 TA Technical Assistance tpa tonnes per annum TRL Technology readiness level VGF Viability Gap Funding WACC Weighted Average Cost of Capital WDV Written Down Value NOTES (i) The fiscal year (FY) of the Government and its agencies ends on March 31. (ii)In this report, "$" refers to US dollars, unless otherwise stated. -

Boral Berrima Cement Works

DETERMINATION OF A DEVELOPMENT APPLICATION FOR STATE SIGNIFICANT AND INTEGRATED DEVELOPMENT UNDER SECTION 80 OF THE ENVIRONMENTAL PLANNING AND ASSESSMENT ACT, 1979 I, the Minister for Infrastructure and Planning, under Section 80 of the Environmental Planning and Assessment Act 1979 ("the Act"), determine the development application ("the Application") referred to in Schedule 1 by granting consent subject to the conditions set out in Schedule 2. The reason for the imposition of conditions is to: a) minimise any adverse environmental impacts associated with the development; b) provide for the on-going environmental management of the development; and c) provide for regular monitoring and reporting on the development. Text in red is amendments made by MOD 2-1-2004-i (Non-Standard Fuels) modified 26 September 2005. Text in blue is amendments made by MOD 109-9-2006-i (remove prohibition of hazardous wastes) modified 22 September 2006. Text in green is amendments made by MOD 12-2-2007-I (trial use of tyre chips) modified 13 February 2007. Text in purple is amendments made by MOD 4 (variation to usage rate of coke fines) modified 24 April 2008. Text in orange is amendments made by MOD 5 (coal deliveries by rail) modified 31 August 2009. Text in navy is amendment made by MOD 6 (coal stockpiling for sale) modified 20 June 2012. Text in pink is amendments made by MOD 7 (GBFS processing) modified 16 April 2012. Text in light green is amendments made by Mod 8 (Approval / EPL Consistency) modified 5 August 2012. Text in light blue is amendments made by MOD 9 (Use of Waste Derived Fuels) modified 5 October 2016. -

Permit Review Report Permit ID: 4-0124-00001/00112 Renewal Number: 1 Modification Number: 12 12/08/2014

New York State Department of Environmental Conservation Permit Review Report Permit ID: 4-0124-00001/00112 Renewal Number: 1 Modification Number: 12 12/08/2014 Facility Identification Data Name: LAFARGE BUILDING MATERIALS INC Address: 1916 US RTE 9W RAVENA, NY 12143-0003 Owner/Firm Name: LAFARGE BUILDING MATERIALS INC Address: 1916 RTE 9W RAVENA, NY 12143, USA Owner Classification: Corporation/Partnership Permit Contacts Division of Environmental Permits: Name: SARAH H EVANS Address: NYSDEC - HEADQUARTERS 625 BROADWAY ALBANY, NY 12233-1750 Phone:5184029156 Division of Air Resources: Name: GARY MCPHERSON Address: NYSDEC - REGION 4 1130 N WESTCOTT RD SCHENECTADY, NY 12306-2014 Phone:5183572278 Air Permitting Contact: Name: SARAH SWEENEY Address: LAFARGE BUILDING MATERIALS 1916 RTE 9W RAVENA, NY 12143 Phone:5187565028 Permit Description Introduction The Title V operating air permit is intended to be a document containing only enforceable terms and conditions as well as any additional information, such as the identification of emission units, emission points, emission sources and processes, that makes the terms meaningful. 40 CFR Part 70.7(a)(5) requires that each Title V permit have an accompanying "...statement that sets forth the legal and factual basis for the draft permit conditions". The purpose for this permit review report is to satisfy the above requirement by providing pertinent details regarding the permit/application data and permit conditions in a more easily understandable format. This report will also include background narrative and explanations of regulatory decisions made by the reviewer. It should be emphasized that this permit review report, while based on information contained in the permit, is a separate document and is not itself an enforceable term and condition of the permit. -

Portland Cement

International Conference on Transport, Civil, Architecture and Environment engineering (ICTCAEE'2012) December 26-27, 2012 Dubai (UAE) Portland Cement Alireza Baghchesaraei1 , Omid Reza Baghchesaraei2 kiln is fired by coal, the ash of the coal acts as a secondary raw Abstract— portland cement is the most common type of cement material. in general usage in many parts of the world, as it is a basic ingredient Portland cement was developed from cements (or correctly of concrete, mortar, stucco and most non-specialty grout. There are hydraulic limes) made in Britain in the early part of the different standards for classification of Portland cement. The two nineteenth century, and its name is derived from its similarity major standards are the ASTM C150 used primarily in the U.S. and to Portland stone, a type of building stone that was quarried on European EN-197. EN 197 cement types CEM I, II, III, IV, and V do the Isle of Portland in Dorset, England. Joseph Aspdin, a not correspond to the similarly-named cement types in ASTM C 150. Portland cement manufacture can cause environmental impacts at all British bricklayer, in 1824 was granted a patent for a process stages of the process. When cement is mixed with water a highly of making a cement which he called Portland cement. His alkaline solution (pH ~13) is produced by the dissolution of calcium, cement was an artificial hydraulic lime similar in properties to sodium and potassium hydroxides. the material known as "Roman Cement" (patented in 1796 by James Parker) and his process was similar to that patented in Keywords—New,Material,Portland Cement 1822 and used since 1811 by James Frost who called his cement "British Cement". -

“Best Available Techniques” for the Cement Industry

“BEST AVAILABLE TECHNIQUES” FOR THE CEMENT INDUSTRY A contribution from the European Cement Industry to the exchange of information and preparation of the IPPC BAT REFERENCE Document for the cement industry December 1999 CEMBUREAU CEMBUREAU - the European Cement Association, based in Brussels, is the representative organisation for the cement industry in Europe. Its Full Members are the national cement industry associations and cement companies of the European Union and the European Economic Area countries plus Poland, Switzerland and Turkey. Associate Members include the national cement associations of Czech Republic, Hungary, Slovakia and the sole cement company in Estonia. The Association acts as spokesman for the cement sector towards the European Union institutions and other authorities, and communicates the industry’s views on all issues and policy developments likely to have an effect on the cement market in the technical, environmental, energy and promotion areas. Permanent dialogue is maintained with the European and international authorities and with other International Associations as appropriate. Serviced by a multi-national staff in Brussels, Standing Committees and issue-related Project Groups, established as required, enable CEMBUREAU to keep abreast of all developments affecting the cement industry. CEMBUREAU also plays a significant role in the world-wide promotion of cement and concrete in co- operation with member associations, and the ready-mix and precast concrete industries. The Association regularly co-hosts conferences on specific issues aimed at improving the image of concrete and promoting the use of cement and concrete products. Since its foundation in 1947, CEMBUREAU has developed into the major centre for the dissemination of technical data, statistics and general information on the cement industry world-wide. -

App #202100061

App #202100061 Via Certified Mail 7018 2290 0001 2080 7056 March 24, 2021 Caryn Owens Air Quality Division Michigan Department of Environment, Great Lakes, and Energy Cadillac District Office 120 West Chapin Street Cadillac, MI 49601 Application to Modify MI-ROP-B1559-2014 St. Marys Cement U.S. LLC (SRN: B1559) Charlevoix, Michigan Dear Ms. Owens: The Renewable Operating Permit (ROP) Application forms for St. Marys Cement U.S. LLC (St. Marys) located at 16000 Bells Bay Road, Charlevoix, Michigan are enclosed. These forms are being provided to incorporate Permit to Install (PTI) No. 140-15B, which was issued on March 5, 2021. This PTI was issued to allow the combustion of additional alternative fuels in the in-line kiln/raw mill at the existing Portland cement plant. A copy of the PTI is included as an attachment. Please note – the ROP is currently in renewal. If you have any questions, please call me at 231.237.1387. Sincerely, Laurie Leaman Environmental Manager Attachments Copy: Rob Dickman – EGLE (by email only) Stephanie A. Jarrett, PE – Fishbeck (By email only) St Marys Cement | 16000 Bells Bay Road | Charlevoix, MI 49720 | Tel 231 547 9971, Fax 231 547 6202 votorantimcimentos.com | stmaryscement.com K:\Environmental\Air\PTI Alt Fuels 2020\ROP Modification Letter March 24 2021.docx App #202100061 App #202100061 Michigan Department of Environment, Great Lakes, and Energy Air Quality Division RENEWABLE OPERATING PERMIT M-001: RULE 215 CHANGE NOTIFICATION RULE 216 AMENDMENT/MODIFICATION APPLICATION This information is required by Part 55, Air Pollution Control, of the Natural Resources and Environmental Protection Act, 1994 PA 451, as amended, and the Federal Clean Air Act of 1990. -

Manual on Best Practices in Indian & International Cement Plants

Manual on Best Practices in Indian & International Cement Plants World Class Energy Efficiency Initiative in Cement Industry Disclaimer © 2006, Confederation of Indian Industry All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means electronic, mechanical, photocopying, recording or otherwise, without the prior written permission from CII - Sohrabji Godrej Green Business Centre, Hyderabad. While every care has been taken in compiling this Manual, neither CII – Godrej GBC nor USAID accepts any claim for compensation, if any entry is wrong, abbreviated, cancelled, omitted or inserted incorrectly either as to the wording, space or position in the Manual. The Manual is only an attempt to create awareness on energy conservation and sharing of best practices being adopted in India as well as abroad. “The Manual on Best Practices in Indian and International Cement Plants” was supported in part by a grant from the Government of India pursuant to the Agreement between India and United States of America for the Trade in Environment Services and Technologies (Clean Technology Initiative) (TEST/CTI). The views and information contained herein are those of the CII – Godrej GBC and not necessarily those of Government of India or ICICI Bank or USAID. The Government of India or USAID or ICICI Bank assumes no liability for the contents of this manual by virtue of the support given. Published by Confederation of Indian Industry, CII – Sohrabji Godrej Green Business Centre, Survey No 64, Kothaguda Post, Near Hitech City, R R Dist, Hyderabad – 500 032. Contents S No Page No 1. -

Pre - Feasibility Report

BHAVYA CEMENTS LIMITED TANGEDA VILLAGE, DACHEPALLY MANDAL, GUNTUR DISTRICT, ANDHRA PRADESH Pre - Feasibility Report Submitted by: Bhavya Cements Ltd., IInd Bhavyas Spoorthi Bhavan, Plot No. A1, Film Nagar, Jubilee Hills, Hyderabad – 500 003. Phone: 040-23558384 Fax: 040-23558393. Email: - [email protected] Submitted to MINISTRY OF ENVIRONMENT AND FORESTS, GOVERNMENT OF INDIA INDIRA PARYAVARAN BHAWAN, JOR BAGH ROAD, ALIGANJ, NEW DELHI Pre-Feasibility Report Bhavya Cements Limited, Pre – Feasibility Report Bhavya Cements Limited, Tangeda Village, Dachepalli Mandal, Guntur District, Andhra Pradesh. 1 Executive Summary M/s. Bhavya Cements Limited,proposes to estbalish integrated cement plant with a of capacity of 2.85 MmTPA clinker and 4.0 MMTPA (Phae I 1.0 + Phase II 3.0 MmTPA) of Ordinary Portland Cement (OPC), Portland Pozzalona Cement (PPC) at Thangeda Village, Dachepally Mandal, Guntur Dist, Andhra Pradesh. 2 Introduction of the Project / Background Information 2.1 Identification of Project and Project Proponent: The objective of this pre-feasibility study is to provide information for existing and proposed capacity 2.85 MMTPA clinker and 4.0 MMTPA of Ordinary Portland cement (OPC), Portland Pozzalona Cement (PPC) in exist plant land at Thangeda Village, Dachepally Mandal, Guntur Dist, Andhra Pradesh. (i) The core promoters of BCL are Mr. V. Ananda Prasad & Mr. P.Siva Kumar. Brief profiles of the promoters are given below: Mr. V. Ananda Prasad He a mechanical engineer with 25 years of experience in Cement and construction industry. He is Promoter and Managing Director of Bhavya Cements Limited and also Bhavya constructions. Bhavya constructions has executed more than 50 projects of around 2.02 million square feet and implementing is implementing projects of about 4.0 million square feet. -

Reduction in Sulphur Emissions from the Norcem Cement Plant in Kjøpsvik

www.usn.no FMH606 Master's Thesis 2018 Process Technology Reduction in Sulphur Emissions from the Norcem Cement Plant in Kjøpsvik Umesh Pandey Faculty of Technology, Natural sciences and Maritime Sciences Campus Porsgrunn www.usn.no Course: FMH606 Master's Thesis, 2018 Title: Reduction in Sulphur Emissions from the Norcem Cement Plant in Kjøpsvik Number of pages: 129 Keywords: SO2 emissions, sulphur emissions, cement plants, Norcem cement plant, reduction in sulphur emissions Student: Umesh Pandey Supervisor: Lars A. Tokheim External partner: Norcem Kjøpsvik (Annika Steien, Manager of Process and Environment) Availability: Open Approved for archiving: ______________________________________________ (supervisor signature) The University of South-Eastern Norway takes no responsibility for the results and conclusions in this student report. www.usn.no Summary: SO2 emissions in the stack gas from the Norcem cement plant in Kjøpsvik was significantly higher than the permitted emission limit in 2017. The plant aims to reduce the emissions by installing a seawater flue gas desulphurization (SWFGD) technology, but an understanding of sulphur behaviour in the kiln process, identification of critical factors, determination of their impact and describing underlying principle behind their effects in the emissions are beneficial for future plant and SWFGD operation. This report presents an analysis of the SO2 emission characteristics in the kiln based on sulphur material balance, and regression model formulation using historical emission data and kiln tests. Analysis of the historical data shows that SO3 content in the kiln feed and rawmill operation mode are the most significant parameters which vary sulphur emission in the stack gas. In the analysis, it was discovered that bypass water supply, tyre feeding, RDF feeding, coal feeding and energy input per unit ton of clinker from rotary kiln fuels influence the emissions from the plant. -

Pre - Feasibility Report Clinker – 3.0 MMTPA, Cement Plant – 4.8 MMTPA and Captive Power Plant - 60 MW

VP CEMENTS PRIVATE LIMITED, UNIT-I, Sy.no 306 (Part), Chinnakomerla Village, Mylavaram Mandal, Y.S.R kadapa District, Andhra Pradesh. Pre - Feasibility Report Clinker – 3.0 MMTPA, Cement Plant – 4.8 MMTPA and Captive Power Plant - 60 MW Submitted by: M/s. VP cements private Limited., 7/347-15B, Simhapuri Colony, Y.S.R Kadapa mandal, Dist, Andhra Pradesh – 516 001. Phone : 08562-243312, Fax : 08562-243959 Email: - [email protected] Submitted To MINISTRY OF ENVIRONMENT AND FORESTS, GOVERNMENT OF INDIA PARYAVARAN BHAVAN, LODHI ROAD, NEW DELHI Pre-Feasibility Report VP Cements Private Limited, Unit-I Pre – Feasibility Report VP Cements Private Limited, Unit –I, Chinnakomerla village, Mylavaram mandal, Y.S.R kadapa district, Andhra Pradesh DISCLAIMER The purpose and scope of this information memorandum is to introduce the subject matter and provide a general idea and information on the said area. All the material included in this document is based on data/information gathered from various sources and is based on certain assumptions. Although, due care and diligence has been taken to compile this document, the contained information may vary due to any change in any of the concerned factors, and the actual results may differ substantially from the presented information. M/s. VP Cements Private Limited, Unit -I does not assume any liability for any financial or other loss resulting from this memorandum in consequence of undertaking this activity. Therefore, the content of this memorandum should not be relied upon for making any decision, investment or otherwise. The prospective user of this memorandum is encouraged to carry out his/her own due diligence and gather any information he/she considers necessary for making an informed decision.