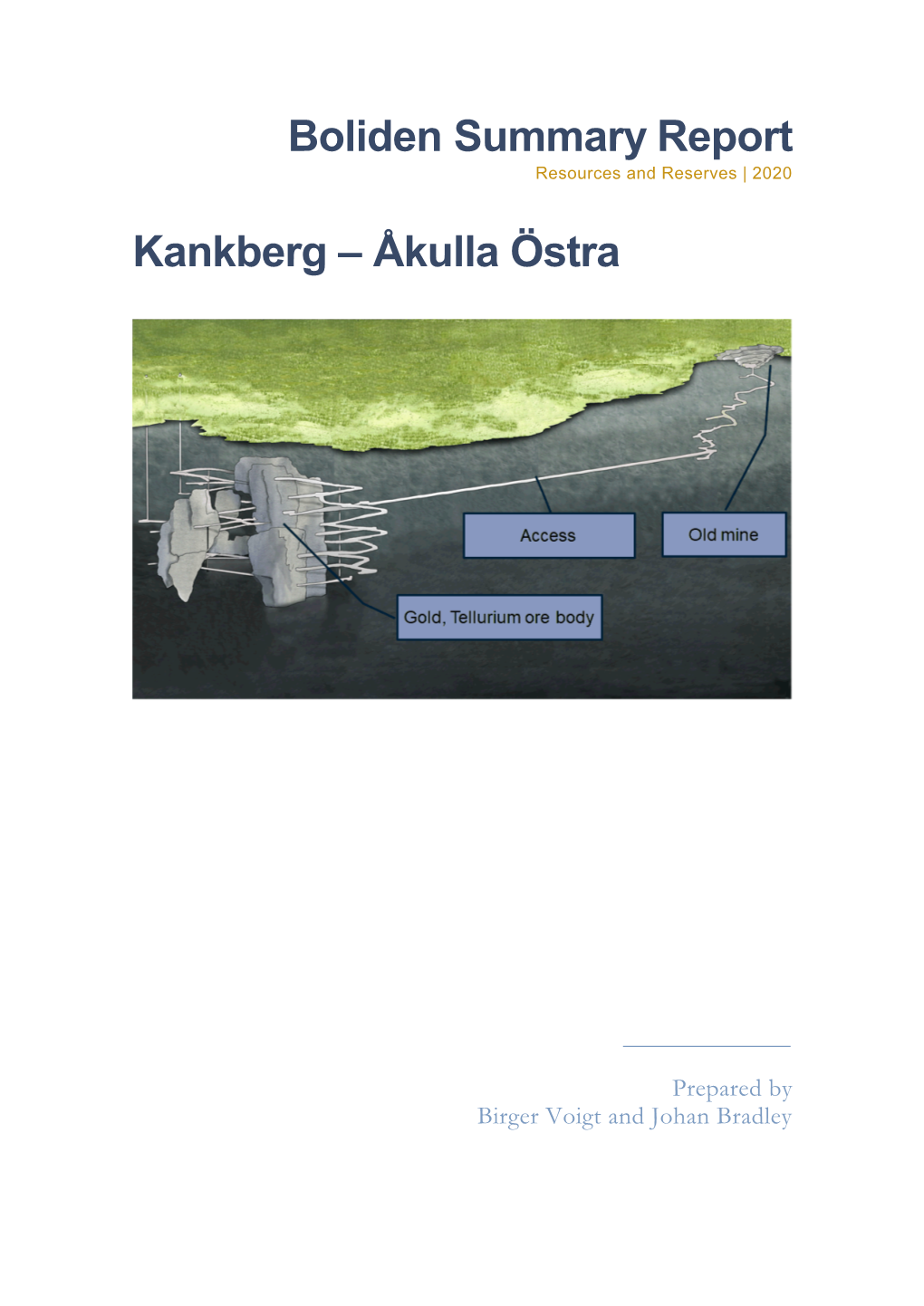

Boliden Summary Report Kankberg – Åkulla Östra

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Washington State Minerals Checklist

Division of Geology and Earth Resources MS 47007; Olympia, WA 98504-7007 Washington State 360-902-1450; 360-902-1785 fax E-mail: [email protected] Website: http://www.dnr.wa.gov/geology Minerals Checklist Note: Mineral names in parentheses are the preferred species names. Compiled by Raymond Lasmanis o Acanthite o Arsenopalladinite o Bustamite o Clinohumite o Enstatite o Harmotome o Actinolite o Arsenopyrite o Bytownite o Clinoptilolite o Epidesmine (Stilbite) o Hastingsite o Adularia o Arsenosulvanite (Plagioclase) o Clinozoisite o Epidote o Hausmannite (Orthoclase) o Arsenpolybasite o Cairngorm (Quartz) o Cobaltite o Epistilbite o Hedenbergite o Aegirine o Astrophyllite o Calamine o Cochromite o Epsomite o Hedleyite o Aenigmatite o Atacamite (Hemimorphite) o Coffinite o Erionite o Hematite o Aeschynite o Atokite o Calaverite o Columbite o Erythrite o Hemimorphite o Agardite-Y o Augite o Calciohilairite (Ferrocolumbite) o Euchroite o Hercynite o Agate (Quartz) o Aurostibite o Calcite, see also o Conichalcite o Euxenite o Hessite o Aguilarite o Austinite Manganocalcite o Connellite o Euxenite-Y o Heulandite o Aktashite o Onyx o Copiapite o o Autunite o Fairchildite Hexahydrite o Alabandite o Caledonite o Copper o o Awaruite o Famatinite Hibschite o Albite o Cancrinite o Copper-zinc o o Axinite group o Fayalite Hillebrandite o Algodonite o Carnelian (Quartz) o Coquandite o o Azurite o Feldspar group Hisingerite o Allanite o Cassiterite o Cordierite o o Barite o Ferberite Hongshiite o Allanite-Ce o Catapleiite o Corrensite o o Bastnäsite -

Standard X-Ray Diffraction Powder Patterns

NBS MONOGRAPH 25—SECTION 4 Standard X-ray Diffraction Powder Patterns U.S. DEPARTMENT OF COMMERCE NATIONAL BUREAU OF STANDARDS THE NATIONAL BUREAU OF STANDARDS The National Bureau of Standards is a principal focal point in the Federal Government for assuring maximum application of the physical and engineering sciences to the advancement of technology in industry and commerce. Its responsibilities include development and mainte- nance of the national standards of measurement, and the provisions of means for making measurements consistent with those standards; determination of physical constants and properties of materials; development of methods for testing materials, mechanisms, and structures, and making such tests as may be necessary, particularly for government agencies; cooperation in the establishment of standard practices for incorporation in codes and specifi- cations advisory service to government agencies on scientific and technical problems ; invention ; and development of devices to serve special needs of the Government; assistance to industry, business, and consumers m the development and acceptance of commercial standards and simplified trade practice recommendations; administration of programs in cooperation with United States business groups and standards organizations for the development of international standards of practice; and maintenance of a clearinghouse for the collection and dissemination of scientific, technical, and engineering information. The scope of the Bureau's activities is suggested in the following listing of its three Institutes and their organizatonal units. Institute for Basic Standards. Applied Mathematics. Electricity. Metrology. Mechanics. Heat. Atomic Physics. Physical Chemistry. Laboratory Astrophysics.* Radiation Phys- ics. Radio Standards Laboratory:* Radio Standards Physics; Radio Standards Engineering. Office of Standard Reference Data. Institute for Materials Research. -

Gold Mineralization in the Black Cloud #3 Carbonate Replacement Orebody, Leadville Mining District, Lake County, Colorado

Gold mineralization in the Black Cloud #3 carbonate replacement orebody, Leadville Mining District, Lake County, Colorado Item Type text; Thesis-Reproduction (electronic) Authors Gray, Matthew Dean, 1933- Publisher The University of Arizona. Rights Copyright © is held by the author. Digital access to this material is made possible by the University Libraries, University of Arizona. Further transmission, reproduction or presentation (such as public display or performance) of protected items is prohibited except with permission of the author. Download date 30/09/2021 01:36:16 Link to Item http://hdl.handle.net/10150/558083 GOLD MINERALIZATION IN THE BLACK CLOUD #3 CARBONATE REPLACEMENT OREBODY, LEADVTLLE MINING DISTRICT, LAKE COUNTY, COLORADO by Matthew Dean Gray Copyright(g>Matthew Dean Gray 1988 A Thesis Submitted to the Faculty of the DEPARTMENT OF GEOSCIENCES In Partial Fulfillment of the Requirements For the Degree of MASTER OF SCIENCE In the Graduate College THE UNIVERSITY OF ARIZONA 1988 STATEMENT BY AUTHOR This thesis has been submitted in partial fulfillment of requirements for an advanced degree at The University of Arizona and is deposited in the University Library to be made available to borrowers under rules of the Library. Brief quotations from this thesis are allowable without special permission, provided that accurate acknowledgement of source is made. Requests for permission for extended quotation from or reproduction of this manuscript in whole or in part may be granted by the copyright holder. APPROVAL BY THESIS DIRECTOR This thesis has been approved on the date shown below: Professor of Geosciences ACKNOWLEDGMENTS The writer wishes to express his sincere appreciation to a number of individuals and organizations whose help and support made this thesis project possible and enjoyable. -

Lone Jack Mine, Mount Baker Mining District, Whatcom County, Washington

INACTIVE AND ABANDONED MINE LANDS— Lone Jack Mine, Mount Baker Mining District, RESOURCES Whatcom County, Washington by Fritz E. Wolff, Donald T. McKay, Jr., Matthew I. Brookshier, and David K. Norman WASHINGTON NATURAL DIVISION OF GEOLOGY AND EARTH RESOURCES Information Circular 98 March 2005 Whatcom County site location INACTIVE AND ABANDONED MINE LANDS— Lone Jack Mine, Mount Baker Mining District, Whatcom County, Washington by Fritz E. Wolff, Donald T. McKay, Jr., Matthew I. Brookshier, and David K. Norman WASHINGTON DIVISION OF GEOLOGY AND EARTH RESOURCES Information Circular 98 March 2005 DISCLAIMER Neither the State of Washington, nor any agency thereof, nor any of their em- ployees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any informa- tion, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or other- wise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the State of Washington or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the State of Washington or any agency thereof. WASHINGTON DEPARTMENT OF NATURAL RESOURCES Doug Sutherland—Commissioner of Public Lands DIVISION OF GEOLOGY AND EARTH RESOURCES Ron Teissere—State Geologist David K. Norman—Assistant State Geologist Washington Department of Natural Resources Division of Geology and Earth Resources PO Box 47007 Olympia, WA 98504-7007 Phone: 360-902-1450 Fax: 360-902-1785 E-mail: [email protected] Website: http://www.dnr.wa.gov/geology/ Published in the United States of America ii Contents Introduction ........................................... -

Types of Tellurium Mineralization of Gold Deposits of the Aldan Shield (Southern Yakutia, Russia)

minerals Article Types of Tellurium Mineralization of Gold Deposits of the Aldan Shield (Southern Yakutia, Russia) Larisa A. Kondratieva *, Galina S. Anisimova and Veronika N. Kardashevskaia Diamond and Precious Metal Geology Institute, SB RAS, 677000 Yakutsk, Russia; [email protected] (G.S.A.); [email protected] (V.N.K.) * Correspondence: [email protected]; Tel.: +7-4112-33-58-72 Abstract: The published and original data on the tellurium mineralization of gold ore deposits of the Aldan Shield are systematized and generalized. The gold content is related to hydrothermal- metasomatic processes caused by Mesozoic igneous activity of the region. The formation of tellurides occurred at the very late stages of the generation of gold mineralization of all existing types of meta- somatic formations. 29 tellurium minerals, including 16 tellurides, 5 sulfotellurides and 8 tellurates have been identified. Tellurium minerals of two systems predominate: Au-Bi-Te and Au-Ag-Te. Gold is not only in an invisible state in sulfides and in the form of native gold of different fineness, but also is part of a variety of compounds: montbrayite, calaverite, sylvanite, krennerite and petzite. In the gold deposits of the Aldan Shield, three mineral types are distinguished: Au-Ag-Te, Au-Bi-Te, and also a mixed one, which combines the mineralization of both systems. The decrease in the fineness of native gold is consistent with the sequence and temperatures of the formation of Te minerals and associated mineral paragenesis from the epithermal–mesothermal Au-Bi-Te to epithermal Au-Ag-Te. The conducted studies allowed us to determine a wide variety of mineral species and significantly ex- Citation: Kondratieva, L.A.; pand the area of distribution of Au-Te mineralization that indicates its large-scale regional occurrence Anisimova, G.S.; Kardashevskaia, in the Aldan Shield. -

Download the Scanned

American Mineralogist, Volume 7l, pages845-847, 1986 NEW MINERAL NAMES'T FnaNx C. H,c,wrHoRNE,PETE J. DuNN, JoBr, D. Gnrco, Jlcnx Puzrnwtczo Jlvrns E. Snrcr,Bv Doyleite* G.Y. Chao, J. Baker, A.P. Sabina,A.C. Roberts (1985) Doyleite, An average of three typical microprobe analyses gave ZnO a new polymorph of Al(OH)r, and its relationship to bayerite, 19.75,CUO 0.02, FerO, 10.81, AlrO3 24.97, AsrO' 31.91, MoO, gibbsite, and nordstrandite. Can. Mineral., 23,21-28. 1.08, HrO (rce) 11.25, sum 99.79 wt0/0,corresponding to (Zno {(AsOJ (OH)r}, or ideally (Zn,Fe)- Doyleite is a new polymorph of AI(OH), that occurs at rrFeo,r)(Al,roFeo ro) | (Al,Fe)r{(AsO.) (OtDr}. Isomorphous replacement of (Zn,Fe) and Mont St. Hilaire and at the Francon quarry, Montreal, | Quebec, (Al,Fe) is indicated. The valence state ofFe is uncertain owing Canada.Wet chemical analysisgave NzO3 65.2,CaO 0.48, HrO to the small amount of pure material available. The mineral is (rcr to ll00'C) 35.76, sum 101.44 wlo/o,corresponding to insoluble in HCl. rce shows a dehydration reaction between 460 AlorrCa"o,(OH)roo.Trace amounts of Na, Fe, Mg, and Si were and 520t with a weight loss of approximately I I wto/o. detected by electron-microprobe analysis. The mineral is not Indexing of the X-ray powder data (Guinier camera) led to a attackedby 1:I HCl, HrSOo,or HNO3 at room temperature.rcA small triclinic cell with lattice constants a : 5.169(5), b : showed a weight loss of 25.630/obetween 280 and 410qCand a 13.038(9),c:4.93r(4) A, a:98.78(7f, B:100.80(6)",r: further gradual loss to I 000€, giving a total weight loss of 35 . -

Au and Te Minerals in Seafloor Massive Sulphides from Semyenov

minerals Article Au and Te Minerals in Seafloor Massive Sulphides from Semyenov-2 Hydrothermal Field, Mid-Atlantic Ridge Anna Firstova 1,2,*, Tamara Stepanova 1, Anna Sukhanova 1, Georgy Cherkashov 1,2,* and Irina Poroshina 1 1 Institute for Geology and Mineral Resources of the Ocean (FSBI “VNIIOkeangeologia”), 1 Angliisky Ave., 190121 St. Petersburg, Russia; [email protected] (T.S.); [email protected] (A.S.); [email protected] (I.P.) 2 Institute of Earth Sciences, St. Petersburg State University, 7/9 Universitetskaya Emb., 199034 St. Petersburg, Russia * Correspondence: anetfi[email protected] (A.F.); [email protected] (G.C.); Tel.: +8-981-828-99-73 (A.F.); +7-812-713-8378 (G.C.) Received: 4 March 2019; Accepted: 10 May 2019; Published: 15 May 2019 Abstract: The Semyenov-2 hydrothermal field located at 13◦310N of the Mid-Atlantic Ridge (MAR) is associated with an oceanic core complex (OCC) and hosted by peridotites and basalts with minor amounts of gabbro and plagiogranites. Seafloor massive sulphides (SMS) are represented by chimneys with zonality, massive sulphides without zonality and sulphide breccia cemented by opal and aragonite. The mean value of Au (20.6 ppm) and Te (40 ppm) is much higher than average for the MAR SMS deposits (3.2 ppm and 8.0 ppm, respectively). Generally, these high concentrations reflect the presence of a wide diversity of Au and Te minerals associated with major mineral paragenesis: primary native gold, melonite (NiTe2) and tellurobismuthite (Bi2Te3) are related to high-temperature chalcopyrite (~350 ◦C); electrum (AuAg)1, hessite (Ag2Te) and altaite (PbTe) are related to medium- and low-temperature Zn-sulphide and opal assemblages (260–230 ◦C). -

Ore Petrography and Chemistry of the Tellurides from the Dongping Gold Deposit, Hebei Province, China

Ore Geology Reviews 64 (2014) 23–34 Contents lists available at ScienceDirect Ore Geology Reviews journal homepage: www.elsevier.com/locate/oregeorev Ore petrography and chemistry of the tellurides from the Dongping gold deposit, Hebei Province, China Shen Gao, Hong Xu ⁎, Desen Zhang, Henan Shao, Shaolong Quan School of Earth Science and Resources, China University of Geosciences (Beijing), Beijing 100083, China article info abstract Article history: The Dongping gold deposit is a mesothermal lode gold deposit hosted in syenite. The ore petrography and chem- Received 5 March 2014 istry of the tellurides from the alteration zone of the deposit have been studied in detail using optical microscopy, Received in revised form 5 June 2014 scanning electron microscopy, electron probe micro-beam and X-ray diffraction facilities. The tellurides, Accepted 12 June 2014 consisting mostly of calaverite, altaite, petzite tellurobismuthite and tetradymite, are hosted irregularly in pyrite Available online 19 June 2014 fractures and voids. In the ore bodies, the species and quantity of tellurides decrease from the top downwards, fi Keywords: accompanied with lowering of gold neness, and the existence of tellurides exhibits a positive correlation with Tellurides gold enrichment. Mineral paragenesis and chemical variations suggest that during evolution of the ore- Ore petrography forming fluids Te preferably incorporated with Pb to form altaite, followed in sequence by precipitation of petzite, Chemistry and calaverite when Ag has been exhausted, and the residue fluids were enriched in Au, giving rise to formation Gold Deposit of native gold. Calculation with reference of the fineness of native gold coexisting with the tellurides indicates Dongping that at 300 °C, log f (Te2) varied between −8.650 and −7.625. -

Ore–Microscopy and Geochemistry of Gold–Silver Telluride Mineralization in Southwestern Hokkaido, Japan

Journal of Mineralogical and Petrological Sciences, Volume 113, page 293–309, 2018 Ore–microscopy and Geochemistry of Gold–Silver Telluride Mineralization in Southwestern Hokkaido, Japan Euis T. YUNINGSIH*, Hiroharu MATSUEDA** and Ildrem SYAFRIE* *Faculty of Geology, Raya Bandung–Sumedang Km. 21, Bandung 45363, West Java, Indonesia **The Hokkaido University Museum, Hokkaido University, Sapporo 060–0810, Japan Tellurium–bearing gold, silver, and base metal assemblages characterize the epithermal mineralization in south- western Hokkaido, Japan. The telluride deposits in this district consist of quartz–filled fracture systems of Late Miocene to Pliocene age. Most of the telluride mineralization in southwestern Hokkaido consists of vein sys- tems or are massive in form. The dominant host rocks for this deposit type are intermediate to acid volcanic rocks. The gangue and alteration minerals are very fine to fine–grained quartz, chalcedony, anatase, zeolite, sericite, barite, adularia, chlorite, smectite or other clay mineral, while carbonate (calcite and rhodocrosite) and Mn minerals are poorly represented and rarely coexist with tellurides. The country rocks suffered argillic and propylitic alterations, silicification, and kaolinitization. Tellurium–bearing mineralization is related to or co– exists with sulfide and sulfosalt mineralization. The tellurides identified in the studied area consist of native tellurium, hessite, stutzite, petzite, sylvanite, calaverite, tellurobismuthite, tetradymite, Se–bearing tetradymite, tellurantimony, goldfieldite, -

Standard X-Ray Diffraction Powder Patterns

E^l Admin. NBS MONOGRAPH 25—SECTION 5 Refecii^M not to be ^ferlrom the library. Standard X-ray Diffraction Powder Patterns ^\ / U.S. DEPARTMENT OF COMMERCE S NATIONAL BUREAU OF STANDARDS THE NATIONAL BUREAU OF STANDARDS The National Bureau of Standards^ provides measurement and technical information services essential to the efficiency and effectiveness of the work of the Nation's scientists and engineers. The Bureau serves also as a focal point in the Federal Government for assuring maximum application of the physical and engineering sciences to the advancement of technology in industry and commerce. To accomplish this mission, the Bureau is organized into three institutes covering broad program areas of research and services: THE INSTITUTE FOR BASIC STANDARDS . provides the central basis within the United States for a complete and consistent system of physical measurements, coordinates that system with the measurement systems of other nations, and furnishes essential services leading to accurate and uniform physical measurements throughout the Nation's scientific community, industry, and commerce. This Institute comprises a series of divisions, each serving a classical subject matter area: —Applied Mathematics—Electricity—Metrology—Mechanics—Heat—Atomic Physics—Physical Chemistry—Radiation Physics— -Laboratory Astrophysics^—Radio Standards Laboratory,^ which includes Radio Standards Physics and Radio Standards Engineering—Office of Standard Refer- ence Data. THE INSTITUTE FOR MATERIALS RESEARCH . conducts materials research and provides associated materials services including mainly reference materials and data on the properties of ma- terials. Beyond its direct interest to the Nation's scientists and engineers, this Institute yields services which are essential to the advancement of technology in industry and commerce. -

Secondary Sulfate Minerals from Thallium Mineralized Areas: Their Formation and Environmental Significance

minerals Review Secondary Sulfate Minerals from Thallium Mineralized Areas: Their Formation and Environmental Significance Fengqi Zhao 1 and Shangyi Gu 1,2,* 1 College of Resource and Environmental Engineering, Guizhou University, Guiyang 550025, China; [email protected] 2 Key Laboratory of Karst Geo-Resources and Environment, Guizhou University, Guiyang 550025, China * Correspondence: [email protected] Abstract: Thallium is a highly toxic metal and is predominantly hosted by sulfides associated with low-temperature hydrothermal mineralization. Weathering and oxidation of sulfides generate acid drainage with a high concentration of thallium, posing a threat to surrounding environments. Thallium may also be incorporated into secondary sulfate minerals, which act as temporary storage for thallium. We present a state-of-the-art review on the formation mechanism of the secondary sulfate minerals from thallium mineralized areas and the varied roles these sulfate minerals play in Tl mobility. Up to 89 independent thallium minerals and four unnamed thallium minerals have been documented. These thallium minerals are dominated by Tl sulfosalts and limited to several sites. Occurrence, crystal chemistry, and Tl content of the secondary sulfate minerals indicate that Tl predominantly occurs as Tl(I) in K-bearing sulfate. Lanmuchangite acts as a transient source and sink of Tl for its water-soluble feature, whereas dorallcharite, Tl-voltaite, and Tl-jarosite act as the long term source and sink of Tl in the surface environments. Acid and/or ferric iron derived from Citation: Zhao, F.; Gu, S. Secondary the dissolution of sulfate minerals may increase the pyrite oxidation process and Tl release from Sulfate Minerals from Thallium Tl-bearing sulfides in the long term. -

New Data on Mineralogy of Deposits of Plutonogenic Gold-Quartz Formation in the Northern Central Kazakhstan

New Data on Minerals. 2014. Vol. 49 57 NEW DATA ON MINERALOGY OF DEPOSITS OF PLUTONOGENIC GOLD-QUARTZ FORMATION IN THE NORTHERN CENTRAL KAZAKHSTAN. PART I Ernst M. Spiridonov Moscow State University, Geological Faculty, Moscow, [email protected] The formation history of mineralogy of plutonogenic gold-quartz deposits of the Stepnyak group in the Northern Central Kazakhstan is discussed. Mineral facies referred to the depth of the deposit formation; mi ne - ralogical features of ore shoots, nature of ore-bearing fluids, white micas, quartz, carbonates, scheelite, pyrite, arsenopyrite, pyrrhotite, gersdorffite, sphalerite, berthierite, argentotennantite, argentotetrahedrite, roshchi- nite, bismuth tellurides and sulfotellurides, mattagamite, Co-bearing frohbergite and melonite, montbrayite, calaverite, sylvanite, petzite, petzite-hessite solid solution, and hessite are reported. The deposition sequence from Au to Ag tellurides and affinity for Te: Co > Fe, Ni > Bi, Sb > Pb > Ag, Hg > Au, Cu are improved. 10 figures, 8 tables, 60 references. Keywords: scheelite, mattagamite, frohbergite, melonite, montbrayite, calaverite, krennerite, sylvanite, pet- zite-hessite solid solution, affinity to Te. Despite many reviews, current state of geo - diately predated or accompanied gold minera- logy causes genetic typification of gold de - lization. posits. One of the ways is the detailed study of Plutonogenic hydrothermal gold-quartz specific gold formations, and separate gold formation. The deposits of the plutonogenic provinces and deposits. gold-quartz beresite-listvenite formation are Hydrothermal gold deposits are frequently paragenetically related to tonalite-grano dio rite- referred to the three formations on the basis of plagiogranite, adamellite, and monzo nite-gra- the formating depth: (1) shallow (with abun- nite intrusive complexes of folded areas.