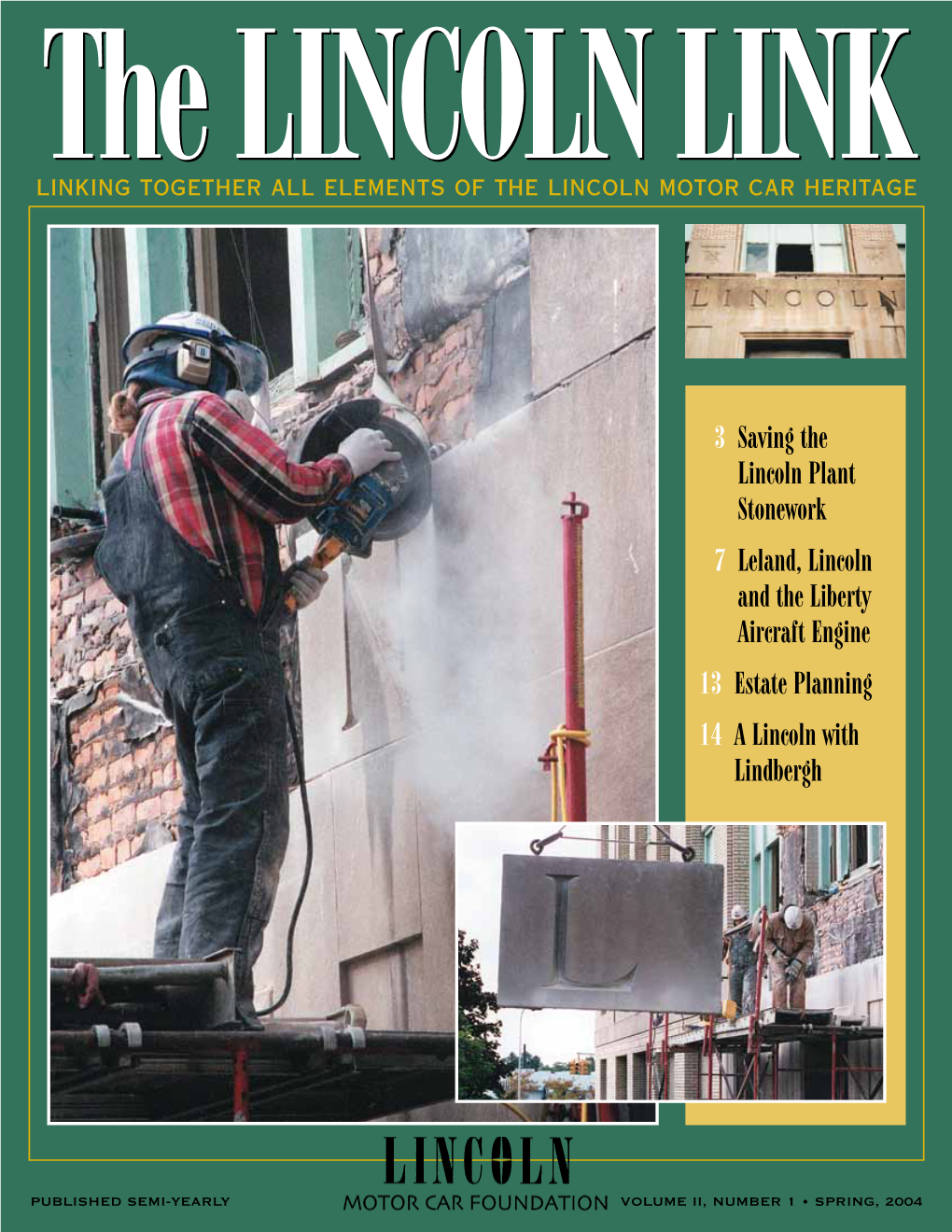

3 Saving the Lincoln Plant Stonework 7 Leland, Lincoln and the Liberty

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Mansions of Grosse Pointe

~""__ "'''' __ ''_-iiiJi'''W'' -- 'i If ,I :''j '1 I I , BY HAWKINS FERRY A SU.hurh In Good Taste By Hawkins Ferry Reprinted by Economee Service, In,c. from March, 1956 Issue, Michigan Society of Architects CENTRA~ GR'OSS,EPOINTE PUBLIC UBRAR1 IJDIJRD IN ~;:OOD Tt\STt; BY HAWKINS FERRY THE npllnmg Yllarn of the eighteenth of It:. "elf]! th", ilhores of Lake St Cbir n~JClr ArntJ:,,'::i'Jn t0n~1'1 allraclt'd settlers in the Gl'Om8~' Gretu !i{; r;t \~fid areCI Eorly French farmers bmlt hap~ It III d'!f,~ihngs rtertr the lake both for acces:1 flvt:J11Vfj h~tlSO;g pr(IVtHl to 1:F'~ by cano,) cmd for a convenient water O;H;j "hn[lfll:'lg ;,\lpply TillS resulted in tho hou8e~ boing '.:md l"Jwns th~y together The land of eelen farm sIOnt Cl of l:vlr:q !bf1t j >d'l)' 'ixwnd!!1d from the lake far into the interior enlld by prohlbi!lYC' and m(ll1ilf}IlCll:,;/"' 111 n'lm1W strips, thus having originated C'o~tJ All thli1 er(l tl1'.1t prociuC'<)'d th~, tNm 'ribbon farm." hom,,!s Ul Y'Jl1l,,!llllq rmcl many thif,"'rJl ~'Te It an ()pprr.)p£:-:~t{) h thl' latter part of the nineteenth century mOln'3nt to rellvl11w,1tAthem ',:1$ mmthetl\; th'l mcreational value of the waterfront phenomena. Tf)cognized, and summer cottages took place of farmhouses; but Grosse On@ of the hut lluba\c:mlial ma:nslon~ in P)mte'f!) role as em isolated summer colony Grosse POlllte was thf>' Joseph H. -

Brian Mcmahon Chad Roberts, Roxanne Sands, James A

RAMSEY COUNTY “Abide with Me” Grace Craig Stork, 1916 Rebecca A. Ebnet-Mavencamp —Page 10 HıstoryA Publication of the Ramsey County Historical Society Fall 2016 Volume 51, Number 3 A Workplace Accident John Anderson’s Fall from the High Bridge John T. Sielaff, page 3 Towering above the Mississippi River flood plain, St. Paul’s Smith Avenue High Bridge, seen here in a 1905 postcard, connected the city’s oldest residential neighborhood, West Seventh Street, with its newest at the time, Cherokee Heights, or the Upper West Side. John Anderson, a painter working on the bridge in 1902, fell and survived the accident. His story tells us much about the dangers in the workplace then and now. Photo by the Detroit Photographic Company, courtesy of the Minnesota Historical Society. RAMSEY COUNTY HISTORY RAMSEY COUNTY President Chad Roberts Founding Editor (1964–2006) Virginia Brainard Kunz Editor Hıstory John M. Lindley Volume 51, Number 3 Fall 2016 RAMSEY COUNTY HISTORICAL SOCIETY THE MISSION STATEMENT OF THE RAMSEY COUNTY HISTORICAL SOCIETY BOARD OF DIRECTORS ADOPTED BY THE BOARD OF DIRECTORS ON JANUARY 25, 2016: James Miller Preserving our past, informing our present, inspiring our future Chair Jo Anne Driscoll First Vice Chair Carl Kuhrmeyer C O N T E N T S Second Vice Chair Susan McNeely 3 A Workplace Accident Secretary Kenneth H. Johnson John Anderson’s Fall from the High Bridge Treasurer John T. Sielaff William B. Frels Immediate Past Chair 10 “Abide with Me” Anne Cowie, Cheryl Dickson, Mari Oyanagi Grace Craig Stork, 1916 Eggum, Thomas Fabel, Martin Fallon, Rebecca A. -

Western Region LCOC Confab – 201309

TINENT ON AL C O D W N N A E Lincoln and R Lincoln and N L S C O C FOUNDED L CONFAB U N 1955 CONFAB I B L Continental WESTERN REGION Western Region Lincoln and Continental Owners Club Publication Volume 42 No 7, September, 2013 Presidential 1950 Lincoln Cosmopolitan “Bubbletop” Limousine, the orange Boano Lincoln Indianapolis Coupe which was a 1955 show car, and a specially painted 2013 Lincoln MKZ. Other Lincolns on display were William Clay Ford’s 1956 Continental Mark II convertible, several classic Lincolns from the twenties and thirties, and a 1956 Continental Mark II originally owned by Elizabeth Taylor. Originally the Western Region planned to have a special class as they did in 1995 but that plan was cancelled due to lack of participation. We are not sure how many, if any, Western Region members attended without cars. One Western Region mem- ber, Jim Ayres, did attend and took these photos. More of his photos appear on Lincoln Honored at Pebble Beach 2013 page 4. For the first time since its 75th Anniversary in 1995 Lincoln was one of the honored marques at the 63rd edition Left, of the Pebble Beach Concours d’Elegance “Bubbltop,” the third weekend of August. Below, This year the concours, held Sunday, Anne August 18, honored Lincoln, Simplex, Ford Vanvooren Coachwork, Aston Martin Mark II. Centennial, Lamborghini, Porsche 911, BMW 507, Indianapolis Roadsters and French Motorcycles. The Pebble Beach Tour d’Elegance saw more than 200 historic cars parade on a 88-mile course along the 17-Mile Drive, winding through the Central Coast includ- to a 1934 Packard ing, for the first time in a decade, the 1108 Twelve Dietrich Corkscrew turn around the track at Mazda Convertible Victoria Raceway Laguna Seca. -

A Publication of the Lincoln and Continental Owners Club Hoosier Region

A publication of the Lincoln and Continental Owners Club Hoosier Region Volume 36 Issue 2 The Lincoln Log Summer 2020 LCOC Hoosier Region Notes from the Director Indiana LCOC Dear Members: Greetings from your club director! Remember me, Joe S. Board of Managers 2019 Columbe? You have not heard much from me this year but nothing much has been going on either. We canceled most Director events due to this year’s turmoil. The February dinner meeting Joe S. Columbe had a fair number in attendance at Bynum’s Steakhouse. The summer picnic was a great success. With the five car clubs that were invited, we had 23 Hoosier Region members in attendance, Treasurer with a total of 73 enjoying the event. The “bring your own pic- Paul Temple nic” or order a box lunch was accepted by all. We had 45 or- ders for box lunches and many told us that they were thoroughly Secretary enjoyed. Darren Klingler Our next event will be on Saturday, October 3, in Seymour with lunch provided by our host and member John Rust. There will be theatre organ concerts along with a car show. This is a Bill Baird first-time event for our club. We hope to have a good showing Erinn Owen of members with their Lincolns and Continentals taking ad- Gary Stapleton vantage of this very interesting fall get together. Charlie Griffith A 1967 Continental Convertible was sold in August at the Raleigh Classic Auction. This red with white top and interior John Madden drop-top sold for $118,000.00 plus bidder’s fee and sales tax if applicable. -

1932-76 Lincoln-Mercury Catalog Automotive Thermal Acoustic Insulation

1932-76 Lincoln-Mercury Catalog Automotive Thermal Acoustic Insulation Roof to Road Solutions to Control Passenger Cabin Noise, Vibration and Heat •Reduce Road Noise •Reduce Exhaust Harmonics Pre-Cut Ready to Install Kits •Eliminate Mechanical Noise •Stop Body Panel Vibration Year • Make • Model Specific •Reduce Radiated & Reflected Heat •Stop Audio System Vibration The Coolest Cars Have QuietRIDE Inside! ™ Roof Kit Roof & Quarter Panels Kits are available for these Vehicles above beltline. Kits are available for these Vehicles See AcoustiTrunk Catalog See AcoustiHood Catalog Trunk Floor Kit Trunk Floor & Tire Well Firewall Insulator Fits under dash against the firewall bulkhead. Body Panel Kit All Panels below the beltline including Package Tray, Seat Divider, Rear Wheel Wells, Fenders, Rear Quarters and Tail Panels Door Kit All Doors Floor Kit Cowl Kit Front Floor, Rear Floor, Transmission Hump/ Panels between the Driveline firewall and front door of the vehicle. Everything in One Box to Do the Job Right! Pre-Cut, Ready To install Kits are Year, Make and Model Specific and include: •Dynamat Xtreme •Heat Shield Barrier Insulation Order Line: 888-777-3410 Tech Line: 209-942-4777 •Spray Adhesive •Seam Tape Fax: 877-720-2360 •Illustrated Instructions 1122 S. Wilson Way Ste. #1, Stockton CA, 95205 For more information contact us at: [email protected] ©2003-21 •Prices Subject to Change Without Notice Lincoln 1932-76 Mercury 1939-72 Automotive Thermal Acoustic Insulation Pre Cut Kits Ready to Install Roof to Road Solutions To Control Passenger Cabin Noise, Vibration and Heat Introducing a multi-stage, automotive insula- tion and sound damping system to give Lin- coln and Mercury cars the “quiet riding comfort” found in today’s new cars. -

Vehicle Make Model Color Year Min Hours Sedan Lincoln Towncar

Office: (949) 494-4223 Concierge Limousine Inc. Fax: (714) 379-4448 5542 Engineer Dr. www.conciergelimo.com Huntington Beach CA 92649 Pax Luggage Min Cancellation Vehicle Make Model Color Year Capacity Capacity Hours Hours Sedan Lincoln Towncar Black 2011 3 3 2 2 Sedan Lincoln Towncar Black 2011 3 3 2 2 Sedan Lincoln Towncar Black 2011 3 3 2 2 Sedan Lincoln Continental Black 2017 3 3 2 2 Sedan Lincoln MKT Black 2013 3 3 2 2 Sedan Lincoln MKT Black 2013 3 3 2 2 Sedan Lincoln MKT Black 2013 3 3 2 2 Sedan Lincoln MKT Black 2014 3 3 2 2 Sedan Lincoln MKT Black 2014 3 3 2 2 SUV Lincoln Navigator Black 2011 6 4 2 2 SUV Lincoln Navigator Black 2015 6 4 2 2 SUV Lincoln Navigator Black 2015 6 4 2 2 Sedan BMW 750Li Black 2015 3 3 2 2 Limo Lincoln Stretch Black 2011 8 4 5 8 Mini -Coach Mercedes Sprinter Black 2015 12 6 5 24 Office: (949) 494-4223 Concierge Limousine Inc. Fax: (714) 379-4448 5542 Engineer Dr. www.conciergelimo.com Huntington Beach CA 92649 MKT Town Car • Seating for three passengers • Best-in-class 2nd legroom and cargo room • USB outlets for passengers • Passenger controls air conditioning • Auxiliary lighting • Black interior,tinted windows • Bottled water and newspaper-Standard • Special beverages and reading material-Upon request • Complimentary use of cell phone chargers for Blackberry and Iphone models 5 and up Lincoln Town Car L Series • Seating for three passengers • Six additional inches of legroom for passengers • USB outlets for passengers • Passenger controls air conditioning Auxiliary lighting • • Black interior,tinted windows • Bottled water and newspaper-Standard • Special beverages and reading material-Upon request • Complimentary use of cell phone chargers for Blackberry and Iphone models 5 and up Office: (949) 494-4223 Concierge Limousine Inc. -

LCOC Trophywinners 2018

Lincoln and Continental Owners Club National Meet Trophy Winners Table of Contents Elliston H. Bell, Founder’s Trophy ................................... 2 Lincoln Trophy #8 ...................................................... 31 Edsel Ford Trophy ............................................................ 4 Lincoln Trophy #9 ...................................................... 33 E.T. Gregorie Trophy ........................................................ 6 Lincoln Trophy #10 .................................................... 35 William Coughlin Trophy ................................................. 8 Lincoln Trophy #11 .................................................... 37 William Clay Ford Trophy .............................................. 10 Lincoln Trophy #12 .................................................... 39 L. Dale Shaeffer Trophy ................................................. 12 Lincoln Trophy #13 .................................................... 41 Robert H. Davis Trophy .................................................. 14 Lincoln Trophy #14 .................................................... 43 Dr. Erwin C. Ruth Trophy ............................................... 16 Lincoln Trophy #15 .................................................... 44 The Douglas W. Mattix Trophy ...................................... 18 Lincoln Trophy #16 .................................................... 45 The Lincoln Trophy ........................................................ 19 Best Modified Custom ................................................. -

AMA Cites Car Industry's Role in Defense Progran

14 (218) AUTOMOTIVE NEWS, MARCH 3, 1941 PEFENSf AMA Cites Car Industry’s Role in Defense Progran Sluing Manpower Contribution Seen GMC Defense Activity . Congress Reaching 150,000 in 1941 Anti-Strike Hil|s At Present DETROIT.—The important part on aviation parts, reported releas- Tim v the automobile industry is playing ing skilled veterans to this exact- WASHINGTON. Anti-stri , in the defense program is graph- ing work by advancing younger legislation is “out the window’’ f Congress. m ically portrayed in pictures and text employes to automotive jobs. this session of in a report issued last week by The report goes into each divi- With that question settled <jq Automobile Manufacturers Assn. sion of the national defense pro- nitely by the Knudsen-Hillmarn j The foreword is written by Pres- gram, as follows: gument against regulatory lawi,y equally ident Alvan Macauley, who states Airplanes seemed certain today 3 that “all along the line job no new labor legislation of any the has Airplane engines auto- 3 fight against from the will stand a chance of passage. |[ been, and is. a time. industry Energetic and devoted efforts of mobile went into service as early as July, 1940. The first Senator Elbert D. Thomas II many of men draft- I*I,ANT FXI’ANSION, orders, being Utah, of hundreds at of several factories, General Mo- made necessary by defense is rapidl> chairman the senate cojl ing boards, in tool departments, on pushed to completion at the main factories of General Motors Truck and Coach on education was turning a story building of mittee and labor, ho3| construction jobs tors’ Allison, them out at I'ontiac. -

Issue Number 111

AL HISTORIANS, INC. November-December 1987 Issue Number 111 MINUTES OF THE SAH BOARD MEETING OFFICERS INTRODUCED, OCTOBER 8, 1987 AWARDS PRESENTED AT ANNUAL BANQUET The October meeting of the SAH Board of Direc tors was called to order by President Keith Marvin at 8:53 p m. after dinner at the home of Mrs. Shelby Newly elected officers and directors were intro Applegate in Mt. Gretna, Pennsylvania. Present we re duced at the society's annual meeting and b anquet Charles Betts, Shelby C. Applegate, George Ward, he ld on the evening of Friday, October 9, 1987. at Matt Joseph, Christopher Foster, Bill Camerom, Tom the Marriott Inn in Harrisburg , Pennsylvania . Elected Bonsall, Jack Ma rtin, Taylor Vinson, newly elected president in the recent balloting was Beverly Rae officers : President Beverly Rae Kim es, Vice President Kimes of New York City, who succeeds Keith Marvin. Henry Austin Clark and Treasurer Robert Gary. Henry Austin Clark Jr., of Glen Cove, New York, The minutes of the February board meeting were was elec ted vice president, succeeding Charles L. read by the secret a ry, and accepted. Treasurer Betts. Robert Gary, of Stevens Point, Wisconsin , was George Ward passed out copies of the treasurer's chosen to succeed George B . P. Ward Jr. , as treasurer. r eport, which was accepted. To facilitate the transfer Gary took office immediately, as Ward submitted his of the treasurer's records, George Ward resigned and resignation effective October 8th , in order to effect Bob Gary took over as treasurer at the meeting an orderly tra nsition of the society's accounts. -

Vehicle Make, Vehicle Model

V8, V9 VEHICLE MAKE, VEHICLE MODEL Format: VEHICLE MAKE – 2 numeric VEHICLE MODEL – 3 numeric Element Values: MAKE: Blanks 01-03, 06-10, 12-14, 18-25, 29-65, 69-77, 80-89, 90-94, 98-99 MODEL: Blanks 001-999 Remarks: SEE REMARKS UNDER VEHICLE IDENTIFICATION NUMBER – V12 2009 181 ALPHABETICAL LISTING OF MAKES FARS MAKE MAKE/ NCIC FARS MAKE MAKE/ NCIC MAKE MODEL CODE* MAKE MODEL CODE* CODE TABLE CODE TABLE PAGE # PAGE # 54 Acura 187 (ACUR) 71 Ducati 253 (DUCA) 31 Alfa Romeo 187 (ALFA) 10 Eagle 205 (EGIL) 03 AM General 188 (AMGN) 91 Eagle Coach 267 01 American Motors 189 (AMER) 29-398 Excaliber 250 (EXCL) 69-031 Aston Martin 250 (ASTO) 69-035 Ferrari 251 (FERR) 32 Audi 190 (AUDI) 36 Fiat 205 (FIAT) 33 Austin/Austin 191 (AUST) 12 Ford 206 (FORD) Healey 82 Freightliner 259 (FRHT) 29-001 Avanti 250 (AVTI) 83 FWD 260 (FWD) 98-802 Auto-Union-DKW 269 (AUTU) 69-398 Gazelle 252 (GZL) 69-042 Bentley 251 (BENT) 92 Gillig 268 69-052 Bertone 251 (BERO) 23 GMC 210 (GMC) 90 Bluebird 267 (BLUI) 25 Grumman 212 (GRUM) 34 BMW 191 (BMW) 72 Harley- 253 (HD) 69-032 Bricklin 250 (BRIC) Davidson 80 Brockway 257 (BROC) 69-036 Hillman 251 (HILL) 70 BSA 253 (BSA) 98-806 Hino 270 (HINO) 18 Buick 193 (BUIC) 37 Honda 213 (HOND) 19 Cadillac 194 (CADI) 29-398 Hudson 250 (HUDS) 98-903 Carpenter 270 55 Hyundai 215 (HYUN) 29-002 Checker 250 (CHEC) 08 Imperial 216 (CHRY) 20 Chevrolet 195 (CHEV) 58 Infiniti 216 (INFI) 06 Chrysler 199 (CHRY) 84 International 261 (INTL) 69-033 Citroen 250 (CITR) Harvester 98-904 Collins Bus 270 38 Isuzu 217 (ISU ) 64 Daewoo 201 (DAEW) 88 Iveco/Magirus -

Lincoln and Continental Owners Club -Sponsoring the Western National

Lincoln and Continental Owners Club Sponsoring the Western National Meet New Mexico Region Hosting Albuquerque, New Mexico October 17 - 21, 2018 Theme: “October in the High Desert, Atoms, Balloons and Cars” Schedule of Events Wednesday, October 17, 2018 12 Noon till 6 PM Registration Desk and Hospitality Room open 1 PM Mechanical Judging begins 6 PM till 9 PM Early Bird Welcome Thursday, October 18, 2018 8 AM till 6 PM Registration Desk /Hospitality Room open 8 AM Mechanical Judging 10 AM to 2:30 PM Driving Tour to National Museum of Nuclear Science and History And Lunch at Sandrago’s Gill and Trip on Sandia Park Tramway Transports 3 PM Balance of afternoon for shopping and antiquing, Thursday night on your own Friday, October 19, 2018 8 AM till 6 PM Registration Desk /Hospitality Room open 8 AM Mechanical Judging 9:30 AM till 3:30 PM Driving tour to Anderson, and Abruzzo Albuquerque International Balloon Museum and lunch/ 6 PM till 7 PM Cocktail hour (cash bar) 7 PM till 9:30 PM Mexican Buffet and Lincoln parts and memorabilia auction Saturday, October 20, 2018 7:30 AM Judges Breakfast and Judges Meeting 8 AM till 9:30 AM Final Registration 8 AM to 10 AM Final Mechanical Judging (For those who arrived Friday night or Saturday Morning 8 AM till 10 AM Lincoln Car Show parking adjacent to the hotel 10 AM till 3 PM Lincoln Car Show (Do not leave until cars are released by the Chief Judge) 12 PM to 1 PM Lunch on your own 4 PM LCOC Membership Meeting 6 PM till 7 PM Happy Hour (cash bar) 7 PM till 10 PM Awards Banquet Sunday, October 21, 2018 9 AM Photos of cars by John Walcek 2018 MID AMERICA NATIONAL MEET FREQUENTLY ASKED QUESTIONS Please read carefully Q: Do I have to participate in all activities? A: No, it is okay to pick and choose the activities in which you wish to participate. -

![The American Legion Weekly [Volume 5, No. 17 (April 27, 1923)]](https://docslib.b-cdn.net/cover/1050/the-american-legion-weekly-volume-5-no-17-april-27-1923-2121050.webp)

The American Legion Weekly [Volume 5, No. 17 (April 27, 1923)]

IS YOUR POST ON THE LIST ?—see pages 10c. a Copy APRIL 27, 1923 Vol. 5, No. 17 MAKERS OF AMERICA HI. THE PILGRIM ;;, — ;; ; AMERICAN LEGION DIRECTORY FOR 1923 NATIONAL OFFICERS Alvin Owsley, Denton, Texas, National Commander Edward J. Barrett, Sheboygan, Wis., Nail. Vice-Comdr. Lemuel Bolles, Seattle, Wash., Natl. Adjutant Dr. Robert 0. Blood, Concord. N. H., Natl. Vice-Conidr. Robert H. Tyndall, Indianapolis, Ind., Natl. Treasurer E. Erle Cocke, Macon, Ga., Nail. Vice-Comdr. Rev. William B. O'Connor, Cincinnati, O., Natl. Chaplain Watson B. Miller, Washington, D. C, Nail. Vice-Comdr. Eben Putnam, Wellesley Farms, Mass., Natl. Historian Chiles P. Pltjmmer, Casper, Wyo., Natl. Vice-Comdr. Robert A. Adams, Indianapolis, Ind., Natl. Judge Advocate Milton J. Foreman, Chicago. 111., Past Natl. Comdr. Franklin D'Olier, Philadelphia, Pa., Past Natl. Comdr. Henry D. Lindsley, Dallas, Tex.. Past Natl' Comdr. John G. Emery, Grand Rapids, Mich., Past Natl. Comdr. Hanford MacNider, Mason City, la-, Past Natl. Comdr. NOTE : National Officers may be addressed at National Headquarters, American Legion, Indianapolis, Indiana.^ Department Officers may be addressed at their Department Head- quarters, care of the Department Adjutant, whose address is in each instance given below. DEPARTMENT OFFICERS Alabama—Comdr., Robert E. Steiner, Mont- Louisiana—Comdr., Michel Provosty, 721 Ca- North Carolina—Comdr., James A. Lockhart, gomery ; Adjt.. James T. Laurie, 303 S. rondelet bldg., New Orleans ; Adjt., A. R. Denny, Greens- Charlotte ; Adjt., Robert E. Lawrence st., Montgomery ; Ex. Comm., Wal- Christovich, Royal and Conti sts.. New Or- boro ; Ex. Comm., Cale K. Burgess, Raleigh. ter E. Bare, Birmingham. igins ; Ex.