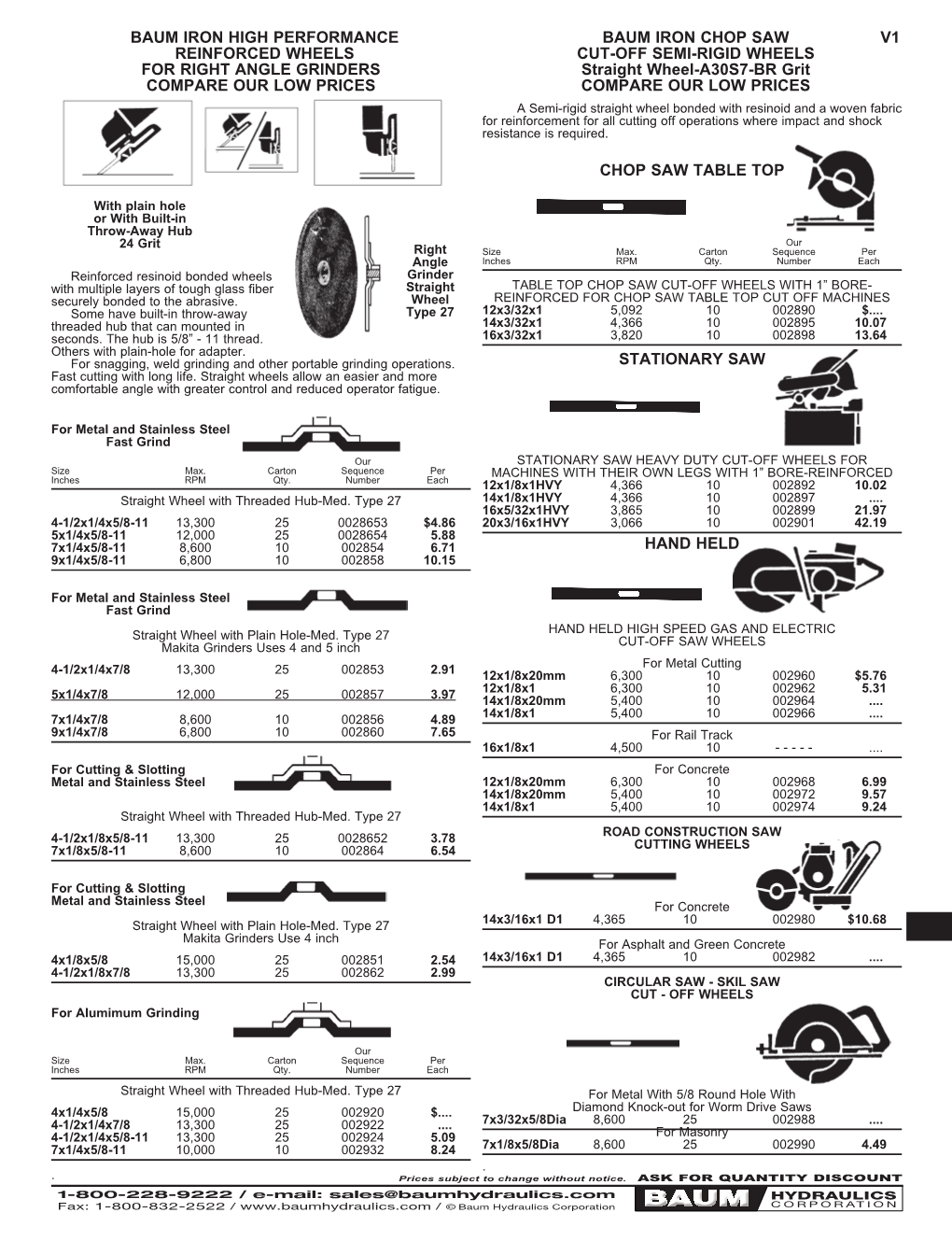

Baum Iron High Performance Reinforced Wheels For

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

The Vernacular in Church Architecture

Le Corbusier’s pilgrimage chapel at Ronchamp, France. Photo: Groucho / CC BY-NC-ND 2.0 / https://www.flickr. com/photos/grou- cho/13556662883 LIVING STONES The Vernacular in Church Architecture Alexis Vinogradov 1 Gregory Dix, The The liturgy of the Early Christian era the heart of worship that is ultimately Shape of the Lit- was about doing rather than saying. to be expressed and enhanced by both urgy (Westminster: Dacre Press, 1945), This distinction is borrowed from Dom art and architecture. Of course this con- 12–15. Kiprian Kern, Gregory Dix by Fr. Kyprian Kern, who sideration must include literature, mu- Евхаристия (Paris: was responsible for the first major Or- sic, and ritual movement and gesture. YMCA-Press, 1947). thodox investigation of the sources 2 and practices of the Christian eccle- Our earliest archaeological discover- Marcel Jousse, L’An- 1 thropologie du geste sia. The Jesuit scholar Marcel Jousse ies substantiate the nature of the “do- (Paris: Gallimard, reinforces this assertion in writing of ing” performed by the Church. The 2008). the early Christian practice and un- celebrants did not initially constitute derstanding of “eating and drinking” a distinct caste, for all who were gath- the word, rooted in a mimesis of ges- ered were involved in the rites. One tures passed on through generations.2 can therefore understand the emer- “Do this in remembrance of me,” says gence throughout Christian history of Christ at the last gathering with his anti-clerical movements, which have disciples (Lk. 22:19). pushed back against the progressive exclusion of the faithful from areas The present essay is about the ver- deemed “sacred” in relation to the nacular in church architecture. -

The History of the Wheel and Bicycles

NOW & THE FUTURE THE HISTORY OF THE WHEEL AND BICYCLES COMPILED BY HOWIE BAUM OUT OF THE 3 BEST INVENTIONS IN HISTORY, ONE OF THEM IS THE WHEEL !! Evidence indicates the wheel was created to serve as potter's wheels around 4300 – 4000 BCE in Mesopotamia. This was 300 years before they were used for chariots. (Jim Vecchi / Corbis) METHODS TO MOVE HEAVY OBJECTS BEFORE THE WHEEL WAS INVENTED Heavy objects could be moved easier if something round, like a log was placed under it and the object rolled over it. The Sledge Logs or sticks were placed under an object and used to drag the heavy object, like a sled and a wedge put together. Log Roller Later, humans thought to use the round logs and a sledge together. Humans used several logs or rollers in a row, dragging the sledge over one roller to the next. Inventing a Primitive Axle With time, the sledges started to wear grooves into the rollers and humans noticed that the grooved rollers actually worked better, carrying the object further. The log roller was becoming a wheel, humans cut away the wood between the two inner grooves to create what is called an axle. THE ANCIENT GREEKS INVENTED WESTERN PHILOSOPHY…AND THE WHEELBARROW CHINA FOLLOWED 400 YEARS AFTERWARDS The wheelbarrow first appeared in Greece, between the 6th and 4th centuries BCE. It was found in China 400 years later and then ended up in medieval Europe. Although wheelbarrows were expensive to purchase, they could pay for themselves in just 3 or 4 days in terms of labor savings. -

Prehistoric Innovations: Wheels and Wheeled Vehicles

PREHISTORIC INNOVATIONS: WHEELS AND WHEELED VEHICLES MÁRIA BONDÁR Hungarian Academy of Sciences, Research Centre for the Humanities, Institute of Archaeology 4, Tóth Kálmán Str, H-1097 Budapest, Hungary [email protected] Abstract: Two of the most significant innovations of the fourth millennium BC were the invention of the wheel and of wheeled vehicles, which led to other major innovations during the Late Copper Age. Discussed here are the major milestones and advances in research on wheeled vehicles, problems of dating, and the issues relating to the actual place of the invention of wheeled vehicles as well as the fruitful collaboration between various analytical disciplines and archaeology concerned with the study of wheels and early wheeled vehicles. I have collected the finds relating to wheels and wheeled vehicles. It would appear that the invention of the wheel and of wheeled conveyances occurred in different centres. Even though we are unable to date the creation of the very first vehicle to the year, it seems quite certain that wheeled vehicles appeared more or less simultaneously in several regions in the fourth millennium BC. Keywords: Late Copper Age, innovations, early wheels, wheeled vehicles 1. INTRODUCTION1 Today, we tend to associate innovations with the industrial inventions of the twenty-first century that have radically transformed our lives. The new advances in nanotechnology, robotics, genomics and information technol - ogy have become part of our daily lives. However, these could hardly have come about without the knowledge and skills accumulated during the previous millennia. Illiterate prehistoric societies can be credited with countless inventions that continue to determine our lives today, in the space age. -

Identifying Simple Machines

Name: _______________________________________ Simple Machines The six types of simple machines are: • inclined plane • lever • wedge • pulley • screw • wheel and axle 1. An ax is used to chop wood. The metal part chops through the wood, pushing it apart into two smaller sections. Which simple machine is found on the head of this ax? ______________________________ 2. The center of this seesaw is used to balance the board with the seats. The children can easily move up and down without much force. The seesaw is an example of which simple machine? ______________________________ 3. The cap on this water bottle has a spiral shape. When you place it on the bottle and twist, the cap pulls itself toward the bottle. The bottle cap is an example of which simple machine? ______________________________ Super Teacher Worksheets - www.superteacherworksheets.com 4. When you turn the large knob on a door, a rod on the inside releases a latch that holds the door closed. It would be difficult to turn the rod, if the knob wasn't attached to it. The door knob and rod make up which simple machine? _____________________________ 5. A wheel with a rope is used to hoist a flag up to the top of a tall flagpole. This simple machine can also be used to help lift heavy objects with less force. The wheel and rope make up which simple machine? ______________________________ 6. A ramp is used for loading this truck. A mover can pull a cart with a heavy object up the ramp. This is much easier than lifting heavy objects into the truck. -

Old Europe Meets the Indo-Europeans Indo-European Languages Shared IE Words Proto-Indoeuropean (PIE) Characteristics

Indo-European Languages Old Europe Meets the Indo-Europeans Spoken today from Europe to India. Alan R. Rogers Examples: Latin, Greek, German, English, Celtic, Armenian, Russian, Sanskrit March 14, 2018 1 / 30 2 / 30 Shared IE Words Inherited from PIE. These shared words tell us something about the PIE homeland. I Numbers I Body parts: heart, hand, foot I Oak, beech, wolf, bear, salmon I Snow I Relatives 3 / 30 4 / 30 Proto-IndoEuropean (PIE) Characteristics I Milk words I Horses, sheep, cattle, pigs, goats, grain I Copper, maybe bronze, not iron I Carts, weaving, mead I Patrilineal clans, raiding, war, revenge I Young male warriors, wolf totem Wheel/Horse area overlap at 5k ago shaded in blue. 5 / 30 6 / 30 PIE Characteristics, continued Gods I Deus, Zeus, Jupiter (Zeu Pater), Duanz Pita, Indra I Three classes: warriors, clergy, farmers I Jove, Sius, Deva I Epic poetry: Rig Veda, Iliad I Thor, Perjanya I “driving cattle,” “undying fame,” “immortal gods” I Hestia, Vesta I slay a dragon I Aphrodite, Venus, Freya, Lakshmi I Various twins 7 / 30 8 / 30 PIE were not technologically advanced Anatolian Hypothesis: Colin Renfrew Sumerians had I wheel IndoEuropean originated in I writing Anatolia (Turkey). I arithmetic I cities Spread north with the early Neolithic, 7 kya I irrigation PIE had domesticated the horse. 9 / 30 10 / 30 Kurgan Hypothesis: Marija Gimbutas Old Europe: 6500–2800 BC IndoEuropean originated in Pontic Steppes (Ukraine) Spread West, East, and South in Bronze Age, 5 kya It now seems clear that Gimbutas was right; Renfrew wrong. 11 / 30 12 / 30 Old Europe Varna Cemetery, Farming Bulgaria Gold, copper 4900–4400 BC Dispersed settlements little Lots of gold ⇒ warfare. -

Prehistoric Britain

Prehistoric Britain Plated disc brooch Kent, England Late 6th or early 7th century AD Bronze boars from the Hounslow Hoard 1st century BC-1st century AD Hounslow, Middlesex, England Visit resource for teachers Key Stage 2 Prehistoric Britain Contents Before your visit Background information Resources Gallery information Preliminary activities During your visit Gallery activities: introduction for teachers Gallery activities: briefings for adult helpers Gallery activity: Neolithic mystery objects Gallery activity: Looking good in the Neolithic Gallery activity: Neolithic farmers Gallery activity: Bronze Age pot Gallery activity: Iron Age design Gallery activity: An Iron Age hoard After your visit Follow-up activities Prehistoric Britain Before your visit Prehistoric Britain Before your visit Background information Prehistoric Britain Archaeologists and historians use the term ‘Prehistory’ to refer to a time in a people’s history before they used a written language. In Britain the term Prehistory refers to the period before Britain became part of the Roman empire in AD 43. The prehistoric period in Britain lasted for hundreds of thousands of years and this long period of time is usually divided into: Palaeolithic, Mesolithic, Neolithic (sometimes these three periods are combined and called the Stone Age), Bronze Age and Iron Age. Each of these periods might also be sub-divided into early, middle and late. The Palaeolithic is often divided into lower, middle and upper. Early Britain British Isles: Humans probably first arrived in Britain around 800,000 BC. These early inhabitants had to cope with extreme environmental changes and they left Britain at least seven times when conditions became too bad. -

History and Technology

This article was downloaded by:[Forman, Paul] [Forman, Paul] On: 23 April 2007 Access Details: [subscription number 777307305] Publisher: Routledge Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK History and Technology An International Journal Publication details, including instructions for authors and subscription information: http://www.informaworld.com/smpp/title~content=t713643058 The Primacy of Science in Modernity, of Technology in Postmodernity, and of Ideology in the History of Technology To cite this Article: , 'The Primacy of Science in Modernity, of Technology in Postmodernity, and of Ideology in the History of Technology', History and Technology, 23:1, 1 - 152 To link to this article: DOI: 10.1080/07341510601092191 URL: http://dx.doi.org/10.1080/07341510601092191 PLEASE SCROLL DOWN FOR ARTICLE Full terms and conditions of use: http://www.informaworld.com/terms-and-conditions-of-access.pdf This article maybe used for research, teaching and private study purposes. Any substantial or systematic reproduction, re-distribution, re-selling, loan or sub-licensing, systematic supply or distribution in any form to anyone is expressly forbidden. The publisher does not give any warranty express or implied or make any representation that the contents will be complete or accurate or up to date. The accuracy of any instructions, formulae and drug doses should be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims, proceedings, demand or costs or damages whatsoever or howsoever caused arising directly or indirectly in connection with or arising out of the use of this material. -

Technology Bulletin a Publication of Consolidated Metco, Inc

November 1, 2017 Technology Bulletin A Publication of Consolidated Metco, Inc. Wheel End Load Ratings for Hubs Used in Single Wheel Applications PURPOSE: Single wheels impose different loading conditions on the hub, bearings, and axles when compared to dual wheels. As a result, the hub load ratings change according to wheel offset. This bulletin details hub load ratings for trailer hubs (SAE N and P type) and drive hubs (SAE R type) with single wheel offsets ranging from 0” to 7”. This bulletin is valid for hubs used on drive, trailer, pusher and tag axles for both drum brakes and disc brakes. Wheel offset is a term referring to the geometry of the wheel; it can be mounted to the hub either outset or inset. Both outset and inset are calculated as the distance from the centerline of the wheel to the wheel mounting surface. The wheel is outset when the centerline of the wheel is outboard of the wheel mounting surface. The wheel is inset when the centerline of the wheel is inboard of the wheel mounting surface. The wheel centerline is depicted by the dashed line in the illustration shown below. The hub load ratings listed in Tables 1 and 2 are tabulated for single wheels mounted both inset and outset. MEASURING WHEEL OUTSET AND INSET (Refer to following figure): Most wheel manufacturers will publish the inset or outset of their wheels by part number. If the part number or manufacturer is unknown, perform the following measurements and calculation to make a determination. For dual wheels, the effective outset is the flange thickness of one wheel. -

Alcoa Wheel Service Manual

HEAVY DUTY TRUCK WWHEELHEEL SSERVICEERVICE | TRAILER | BUS | MMANUALANUAL MOTOR HOME IIMPORTANTMPORTANT SAFETYSAFETY PRECAUTIONSPRECAUTIONS FORFOR TRUCKTRUCK RIMSRIMS ANDAND WHEELSWHEELS JANUARY 2012 SUPERSEDES APRIL 2011 IMPORTANT: Federal OSHA Regulations require all employers to make sure their employees who service rims/wheels understand the safety information contained in this manual. Do not let your employees service rims/wheels unless they are thoroughly trained and completely understand this safety information. If you are a service technician do not service rims/wheels unless you are thoroughly trained and completely understand this safety information. 01 AALC_ServiceManual2012_rem.inddLC_ServiceManual2012_rem.indd 0011 11/28/12/28/12 77:06:06 AAMM WARNING Wheels that are not properly ALCOA installed or maintained may not be safe. Failure to follow proper wheel installation or LIMITED WARRANTY maintenance practices may result in injury or FOR HEAVY DUTY TRUCKS, TRUCK TRAILERS, WARNING death. BUSES, RV and MOTORHOME WHEELS Follow the proper wheel installation and maintenance practices as contained in this Alcoa Service This limited warranty applies to Alcoa forged aluminum wheels with bead seat H diameters measured in .5 inch increments ("Wheels") and the surface of rim flange Manual. For additional copies of the manual and other useful treatments applied to the Wheels. "Transit Wheels" means Wheels used on transit items listed below, available free of charge, or for the most t vehicles, such as buses and vans, whose primary purpose is to transport people. recent updates, contact Alcoa Wheel and Transportation Products at 1-800-242-9898 or on the web at Alcoa warrants to the original purchaser, from Alcoa or its authorized distributor, that www.alcoawheels.com. -

WTC Aftermarket Wheel Installation Guidelines

Aftermarket Wheel Installation Guidelines DISCLAIMER: It is the installer’s responsibility to correctly TIRES WHEEL INSTALLATION WARNING install wheels and related accessories. The information 4. Do not allow a lug nut to bottom out on the stud or contained in these Guidelines is believed to be reliable, but WARNING 1. Clean and inspect all stud threads and mounting many factors can lead to installation concerns. The installer a shank or lug bolt to bottom out on the mounting surfaces before installation. Threads must not surface. This is extremely dangerous and unsafe must review all available manufacturer information, test fit WHEELS AND TIRES ARE MARKED WITH THEIR be lubricated, and must be free of corrosion, each wheel before mounting tires to ensure clearance with because the clamping force of the fastener is not SIZES. THE WHEEL AND TIRE MUST MATCH rust, burrs, fractures and damage. Replace if any suspension and braking components, and check all load being applied to the wheel. Check for these problems BEFORE MOUNTING. corrosion, stripping, damage, or fractures are ratings, offsets and clearance before installation. Neither on every stud, some may be different lengths. IF YOU 1. Mount all tires according to the wheel fitment and found. Always use new fasteners (lug nuts or lug SEMA, WTC nor their affiliates are responsible for installation FIND A PROBLEM; DO NOT INSTALL WHEELS. the tire and rim manufacturer book. There are bolts) when installing new wheels. errors or the information compiled for these Guidelines. several brands and types of tire mounting equipment 2. Be certain the fasteners are correct for the available for mounting tires on aftermarket wheels, application. -

Graham Engineering Rotary Wheel Blow Molding Machines

Rotary wheel technology blow molding machines GRAHAM ROTARY wheel systems installed • In-mold labeling The MINI™ Wheel is Graham’s WHEEL BLOW since 1968 on four continents. • View stripe latest breakthrough. It is MOLDING SYSTEMS Graham rotary machines • Aseptic blow molding intended for mid-sized blow process virtually any • Systems for bottles as small molders and emerging Worldwide, only one name is thermoplastic. as 60-110 ml markets. It is small enough synonymous with the mass • Systems for bottles as large to ship in a standard freight production of superior quality Graham wheel machines offer as 30 liters container, but can produce plastic bottles on rotary maximum flexibility for the • Turnkey engineering and coextruded plastic containers extrusion blow molding delivery of ideal packaging installation (up to seven layers) of machinery. That name is solutions. • Other key advantages include exceptional repeatable quality. Graham Engineering • Single and multi-cavity molds bottle lightweighting, Corporation. • Monolayer structures and unsurpassed energy Our equipment coextrusion up to seven layers efficiency, and labor savings. conforms to all national and Our rotary wheel blow molding international safety and equipment is the result of operating standards with ANSI advanced technology developed certification and CE capability. and refined on hundreds of Our sales and service professionals work closely with customers to identify and install optimal production machinery solutions and to provide responsive 24-hour support for reliable, consistent production line performance. THE TECHNOLOGY KEY OF CHOICE ADVANTAGES Graham Engineering’s wheel • Graham’s proprietary parison systems are used extensively programming requires only for the production of HDPE a small, simple hydraulic and PP extrusion blow molded system containers. -

Re-Theorising Mobility and the Formation of Culture and Language Among the Corded Ware Culture in Europe Kristian Kristiansen1,∗, Morten E

Re-theorising mobility and the formation of culture and language among the Corded Ware Culture in Europe Kristian Kristiansen1,∗, Morten E. Allentoft2, Karin M. Frei3, Rune Iversen4, Niels N. Johannsen5, Guus Kroonen6, Łukasz Pospieszny7, T. Douglas Price8, Simon Rasmussen9, Karl-Göran Sjögren1, Martin Sikora2 & Eske Willerslev2,10,11 Recent genetic, isotopic and linguistic research has dramatically changed our understanding of how the Corded Ware Culture in Europe was formed. Here the authors explain it in terms of local adaptations and interactions between migrant Yamnaya people from the Pontic-Caspian steppe and indigenous North European Neolithic cultures. The original herding economy of the Yamnaya migrants gradually gave way to new practices of crop cultivation, which led to the adoption of new words for those crops. The result of this hybridisation process was the formation of a new material culture, the Corded Ware Culture, and of a new dialect, Proto-Germanic. Despite a degree of hostility between expanding Corded Ware groups and indigenous Neolithic groups, stable isotope data suggest that exogamy provided a mechanism facilitating their integration. This article should be read in conjunction with that by Heyd (2017, in this issue). 1 Department of Historical Studies, University of Gothenburg, SE Box 200, 405 30 Gothenburg, Sweden 2 Centre for GeoGenetics, Natural History Museum of Denmark, University of Copenhagen, Øster Voldgade 5–7, 1350 Copenhagen K, Denmark 3 Environmental Archaeology and Materials Science, The National Museum of Denmark, I.C. Modewegsvej, Brede, 2800 Kongens Lyngby, Denmark 4 The Saxo Institute, University of Copenhagen, Karen Blixens Plads 8, 2300 Copenhagen S, Denmark 5 Department of Archaeology, Aarhus University, Moesgård Allé 20, 8270 Højbjerg, Denmark 6 Department of Nordic Studies and Linguistics, University of Copenhagen, Njalsgade 120, 2300 Copenhagen S, Denmark 7 Institute of Archaeology and Ethnology, Polish Academy of Sciences, ul.