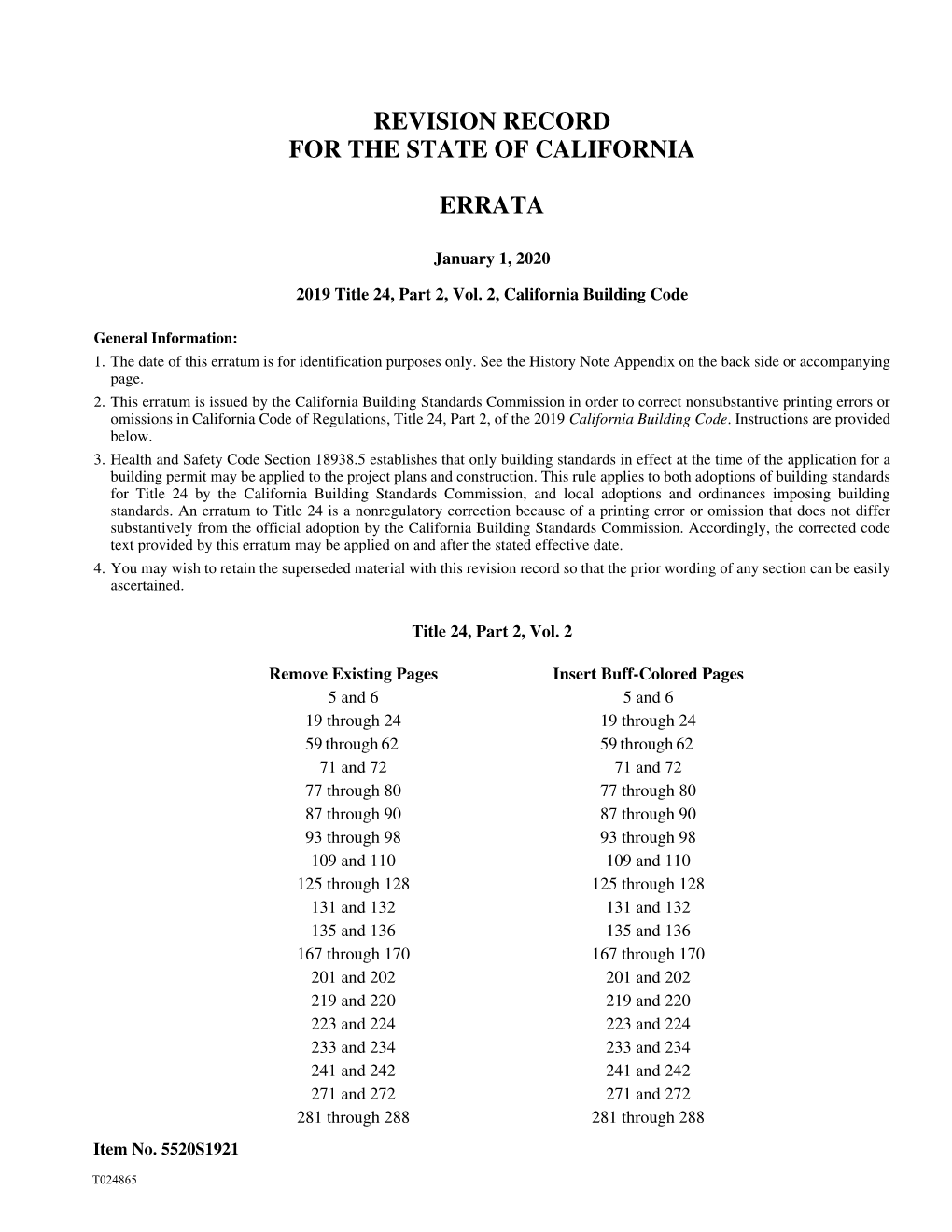

Revision Record for the State of California Errata

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

98 of 127 DOCUMENTS Administrative Code of the City Of

Page 459 98 of 127 DOCUMENTS Administrative Code of the City of New York Copyright 2010 New York Legal Publishing Corporation a New York corporation, All Rights Reserved ***** Current through December 2009 **** NYC Administrative Code SECTION BC 909 Administrative Code of the City of New York Title 28 New York City Construction Codes CHAPTER 7 THE NEW YORK CITY BUILDING CODE*1 CHAPTER 9 FIRE PROTECTION SYSTEMS SECTION BC 909 SMOKE CONTROL SYSTEMS 909.1 Scope and purpose. This section applies to mechanical or passive smoke control systems when they are required by other provisions of this code. The purpose of this section is to establish minimum requirements for the design, installation and acceptance testing of smoke control systems that are intended to provide a tenable environment for the evacuation or relocation of occupants. These provisions are not intended for the preservation of contents, the timely restoration of operations or for assistance in fire suppression. Smoke control systems regulated by this section serve a different purpose than the smoke- and heat-venting provisions found in Section 910. Mechanical smoke control systems shall not be considered exhaust systems under Chapter 5 of the New York City Mechanical Code. 909.1.1 Definitions. These definitions are added for the purposes of Section 909 only. POST-FIRE SMOKE PURGE SYSTEM. A mechanical or natural ventilation system intended to move smoke from the smoke zone to the exterior of the building. PRESSURIZATION. Creation and maintenance of pressure levels in zones of a building, including elevator Page 460 shafts and stairwells, that are higher than the pressure level at the smoke source, such pressure levels being produced by positive pressures of a supply of uncontaminated air; by exhausting air and smoke at the smoke source; or by a combination of these methods. -

Seismic Fragility Assessment of Lng Pipe Rack Accounting for Soil-Structure Interaction

Luigi Di Sarno and George Karagiannakis COMPDYN 2019 7th ECCOMAS Thematic Conference on Computational Methods in Structural Dynamics and Earthquake Engineering M. Papadrakakis, M. Fragiadakis (eds.) Crete, Greece, 24–26 June 2019 SEISMIC FRAGILITY ASSESSMENT OF LNG PIPE RACK ACCOUNTING FOR SOIL-STRUCTURE INTERACTION Luigi Di Sarno1,2,*, George Karagiannakis1 1 University of Sannio Piazza Roma, 21, 82100 Benevento, Italy [email protected] [email protected] 2 University of Liverpool, Liverpool L69 3BX, UK [email protected] Abstract The increasing momentum for Natural Gas exploitation in Europe and worldwide constitutes Liquified Gas terminals indispensable links of energy supply network. Infrastructures of this kind should be resilient against the earthquake hazard and thus designed accounting for as much as possible sources of uncertainty such as modelling issues, analysis methods, seismic input selection, soil effects and others. To date, research efforts have not assessed the response of pipe racks sufficiently, let alone the interaction between the rack and piping system and analysis methods of the past have proved to be neither adequate nor efficient towards evaluat- ing the earthquake hazard potentiality. Further, soil-structure-interaction has not been incor- porated into a fragility analysis framework; albeit it is considered as a critical parameter since midstream and downstream facilities are usually rested on alluvial deposits. In the present work, a supporting RC rack is analysed through a 3D finite element model in the nonlinear regime both as coupled and decoupled vis-à-vis a piping system. The fragility func- tions are evaluated for structural components and limit states in the global and meso-scale, through the Incremental Dynamic Analysis (IDA) considering far-field conditions. -

Nonbuilding Structures

NONBUILDING STRUCTURES Instructional Material Complementing FEMA 451, Design Examples Non-Building Systems 15-8 1 This unit is only a brief introduction to the subject of earthquake resistant design of nonbuilding structures. It has been developed by Jim Harris from two primary sources: the content of the NEHRP Recommended Provisions for Seismic Regulations for New Buildings and Other Structures and two slide collections of the Earthquake Engineering Research Institute: the “Annotated Slide Collection” and the “EERI Northridge Earthquake of January 1994 Collection.” The images here are all taken from the 1994 Northridge event: failed transformers in an electric power distribution substation (Sylmar), fire and flood from breaks in buried gas and water mains (Balboa Blvd, Granada Hills), and demolition of damaged highway interchange structures (Gavin Canyon undercrossing, Interstate 5). Advanced Earthquake Topic 15 - 8 Slide 1 Nonbuilding Structures Same: Different: • Basic ground •Structural motion hazards characteristics • Basic structural • Fault rupture dynamics • Fluid dynamics • Performance objectives • Networked systems Instructional Material Complementing FEMA 451, Design Examples Non-Building Systems 15-8 2 There are many issues with nonbuilding structures that are not considered in earthquake engineering for buildings Advanced Earthquake Topic 15 - 8 Slide 2 Dams with Damage Instructional Material Complementing FEMA 451, Design Examples Non-Building Systems 15-8 3 Left: San Fernando EQ (1971); partial failure of upstream face -

Construction, Industrial Nonbuilding Structure Construction

Industrial Nonbuilding Structure Construction 1997 Issued January 2000 EC97C-2349C 1997 Economic Census Construction Industry Series U.S. Department of Commerce Economics and Statistics Administration U.S. CENSUS BUREAU ACKNOWLEDGMENTS Many persons participated in the various The Economic Product Team, with primary activities of the 1997 Economic Census for contributions from Christina Arledge, the Construction sector. The Economic Andrew W. Hait, Barbara L. Lambert, Census Staff of the Economic Planning and and Jennifer E. Lins, was responsible for Coordination Division did the overall plan- the development of the product creation ning and review of the census operations. system to support the 1997 Economic Census product dissemination. Manufacturing and Construction Division prepared this report. Judy M. Dodds, The Geography Division staff developed Assistant Chief for Census and Related geographic coding procedures and associ- Programs, was responsible for the overall ated computer programs. planning, management, and coordination. The Economic Statistical Methods and Pro- Patricia L. Horning, Chief, Construction gramming Division, Charles P. Pautler and Minerals Branch, assisted by Susan L. Jr., Chief, developed and coordinated the Hostetter, Section Chief, performed the computer processing systems. Martin S. planning and implementation. Carla M. Harahush, Assistant Chief for Quinquen- Bailey, Michael A. Blake, Tamara A. nial Programs, was responsible for design Cole, Nina S. Heggs, Donald G. and implementation of the computer Powers, Linda M. Taylor, and Robert A. systems. Samuel Rozenel, Chief, Current Wright provided primary staff assistance. Construction Branch, Kevin J. Brian Greenberg, Assistant Chief for Montgomery and Leonard S. Research and Methodology Programs, Sammarco, Section Chiefs, supervised the assisted by Stacey Cole, Chief of Manu- preparation of the computer programs. -

IAC Ch 23, P.1 871—23.82(96) Definition of Construction Employer

IAC Ch 23, p.1 871—23.82(96) Definition of construction employer. 23.82(1) Construction. The department will utilize the North America Industry Classification System manual (2002 edition) to determine which employers will be classified as construction. The manual may be purchased through Bernan Press, 4611F Assembly Drive, Landham, MD 20706-4391, and is available on the Internet at http://www.ntis.gov/naics. a. The construction sector is comprised of establishments primarily engaged in the construction of buildings and other structures, heavy construction (except buildings), additions, alterations, reconstruction, installation, and maintenance and repairs. Establishments engaged in demolition or wrecking of buildings and other structures, clearing of building sites, and sale of materials from demolished structures are also included. This sector also includes those establishments engaged in blasting, test drilling, landfill, leveling, earthmoving, excavating, land drainage, and other land preparation. The industries within this sector have been defined on the basis of their unique production processes. As with all industries, the production processes are distinguished by their use of specialized human resources and specialized physical capital. Construction activities are generally administered or managed at a relatively fixed place of business, but the actual construction work is performed at one or more different project sites. Employers that provide workers primarily for construction will be classified as construction employers. b. This sector is divided into three subsectors of construction activities: (1) building construction and land subdivision and land development; (2) heavy construction (except buildings), such as highways, power plants, and pipelines; and (3) construction activity by special trade contractors. c. -

FMI's Construction Outlook

2016 FMI’s Construction Outlook Third Quarter Report Table of Contents Third Quarter 2016 Construction Outlook Construction Forecast ..............................................................................................1 Residential Construction ...........................................................................................3 FMI Nonresidential Construction Forecast ....................................................................6 Lodging ..........................................................................................................6 Office ............................................................................................................. 7 Commercial .....................................................................................................8 Health Care .....................................................................................................9 Education ........................................................................................................10 Religious .........................................................................................................11 Public Safety ....................................................................................................12 Amusement and Recreation .................................................................................13 Transportation ..................................................................................................14 Communication .................................................................................................15 -

FEMA 177-Estimating Losses from Future Earthquakes (Panel Report

FEDERAL EMERGENCY MANAGEMENT AGENCY FEMA-177/ JUNE 1989 Estimating Losses From Future Earthquakes (Panel Report and Technical Background) A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A • A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A A EARTHQUAKE HAZARDS REDUCTION SERIES 51 Issued by FEMA in furtherance of the Decade for Natural Disaster Reduction. FEDERALEMERGENCYMANAGEMENTAGENCY Estimating Losses From Future Earthquakes (Panel Report and Technical Background) Panel on Earthquake Loss Estimation Methodology Committee on Earthquake Engineering Commission on Engineering and Technical Systems National Research Council NOTICE: The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. -

On the Seismic Fragility of Pipe Rack—Piping Systems Considering Soil–Structure Interaction

Bulletin of Earthquake Engineering https://doi.org/10.1007/s10518-020-00797-0 ORIGINAL RESEARCH On the seismic fragility of pipe rack—piping systems considering soil–structure interaction Luigi Di Sarno1,2 · George Karagiannakis1 Received: 24 May 2019 / Accepted: 29 January 2020 © The Author(s) 2020 Abstract Piping systems constitute the most vulnerable component in down- and mid-stream facili- ties posing immediate threat to human lives, communities fnancial robustness and environ- ment. Pipe racks present several mechanical and geometrical idiosyncrasies compared to common buildings and the seismic response is governed by the pipework layout. Important design requirements e.g. dynamic interaction between pipelines and supporting structure are commonly overlooked during pipe racks design process and uncertainties relevant to modelling of soil or seismic input are not quantifed. In the present work, after review- ing the technical literature and codes, a 3D RC rack was used as a testbed and analysed as coupled and decoupled with a non-seismic code conforming piping system accounting for soil–structure interaction. Incremental dynamic analysis was adopted as an assessment methodology for deriving fragility curves considering ground motions in near- and far-feld conditions. It was deduced that the modelling (boundary conditions of pipes) was the most considerable uncertainty since it increased the probability of collapse limit state of struc- tural members from 0 to 59%. It was also demonstrated that soil deformability as well as source conditions altered considerably the dispersion of intensity measure conditional on engineering demand parameter of structural and nonstructural members. The results may be another indication that code provisions should be more normative regarding industrial pipe racks. -

Guide to Understanding IBC Seismic for MEP

KINETICS™ Guide to Understanding IBC Seismic for MEP TABLE OF CONTENTS Section Title D2.1 – 1.0 Introduction D2.1 – 2.0 Required Basic Project Information D2.1 – 2.1 Introduction D2.1 – 2.2 Building Use – Nature of Occupancy D2.1 – 2.3 Site Class D2.1 – 2.4 Mapped Acceleration Parameters D2.1 – 2.5 Seismic Design Category D2.1 – 2.6 Summary D2.1 – 3.0 Component Importance Factor D2.1 – 3.1 Introduction D2.1 – 3.2 Criteria for Assigning a Component Importance Factor D2.1 – 3.3 Summary D2.1 – 4.0 General Exemptions and Requirements D2.1 – 4.1 Introduction D2.1 – 4.2 Exemptions for Seismic Design Categories A and B D2.1 – 4.3 Exemptions for Seismic Design Category C D2.1 – 4.4 Exemptions for Seismic Design Categories D, E, and F D2.1 – 4.5 “Chandelier” Exemption D2.1 – 4.6 Component Size Relative to the Building Structure D2.1 – 4.7 Reference Documents D2.1 – 4.8 Allowable Stress Design D2.1 – 4.9 Submittals and Construction Documents D2.1 – 4.10 Equipment Certification for Essential Facilities D2.1 – 4.11 Consequential or Collateral Damage D2.1 – 4.12 Flexibility of Components and Their Supports and Restraints D2.1 – 4.13 Summary TABLE OF CONTENTS PAGE 1 of 3 D2.1 – 0.0 Toll Free (USA Only): 800-959-1229 RELEASED ON: 05/29/2008 International: 614-889-0480 FAX 614-889-0540 World Wide Web: www.kineticsnoise.com E-mail: [email protected] Dublin, Ohio, USA Ã Mississauga, Ontario, Canada Member KINETICS™ Guide to Understanding IBC Seismic for MEP Section Title D2.1 – 5.0 Exemptions for Piping Systems D2.1 – 5.1 Introduction D2.1 – 5.2 -

Is It a Nonstructural Component Or a Nonbuilding Structure? by Robert Bachman, S.E., and Susan Dowty, S.E

Is It a Nonstructural Component or a Nonbuilding Structure? By Robert Bachman, S.E., and Susan Dowty, S.E. This article provides guidance to code users on how to determine whether or not an item should be treated as a nonstructural component or a nonbuilding structure for purposes of seismic design. In order to explain the differences ® between nonstructural components and nonbuilding struc- tures, many generalizations need to be made so that the discussion can be simplified as much as possible. Common sense also needs to be exercised, as these generalizations don’t always apply. Also, it should be noted, that the guid- ance provided herein represents only the collective opinion of the authors at this point in time. It is hoped that as the nonstructural component and nonbuilding structure code Figure 1: Nonbuilding Structure Similar to Building. provisions evolve, some of these guidelines will become ob- solete as the code will directly address theseCopyright issues. Nonstructural Components Traditionally, nonstructural components system similar to build- have been identified as architectural, me- ings and the other type chanical and electrical components found has a structural system in buildings. Prior to adoption of the that is not similar to International Building Code (IBC), the buildings (Figures 1 and focus had been on the design of anchor- 2). The focus of this age and bracing of these components article is on nonbuild- and not the components themselves. The ing structures which are Figure 2: Nonbuilding Structure Not Similar to Building. components themselves had been treated not similar to build- as a “black box” and whatever was inside ings, and the determination of when “big” now need to be described in a more the “black box” was not required to be the design rules of ASCE 7-05 Chapter definitive way. -

Seismic Design of Utility-Scale Wind Farm Towers in the Americas: a Comparison of Us, Mexican, and Chilean Code Requirements

16th World Conference on Earthquake Engineering, 16WCEE 2017 Santiago Chile, January 9th to 13th 2017 Paper N° 3989 Registration Code: S-601032804 SEISMIC DESIGN OF UTILITY-SCALE WIND FARM TOWERS IN THE AMERICAS: A COMPARISON OF US, MEXICAN, AND CHILEAN CODE REQUIREMENTS N. Agbayani(1), T. Taylor(2), and E. Cruz(3) (1) P.E., S.E., Principal Engineer, Agbayani Structural Engineering – Bakersfield, California, USA, [email protected] (2) P.E., Specialist - Structures, Vestas Wind Systems A/S – Portland, Oregon, USA, [email protected] (3) Ph.D., Senior Seismic Specialist, EQCO Earthquake Engineering Consultants – Santiago, Chile, [email protected] Abstract With its beginnings in Europe, the commercial utility-scale wind industry has been evolving in North America for approximately thirty years, yet only recently have there been attempts to reconcile building code requirements with industry practices for the seismic design of the wind turbine support structures, the most predominant of which is the modern fabricated tubular tower. One such attempt was a joint effort of the American Society of Civil Engineers (ASCE) and the American Wind Energy Association (AWEA) that resulted in the publication in 2011 of a tower design guideline titled “Recommended Practice for Compliance of Large Land-based Wind Turbine Support Structures,” also known as “ASCE/AWEA RP2011.” Although perhaps just a first step, RP2011 represented a milestone in the level of design maturity for wind towers and in the level of coordination with the US building code, i.e., the International Building Code (IBC) and ASCE 7. Now in recent years, utility-scale wind project development has expanded and continues to gain momentum in Central and South America. -

List of Building Types

List of building types A list of structural structure types and forms of • Hotel architecture. • Internet cafe For individual buildings, see List of buildings and struc- • tures. For other types of structures see nonbuilding struc- Market ture. • Market house • Pharmacy 1 Agricultural buildings • Skyscraper • Shop • Abbatoir • Shopping mall • Barn • Supermarket • Chicken coop or chickenhouse • Warehouse • Cow-shed • Restaurant • Farmhouse • Office • Granary, Hórreo • Greenhouse 3 Residential buildings • Hayloft • Apartment block • Pigpen or sty • Block of flats • Bungalow • Root cellar • Condominium • Shed • Dormitory • Silo • Duplex • Slaughterhouse • House - see List of house types • Stable • Townhouse • Storm cellar • Unit • Well house • Villa 2 Commercial buildings 4 Medical buildings • • Automobile repair shop Psychiatric Hospital • Hospital • Car wash • Nursing Home • Convention center • Quarantine • Drugstore • Asylum • Filling station See also: List of human habitation forms • Forum 1 2 10 RELIGIOUS BUILDINGS 5 Educational buildings 8 Military buildings • Archive • Arsenal • College • Barracks • School • Bunker • Library • Blockhouse • Museum • Citadel • Art gallery • Theater (building) 9 Parking structures and storage • Amphitheater • • Concert hall Boathouse • Cinema • Garage • Opera house • Hangar, of aircraft or spacecraft • Boarding schools • Storage silo 6 Government buildings 10 Religious buildings • City hall • Church • Consulate • Basilica • Courthouse • Cathedral • Embassy • Duomo • Fire station • Chapel • Meeting house