The Rolex Deepsea Challenge Press

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Ocean Trench

R E S O U R C E L I B R A R Y E N C Y C L O P E D I C E N T RY Ocean trench Ocean trenches are long, narrow depressions on the seafloor. These chasms are the deepest parts of the ocean—and some of the deepest natural spots on Earth. G R A D E S 5 - 12+ S U B J E C T S Earth Science, Geology, Geography, Physical Geography C O N T E N T S 11 Images, 1 Video, 2 Links For the complete encyclopedic entry with media resources, visit: http://www.nationalgeographic.org/encyclopedia/ocean-trench/ Ocean trenches are long, narrow depressions on the seafloor. These chasms are the deepest parts of the ocean—and some of the deepest natural spots on Earth. Ocean trenches are found in every ocean basin on the planet, although the deepest ocean trenches ring the Pacific as part of the so-called “Ring of Fire” that also includes active volcanoes and earthquake zones. Ocean trenches are a result of tectonic activity, which describes the movement of the Earth’s lithosphere. In particular, ocean trenches are a feature of convergent plate boundaries, where two or more tectonic plates meet. At many convergent plate boundaries, dense lithosphere melts or slides beneath less-dense lithosphere in a process called subduction, creating a trench. Ocean trenches occupy the deepest layer of the ocean, the hadalpelagic zone. The intense pressure, lack of sunlight, and frigid temperatures of the hadalpelagic zone make ocean trenches some of the most unique habitats on Earth. -

History of Scuba Diving About 500 BC: (Informa on Originally From

History of Scuba Diving nature", that would have taken advantage of this technique to sink ships and even commit murders. Some drawings, however, showed different kinds of snorkels and an air tank (to be carried on the breast) that presumably should have no external connecons. Other drawings showed a complete immersion kit, with a plunger suit which included a sort of About 500 BC: (Informaon originally from mask with a box for air. The project was so Herodotus): During a naval campaign the detailed that it included a urine collector, too. Greek Scyllis was taken aboard ship as prisoner by the Persian King Xerxes I. When Scyllis learned that Xerxes was to aack a Greek flolla, he seized a knife and jumped overboard. The Persians could not find him in the water and presumed he had drowned. Scyllis surfaced at night and made his way among all the ships in Xerxes's fleet, cung each ship loose from its moorings; he used a hollow reed as snorkel to remain unobserved. Then he swam nine miles (15 kilometers) to rejoin the Greeks off Cape Artemisium. 15th century: Leonardo da Vinci made the first known menon of air tanks in Italy: he 1772: Sieur Freminet tried to build a scuba wrote in his Atlanc Codex (Biblioteca device out of a barrel, but died from lack of Ambrosiana, Milan) that systems were used oxygen aer 20 minutes, as he merely at that me to arficially breathe under recycled the exhaled air untreated. water, but he did not explain them in detail due to what he described as "bad human 1776: David Brushnell invented the Turtle, first submarine to aack another ship. -

The Next Generation of Ocean Exploration. Kelly Walsh Repeats Father’S Historic Dive, 60 Years Later, on Father’S Day Weekend

From father to son; the next generation of ocean exploration. Kelly Walsh repeats father’s historic dive, 60 years later, on Father’s Day weekend DSSV Pressure Drop. Challenger Deep, Mariana Trench 200miles SW of Guam. June 20th, 2020 – Kelly Walsh, 52, today completed a historic dive to approximately 10,925m in the Challenger Deep. The dive location was the Western Pool, the same area that was visited by Kelly’s father, Captain Don Walsh, USN (Ret), PhD, who was the pilot of the bathyscaph ‘Trieste’ during the first dive to the Challenger Deep in 1960. Mr. Walsh’s 12- hour dive, coordinated by EYOS Expeditions, was undertaken aboard the deep-sea vehicle Triton 36000/2 ‘Limiting Factor” piloted by the owner of the vehicle Victor Vescovo, a Dallas, Texas based businessman and explorer. The expedition to the Challenger Deep is a joint venture by Caladan Oceanic, Triton Submarines and EYOS Expeditions. Mr. Vescovo and his team made headlines last year by completing a circumnavigation of the globe that enabled Mr. Vescovo to become the first person to dive to the deepest point of each of the worlds five oceans. The dives by father and son connect a circle of exploration history that spans 60 years. “It was a hugely emotional journey for me,” said Kelly Walsh aboard DSSV Pressure Drop, the expedition’s mothership. “I have been immersed in the story of Dad’s dive since I was born-- people find it fascinating. It has taken 60 years but thanks to EYOS Expeditions and Victor Vescovo we have now taken this quantum leap forward in our ability to explore the deep ocean. -

Dives of the Bathyscaph Trieste, 1958-1963: Transcriptions of Sixty-One Dictabelt Recordings in the Robert Sinclair Dietz Papers, 1905-1994

Dives of the Bathyscaph Trieste, 1958-1963: Transcriptions of sixty-one dictabelt recordings in the Robert Sinclair Dietz Papers, 1905-1994 from Manuscript Collection MC28 Archives of the Scripps Institution of Oceanography University of California, San Diego La Jolla, California 92093-0219: September 2000 This transcription was made possible with support from the U.S. Naval Undersea Museum 2 TABLE OF CONTENTS INTRODUCTION ...........................................................................................................................4 CASSETTE TAPE 1 (Dietz Dictabelts #1-5) .................................................................................6 #1-5: The Big Dive to 37,800. Piccard dictating, n.d. CASSETTE TAPE 2 (Dietz Dictabelts #6-10) ..............................................................................21 #6: Comments on the Big Dive by Dr. R. Dietz to complete Piccard's description, n.d. #7: On Big Dive, J.P. #2, 4 Mar., n.d. #8: Dive to 37,000 ft., #1, 14 Jan 60 #9-10: Tape just before Big Dive from NGD first part has pieces from Rex and Drew, Jan. 1960 CASSETTE TAPE 3 (Dietz Dictabelts #11-14) ............................................................................30 #11-14: Dietz, n.d. CASSETTE TAPE 4 (Dietz Dictabelts #15-18) ............................................................................39 #15-16: Dive #61 J. Piccard and Dr. A. Rechnitzer, depth of 18,000 ft., Piccard dictating, n.d. #17-18: Dive #64, 24,000 ft., Piccard, n.d. CASSETTE TAPE 5 (Dietz Dictabelts #19-22) ............................................................................48 #19-20: Dive Log, n.d. #21: Dr. Dietz on the bathysonde, n.d. #22: from J. Piccard, 14 July 1960 CASSETTE TAPE 6 (Dietz Dictabelts #23-25) ............................................................................57 #23-25: Italian Dive, Dietz, Mar 8, n.d. CASSETTE TAPE 7 (Dietz Dictabelts #26-29) ............................................................................64 #26-28: Italian Dive, Dietz, n.d. -

History of the Harte Research Institute for Gulf of Mexico Studies at Texas A&M University–Corpus Christi John W

Gulf of Mexico Science Volume 28 Article 8 Number 1 Number 1/2 (Combined Issue) 2010 History of the Harte Research Institute for Gulf of Mexico Studies at Texas A&M University–Corpus Christi John W. Tunnell Jr. Texas A&M University, Corpus Christi DOI: 10.18785/goms.2801.08 Follow this and additional works at: https://aquila.usm.edu/goms Recommended Citation Tunnell, J. W. Jr. 2010. History of the Harte Research Institute for Gulf of Mexico Studies at Texas A&M University–Corpus Christi. Gulf of Mexico Science 28 (1). Retrieved from https://aquila.usm.edu/goms/vol28/iss1/8 This Article is brought to you for free and open access by The Aquila Digital Community. It has been accepted for inclusion in Gulf of Mexico Science by an authorized editor of The Aquila Digital Community. For more information, please contact [email protected]. Tunnell: History of the Harte Research Institute for Gulf of Mexico Studie Gulf of Mexico Science, 2010(1–2), pp. 56–70 History of the Harte Research Institute for Gulf of Mexico Studies at Texas A&M University–Corpus Christi JOHN W. TUNNELL,JR. n 19 Sep. 2000, Mr. Edward H. Harte try, and conservation, as well as all three countries O donated $46 million to establish a new surrounding the Gulf of Mexico: the United research institute at Texas A&M University– States, Mexico, and Cuba (Table 1). I was Corpus Christi (TAMU-CC) to focus on the Gulf appointed Associate Director in September of Mexico. Mr. Harte, philanthropist and former 2001, and that fall the new institute was officially owner of Harte-Hanks, Inc., and the Corpus named the Harte Research Institute for Gulf of Christi Caller-Times newspaper, worked with Dr. -

Altitude on Cartographic Materials and Its Correction According to New Measurement Techniques

remote sensing Article Altitude on Cartographic Materials and Its Correction According to New Measurement Techniques Kamil Maciuk 1,* , Michał Apollo 2 , Joanna Mostowska 3 , Tomáš Lepeška 4 , Mojca Poklar 5 , Tomasz Noszczyk 6 , Pawel Kroh 7 , Artur Krawczyk 8 , Łukasz Borowski 9 and Polona Pavlovˇciˇc-Prešeren 10 1 Department of Integrated Geodesy and Cartography, AGH University of Science and Technology, Al. Mickiewicza 30, 30-059 Krakow, Poland 2 Department of Tourism and Regional Studies, Institute of Geography, Pedagogical University of Cracow, ul. Podchor ˛azych˙ 2, 30-084 Krakow, Poland; [email protected] 3 Faculty of Geography and Regional Studies, University of Warsaw, ul. Krakowskie Przedmie´scie30, 00-927 Warszaw, Poland; [email protected] 4 Department of Applied Ecology, Faculty of Ecology and Environmental Sciences, Technical University in Zvolen, ul. T. G. Masaryka 24, 960 01 Zvolen, Slovakia; [email protected] 5 Faculty of Humanities, University of Primorska, Titov trg 5, 6000 Koper, Slovenia; [email protected] 6 Department of Land Management and Landscape Architecture, Faculty of Environmental Engineering and Land Surveying, University of Agriculture in Krakow, ul. Balicka 253 C, 30-198 Kraków, Poland; [email protected] 7 Faculty of Geography and Biology, Pedagogical University of Cracow, ul. Podchor ˛azych˙ 2, 30-084 Kraków, Poland; [email protected] 8 Department of Mine Areas Protection, Geoinformatics and Mine Surveying, AGH University of Science and Technology, Al. Mickiewicza -

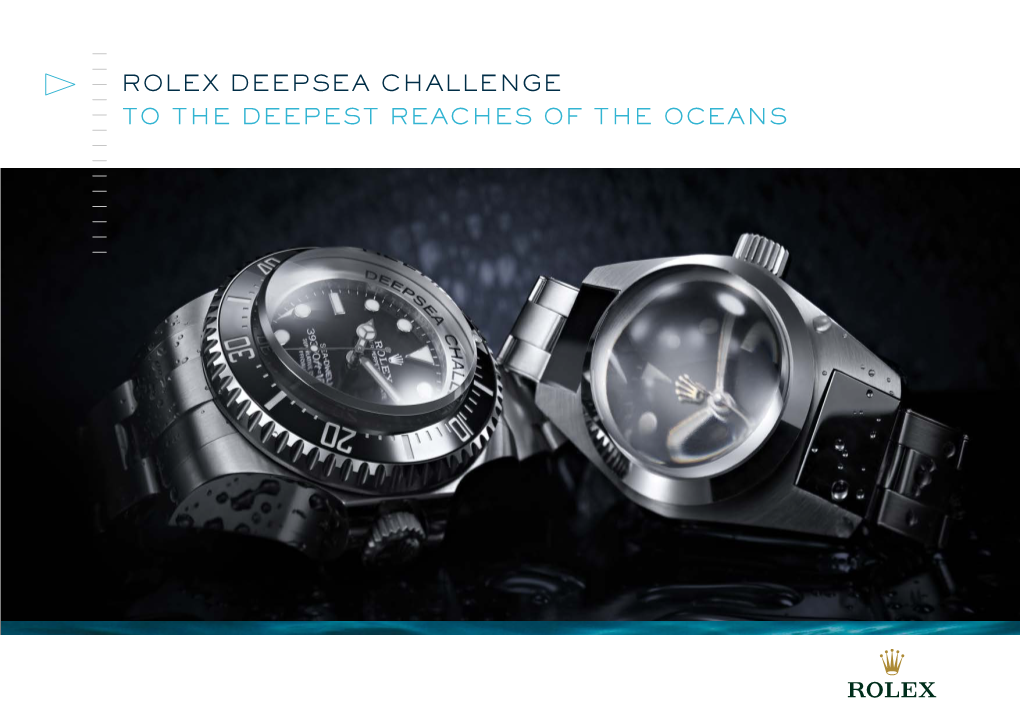

History of Rolex

HISTORY OF ROLEX Rolex’s status and identity are products of a history driven by a passion for innovation and a constant quest for excellence. A succession of pioneering achievements encompassing a watchmaking, industrial and human adventure, this story is interwoven with the history of the Oyster, the first waterproof wristwatch. Launched in 1926, the Oyster was the starting point for a collection of legendary watches. HISTORY OF ROLEX The success of Rolex is inextricably linked to the extraordinary spirit of enterprise of its founder, Hans Wilsdorf (1881-1960). Through his visionary genius and uncommon capacity to embrace all fields of the company’s activities – technology, communication, organization and distribution – and as the head of the company for more than 50 years, Hans Wilsdorf set the course for an adventure which has given rise to exceptional watches and an unparalleled brand. Today, his personality and his work continue to inspire the company and permeate its corporate culture. The entrepreneur’s influence is also evident in the aesthetics and principal characteristics of the watches that remain faithful to the original Oyster, as well as in Rolex’s ability to draw on its prodigious heritage to continuously advance towards new horizons. HANS WILSDORF AND HIS VISIONARY GENIUS The Rolex adventure began in the early 1900s. Born in Bavaria, Germany, Hans Wilsdorf started his career in watchmaking in La Chaux-de-Fonds, Switzerland. In an era when pocket watches were the order of the day, he was quick to see the potential of the wristwatch for the 20th century, despite their not yet being very precise and being generally considered to be items of jewellery of particular appeal to women. -

Challenger Deep Pdf, Epub, Ebook

CHALLENGER DEEP PDF, EPUB, EBOOK Neal Shusterman,Brendan Shusterman | 320 pages | 21 May 2015 | HarperCollins Publishers Inc | 9780062413093 | English | New York, United States Challenger Deep PDF Book January It was the first solo dive and the first to spend a significant amount of time three hours exploring the bottom. Raid on Alexandria Sinking of the Rainbow Warrior. The report by the HMS Challenger expedition reported two species of radiolarian when they discovered in the Challenger Deep. I kept thinking - am I going to spiral down one day? Enlarge cover. Other than that, the rest of the story kind of clicked and made sense. They are. The parrot is no better; he is malevolent, too, but funny. Each decade has its own civil rights fight, and I truly hope we tackle this next. In many mental-health books mental hospitals are demonized and described as prisons and mental torture houses run by cruel doctors and orderlies. The system was so new that JHOD had to develop their own software for drawing bathymetric charts based on the SeaBeam digital data. Marine Geophysical Research. Lin joined VictorVescovo to become, not only the first person born in Taiwan to go to the bottom of the Mariana Trench, but also the first from the Asian continent to do so. In , researchers on RV Kilo Moana doing sonar mapping determined that it was 35,ft deep with a 72ft error. Underwater vents cause liquid sulfur and carbon dioxide to bubble up from the crescent-shaped vent. I will admit that this book was a little confusing at the beginning but when the parallels made themselves more evident, I really started enjoying the book. -

E D I T O R I Al

BOLETIM INFORMATIVO DA ASSOCIAÇÃO ABBM BRASILEIRA DE BIOLOGIA MARINHA ISSN 1983 -1889 Volume 5, Número 1 jan/fev/mar/abr 2012 E D I T O R I A L Associação Brasileira de Biologia Marinha CNPJ: 09.304.946/0001-16 Chegamos ao primeiro fascículo do Boletim Informativo da ABBM de 2012. Isto significa que Diretoria Nacional (2011-2013) estamos iniciando o quinto ano de existência do Presidente Boletim Informativo , um marco importante para a Elisabete Barbarino (UFF) Associação Brasileira de Biologia Marinha, digno de Vice-Presidente celebração. Esta é uma conquista de todos nós, Edson Pereira da Silva (UFF) membros da ABBM. Secretária O presente fascículo do Boletim Informativo Diana Negrão Cavalcanti (UFF) traz diversos destaques. Em Palavras da ABBM , Secretária-Executiva nossa nova presidente, Elisabete Barbarino, Bruna Christina Marques Tovar Faro (UFRJ/UFF) contempla diferentes assuntos: ela comenta a Editor-Chefe conjuntura nacional da C,T&I, aborda alguns fatos Sergio de Oliveira Lourenço (UFF) marcantes para a área de Ciências do Mar no primeiro quadrimestre de 2012 e relata progressos Tesoureira recentes da ABBM. Andyara do Nascimento Silva (SEEDUC-RJ) Quatro artigos compõem o presente fascículo do BI . Fernando F. Mendonça & Fausto Conselho Consultivo, Fiscal e Arbitral Foresti abordam a aplicação de técnicas genéticas Giuliano Buzá Jacobucci (UFU) para a identificação de tubarões e raias. Os autores Luiz Muri Bassani Costa (WINDIVE) explicam como utilizar informações genéticas como Paulo Cesar de Paiva (UFRJ) ferramentas poderosas para a análise de espécimes Antonia Cecília Zacargnini Amaral (UNICAMP) de elasmobrânquios apreendidos por órgãos de Fausto Foresti (UNESP) fiscalização. Pleno de exemplos do Brasil e do mundo, o artigo mostra brilhantemente como a Genética pode contribuir para a conservação de Secretaria da ABBM espécies marinhas. -

BOULDERS on ASTEROIDS DIDYMOS and DIMORPHOS: FUTURE DART-Liciacube OBSERVATIONS

52nd Lunar and Planetary Science Conference 2021 (LPI Contrib. No. 2548) 1116.pdf BOULDERS ON ASTEROIDS DIDYMOS AND DIMORPHOS: FUTURE DART-LICIACube OBSERVATIONS M. Pajola1, A. Lucchetti1, S. Ivanovski2, G. Poggiali3,4, S. Ieva5, D. Perna5, E. Dotto5, V. Della Corte6, G. Cremonese1, M. Amoroso7, S. Pirrotta7, E. Mazzotta Epifani5, A. Cheng8, N. Chabot8, A. Rivkin8, O. Barnouin8, C. Ernst8, R.T. Daly8, M. Hirabayashi9, E. Asphaug10, S.R. Schwartz10, J.M. Trigo-Rodriguez11, E.G. Fahnestock12, P. Michel13, I. Bertini14, J.R. Brucato3, A. Capannolo15, B. Cotugno16, V. Di Tana16, I. Gai17, G. Impresario7, M. Lavagna15, A. Meneghin3, F. Miglioretti16, D. Modenini17, P. Palumbo14,6, A. Rossi18, E. Simioni1, S. Simonetti16, P. Tortora17, M. Zannoni17, G. Zanotti15, A. Zinzi19,7. 1INAF-Astronomical Observatory of Padova, Vic. Osservatorio 5, 35122 Padova, Italy ([email protected]); 2INAF Osservatorio Astronomico di Trieste, Trieste, Italy; 3INAF Osservatorio Astrofisico di Arcetri, Firenze, Italy; 4Università di Firenze, Dipartimento di Fisica e Astronomia, Sesto Fiorentino (Firenze), Italy; 5INAF Osservatorio Astronomico di Roma, Monte Porzio Catone (Roma), Italy; 6INAF Istituto di Astrofisica e Planetologia Spaziali, Roma, Italy; 7Agenzia Spaziale Italiana, via del Politecnico, 00133 Roma, Italy; 8Johns Hopkins University Applied Physics Laboratory, Laurel, MD-USA; 9Auburn University, Auburn, AL-USA; 10Lunar and Planetary Laboratory, University of Arizona, Tucson, AZ-USA; 11Institute of Space Sciences (IEEC-CSIC), Dept. of Astrophysics, -

The Waterfront of Trieste

City of Trieste - ITALY “Not only cruising” 2011 July URBACTII Plan Action Local - of Trieste City Trieste: aerial view of the city IndEX Introduction ............................................................................................................................................................................................................. 2 1.1 Synopsis........................................................................................................................................................................................................................................ 3 1.2 The URBACT II Programme ......................................................................................................................................................................................................... 4 The city of Trieste .................................................................................................................................................................................................... 6 Trieste as port city in a nutshell .......................................................................................................................................................................................................... 7 Local economy .................................................................................................................................................................................................................................... 8 Infrastructural system -

Twenty Years After the •Œtriesteâ•Š Dive

ARCHIVE PAPER Published in Feb/Mar 1980, Vol. 14, No. 1 Twenty Years After the "Trieste" Dive On January 23, at the Naval Memorial Museum in Washington, D.C., the U.S. Navy held a special ceremony in commemoration of the twentieth anniversary of the Bathyscaph Trieste dive. (See reports in the MTS Newsletters for December-January and February.) Dr. Don Walsh, MTS Council Member and Editor of the MTS Journal, was one of the two men who completed the original dive to a record depth of 35,800 feet into the Challenger Deep. The other man, of course, was Jacques Piccard, son of the Swiss physicist and inventor of the Bathyscaph. For those of you in or visiting WaShing- ton, the Bathyscaph will be on permanent display at the Naval Museum. On February 4, the Honorable Paul N. McCloskey, Jr. made the following appeal in the House of Representatives and included in the record Dr. Walsh's own account of the Trieste adventure. Both are reproduced here for the information and interest of our members. - The Managing Editor. Mr. Speaker, last year 53 of our colleagues asked the tion, research during the past several decades has President to dedicate the 1980's as a decade for ocean resulted in the development of new uses and markets resource use and management. It is appropriate that we for marine life Including underutilized species of fish, do so. The oceans are a frontier which have not been marine plants, and other marine organisms. developed to their full potential, and which must be, if we hope to maintain our standard of living and raise the One of the pioneers of basic oceans research is Don standard of living of those who are currently less Walsh, currently director of the Institute for Marine and fortunate than us.