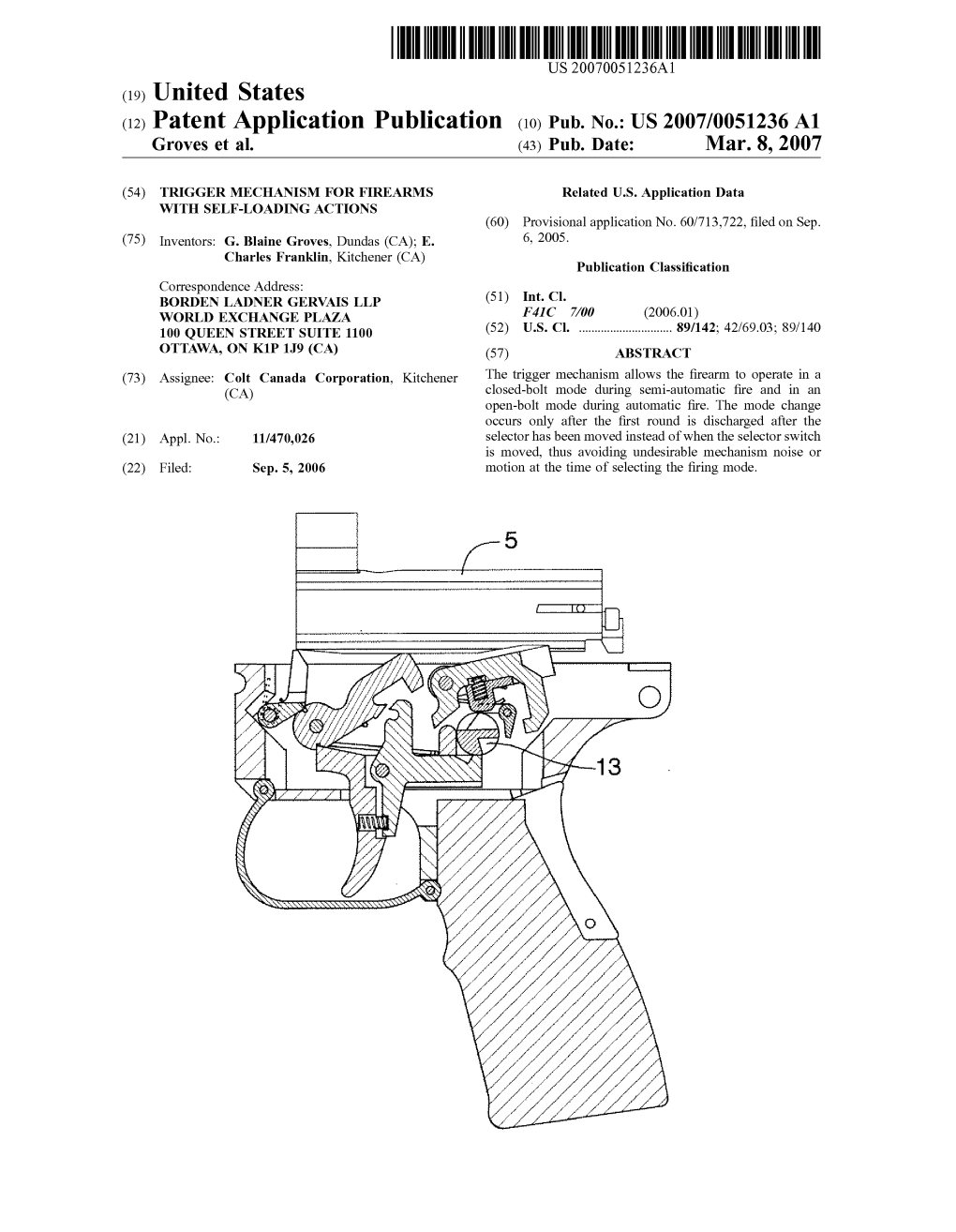

(12) Patent Application Publication (10) Pub. No.: US 2007/0051236A1 Groves Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Download Enemy-Threat-Weapons

UNITED STATES MARINE CORPS THE BASIC SCHOOL MARINE CORPS TRAINING COMMAND CAMP BARRETT, VIRGINIA 22134-5019 ENEMY THREAT WEAPONS B2A2177 STUDENT HANDOUT/SELF PACED INSTRUCTION Basic Officer Course B2A2177 Enemy Threat Weapons Enemy Threat Weapons Introduction In 1979, the Soviets invaded Afghanistan. The Soviets assumed this would be a short uneventful battle; however, the Mujahadeen had other plans. The Mujahadeen are guardians of the Afghani way of live and territory. The Soviets went into Afghanistan with the latest weapons to include the AK-74, AKS-74, and AKSU-74, which replaced the venerable AK-47 in the Soviet Arsenals. The Mujahadeen were armed with Soviet-made AK-47s. This twist of fate would prove to be fatal to the Soviets. For nearly 11 years, the Mujahadeen repelled the Soviet attacks with Soviet-made weapons. The Mujahadeen also captured many newer Soviet small arms, which augmented their supplies of weaponry. In 1989, the Soviet Union withdrew from Afghanistan back to the other side of the mountain. The Mujahadeen thwarted a communist take- over with their strong will to resist and the AK-47. This is important to you because it illustrates what an effective weapon the AK-47 is, and in the hands of a well-trained rifleman, what can be accomplished. Importance This is important to you as a Marine because there is not a battlefield or conflict that you will be deployed to, where you will not find a Kalashnikov AK-47 or variant. In This Lesson This lesson will cover history, evolution, description, and characteristics of foreign weapons. -

Mg 34 and Mg 42 Machine Guns

MG 34 AND MG 42 MACHINE GUNS CHRIS MC NAB © Osprey Publishing • www.ospreypublishing.com MG 34 AND MG 42 MACHINE GUNS CHRIS McNAB Series Editor Martin Pegler © Osprey Publishing • www.ospreypublishing.com CONTENTS INTRODUCTION 4 DEVELOPMENT 8 The ‘universal’ machine gun USE 27 Flexible firepower IMPACT 62 ‘Hitler’s buzzsaw’ CONCLUSION 74 GLOSSARY 77 BIBLIOGRAPHY & FURTHER READING 78 INDEX 80 © Osprey Publishing • www.ospreypublishing.com INTRODUCTION Although in war all enemy weapons are potential sources of fear, some seem to have a deeper grip on the imagination than others. The AK-47, for example, is actually no more lethal than most other small arms in its class, but popular notoriety and Hollywood representations tend to credit it with superior power and lethality. Similarly, the bayonet actually killed relatively few men in World War I, but the sheer thought of an enraged foe bearing down on you with more than 30cm of sharpened steel was the stuff of nightmares to both sides. In some cases, however, fear has been perfectly justified. During both world wars, for example, artillery caused between 59 and 80 per cent of all casualties (depending on your source), and hence took a justifiable top slot in surveys of most feared tools of violence. The subjects of this book – the MG 34 and MG 42, plus derivatives – are interesting case studies within the scale of soldiers’ fears. Regarding the latter weapon, a US wartime information movie once declared that the gun’s ‘bark was worse than its bite’, no doubt a well-intentioned comment intended to reduce mounting concern among US troops about the firepower of this astonishing gun. -

The QCB (Quick Change Barrel) M16 Upper Receiver Is One of the Most Radical Modifications to the AR-15/M16/M4 Weapons System That the Author Has Seen to Date

Visit us on line at: www.smallarmsreview.com The QCB (Quick Change Barrel) M16 Upper Receiver is one of the most radical modifications to the AR-15/M16/M4 weapons system that the author has seen to date. While I am not aware of any other weapon system with so many options, accessories and available configurations, the list of options contin- ues to grow at an amazing pace. There are countless manufacturers who have products and upgrades for this family of firearms, from muzzle brakes to custom stocks and every piece in between. Some are simple attachments and enhancements such as grips and scope mounts, and others are so radical that the rifle hardly even resembles the original “Black Rifle” anymore. The MGI QCB Upper Receiver falls into the latter category, in both design and function. Quick-change barrel mechanisms are ary Rifle by Robinson Armament also uti- eral firearms companies including Bush- common in machine guns but are more of lizes a QCB similar to the Stoner 63 Sys- master and MWG, Gwinn is far from a a rarity in assault rifles. Examples of QCB tem it was based on. newcomer to the world of gun design. systems in larger machine guns would in- Mack Gwinn, the designer of the MGI Military currently offers several clude the M60, the Stoner 63 Rifles, M2HB-QCB, designed this latest addition upgrades for the M16 weapons system. M249, the M240 and the M2HB-QCB by to the QCB family. Having over 25 fire- Their product line includes a rate-reduc- FN-Herstal. -

Portugal Country Report

SALW Guide Global distribution and visual identification Portugal Country report https://salw-guide.bicc.de Weapons Distribution SALW Guide Weapons Distribution The following list shows the weapons which can be found in Portugal and whether there is data on who holds these weapons: AR 15 (M16/M4) G HK MP5 G Beretta M 12 U HK USP G Browning M 2 G IWI Tavor TAR-21 G Carl Gustav recoilless rifle G Lee-Enfield SMLE G FIM-92 Stinger G M1919 Browning G FN FAL G M60 G FN Herstal FN MAG G M79 G FN High Power U Mauser K98 G FN P90 G MBDA MILAN G Glock 17 G MG 3 / MG 42 U HK 21 G MP UZI G HK 23 U SIG SG540 G HK33 G Sterling MP L2A3 G HK G3 G Thompson M1928 G HK G36 G Explanation of symbols Country of origin Licensed production Production without a licence G Government: Sources indicate that this type of weapon is held by Governmental agencies. N Non-Government: Sources indicate that this type of weapon is held by non-Governmental armed groups. 2 salw-guide.bicc.de SALW Guide Weapons Distribution U Unspecified: Sources indicate that this type of weapon is found in the country, but do not specify whether it is held by Governmental agencies or non-Governmental armed groups. It is entirely possible to have a combination of tags beside each country. For example, if country X is tagged with a G and a U, it means that at least one source of data identifies Governmental agencies as holders of weapon type Y, and at least one other source confirms the presence of the weapon in country X without specifying who holds it. -

Bushmaster Operating and Safety Instruction Manual

Part # BFIMANA2OP Revision of 2005 For all BUSHMASTER XM15 and C15 Models BUSHMASTERBUSHMASTER OPERATINGOPERATING PLEASEPLEASE PRACTICEPRACTICE ANDAND SAFETYSAFETY SAFESAFE FIREARMSFIREARMS INSTRUCTIONINSTRUCTION HANDLING!HANDLING! MANUALMANUAL WARNING: BEFORE USING THlS FIREARM, READ AND FOLLOW THESE INSTRUCTIONS. TABLETABLE OFOF CONTENTS…CONTENTS… Warnings / Cautions / Safe Handling…… 1 Front & Rear Sight Adjustment…… 21 Dangerous Procedures…… 2 Disassembling Your Rifle…… 22 About Your Bushmaster Rifle…… 3 Inspection / Cleaning / Lubrication…… 27 Rifle Controls - Identification / Location…… 4 Detailed Cleaning Techniques…… 28 Carbon 15 Models - Identification…… 6 Cleaning the Upper Receiver…… 30 Clearing Your Rifle…… 7 Cleaning the Bolt & Carrier…… 31 Preventative Maintenance Checks…… 8 Cleaning the Ejector…… 32 Safety Function Check…… 8 Cleaning the Lower Receiver…… 33 Preparing to Fire / Loading a Magazine…… 9 Lubrication / Upper & Lower Receivers…… 34 Operation of Your Rifle / Loading…… 10 Lubrication / Bolt Carrier Group…… 35 Operation / Inserting a Magazine…… 10 Lubrication / Adjustable Rear Sight…… 36 Operation / Chambering from Open Bolt…… 11 Reassembling Your Rifle…… 37 Operation / Chambering from Closed Bolt…… 12 Magazine Disassembly / Reassembly…… 43 Immediate Actions - in Case of Trouble…… 14 Problems / Solutions…… 44 Remedial Actions…… 16 Cold Weather Shooting…… 52 Bullet Stuck in the Bore…… 17 Maintenance in Extreme Weather…… 52 Front & Rear Sights…… 18 Component Variations…… 53 Zeroing Your Sights…… 19 Parts Schematics…… 54 25 Meter Zeroing Procedures…… 19 Carbon 15 Models / Differences…… 60 Warranty…… 64 P.O. Box 1479 • 999 Roosevelt Trail • Windham, Maine 04062 U.S.A. Sales: 1 800 998 7928 • Customer Service: 1 800 883 6229 • Tel. 207 892 3594 • Fax: 1 207 892 8068 http://www.bushmaster.com • E-mail: [email protected] PLEASEPLEASE PRACTICEPRACTICE SAFESAFE FIREARMSFIREARMS HANDLING!HANDLING! WARNING: IF THIS FIREARM IS CARELESSLY OR IMPROPERLY HANDLED, UNINTENTIONAL DISCHARGE COULD RESULT AND COULD CAUSE INJURY, DEATH, OR DAMAGE TO PROPERTY. -

BLM 1999-04.Pdf

Flying Cross Command® uniform garments are For a free catalogue of all the quality Flying Cross by woven with a breathable polyester fabric that resists Fechheimer garments, just call Tricia Rudy Enterprises, stains, is machine washable, and never needs ironing. Inc., Kettleby, Ontario at 905-726-4404 or Fechheimer Command® Shirt Imodel 85R7886Z1 is form-fiHed at 1-800-543-1939. and has military dress style detailing with a 7-buHon Visit our web site at www.fechheimer.com placket front, permanent collar stays, and double-stitched shoulder straps and pocket flaps. Coordinated 100% Dacron® Polyester Trousers Imodel 39001 are available in a wide variety of colors FLYING CROSS and weaves to suit your specifications and climate. Each BY FECHHEIM R pair is made with a BanRoI® waistband and rubberized Snug-T eX® strips to prevent shirt pull out. Wear It With Pride. Volume 11 Number 4 ~.Ii.~ April 1999 - Editor I Publisher Publisher 's Commentary 5 Morley S . Lymburner New body armour ta kes 6 Phone (905) 640·3048 . Fax (905) 640·7547 canine policing by storm E-mail: [email protected] K9 Storm body armour is the world's Web Page: www.blueline.ca jirst custom jitted vest for police - News Editor - dogs. The Kevlar vest meets the Blair McQuillan Threat Level Ii Standard. General Manager Mary K. Lymburner, M.Ed. Barrie Police Headquarters 10 - Advertising - From dream to a reality Mary Lymburner (Director) Phone (905) 640-3048 Fax (905) 640-7547 Emerging Technologies 14 Bob Murray The Canadian Police Research Centre Phone (905) 640-6506 Fax (905) 642-0900 presents 7 companies displaying new and - Illustration - innovative police technology at Response 99. -

Impacts of the 1994 Assault Weapons

NT OF ME J T US U.S. Department of Justice R T A I P C E E D B O J C S Office of Justice Programs F A V M F O I N A C I J S R E BJ G O OJJ DP O F PR National Institute of Justice JUSTICE National Institute of Justice R e s e a r c h i n B r i e f Jeremy Travis, Director March 1999 Issues and Findings Impacts of the 1994 Assault Discussed in this Brief: This study examines the short-term impact Weapons Ban: 1994–96 (1994–96) of the assault weapons ban on gun markets and gun- by Jeffrey A. Roth and Christopher S. Koper related violence as contained in Title XI of the Federal Violent Crime On January 17, 1989, Patrick Edward zines. The legislation required the Attor- Control and Law Enforcement Act Purdy, armed with an AKS rifle—a ney General to deliver to Congress within of 1994. Title XI prohibits the semiautomatic variant of the military 30 months an evaluation of the effects of manufacture, sale, and possession AK–47—returned to his childhood the ban. To meet this requirement, the of specific makes and models of military-style semiautomatic fire- elementary school in Stockton, California, National Institute of Justice (NIJ) funded arms and other semiautomatics and opened fire, killing 5 children and research from October 1995 to December with multiple military-style features wounding 30 others. Purdy, a drifter, 1996 to evaluate the impact of Subtitle A. -

Foy (2/Imer, & 6.42724.4

Nov. 9, 1971 R. D. PLUMER ET All- 3,618,455 MANUAL OF EN AND CLOSED BOLT WEAPON FIRE CONCROL WITH AUTOMATIC HEAT RESPONSIVE OWERRIDE Filed July 25, 1969 y M & W. W 242 w 2.3227 SEl Of \: - and 2N ( . 22-A-TT T N foy (2/imer,INVIENIORS. & BY throa Shroud 6.42724.4 ATTORNEY 3,618,455 United States Patent Office Patented Nov. 9, 1971 2 a position to provide automatic closed-bolt operation of 3,618,455 MANUAL OPEN AND CLOSED-BOLT WEAPON the firearm; FIRE CONTROL WITH AUTOMATIC HEAT FIG. 3 is a view like FIG. 2 but illustrating the fire con RESPONSEVE OVERRIDE trol cam in a position to provide an automatic open-bolt Roy D. Plumer, Santa Barbara, and Harold Shrout, mode of operation for the firearm; and Goleta, Calif., assignors to General Motors Corp0 FIG. 4 is a view like FIGS. 2 and 3 but illustrating the ration, Detroit, Mich. fire control cam in a position to provide a semiautomatic Filed July 25, 1969, Ser. No. 844,926 closed-bolt mode of operation for the firearm. Int, C. F41d 11/02, 1 1/20 Referring now to the drawings and more particularly U.S. C. 89-132 3 Claims 10 to FIG. 1 a firearm which takes the form of a rifle is illus trated and is generally designated by reference numeral 10. This firearm includes a receiver 12 and a barrel 4 ABSTRACT OF THE DISCLOSURE Suitably connected to the receiver. The firearm has a stock A fire control system for an automatic firearm capable which is not illustrated and has a housing 16 which sup of being manually set to selectively provide automatic 5 ports the trigger 18 and a plurality of sear parts forming closed-bolt operation, automatic open-bolt operation and a fire control mechanism which is to be described. -

20 Ahern Under the Gun: Century International Arms, Benchmade–Names You Trust

May 11 Blue Press Section 1 3/14/11 2:00 PM Page 20 20 Ahern Under the Gun: Century International Arms, Benchmade–Names You Trust By Jerry Ahern, Photos by Sharon Ahern round drum magazines, either the RPK or the I have just been interacting with a firearm AES10B is capable of relentless defensive firepow- which so impresses me that I must say I would rec- er, when several magazines are available and there ommend it for anyone who is seriously concerned is an adequate supply of ammunition. It should be about home or retreat defense in the event of mas- remembered, however, albeit a concern principally sive civil unrest, a protracted survival situation or with the RPK rather than the AES10B, barrels can- family protection in time of disaster. And, under not be changed in the field. Romanian 75-round less grim circumstances, it’s a firearm that’s a lot of drum magazines are loaded one round at a time, a fun to shoot. It is not rare, but it is unique. It is clutch having to be operated before the next round strong, accurate, battle proven and has all the con- is inserted. Chinese drums open like a clamshell, veniences for which one might wish with such a allowing much faster, mass loading. firearm. As you might already suspect, I am very The RPK, the AES10B and the entire AK-47 rifle taken with it. series fire from a closed bolt, safer and more prac- The firearm in question is the AES10B rifle from tical than open bolt designs under rugged field Century International Arms (centuryarms.com). -

AR-556 Instruction Manual

S PM263 INSTRUCTION MANUAL FOR CALIBERS 223 Rem / 5.56 NATO RUGER® AR-556® AUTOLOADING RIFLE – Rugged, Reliable Firearms® – READ THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL CAREFULLY BEFORE USING THIS FIREARM © 2015 Sturm, Ruger & Co., Inc. This manual may not be reproduced in whole or in part without the express written permission of Sturm, Ruger & Co., Inc. For Service on This Model Please Call: (336) 949-5200 (See p. 40) THIS INSTRUCTION MANUAL SHOULD ALWAYS ACCOMPANY THIS FIREARM AND BE TRANSFERRED WITH IT UPON CHANGE OF OWNERSHIP, OR WHEN THE FIREARM IS LOANED OR PRESENTED TO ANOTHER PERSON www.ruger.com ND 12-15 R4 State-By-State Warnings Certain states require by law that their own specified warning notices in larger-than-normal type be conspicuously included by the manufacturer, distributor or retailer with firearms sold in that state. Sturm, Ruger & Co., Inc. sells its products in compliance with applicable laws and regulations. Because our products may be sold in these states, we include the following: California: WARNING ADVERTENCIA “A los niños los atraen las armas “Children are attracted to and de fuego y las pueden hacer can operate firearms that can funcionar. Ellos pueden causarses cause severe injuries or death. lesions graves y la muerte. Evite Prevent child access by always que los niños tengan accesso a las keeping guns locked away and armas de fuego guardándolas unloaded when not in use. If you siempre con llave y descargadas keep a loaded firearm where a cuando no las esté utilizando. Si child obtains and improperly -

Documenting Small Arms and Light Weapons a Basic Guide

Issue Brief Number 14 July 2015 Documenting Small Arms and Light Weapons A Basic Guide Introduction of accurate identification of arms and both civilian and military weapons that munitions, the basic elements of arms fire a projectile, with the condition that This Issue Brief was written with a tracing, and the relevant legal frame- the unit or system may be carried by an range of professionals in mind. For work, this Issue Brief offers a step-by- individual or a small number of people, those who are involved in the military step approach to documenting small or transported by a pack animal or a or law enforcement communities, or arms and light weapons. It also features light vehicle. This Issue Brief covers who spend time in conflict zones as a section on safety procedures (see techniques applicable to the following journalists or with non-governmental Box 1) and guidelines for undertaking small arms and light weapons: organizations (NGOs) or government documentation work in the field (see agencies, this Brief should provide some Box 2). The Brief concludes with a section small arms: handguns, rifles and insight into the often-murky world on the weapon that is most commonly carbines, assault rifles, shotguns, of arms identification. It is designed observed in conflict zones: the AK rifle sub-machine guns, and light and to serve as a basic how-to guide for and its variants, copies, and derivatives. medium (‘general-purpose’) machine recording relevant identification char- guns; and acteristics of small arms and light light weapons: heavy machine weapons that may be encountered Scope of this Issue Brief guns, grenade launchers, portable in the field. -

C39v2 the AMERICAN AK Century Arms Introduced the First 100% American Made AK Rifle to the Market 5 Years Ago

C39v2 THE AMERICAN AK Century Arms introduced the first 100% American made AK rifle to the market 5 years ago. We are excited to now offer the newest addition to the C39 line of rifles, the new C39v2, the American AK. It is 100% American made with no imported parts, built on a milled receiver machined from a solid 11 lb. block of 4140 ordnance quality steel. Enhancements include a T shaped magazine catch, compatibility with AKM furniture, a bolt hold open safety, an enhanced dust cover and standard AK sights. The C39v2 is coated with black nitrite and uses a new enhanced trigger group. The C39v2 barrel has a concentric left hand 14x1 metric thread and is ready for a variety of muzzle attachments. SPECS Caliber: 7.62x39mm Barrel: 16.5” with a 1:10 twist Barrel Thread: 14x1 LH Overall: 37.25” Weight: 8.2 lbs. Receiver: Milled 4140 steel Mag. Capacity: 30 rounds Comes with: Two 30 round Magpul magazines and a 1 year manufacturer’s warranty Country of Mfr: USA Product Code: RI2245-N RI2245CA-N California Compliant centuryarms.com 800.527.1252 RAS47 Born overseas and perfected in the USA, the all new 100% American made stamped AK, RAS47, is now available. Features a T shaped magazine catch, compatibility with AKM furniture, slant muzzle brake, side scope rail, bolt hold open safety, an enhanced dust cover and has standard AK sights. The RAS47 is coated with black nitrite and uses a new enhanced trigger group. SPECS Caliber: 7.62x39mm Barrel: 16.5” with a 1”10 twist Barrel Thread: 14x1 LH Overall: 37.25” Weight: 7.8 lbs.