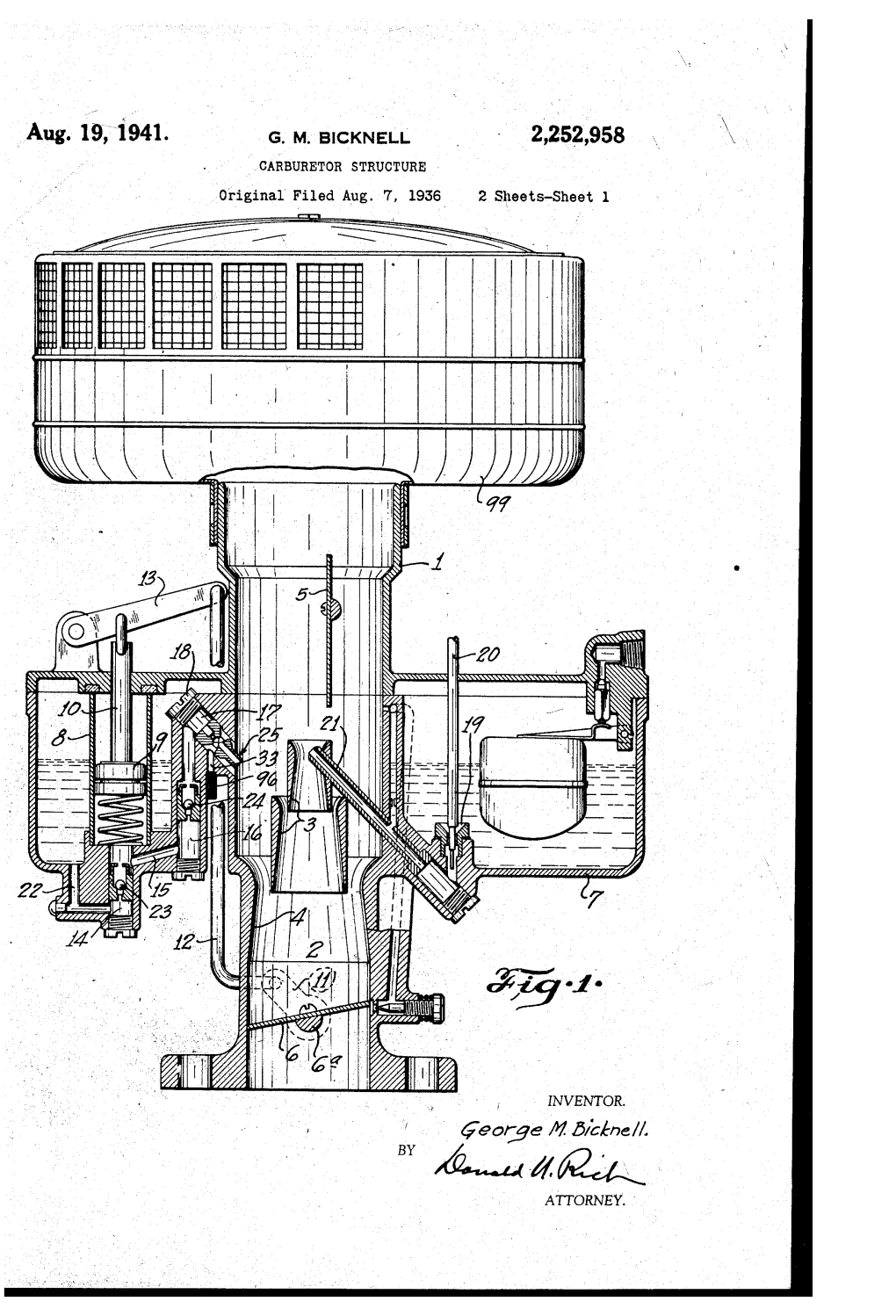

CARBURETOR STRUCTURE Original Filed Aug

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Horizontal Directional Drilling Glossary

AN HDD GUIDE HORIZONTAL DIRECTIONAL DRILLING GLOSSARY A comprehensive guide to all terms HDD to make sure you can “talk the talk” when on the job. Horizontal directional drilling has been gaining ground for quite some time in the construction industry as the ideal solution for installing pipes and utilities without having to dig up long trenches. At Melfred Borzall, with our 70+ years of experience designing and building groundbreaking drilling solutions, we understand the best way to push the industry forward is to have innovative solutions and increase education about HDD. In our HDD Glossary, we’ve compiled 70 HDD terms along with clear definitions for each term to help expert drillers and new drillers to all talk the same talk and help streamline communication on your next job. HORIZONTAL DIRECTIONAL DRILLING GLOSSARY 2 "TALK THE TALK" HDD GLOSSARY HDD Tooling & Equipment Terms TERM & ALTERNATE DEFINITION DRILL HEAD The lead portion of the drilling process that TERMS Housing, Transmitter houses the transmitter inside to enable the Housing, Head, locator to see where the drill bit is located A ADAPTER Configurable adapter piece that allows drillers to Sonde Housing underground. It comes in different bolt patters Sub, Crossover, and can connect to various types of blades and Tailpiece use various manufacturer’s drill bits and blades with others’ starter rods, housings, and other bits depending upon the ground condition. configurations. Often customizable to fit specific needs of a jobsite tooling setup. DRILL RIG A trenchless machine that installs pipes and Rig, Drill cables by drilling a pilot bore to establish the AIR HAMMER Tool used in HDD designed to bore through location of the underground utility before difficult rock formations using a combination of enlarging the hole if needed and pulling back thrust, pressure and rotation to chip and carve the product. -

Optimizing the Cylinder Running Surface / Piston System of Internal

THIS DOCUMENT IS PROTECTED BY U.S. AND INTERNATIONAL COPYRIGHT. It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Peter Ernst, Saturday, September 15, 2012 04:51:57 PM Optimizing the Cylinder Running Surface / Piston 2012-32-0092 System of Internal Combustion Engines Towards 20129092 Published Lower Emissions 10/23/2012 Peter Ernst Sulzer Metco AG (Switzerland) Bernd Distler Sulzer Metco (US) Inc. Copyright © 2012 SAE International doi:10.4271/2012-32-0092 engine and together with the adjustment of the ring package ABSTRACT and the piston a reduction of 35% in LOC was achieved. This Rising fuel prices and more stringent vehicle emissions engine will go into production in September 2012 with requirements are increasing the pressure on engine limited numbers coated in the Sulzer Metco Wohlen facility manufacturers to utilize technologies to increase efficiency in Switzerland, until an engineered coating system is ready on and reduce emissions. As a result, interest in cylinder surface site to start large series production. More details on the coatings has risen considerably in the past few years. Among engine performance and design changes made to the cast these are SUMEBore® coatings from Sulzer Metco. These aluminium block in order to take full advantage of the coating coatings are applied by a powder-based air plasma spray on the cylinder running surfaces is presented in the paper (APS) process. The APS process is very flexible, and can from Zorn et al. [1]. -

Swampʼs Diesel Performance Tips to Help Remove and Install Power

Injectors-Chips-Clutches-Transmissions-Turbos-Engines-Fuel Systems Swampʼs Diesel Performance Competition Parts For Your Diesel 304-A Sand Hill Rd. La Vergne, TN 37086 Tel 615-793-5573 or (866) 595-8724/ Fax 615-793-5572 Email: [email protected] Tips to help remove and install Power Stroke injectors. Removal: After removing the valve covers and the valve cover gaskets, but before removing any injectors, drain the oil rails by removing the drain plugs inside the valve cover. On 94-97 trucks theyʼre just under where the electrical connectors are on the gasket. These plugs are very tight; give them a sharp blow with a hammer and punch to help break them loose, then use a 1/8" Allen wrench. The oil will drain out into the valve train area and from there into the crankcase. Donʼt drop the plugs down the push rod holes! Also remove one of the plugs on top of each oil rail, (beside where the lines from the High Pressure Oil Pump enter) for a vent to allow air to enter so the oil can drain. The plugs are 5/8”. Inspect the plug O-rings and replace if necessary. If the plugs under the covers leak, it will cause a substantial loss of performance. When removing the injectors, oil and fuel from the passages in the cylinder head drains down through the injector bore into the cylinders. If not removed, this can hydro-lock the engine when cranking. There is a ~40cc dish in the center of each piston. Fluid accumulates in it, as well as in the corner on the outside of the piston between the piston top and the cylinder wall, due to the 45* slope of the cylinder bank. -

Electronic Throttle Body

New ELECTRONIC THROTTLE BODY Because of the exacting standards of our proprietary engineering Product Description processes, all CARDONE 100% New Electronic Throttle Bodies are guaranteed to fit and function like the original. Critical components Features and Benefits such as the housing, throttle plate, position sensors, and throttle Signs of Wear and actuator motor, all conform to the precise dimensions as designed by Troubleshooting the O.E. Manufacturer – meaning each unit is guaranteed to last and perform consistently under all driving conditions. FAQs • Critical components used in manufacturing the electronic throttle body, including the housing, throttle plate, position sensors, throttle actuator motor and throttle plate return spring conform to precise O.E. dimensions. • Each throttle body is tested for all critical functions, including response time and air flow at multiple points, ensuring an optimal fuel/air ratio. • 100% computerized testing of motor, throttle position sensor and articulation ensures reliable and consistent performance. • Each unit is guaranteed to fit and function like the original. Signs of Wear and Troubleshooting • Throttle position sensor codes stored • Consistent reduced engine power • Intermittent reduced engine power • Low idle RPM • Idle RPM hunt or erratic idle Subscribe to receive email notification whenever cardone.com we introduce new products or technical videos. Tech Service: 888-280-8324 Click Electronics Tech Help for technical tips, articles and installation videos. Rev Date:Rev 063015 Date: -

1/8” Poppet Valves

1/8” POPPET VALVES 1/8" POPPET TYPE-VALVES provide a complete line of economical, compact, trouble-free units. They are available in a wide variety of manually operated 2-way, 3-way and 4-way models. The valve bodies are corrosion resistant aluminum. All other parts are treated or plated to provide long service and resist corrosion. The poppet seal is Buna-N. Air flow capacity is 25 Cu. Ft. free air per minute at 100 P.S.I. Maximum operating pressure is 150 P.S.I. Maximum temperature range is 250°F. V2 TWO-WAY BUTTON VALVE Depressing button will permit flow. May be mounted on any one of three sides. V23 THREE-WAY BUTTON VALVE Depressing button will permit flow. Releasing button will permit exhaust flow through button stem. V2H TWO WAY TWO BUTTON VALVE One common inlet Two separate outlets. THREE-WAY VALVES During operation, air will not escape to atmosphere. Lever bearings are of hardened steel for long service. The utilizable exhaust port will accept our Bleed Control Valve PTV305 for controlling the exhaust. Can be mounted on either of two sides. LEVER OPERATED V3NC THREE-WAY NORMALLY CLOSED V3NO THREE-WAY NORMALLY OPEN HAND OPERATED HV3NC THREE-WAY NORMALLY CLOSED HV3NO THREE-WAY NORMALLY OPEN CAM OPERATED CV3NC THREE-WAY NORMALLY CLOSED CV3NO THREE-WAY NORMALLY OPEN FOOT OPERATED FT300NC THREE-WAY NORMALLY CLOSED FT300NO THREE-WAY NORMALLY OPEN PILOT TIMER VALVE PTV3NC THREE-WAY NORMALLY CLOSED PTV3NO THREE-WAY NORMALLY OPEN Valve consists of a diaphragm pilot chamber which operates the 3-way valve section. -

Recommended Bearing Installation Tolerances

Recommended Bearing Installation Tolerances CRANKCASE TOLERANCES CRANKSHAFT END CLEARANCE Finish of Main Bores: Shaft Diameter End Clearance • 60-90 micro inches Ra. 2.000”-2.750”(50mm-70mm) .003”-.007”(.075mm-.175mm) Bore Tolerance: 2.813”-3.500” (71mm-88mm) .005”-.009”(.125mm-.225mm) • .001” (.025mm) up to 10.000” (250mm) bore 3.500” or over (89mm or over) .007”-.011”(.175mm-.275mm) Out-of-Round: • .001” (.025mm) maximum if horizontal is larger than CONNECTING ROD TOLERANCES Finish of Rod Bores: vertical • 60-90 micro inches Alignment: Rod Tolerance: • .002” (.050mm) maximum overall misalignment (.001”- • .0005” (.013mm) up to 3.250” (81mm) diameter .025mm for heavy duty or highly loaded engines) • .001” (.025mm) from 3.250”(81mm)to 10.000” (250mm) • .001” (.025mm) maximum misalignment on adjacent diameter bores (.0005”-.013mm for heavy duty or highly loaded Out-of-Round: engines) • .001” (.025mm) maximum if horizontal is larger than CRANKSHAFT TO LERANCES vertical Taper: MAIN BEARING AND CRANKPIN JOURNALS • .0002” (.005mm) up to 1.000” (25mm) length (.0001”- Finish of Journals: .003mm for heavy duty or highly loaded engines) • 15 micro inches Ra or better (10 micro inches Ra or • .0004” (.010mm) for 1.000” (25mm) to 2.000” (50mm) better for heavy duty or highly loaded engines) length (.0002”-.005mm for heavy duty or highly loaded Diameter Tolerance: engines). • .0005” (.013mm) up to 1.500” (38mm) journal • .0005” (.013mm) for 2.000” (50mm) or longer (.0003”- • .001” (.025mm) for 1.500” (38mm) to 10.000” (250mm) .008mm for heavy duty or highly loaded engines) journal Hour-Glass or Barrel Shape Condition: Same as taper Out-of-Round: Parallelism between rod bore and wrist pin hole .001” • .0005”(.013mm) maximum up to 5.000” (125mm) journal (.025mm) in 5.000” (125mm) (.0002”-.005mm for heavy duty or highly loaded engines) Twist .001” (.025mm) in 6.000” (150mm) • Never use a maximum out-of-round journal with a maximum out-of-round bore. -

Tapered Bore Throttle Bodies Increase Power and Torque

Tapered Bore Throttle Bodies Increase Power And Torque EFI Hardware have increased the range of high performance Tapered Bore Throttle Bodies to include 43mm, 45mm, 48mm, 50mm and 53mm throttle plate sizes. The tapered bore results in an increase in air speed over conventional straight bore throttle bodies. This extra air speed enhances the engine's scavenging cycle to provide increased filling on each cylinder intake stroke. More air, plus the corrected fuel and spark delivery equals more engine torque and power. Tapered Bores are available in the EFI Hardware Pro Race Series Throttle Bodies. TAPERED BORE THROTTLES Tapered Bore Throttles have a clear advantage over Parallel Bore Throttles at increasing power and torque. By accelerating the air through a venturi (in this case a tapered bore) the air speed through the throttle body is increased. This enhances the engine cycle's scavenging effect to provide more air and fuel in the combustion chamber and therefore more power and torque. The Tapered Bore Throttle Body has 3 sections: ● Inlet from ram tube is the largest diameter of between 45mm and 55mm ● This then tapers down to a short parallel section for the throttle plate between 43 and 53mm ● There is a second taper down to the outlet flange of the throttle body of between 40 and 50mm HP RATINGS HP/kW Ratings vary from engine to engine. The power ratings given here are only a guide, and are not absolute power ratings. Engine power is determined by intake, exhaust, cylinder head design, camshaft design, compression ratio, fuel type and quality and many other factors. -

Not for Reproduction

BRIGGS & STRATTON CORPORATION ADVANCE PRODUCT SERVICE INFORMATION APSI NO: 73 DATE: 02/11/2011 SUBJECT: PROFESSIONAL SERIES™ ENGINE MODELS: 950 Series (Model 140000) Briggs & Stratton recently introduced the 950 Series OHV vertical shaft engine in the single-cylinder Professional Series product line. Some of the features of this engine include: • Electric ReadyStart® starting system • Commercial quality oval air cleaner element with dual seals allows for increased maintenance intervals • 2 year consumer / 90 day commercial limited warranty This APSI provides basic servicing information in advance of the repair manual currently in development. See the Illustrated Parts List for service part numbers. The following specifi cations, part numbers, and/or procedures are PRELIMINARY and subject to change. Reproduction For Not © Briggs & Stratton Corporation Page 1 of 6 Dimensions BRIGGS & STRATTON CORPORATION 6.204Ŋ 7.142Ŋ (157.58) (181.4) 5.874Ŋ (149.2) 15.806Ŋ (401.47) 9.926Ŋ (252.13) 2.41Ŋ 3.68Ŋ (61.0) (94.0) 13.346Ŋ (338.98) 3.20Ŋ (81.0) 1.56Ŋ 3.02Ŋ (40.0) (77.0) 9.866Ŋ (250.6) 1.94Ŋ (49.0) Reproduction 6.9Ŋ 2.06Ŋ (175.16) (52.0) 2.62Ŋ CLEARANCE HOLE For (267.0) FOR SUMP Not Page 2 of 6 Torque Patterns 1 4 1 4 3 2 2 3 Figure 1 Figure 2 On engines built between date codes 101206xx and 110201xx, a penetrating oil should be applied to the ex- posed threads before backing out the cylinder head screws (Fig 1). Reproduction For Not Loc-patch screw 4 6 2 1 7 5 3 Figure 3 Page 3 of 6 Common Specifications SAE Metric Armature Air Gap .010 - .014 -

Melfred Borzal Resource Guide

2712 Airpark Drive Santa Maria, CA 93455 800-558-7500 phone 805-739-0118 international www.melfredborzall.com WHERE TO GET AMAZING TOOLS HDD RESOURCE GUIDE Metric to Standard Weight/Force: Length: kilograms (kg) to pounds (lb) meters (m) to feet (ft) lb = (kg x 2.2 lbs.) ft = (m x 3.28) Ex: 70 kg = 154.3 lbs. Ex: 10m x 3.28 = 32.8 ft millimeters (mm) to inches (in) in = (mm x 0.0394) Ex: 50mm x 0.0394 = 1.97 in Flow: 0 1 INCHES 2 liters per min (lpm) to gallons per min (gpm) gpm = (lpm x 0.264) Ex: 500 lpm x 0.264 = 132.1 gpm MM 10 20 30 40 50 Volume: Torque: liter (l) to US gallon (gal) newton-meters (Nm) to pounds-foot (lb-ft) gal = (l x 0.264) lb-ft = (Nm x 0.738) Ex: 10l x 0.264 = 2.64 gal Ex: 200Nm x 0.738 = 147.6 lb-ft 1 UK Imperial gallon is about 1.2 US gallons Temperature: Pressure: kilopascal (kPa) to pounds per square inch (psi) degrees Celsius (C) to degrees Fahrenheit (F) psi = (kPa x .145) °F = (°C*9/5) +32 Ex: (300kPa x 0.145) = 43.51 psi Ex: If it is 30°C: (30x9/5) + 32 = 86°F Melfred Borzall 2 melfredborzall.com | 800.558.7500 TABLE OF CONTENTS Find the Right Melfred Borzall Product for the Job 4 HDD Drill Rig Glossary 6 Basic Drill Fluid Additives 8 Swivel Dimensions for Pulling Eyes 10 Drilling a Big Hole? Use a Barrel Stabilizer 12 Depth & Pitch Guide 13 Rock Drilling 101 14 Size Your Reamer Right 16 Locating the Right Way 17 “Talk the Talk” HDD Glossary 18 Bolts and O-rings Guide 21 melfredborzall.com | 800.558.7500 3 FIND THE RIGHT MELFRED BORZALL PRODUCT FOR THE JOB When you’re deep in an HDD job, you need tools you can count on. -

Internal Combustion Engines (Elective) (Me667) Sixth Semester

INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667) SIXTH SEMESTER INTERNAL COMBUSTION ENGINES An Engine is a device which transforms the chemical energy of a fuel into thermal energy and uses this thermal energy to produce mechamechanicalnical work.work. Engines normally conveconvertrt thermal energy into mechanical work and therefore they are called heat engines. Heat engines can be broadly classified into : i)i)i) External combustion engines ( E C Engines) ii)ii)ii) Internal combustion engines ( I C Engines ) External combustion engines are those in which combustion takes place outside the engine. FoFoForFo r example, IIInInnn sssteamsteam engine or steam turbine the heat generated due to combustion of fuel and it is employed to generate high pressure steamsteam,, which is used as working fluid in a reciprocating engine or turbine. See Figure 1. Figure 1 : External Combustion Engine Internal combustion engines cacann be classified as CContinuousontinuous IC engines and Intermittent IC engines. In continuous IC engines products of combustion of the fuel enterenterssss into the prime mover as the working fluid. For example : IInn Open cycle gas turbine plant. Products of combustion ffromrom the combustion chamber enters through the turbine to generate the power continuously . See Figure 2. Figure 2: Continuous IC EEEnginesEngines In this case, same working fluid cannot be uuusussseded again in the cycle. Jagadeesha T, Assistant Professor, Department of Mechanical Engineering, Adichunchanagiri Institute of Technology, Chikmagalur INTERNAL COMBUSTION ENGINES (ELECTIVE) (ME667) SIXTH SEMESTER In Intermittent internal combustion engine combustion of fuel takes place insidinsidee the engine cylinder. Power is generated intermittently (only during power stroke) and flywheel is used to provide uniform output torque. -

A Novel Steam Engine Concept

A Novel Steam Engine Concept Hadeel Solaka 4F1824 – Project Course in Machine Engineering School of Industrial Engineering and Management January 2007 Fördjupningsarbete i Maskinkonstruktion 2007 Ett modernt ångmotorkoncept Hadeel Solaka Datum Examinator Handledare 2007-Maj-02 Ulf Sellgren Ulf Sellgren Uppdragsgivare Kontaktperson Ulf Sellgren Ove och Peter Patell Sammanfattning Projekt uppgiften var att bygga upp en solidmodell av en BC-hybrid och att använda denna modell för att visualisera systemets funktion och för att illustrera dess kompakthet. Först skulle ett affärskoncept tänkas ut. Sedan skulle design och tekniska lösningar skapas, för att sedan leda till teknisk utvärdering och dimensionering. Projektet handlade om uppbyggandet av en solidmodell av en modern kompakt ångmotor som utnyttjar avgasenergin från en lastbilmotor. Detta kallas för en BC-Hybrid (Bottoming-Cycle Hybrid). För att kunna utnyttja avgasenergin från en lastbilmotor på ett effektiv sätt, kopplade ångmotorn direkt efter dieselmotorns utloppsportare(6-cylendrig). Detta medförde ett riskabelt koncept med ett vanligt dieselgrenrör eller med ett rakt grenrör. Kombinationen blev ett X-grenrör. Resultat utav detta blev en designmässigt lämpad produkt som har goda förutsättningar att lyckas väl på marknaden. Hybrid ångmotor är i enlighet med vår projektidé mycket slitstark, kompakt och miljö vänligt. Figur 1. Visar den slutliga kompakta lösning för BC-Hybrid 2 Project course in Machine Design 2007 A Novel Steam Engine Concept Hadeel Solaka Date Examiner Supervisor 2007-May-02 Ulf Sellgren Ulf Sellgren Commissioner Contact person Ulf Sellgren Ove and Peter Patell Abstract Project’s task was to build a solid model of a BC- hybrid and use the model to visualise system function and to illustrate its compactness. -

Methods of Preparing Internal Combustion Engine Cylinder Bore Surfaces for Frictional Improvement

MATEC Web of Conferences 90 , 01055 (2017)DOI: 10.1051/ matecconf/201 79001055 AiGEV 2016 Methods of preparing internal combustion engine cylinder bore surfaces for frictional improvement Kong Chung Hwa1,2, D.Ramasamy1,2,*, K. Kadirgama1,2, M. M.Noor1,2, M. M.Rahman1,2, M. Samykano1,2 1Faculty of Mechanical Engineering, Universiti Malaysia Pahang, 26600 Pekan, Pahang, Malaysia 2Automotive Engineering Centre, Universiti Malaysia Pahang, 26600 Pekan, Pahang, Malaysia Abstract. Frictional losses piston to cylinder bore contact is a major sources of mechanical losses in an internal combustion engine (ICE). Traditional plateau honing produces a relatively rough cylinder bore surface with many valleys for oil retention and plateau surfaces that are usually has micro roughness's that causes mechanical friction to act as a bearing surface. A smooth polished dimpled surface is more ideal to achieve low friction and wear in an ICE. Alternative methods to create a smooth dimpled surface on a hypereutectic aluminum ADC12 substrate for frictional improvements are evaluated in this study using an oscillating wear tester (OWT). The methods include casting in the dimples in the aluminum matrix, sandblasting as well as embossing the pits. The texture samples are evaluated by examining the surface properties, measuring frictional coefficient as well as wear characteristics. It was found that the samples embossed with #320 grit sandpaper and sandblasted with #240 sieve sand samples had a reduced coefficient of friction (μ) of 23% at low sliding speeds before hydrodynamic lubrication mode and 6.9% in the fully hydrodynamic lubrication region. 1 Introduction The wheel revolutionized human civilization as it enabled heavy transportation of goods and commodities, fostered trade, made construction of larger structures possible and revolutionized human transport in the form of wheel barrows, horse carriages and ox carts.