United States Patent Office Patented Mar

Total Page:16

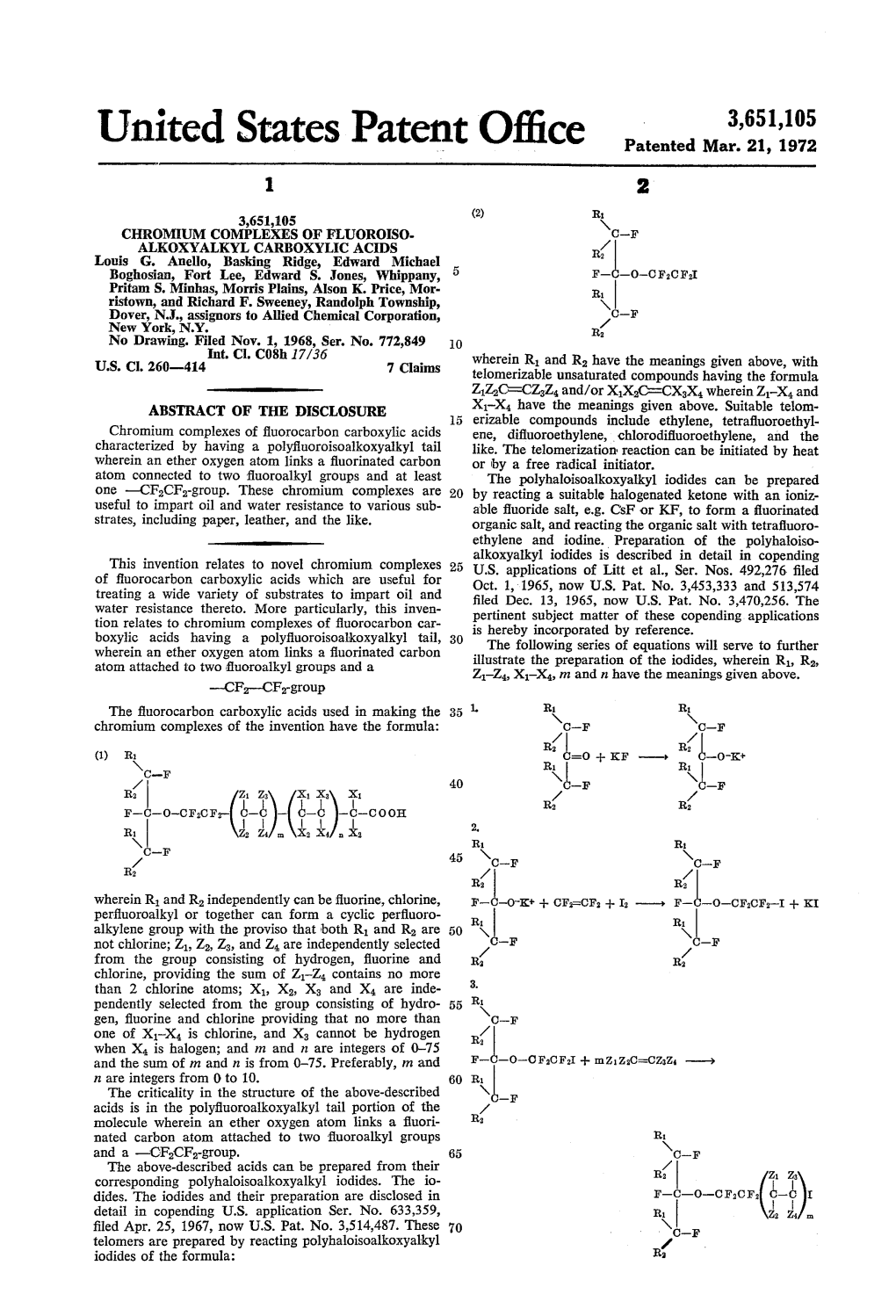

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Packet of Wiser Reports on Acetone Acetonitrile

Ac&tone ^Hazmat - NFPA Hazard Classification Page 1 of Acetone CAS RN: 67-64-1 Hazmat - NFPA Hazard Classification SOMS DocID 2085807 Health: 1 (Slight) Materials that, on exposure, would cause significant irritation, but only minor residual injury, including those requiring the use of an approved air-purifying respirator. These materials are only slightly hazardous to health and only breathing protection is needed. Flammability: 3 (Severe) rhis degree includes Class IB and 1C flammable liquids and materials that can be easily ignited under almost all normal temperature conditions. Water may be ineffective in controlling or extinguishing fires in such materials. Instability: 0 (Minimal) This degree includes materials that are normally stable, even under fire exposure conditions, and that do not react with water.- Norma lire fighting procedures may be used. Printed by WISER for Windows (v2.3.231, database v2.108) HHS/NIH, National Library of Medicine AR000018 iile://C:\Documents and Settings\Gham\Application Data\National Library of Medicine\WISER\2.3.231.628... 9/27/20 Acetone ^Key Info Page 1 of Acetone CAS RN: 67-64-1 Key Info FLAMMABLE LIQUIDS (Polar / Water-Miscible) • HIGHLY FLAMMABLE: Easily ignited by heat, sparks or flames • CAUTION: Very low flash point; use of water spray when fighting fire may be inefficient Printed by WISER for Windows (v2.3.231, database v2.108) HHS/NIH, National Library of Medicine AR000019 file://C:\Documents and Settings\Gham\Application Data\National Library of Medicine\WISER\2.3.231.628../ 9/27/20 Acetone - -Hazmat - Explosive Limits / Potential Page 1 of Acetone CAS RIM: 67-64-1 Hazmat - Explosive Limits / Potential Highly flammable liquid. -

(VI) and Chromium (V) Oxide Fluorides

Portland State University PDXScholar Dissertations and Theses Dissertations and Theses 1976 The chemistry of chromium (VI) and chromium (V) oxide fluorides Patrick Jay Green Portland State University Follow this and additional works at: https://pdxscholar.library.pdx.edu/open_access_etds Part of the Chemistry Commons Let us know how access to this document benefits ou.y Recommended Citation Green, Patrick Jay, "The chemistry of chromium (VI) and chromium (V) oxide fluorides" (1976). Dissertations and Theses. Paper 4039. https://doi.org/10.15760/etd.5923 This Thesis is brought to you for free and open access. It has been accepted for inclusion in Dissertations and Theses by an authorized administrator of PDXScholar. Please contact us if we can make this document more accessible: [email protected]. All ABSTRACT OF THE TllESIS OF Patrick Jay Green for the Master of Science in Chemistry presented April 16, 1976. Title: Chemistry of Chromium(VI) and Chromium(V) Oxide Fluorides. APPROVEO BY MEMBERS OF THE THESIS CO'"o\l TIEE: y . • Ii . ' I : • • • • • New preparative routes to chromyl fluoride were sought. It was found that chlorine ironofluoride reacts with chromium trioxide and chromyl chlo ride to produce chromyl fluoride. Attempts were ~ade to define a mechan ism for the reaction of ClF and Cr0 in light of by-products observed 3 and previous investigations. Carbonyl fluoride and chromium trioxide react to fom chro·yl fluoride and carbo:i dioxide. A mechanism was also proposed for this react10n. Chromium trioxide 11itl\ l~F6 or WF5 reacts to produce chromyl fluoride and the respective oxide tetrafluoride. 2 Sulfur hexafluoride did not react with Cr03. -

Chemical Chemical Hazard and Compatibility Information

Chemical Chemical Hazard and Compatibility Information Acetic Acid HAZARDS & STORAGE: Corrosive and combustible liquid. Serious health hazard. Reacts with oxidizing and alkali materials. Keep above freezing point (62 degrees F) to avoid rupture of carboys and glass containers.. INCOMPATIBILITIES: 2-amino-ethanol, Acetaldehyde, Acetic anhydride, Acids, Alcohol, Amines, 2-Amino-ethanol, Ammonia, Ammonium nitrate, 5-Azidotetrazole, Bases, Bromine pentafluoride, Caustics (strong), Chlorosulfonic acid, Chromic Acid, Chromium trioxide, Chlorine trifluoride, Ethylene imine, Ethylene glycol, Ethylene diamine, Hydrogen cyanide, Hydrogen peroxide, Hydrogen sulfide, Hydroxyl compounds, Ketones, Nitric Acid, Oleum, Oxidizers (strong), P(OCN)3, Perchloric acid, Permanganates, Peroxides, Phenols, Phosphorus isocyanate, Phosphorus trichloride, Potassium hydroxide, Potassium permanganate, Potassium-tert-butoxide, Sodium hydroxide, Sodium peroxide, Sulfuric acid, n-Xylene. Acetone HAZARDS & STORAGE: Store in a cool, dry, well ventilated place. INCOMPATIBILITIES: Acids, Bromine trifluoride, Bromine, Bromoform, Carbon, Chloroform, Chromium oxide, Chromium trioxide, Chromyl chloride, Dioxygen difluoride, Fluorine oxide, Hydrogen peroxide, 2-Methyl-1,2-butadiene, NaOBr, Nitric acid, Nitrosyl chloride, Nitrosyl perchlorate, Nitryl perchlorate, NOCl, Oxidizing materials, Permonosulfuric acid, Peroxomonosulfuric acid, Potassium-tert-butoxide, Sulfur dichloride, Sulfuric acid, thio-Diglycol, Thiotrithiazyl perchlorate, Trichloromelamine, 2,4,6-Trichloro-1,3,5-triazine -

Chemical Name Federal P Code CAS Registry Number Acutely

Acutely / Extremely Hazardous Waste List Federal P CAS Registry Acutely / Extremely Chemical Name Code Number Hazardous 4,7-Methano-1H-indene, 1,4,5,6,7,8,8-heptachloro-3a,4,7,7a-tetrahydro- P059 76-44-8 Acutely Hazardous 6,9-Methano-2,4,3-benzodioxathiepin, 6,7,8,9,10,10- hexachloro-1,5,5a,6,9,9a-hexahydro-, 3-oxide P050 115-29-7 Acutely Hazardous Methanimidamide, N,N-dimethyl-N'-[2-methyl-4-[[(methylamino)carbonyl]oxy]phenyl]- P197 17702-57-7 Acutely Hazardous 1-(o-Chlorophenyl)thiourea P026 5344-82-1 Acutely Hazardous 1-(o-Chlorophenyl)thiourea 5344-82-1 Extremely Hazardous 1,1,1-Trichloro-2, -bis(p-methoxyphenyl)ethane Extremely Hazardous 1,1a,2,2,3,3a,4,5,5,5a,5b,6-Dodecachlorooctahydro-1,3,4-metheno-1H-cyclobuta (cd) pentalene, Dechlorane Extremely Hazardous 1,1a,3,3a,4,5,5,5a,5b,6-Decachloro--octahydro-1,2,4-metheno-2H-cyclobuta (cd) pentalen-2- one, chlorecone Extremely Hazardous 1,1-Dimethylhydrazine 57-14-7 Extremely Hazardous 1,2,3,4,10,10-Hexachloro-6,7-epoxy-1,4,4,4a,5,6,7,8,8a-octahydro-1,4-endo-endo-5,8- dimethanonaph-thalene Extremely Hazardous 1,2,3-Propanetriol, trinitrate P081 55-63-0 Acutely Hazardous 1,2,3-Propanetriol, trinitrate 55-63-0 Extremely Hazardous 1,2,4,5,6,7,8,8-Octachloro-4,7-methano-3a,4,7,7a-tetra- hydro- indane Extremely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]- 51-43-4 Extremely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]-, P042 51-43-4 Acutely Hazardous 1,2-Dibromo-3-chloropropane 96-12-8 Extremely Hazardous 1,2-Propylenimine P067 75-55-8 Acutely Hazardous 1,2-Propylenimine 75-55-8 Extremely Hazardous 1,3,4,5,6,7,8,8-Octachloro-1,3,3a,4,7,7a-hexahydro-4,7-methanoisobenzofuran Extremely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime 26419-73-8 Extremely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime. -

Acutely / Extremely Hazardous Waste List

Acutely / Extremely Hazardous Waste List Federal P CAS Registry Acutely / Extremely Chemical Name Code Number Hazardous 4,7-Methano-1H-indene, 1,4,5,6,7,8,8-heptachloro-3a,4,7,7a-tetrahydro- P059 76-44-8 Acutely Hazardous 6,9-Methano-2,4,3-benzodioxathiepin, 6,7,8,9,10,10- hexachloro-1,5,5a,6,9,9a-hexahydro-, 3-oxide P050 115-29-7 Acutely Hazardous Methanimidamide, N,N-dimethyl-N'-[2-methyl-4-[[(methylamino)carbonyl]oxy]phenyl]- P197 17702-57-7 Acutely Hazardous 1-(o-Chlorophenyl)thiourea P026 5344-82-1 Acutely Hazardous 1-(o-Chlorophenyl)thiourea 5344-82-1 Extemely Hazardous 1,1,1-Trichloro-2, -bis(p-methoxyphenyl)ethane Extemely Hazardous 1,1a,2,2,3,3a,4,5,5,5a,5b,6-Dodecachlorooctahydro-1,3,4-metheno-1H-cyclobuta (cd) pentalene, Dechlorane Extemely Hazardous 1,1a,3,3a,4,5,5,5a,5b,6-Decachloro--octahydro-1,2,4-metheno-2H-cyclobuta (cd) pentalen-2- one, chlorecone Extemely Hazardous 1,1-Dimethylhydrazine 57-14-7 Extemely Hazardous 1,2,3,4,10,10-Hexachloro-6,7-epoxy-1,4,4,4a,5,6,7,8,8a-octahydro-1,4-endo-endo-5,8- dimethanonaph-thalene Extemely Hazardous 1,2,3-Propanetriol, trinitrate P081 55-63-0 Acutely Hazardous 1,2,3-Propanetriol, trinitrate 55-63-0 Extemely Hazardous 1,2,4,5,6,7,8,8-Octachloro-4,7-methano-3a,4,7,7a-tetra- hydro- indane Extemely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]- 51-43-4 Extemely Hazardous 1,2-Benzenediol, 4-[1-hydroxy-2-(methylamino)ethyl]-, P042 51-43-4 Acutely Hazardous 1,2-Dibromo-3-chloropropane 96-12-8 Extemely Hazardous 1,2-Propylenimine P067 75-55-8 Acutely Hazardous 1,2-Propylenimine 75-55-8 Extemely Hazardous 1,3,4,5,6,7,8,8-Octachloro-1,3,3a,4,7,7a-hexahydro-4,7-methanoisobenzofuran Extemely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime 26419-73-8 Extemely Hazardous 1,3-Dithiolane-2-carboxaldehyde, 2,4-dimethyl-, O- [(methylamino)-carbonyl]oxime. -

Working with Hazardous Chemicals

A Publication of Reliable Methods for the Preparation of Organic Compounds Working with Hazardous Chemicals The procedures in Organic Syntheses are intended for use only by persons with proper training in experimental organic chemistry. All hazardous materials should be handled using the standard procedures for work with chemicals described in references such as "Prudent Practices in the Laboratory" (The National Academies Press, Washington, D.C., 2011; the full text can be accessed free of charge at http://www.nap.edu/catalog.php?record_id=12654). All chemical waste should be disposed of in accordance with local regulations. For general guidelines for the management of chemical waste, see Chapter 8 of Prudent Practices. In some articles in Organic Syntheses, chemical-specific hazards are highlighted in red “Caution Notes” within a procedure. It is important to recognize that the absence of a caution note does not imply that no significant hazards are associated with the chemicals involved in that procedure. Prior to performing a reaction, a thorough risk assessment should be carried out that includes a review of the potential hazards associated with each chemical and experimental operation on the scale that is planned for the procedure. Guidelines for carrying out a risk assessment and for analyzing the hazards associated with chemicals can be found in Chapter 4 of Prudent Practices. The procedures described in Organic Syntheses are provided as published and are conducted at one's own risk. Organic Syntheses, Inc., its Editors, and its Board of Directors do not warrant or guarantee the safety of individuals using these procedures and hereby disclaim any liability for any injuries or damages claimed to have resulted from or related in any way to the procedures herein. -

Systematic Qualitative Analysis

UNIT-7 SYSTEMATIC QUALITATIVE ANALYSIS NALYSIS always does not mean breaking of substance into its ultimate constituents. Finding out the nature of substance and identity of Aits constituents is also analysis and is known as qualitative analysis. Qualitative analysis of inorganic salts means the identification of cations and anions present in the salt or a mixture of salts. Inorganic salts may be obtained by complete or partial neutralisation of acid with base or vice-versa. In the formation of a salt, the part contributed by the acid is called anion and the part contributed by the base is called cation. For example, in the salts CuSO4 and 2+ + 2– – NaCl, Cu and Na ions are cations and SO4 and Cl ions are anions. Qualitative analysis is carried out on various scales. Amount of substance employed in these is different. In macro analysis, 0.1 to 0.5 g of substance and about 20 mL of solution is used. For semimicro analysis, 0.05 g substance and 1 mL solution is needed while for micro analysis amount required is very small. Qualitative analysis is carried out through the reactions which are easily perceptible to our senses such as sight and smell. Such reactions involve: (a) Formation of a precipitate (b) Change in colour (c) Evolution of gas etc. Systematic analysis of an inorganic salt involves the following steps: (i) Preliminary examination of solid salt and its solution. (ii) Determination of anions by reactions carried out in solution (wet tests) and confirmatory tests. (iii) Determination of cations by reactions carried out in solution (wet tests) and confirmatory tests. -

IIIHIIII USOO55.71489A United States Patent 19 11) Patent Number: 5,571,489 Holsen Et Al

IIIHIIII USOO55.71489A United States Patent 19 11) Patent Number: 5,571,489 Holsen et al. (45) Date of Patent: Nov. 5, 1996 54) PROCESS FOR CHROMUM RECOVERY 4,349,514 9/1982 Watanabe et al. ........................ 423154 FROMAQUEOUS SOLUTIONS 4,446,026 5/1984 Beutier et al. ..... ... 42.3/54 4,704,259 11/1987 Lipsztajn ............ ... 42.3/55 75) Inventors: Thomas M. Holsen, Oak Forest; Jan 5,112,583 5/1992 Bruzzone et al. ... 42.3/55 5,120,523 6/1992 Nakao et al. ...... ... 423/22 R. Selman; Subbarao L. Guddati, 5,260,039 11/1993 Schwab et al. ........ ... 423/24 both of Chicago, all of Ill. 5,271,910 12/1993 van der Meer et al. ................. 423/55 73) Assignee: Illinois Institute of Technology, FOREIGN PATENT DOCUMENTS Chicago, Ill. 1249841 9/1967 Germany ............................... 423f472 54-043172 4/1979 Japan ........ ... 423/53 21 Appl. No.: 380,851 56-015883 2/1981 Japan ... 423,595 22 Filed: Jan. 27, 1995 57-135724 8/1982 Japan ....................................... 423/53 OTHER PUBLICATIONS (51) Int. Cl.' .......................... C01G 37/00; CO1G 37/14; COG 37/02; CO1B 11/00 West, T. S., "Liquid-Liquid Extraction Procedures in Inor (52) U.S. C. ............................... 423/53; 423/54; 423/58; ganic Analysis', Metallurigia, p. 47, Jul., 1956. 423/472; 423/595; 42.3/596; 42.3/597; 423/607 Primary Examiner-Steven Bos (58 Field of Search .................................. 423/53, 54,58, Attorney, Agent, or Firm-Speckman, Pauley & Fejer 423/61, 472,595,596,597, 607 57 ABSTRACT 56 References Cited A process for recovery of chromium in an aqueous solution U.S. -

Chromium (Vi) Compounds

ARSENIC, METALS, FIBRES, AND DUSTS volume 100 C A review of humAn CArCinogens This publication represents the views and expert opinions of an IARC Working Group on the Evaluation of Carcinogenic Risks to Humans, which met in Lyon, 17-24 March 2009 LYON, FRANCE - 2012 iArC monogrAphs on the evAluAtion of CArCinogeniC risks to humAns CHROMIUM (VI) COMPOUNDS Chromium (VI) compounds were considered by previous IARC Working Groups in 1972, 1979, 1982, 1987, and 1989 (IARC, 1973, 1979, 1980, 1982, 1987, 1990). Since that time, new data have become available, these have been incorporated in the Monograph, and taken into consideration in the present evaluation. 1. Exposure Data Chromium (VI) compounds are customarily classed as soluble or insoluble in water. Examples 1.1 Identification of the agents of water-soluble chromium (VI) compounds are sodium chromate (873 g/L at 30 °C) and Synonyms, trade names, and molecular potassium chromate (629 g/L at 20 °C). Water- formulae for selected chromium (VI) compounds insoluble chromium (VI) compounds include are presented in Table 1.1. This list is not exhaus- barium chromate (2.6 mg/L at 20 °C), and lead tive, nor does it necessarily reflect the commercial chromate (0.17 mg/L at 20 °C) (Lide, 2008). importance of the various chromium-containing Compounds with solubilities in the middle of substances. Rather, it is indicative of the range of this range are not easily classified, and tech- chromium (VI) compounds available. nical-grade compounds, such as the various zinc chromates, can have a wide range of solubilities (IARC, 1990). -

Collodion, Usp

SAFETY DATA SHEET Preparation Date: 6/17/2015 Revision Date: 4/18/2017 Revision Number: G2 1. IDENTIFICATION Product identifier Product code: CO120 Product Name: COLLODION, USP Other means of identification Synonyms: No information available CAS #: Mixture RTECS # Not available CI#: Not available Recommended use of the chemical and restrictions on use Recommended use: No information available. Uses advised against No information available Supplier: Spectrum Chemical Mfg. Corp 14422 South San Pedro St. Gardena, CA 90248 (310) 516-8000. Order Online At: https://www.spectrumchemical.com Emergency telephone number Chemtrec 1-800-424-9300 Contact Person: Martin LaBenz (West Coast) Contact Person: Ibad Tirmiz (East Coast) 2. HAZARDS IDENTIFICATION Classification This chemical is considered hazardous according to the 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200) Considered a dangerous substance or mixture according to the Globally Harmonized System (GHS) Acute toxicity - Oral Category 4 Skin corrosion/irritation Category 2 Serious eye damage/eye irritation Category 2 Reproductive toxicity Category 1B Specific target organ toxicity (single exposure) Category 3 Specific target organ toxicity (repeated exposure) Category 1 Flammable liquids Category 1 Label elements Danger Hazard statements Harmful if swallowed Causes skin irritation Causes serious eye irritation May damage fertility or the unborn child May cause respiratory irritation. May cause drowsiness or dizziness Product code: CO120 Product name: COLLODION, USP 1 / 15 Causes -

Chromium Hexavalent Compounds

SUBSTANCE PROFILES Chromium Hexavalent Compounds* Additional Information Relevant to Carcinogenicity Known to be human carcinogens Chromosomal aberrations (changes in chromosome structure or First Listed in the First Annual Report on Carcinogens (1980) number), sister chromatid exchange, and aneuploidy (extra or missing Carcinogenicity chromosomes) were observed in workers exposed to chromium(VI) compounds. Chromium(VI) compounds also caused genetic damage Chromium hexavalent (VI) compounds are known to be human in a variety of test systems. Most caused mutations and DNA damage carcinogens based on sufficient evidence of carcinogenicity in humans. in bacteria; however, the poorly soluble compounds had to be Epidemiological studies in various geographical locations have dissolved in acids or alkalies to produce genetic effects. A few consistently reported increased risks of lung cancer among workers compounds also caused mutations in yeast and insects. Many engaged in chromate production, chromate pigment production, and chromium(VI) compounds caused genetic damage in cultured human chromium plating. Epidemiological studies of lung cancer among and other animal cells and in experimental animals exposed in vivo. ferrochromium workers were inconclusive. Exposure to specific The compounds tested included ammonium chromate and chromium compounds varies by industry. Chromate production workers dichromate, calcium chromate, chromium trioxide, sodium chromate are exposed to a variety of chromium compounds, including and dichromate, potassium chromate and dichromate, strontium chromium(VI) and trivalent (III) compounds. Chromate pigment chromate, and the industrial product basic zinc chromate (zinc workers are exposed to chromates in the pigment and to soluble yellow). Among the types of genetic damage observed were gene chromium(VI) compounds used in pigment production. -

BY Ty 1. AGENT 3,412,040 United States Patent Office Patented Nov

Nov. 19, 1968 P. SACCARDO EA 3,412,040 CHROMYL-OXYHALIDE TREATED CARRIER AS AN OLEFIN FOLYMERIZATION CATALYST Filed Aug. 5, 1964 FLUIDZED-BED E-Wasta Gasos REACTOR - SiOlAO : O. 15O-8OOC (Activation) PIETRO SACCARDO GIANNI TRADA VIITORIO FATTORE JEAN HERZENBERG INVENTORS. BY ty 1. AGENT 3,412,040 United States Patent Office Patented Nov. 19, 1968 1 2 3,412,040 the oxide which appears to be present as a molecular CHROMYL-OXYHALIDE TREATED CARRIER AS layer. AN OLEFIN POLYMERIZATION CATALYST It is the principal object of the present invention to Pietro Saccardo, Gianni Trada, Vittorio Fattore, and Jean provide an improved method of producing chromium Herzenberg, Milan, Italy, assignors to Montecatini Edi 5 containing catalytic systems suitable for use in the polym son, S.p.A., Milan, Italy, a corporation of Italy erization of olefins and for similar purposes. Filed Aug. 5, 1964, Ser. No. 387,732 Still another object of this invention is to provide a Claims priority, application Italy, Aug. 9, 1963, catalyst system having particular effectiveness in promot 16,875/63 2 Claims. (Cl. 252-441) ing polymerization reactions as described above. 10 These objects and others which will become apparent hereinafter are attained, in accordance with the method of the present invention, by treating a catalyst carrier ABSTRACT OF THE DISCLOSURE with a chromium oxychloride and, more specifically, with A single-component catalyst for the polymerization of a chromyl halide containing chlorine. The catalyst car alpha-olefins, consisting essentially of a silica-containing rier, thus coated with the chromium compound, is then catalyst carrier reacted with chromyl chloride (CrO2Cl2) subjected to activation by heating in the presence of a and/or chromyl fluorochloride (CrOFCI), alone or in fluid such as pure orygen, oxygen-containing gases or the presence of chromyl fluoride (CrOF), and there inert gases.