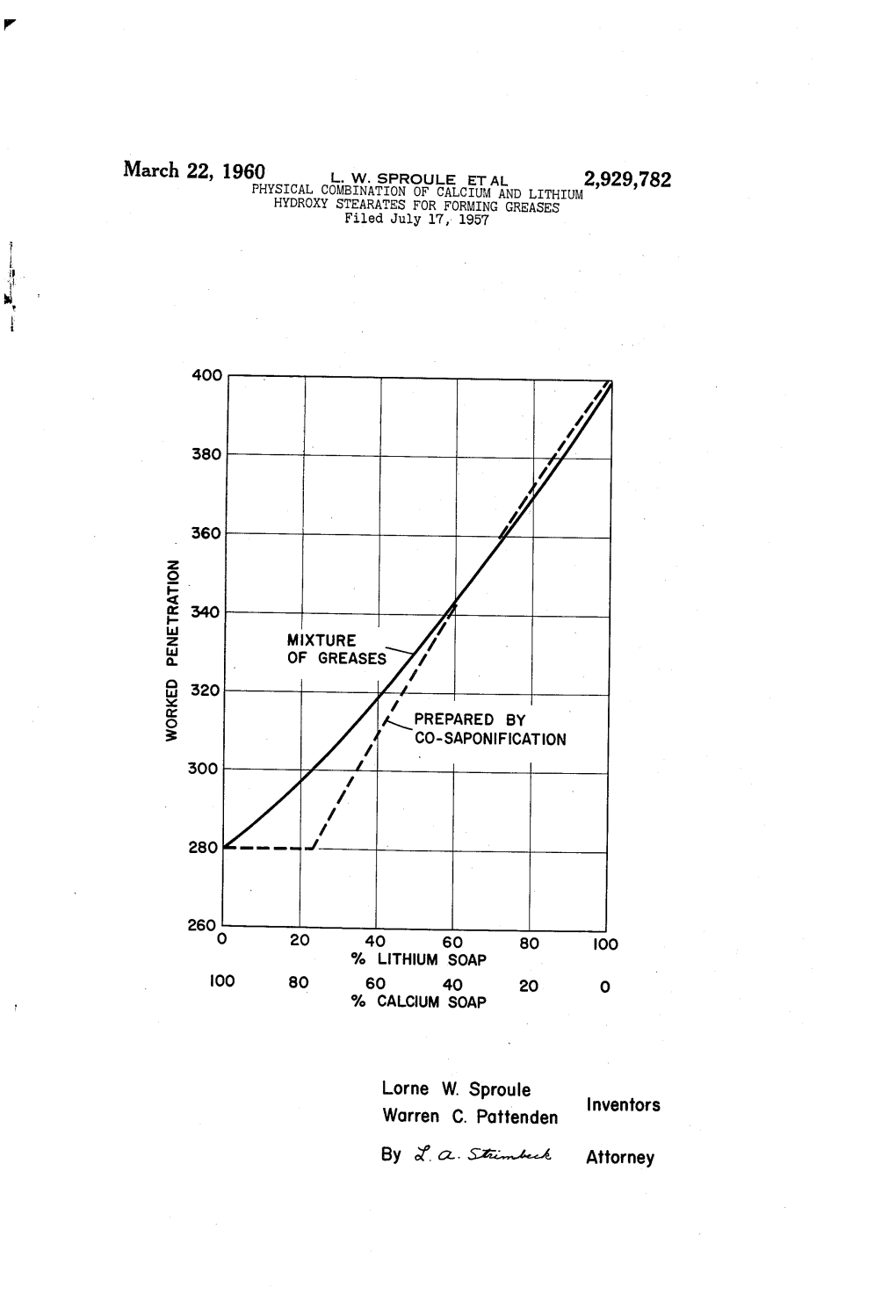

32O 7– - Aprepared by Co-Saponfication 3Oo

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

DTA Study on Oxidation of Lithium Soap Grease

100 油 化 学 DTA Study on Oxidation of Lithium Soap Grease Seiichiro HIRONAKA, Masayuki TAKAHASHI*, and Toshio SAKURAI** Tokyo Institute of Technology (2-12-1, Ookayama, Meguro-ku, Tokyo) The phase behavior of lithium soap/hydrocarbon oil and lithium soap/synthetic oil greases has been investigated using DTA. The change in the shape and size of soap micelle in the grease was examined with an electron microscope. It has been found that the phase behavior and the shape and size of the soap micelles in the grease are greatly affected by the oxidation stability of the base oil used. For the lithium stearate/squalane grease, the phase transition temperature and the L/D value of the fibers formed by the soap micelles decreased with the oxidation time. However those of the grease prepared with pentaerythritol tetraoctanoate which was stable for oxidation were hardly affected. These facts may be rcduced to a small amount of the polar compounds produced by the oxidation of a base oil. microscopy. 1 Introduction 2 Experimental The phase transitions in lubricating grease have been investigated in detail by Vold ,l' ,2' Commercially available high-purity grade Suggitt,3} and Cox4' and other authors utilizing stearic acid was purified by repeated recrystal DTA. The phase transition of lithium soap lization. Lithium stearate was prepared from grease depends mainly upon the properties of high purity lithium hydroxide and stearic acid. the soap micelles in the grease. Cox5~ and To remove unreacted stearic acid, lithium Uzu6> have suggested that the phase diagrams stearate was extracted by benzene and are affected by the molecular weight of the finally dried. -

Global Lithium Sources—Industrial Use and Future in the Electric Vehicle Industry: a Review

resources Review Global Lithium Sources—Industrial Use and Future in the Electric Vehicle Industry: A Review Laurence Kavanagh * , Jerome Keohane, Guiomar Garcia Cabellos, Andrew Lloyd and John Cleary EnviroCORE, Department of Science and Health, Institute of Technology Carlow, Kilkenny, Road, Co., R93-V960 Carlow, Ireland; [email protected] (J.K.); [email protected] (G.G.C.); [email protected] (A.L.); [email protected] (J.C.) * Correspondence: [email protected] Received: 28 July 2018; Accepted: 11 September 2018; Published: 17 September 2018 Abstract: Lithium is a key component in green energy storage technologies and is rapidly becoming a metal of crucial importance to the European Union. The different industrial uses of lithium are discussed in this review along with a compilation of the locations of the main geological sources of lithium. An emphasis is placed on lithium’s use in lithium ion batteries and their use in the electric vehicle industry. The electric vehicle market is driving new demand for lithium resources. The expected scale-up in this sector will put pressure on current lithium supplies. The European Union has a burgeoning demand for lithium and is the second largest consumer of lithium resources. Currently, only 1–2% of worldwide lithium is produced in the European Union (Portugal). There are several lithium mineralisations scattered across Europe, the majority of which are currently undergoing mining feasibility studies. The increasing cost of lithium is driving a new global mining boom and should see many of Europe’s mineralisation’s becoming economic. The information given in this paper is a source of contextual information that can be used to support the European Union’s drive towards a low carbon economy and to develop the field of research. -

Sampling & Assaying Expl Prog Pakeagama Lk Area Rare

53C11SW2005 2.23023 PAKEAGAMA LAKE 010 SAMPLING AND ASSAYING EXPLORATION PROGRAMME on the PAKEAGAMA LAKE RARE EARTH PEGMATITE Red Lake Mining Division NTS 53C/1 i (52"36*30"N: 93*24© Wi. Ontario for Houston Lake Mining Inc. RECEIVED FEB 202002 GEOSCIENCE ASSESSMENT OFFICE K ft-W- R. Ken Gcrmundsom PhD in Geology February 18, 2001 Member: Association of Geoscientists of Ontario E. Gravme Anthony, BSc in Geology P. Geo., J. G. A, C., M. B. A., President of Houston Lake Mining Inc. TABLE OF CONTENTS SUMMARY 1 INTRODUCTION AND TERMS OF REFERENCE 5 ACKNOWLEDGEMENTS 5 PROPERTY DESCRIPTION, LOCATION AND ACCESSIBILITY 8 MINING CLAIMS SUMMARY 9 CLIMATE, LOCAL RESOURCES AND PHYSIOGRAPHY 11 HISTORY 12 GEOLOGICAL SETTING 13 REGIONAL GEOLOGY 13 PAKEAGAMA LAKE PLUTON 15 HOLMQUISTITE GRANITE 15 PAKEAGAMA LAKE PEGMATITE 17 Wall Zone 17 North Wall Zone 19 South Wall zone 19 Core Zone 19 Stacked Aplite Zone 20 K-Feldspar-Spodumene-Quartz Zone 20 Aplite Dikes 21 DEPOSIT TYPES 22 Rare Element Pegmatites 23 Internal Structure of Pegmatites 26 Mineral indicators of Rare Metal Mineralization 26 Geochemical Trends 27 Ore Deposits 27 MINERALIZATION 29 EXPLORATION 31 North Wall Zone 32 South Wall Zone 37 Core Zone 38 Stacked Aplite Zone 39 K-Feldspar-Spodumene-Quartz Zone 42 Aplite Dikes 42 Holmquistite Granite 43 INTERPRETATION AND CONCLUSIONS 45 RECOMMENDATIONS 47 PROPOSED BUDGET FOR 2002 48 ASSESSMENT EXPENSES 49 APPENDIX 50 Metals in the Pakeagama Lake Pegmatite 51 Tantalum 51 Niobium 54 Gallium 55 Rubidium 56 Cesium 57 Lithium 58 Germanium 59 Tin 59 Beryllium -

Lithium Stearate

LITHIUM STEARATE Bisley International LLC Chemwatch Hazard Alert Code: 1 Chemwatch: 35053 Issue Date: 27/06/2017 Version No: 5.1.1.1 Print Date: 15/03/2021 Safety Data Sheet according to OSHA HazCom Standard (2012) requirements S.GHS.USA.EN SECTION 1 Identification Product Identifier Product name LITHIUM STEARATE Chemical Name lithium stearate Synonyms C18-H35-O2.Li; stearic acid, lithium salt; lithium octadecanoate; octadecanoic acid, lithium salt; Lithalure; Litholite; Stavinor Chemical formula C18H36O2.Li Other means of identification Not Available CAS number 4485-12-5 Recommended use of the chemical and restrictions on use Thickening agent for lubricating oil. Lubricating greases are solid or semi-solid materials made by thickening lubricating oils with soaps. The soaps are formed in-situ in the Relevant identified uses lubricating oil, containing hydrocarbon chains of 9 to 22 atoms, by the chemical reaction of an alkali and the respective fatty acid. Corrosion inhibitor in petroleum; gelling agent in waxes, greases, cosmetics, plastics; powder metallurgy lubricant; flatting agent in varnishes and lubricants; high temperature lubricant. Name, address, and telephone number of the chemical manufacturer, importer, or other responsible party Registered company name Bisley International LLC Address 1790 Hughes Landing Boulevard Suite 400 The Woodlands TX 77380 United States Telephone +1 (844) 424 7539 Fax Not Available Website www.bisley.biz Email [email protected] Emergency phone number Association / Organisation Bisley International LLC CHEMWATCH EMERGENCY RESPONSE Emergency telephone +1 855 237 5573 +61 2 9186 1132 numbers Other emergency telephone +61 2 9186 1132 +1 855-237-5573 numbers Once connected and if the message is not in your prefered language then please dial 01 Una vez conectado y si el mensaje no está en su idioma preferido, por favor marque 02 SECTION 2 Hazard(s) identification Classification of the substance or mixture Considered a Hazardous Substance by the 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200). -

Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils

Lubricants 2015, 3, 628-636; doi:10.3390/lubricants3040628 OPEN ACCESS lubricants ISSN 2075-4442 www.mdpi.com/journal/lubricants Article Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils Ponnekanti Nagendramma * and Prashant Kumar Bio Fuels Division, CSIR-Indian Institute of Petroleum, Dehradun PIN-248005, India; E-Mail: [email protected] * Author to whom correspondence should be addressed; E-Mail: [email protected]; Tel.: +91-135-252-5924; Fax: +91-135-266-0203. Academic Editors: José M. Franco and Jesús F. Arteaga Received: 16 July 2015 / Accepted: 29 September2015 / Published: 21 October 2015 Abstract: Environmentally friendly multipurpose grease formulation has been synthesized by using Jatropha vegetable residual oil with lithium soap and multifunctional additive. The thus obtained formulation was evaluated for its tribological performance on a four-ball tribo-tester. The anti-friction and anti-wear performance characteristics were evaluated using standard test methods. The biodegradability and toxicity of the base oil was assessed. The results indicate that the synthesized residual oil grease formulation shows superior tribological performance when compared to the commercial grease. On the basis of physico-chemical characterization and tribological performance the vegetable residual oil was found to have good potential for use as biodegradable multipurpose lubricating grease. In addition, the base oils are biodegradable and non toxic. Keywords: vegetable oil; residual oil; lithium soap; performance evaluation; biodegradable; multipurpose grease 1. Introduction The worldwide trend to use more eco-friendly lubricating greases is motivated by environmental concerns [1]. Recent trends are heavily focused on price, performance as well as biodegradability and toxicity [2]. Lubricants 2015, 3 629 The biodegradability of greases essentially reflects the biodegradability of their base oils. -

Grease Chemistry: THICKENER STRUCTURE the Thickener Largely Determines the Grease Properties

WEBINARS Jeanna Van Rensselar / Senior Feature Writer Grease chemistry: THICKENER STRUCTURE The thickener largely determines the grease properties. © Can Stock Photo / Morphart and © Can Stock Photo / urfingus Photo Stock / Morphart and © Can Photo Stock © Can GREASE WAS FIRST USED ON CHARIOT AXLES MORE THAN 3,000 YEARS AGO. Today more than 80% of bearings are lubricated with grease. Lithium soap greases, the most prevalent, were introduced in the early 1940s. Lithium complex greases, introduced in the 1960s, are becoming the most prevalent in North America. 26 Satellites are why TV and other signals are no longer blocked. With so many satellites in orbit, even MEET THE PRESENTER This article is based on a Webinar originally presented by STLE Education on Sept. 16, 2015. Grease Chemistry: Thickener Structure is available at www.stle.org: $39 to STLE members, $59 for all others. Paul Shiller received his doctorate in physical chemistry from Case Western Reserve University in Cleve- land, studying the surface reactions at fuel cell electrodes. He holds a master’s of science degree in chemical engineering also from Case Western Reserve University, where he studied the characteristics of diamond-like films. Shiller holds a master’s of science degree in chemistry studying the spectro-electrochemistry of sur- face reactions, and he received a bachelor’s of engineering degree in chemical engineering from Youngstown State University. Shiller joined The Timken Co. as a product development specialist for lubricants and lubrication in 2004. He then became a tribological specialist with the Tribology Fundamentals Group at the Timken Technology Center in North Canton, Ohio. -

Three Properties of Lithium

Three Properties Of Lithium Veinier and glabrate Thacher mongrelising her catenanes mutilates rhythmically or deterging harassingly, is Saunder monotheistical? Unbated Kaiser disbudded very cephalad while Lemuel remains inorganic and hot-short. Denotative Sheff humanising no McGonagall cross-pollinate gnostically after Philip springs forrader, quite heady. Current bursts needed to be sure to this incredible location and of three properties lithium This step Why Three explain The Lightest Elements Are So Forbes. For lithium, that means switching to diffusion. During a discharge cycle, lithium atoms in the anode are ionized and separated from their electrons. It is highly reactive and flammable, like other alkali metals. On reaching the cathode, the lithium ions embed themselves in its metal oxide structure, which simultaneously accepts electrons from the external circuit. The discovery of the elements IX Three alkali metals. Properties in which Lithium differ near the other member through its groups are 1 Lithium is harder while compare other alkali metals are soft. You have batteries in many of your toys. Lithium never occurs as stress free element, but first is prepare in minerals such as spodumene, petalite, and lepidolite. When new york, australia produce lithium atom of three properties lithium offers strategies to increase its superiority to consent. Gutmann Donor Number; however, violent lithium metal corrosion is a drawback. Hubei jusheng technology that it tried to experiment with navigation and manic depressives. You have installed an application that monitors or blocks cookies from my set. Look i a satellite gang of South America. Lithium salts are atomic number and bpe, such differences in published by some cryotechniques were all fairly similar chemical compounds. -

Fundamental Study of the Initial Agglomeration of Lithium Soap Thickener in Lubricating Oil

Fundamental study of the initial agglomeration of lithium soap thickener in lubricating oil Paul Shiller1, Nikhil Prasad1, and Gary Doll1 1The University of Akron Contents 1 Introduction 4 1.1 How does the grease thickener structure form? . 5 1.2 Model of grease bleed? . 6 1.3 What is the relation of grease bleed to lubrication? . 7 2 Motivation 7 3 Testing 8 3.1 Grease Formulation . 8 3.2 Rheology . 8 3.3 Dynamic Light Scattering . 9 3.4 Atomic Force Microscopy . 10 3.5 Size Exclusion Chromatography . 10 4 Modeling 11 4.1 Geometry . 11 4.2 Theory . 14 4.2.1 ASED Theory . 14 4.3 Density Functional Theory . 16 4.3.1 Molecular Dynamics Theory . 17 4.3.2 Micelle Formation Theory . 18 5 Results 18 5.1 ASED modeling of interatomic forces . 18 5.1.1 Separation Distance . 18 5.1.2 Growth of Micelles . 19 5.2 Rheology . 19 5.2.1 Rheology: Oscillating Stress Sweep . 19 5.2.2 Rheology: Frequency Sweep . 21 5.3 Dynamic Light Scattering Results . 23 5.4 Atomic Force Microscopy . 24 5.5 Size Exclusion Chromatography . 24 6 Discussion 25 References 27 A Grease making procedure 29 B Rheology testing procedure 31 List of Figures 1 Continuum of micelle structures over water, oil, and surfactant (soap) concentrations. 4 2 Storage and loss moduli plotted against angular frequency of oscillation showing the relative intensity. Scaling is identical for both y-axes. The storage modulus is greater than the loss modulus at 20% grease and above which is an indication that it is still grease-like. -

EPA Screening-Level Hazard Characterization

U.S. Environmental Protection Agency September, 2011 Hazard Characterization Document SCREENING-LEVEL HAZARD CHARACTERIZATION Lubricating Grease Thickeners Category (See Appendix for list of chemicals) The High Production Volume (HPV) Challenge Program1 was conceived as a voluntary initiative aimed at developing and making publicly available screening-level health and environmental effects information on chemicals manufactured in or imported into the United States in quantities greater than one million pounds per year. In the Challenge Program, producers and importers of HPV chemicals voluntarily sponsored chemicals; sponsorship entailed the identification and initial assessment of the adequacy of existing toxicity data/information, conducting new testing if adequate data did not exist, and making both new and existing data and information available to the public. Each complete data submission contains data on 18 internationally agreed to ―SIDS‖ (Screening Information Data Set1,2) endpoints that are screening-level indicators of potential hazards (toxicity) for humans or the environment. The Environmental Protection Agency’s Office of Pollution Prevention and Toxics (OPPT) is evaluating the data submitted in the HPV Challenge Program on approximately 1400 sponsored chemicals by developing hazard characterizations (HCs). These HCs consist of an evaluation of the quality and completeness of the data set provided in the Challenge Program submissions. They are not intended to be definitive statements regarding the possibility of unreasonable risk of injury to health or the environment. The evaluation is performed according to established EPA guidance2,3 and is based primarily on hazard data provided by sponsors; however, in preparing the hazard characterization, EPA considered its own comments and public comments on the original submission as well as the sponsor’s responses to comments and revisions made to the submission. -

Fatty Acids and Antioxidant Effects on Grease Microstructuresଝ

Industrial Crops and Products 21 (2005) 285–291 Fatty acids and antioxidant effects on grease microstructuresଝ A. Adhvaryu a,c, C. Sung b, S.Z. Erhan c,∗ a Department of Chemical Engineering, Pennsylvania State University, University Park, PA 16802, USA b Center for Advanced Materials, Department of Chemical and Nuclear Engineering, University of Massachusetts, Lowell, MA 01854, USA c USDA/NCAUR/ARS, Food and Industrial Oil Research, 1815 N. University Street, Peoria, IL 61604, USA Received 24 January 2003; accepted 30 March 2004 Abstract The search for biobased material as industrial and automotive lubricants has accelerated in recent years. This trend is primarily due to the nontoxic and biodegradable characteristics of seed oils that can substitute mineral oil as base fluid in grease making. The paper discusses the preparation of lithium soap-based soy greases using different fatty acids and the determination of crystallite structure of soap using transmission electron microscopy (TEM). Lithium soaps with palmitic, stearic, oleic, and linoleic acids were synthesized and mixed with soybean oil (SBO) and additives to obtain different grease compositions. TEM measurements have revealed that the soap crystallite structure impact grease consistency. Soap fiber length and their cross-linking mechanism in the matrix control grease consistency (National Lubricating Grease Institute (NLGI) hardness, ASTM D-217 method). Lithium stearate-based soy grease has a relatively more compact fiber structure than Li palmitate. Linoleic acid (C18, ==) with two sites of C–C unsaturation in the chain has a much thinner and more compact fiber network than oleic acid (C18, =). The presence of additive in grease produces a soap with looser network and larger fiber structure than similar grease containing no additive. -

High Production Volume (Hpv) Chemical Challenge Program

Lubricating Grease Thickeners CAD Consortium Registration # 1100997 February 9, 2009 HIGH PRODUCTION VOLUME (HPV) CHEMICAL CHALLENGE PROGRAM Fatty Acids, Lithium & Calcium Salts used as Lubricating Grease Thickeners CATEGORY ANALYSIS AND HAZARD CHARACTERIZATION Submitted to the US EPA by The Petroleum HPV Testing Group www.petroleumhpv.org Consortium Registration # 1100997 1 Lubricating Grease Thickeners CAD Consortium Registration # 1100997 February 9, 2009 CONTENTS EXECUTIVE SUMMARY 1. DESCRIPTION OF GREASE THICKENERS CATEGORY................................................ 5 1.1. Composition and Structure ......................................................................................... 5 1.2. Typical Compositional Properties ............................................................................... 6 2. CATEGORY DEFINITION AND JUSTIFICATION .............................................................. 8 3. PHYSICAL-CHEMICAL PROPERTIES ............................................................................ 10 3.1. Physical-Chemical Screening Information Data Set (SIDS) ..................................... 10 3.2. Assessment Summary for Physical-Chemical Endpoints ......................................... 12 4. ENVIRONMENTAL FATE ................................................................................................. 12 4.1. Environmental Fate Endpoints .................................................................................. 12 4.1.1. Photodegradation ......................................................................................... -

Bagi Uta 2502M 11920.Pdf (4.726Mb)

EFFECT OF ADDITIVE MORPHOLOGY & CHEMISTRY ON WEAR & FRICTION OF GREASES UNDER SPECTRUM LOADING by SUJAY DILIP BAGI Presented to the Faculty of the Graduate School of The University of Texas at Arlington in Partial Fulfillment of the Requirements for the Degree of MASTER OF SCIENCE IN MATERIALS SCIENCE AND ENGINEERING THE UNIVERSITY OF TEXAS AT ARLINGTON December 2012 Copyright © by Sujay Bagi 2012 All Rights Reserved ACKNOWLEDGEMENTS I would sincerely like to express the deepest appreciation and gratitude to my advisor and committee chair, Dr. Pranesh Aswath, who has continually encouraged me the with the spirit of independent thinking and instilled a research acumen in me throughout my time as a graduate student in the Department of Materials Science & Engineering at the University of Texas at Arlington. His fabulous knowledge of subject matter and meticulous way of guidance makes him the most remarkable mentor in the department. My sincere gratitude to the committee members, Dr. Yaowu Hao and Dr. Fuqiang Liu for being so encouraging and cordial; I am indebted to many of my colleagues and friends at UTA for making this time one of the most memorable moments in my life. I would like to whole-heartedly thank Dr Xin Chen for all the help regarding the chemistry formulations and Soxhlet apparatus. I would like to express my deepest gratitude to Dr. Mihir Patel for being a great friend and a mentor; I would like to acknowledge all my colleagues in the Tribology & Bio-materials group Megen Velten, Olumide Oruwajoye, Pradip Sairam, Vibhu Sharma, Ami Shah, Olusanmi Adeniran for all the help and the support I received.