United States Patent Office Patented Oct

Total Page:16

File Type:pdf, Size:1020Kb

Load more

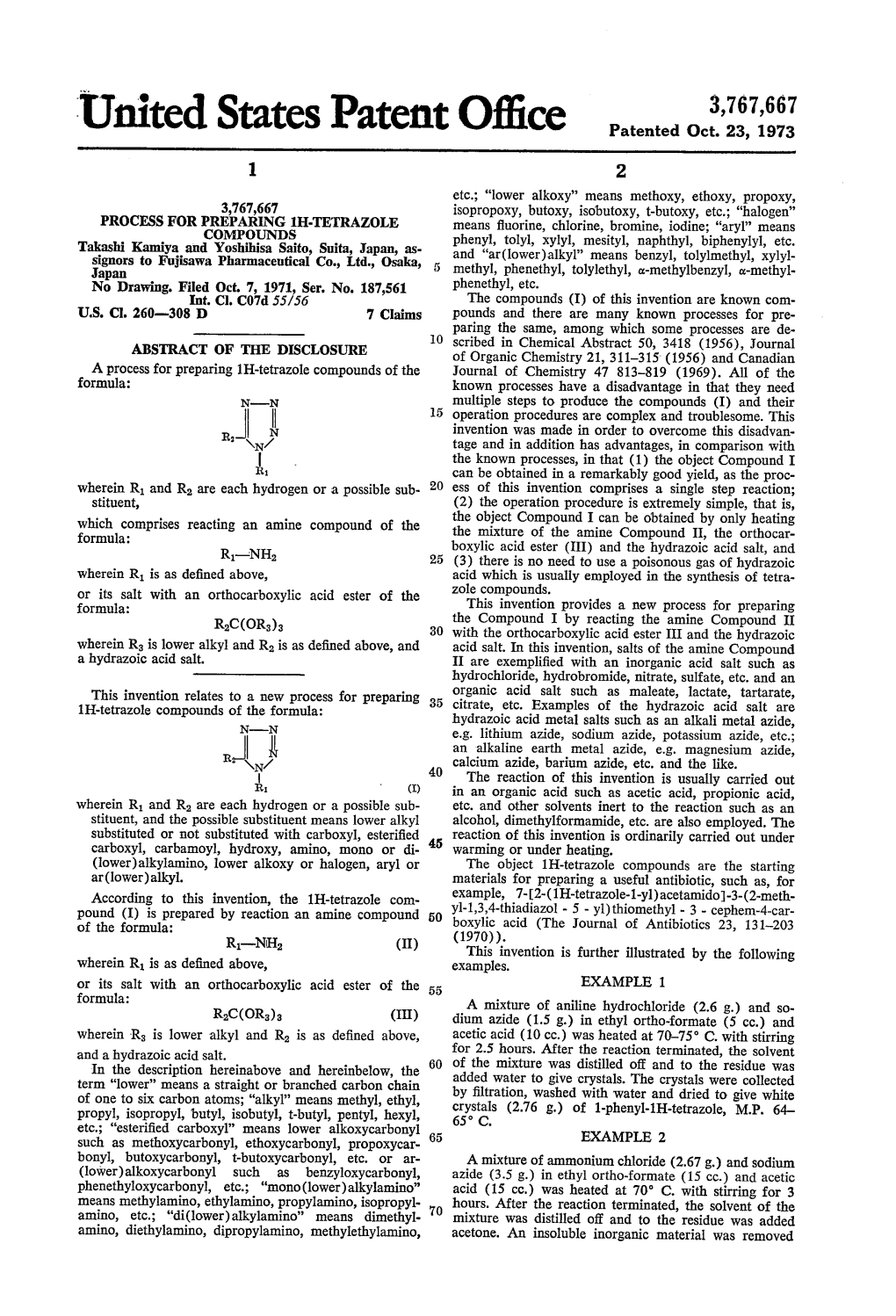

Recommended publications

-

Transport of Dangerous Goods

ST/SG/AC.10/1/Rev.16 (Vol.I) Recommendations on the TRANSPORT OF DANGEROUS GOODS Model Regulations Volume I Sixteenth revised edition UNITED NATIONS New York and Geneva, 2009 NOTE The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the Secretariat of the United Nations concerning the legal status of any country, territory, city or area, or of its authorities, or concerning the delimitation of its frontiers or boundaries. ST/SG/AC.10/1/Rev.16 (Vol.I) Copyright © United Nations, 2009 All rights reserved. No part of this publication may, for sales purposes, be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, electrostatic, magnetic tape, mechanical, photocopying or otherwise, without prior permission in writing from the United Nations. UNITED NATIONS Sales No. E.09.VIII.2 ISBN 978-92-1-139136-7 (complete set of two volumes) ISSN 1014-5753 Volumes I and II not to be sold separately FOREWORD The Recommendations on the Transport of Dangerous Goods are addressed to governments and to the international organizations concerned with safety in the transport of dangerous goods. The first version, prepared by the United Nations Economic and Social Council's Committee of Experts on the Transport of Dangerous Goods, was published in 1956 (ST/ECA/43-E/CN.2/170). In response to developments in technology and the changing needs of users, they have been regularly amended and updated at succeeding sessions of the Committee of Experts pursuant to Resolution 645 G (XXIII) of 26 April 1957 of the Economic and Social Council and subsequent resolutions. -

Green Synthetic Approach to 5-Substituted-1H-Tetrazoles Via Recycle and Reuse of Tributyltin Chloride

Asian Journal of Chemistry; Vol. 25, No. 1 (2013), 393-396 http://dx.doi.org/10.14233/ajchem.2013.13106 Green Synthetic Approach to 5-Substituted-1H-Tetrazoles via Recycle and Reuse of Tributyltin Chloride 1,* 2 1 3 A. SAMPATH , V. PRABHAKAR REDDY , A. KALYAN CHAKRAVARTHY and P. PRATAP REDDY 1Research and Development, Integrated Product Development, Innovation Plaza, Dr Reddy's Laboratories Ltd., Survey Nos. 42, 45, 46 and 54, Bachupally, Qutubullapur, Ranga Reddy District-500 123, India 2Department of Chemistry, P.G. College of Science, Osmania University, Saifabad, Hyderabad-500 004, India 3Research and Development, Macleods Pharmaceuticals Limited, G-2, Mahakali Caves Road, Andheri (E), Mumbai-400 093, India *Corresponding author: E-mail: [email protected] (Received: 25 November 2011; Accepted: 28 July 2012) AJC-11886 A simple, safe and efficient process for the recycle of tributyltin chloride from tributyltin hydroxide is developed and its reuse in the synthesis of 5-substituted-1H-tetrazoles is successfully demonstrated, which paved a way to reduce the toxic tin waste significantly. Recycling of tributyltin chloride is possible over six cycles without loss of its activity. Key Words: 5-Substituted-1H-tetrazole, [3+2] Cycloaddition, Nitrile, Recycle, Tributyltin chloride, Tributyltin hydroxide. INTRODUCTION fluorous tin bromide, used in the preparation of tetrazoles as fluorous tin chloride by acidic hydrolysis of stannyl tetrazole. The nitrogen-rich tetrazole moiety is an integral part of But the usage of fluorous tin bromide is commercially not 1 several molecules, which find application as propellants , viable, as it is more expensive than tributyltin chloride. More- 2 3 explosives and pharmaceuticals . -

Download Author Version (PDF)

Organic & Biomolecular Chemistry Accepted Manuscript This is an Accepted Manuscript, which has been through the Royal Society of Chemistry peer review process and has been accepted for publication. Accepted Manuscripts are published online shortly after acceptance, before technical editing, formatting and proof reading. Using this free service, authors can make their results available to the community, in citable form, before we publish the edited article. We will replace this Accepted Manuscript with the edited and formatted Advance Article as soon as it is available. You can find more information about Accepted Manuscripts in the Information for Authors. Please note that technical editing may introduce minor changes to the text and/or graphics, which may alter content. The journal’s standard Terms & Conditions and the Ethical guidelines still apply. In no event shall the Royal Society of Chemistry be held responsible for any errors or omissions in this Accepted Manuscript or any consequences arising from the use of any information it contains. www.rsc.org/obc Page 1 of 10 OrganicPlease & doBiomolecular not adjust margins Chemistry Journal Name ARTICLE Steering the Azido-Tetrazole Equilibrium of 4-Azidopyrimidines via Substituent Variation – Implications for Drug Design and Received 00th January 20xx, Azide-Alkyne Cycloadditions Accepted 00th January 20xx Manuscript a b c ,a ,a,d DOI: 10.1039/x0xx00000x A. Thomann, J. Zapp, M. Hutter, M. Empting* and R. W. Hartmann* www.rsc.org/ This paper focuses on an interesting constitutional isomerism called azido-tetrazole equilibrium which is observed in azido- substituted N-heterocycles. We present a systematic investigation of substituent effects on the isomer ratio within a 2- substituted 4-azidopyrimidine model scaffold. -

Synthesis of 5-Substituted 1H-Tetrazoles from Nitriles And

Angewandte Chemie DOI: 10.1002/anie.201003733 Microreactors Synthesis of 5-Substituted 1H-Tetrazoles from Nitriles and Hydrazoic Acid by Using a Safe and Scalable High-Temperature Microreactor Approach** Bernhard Gutmann, Jean-Paul Roduit, Dominique Roberge,* and C. Oliver Kappe* Dedicated to Professor K. Barry Sharpless Interest in tetrazole chemistry over the past few years has have been introduced as comparatively safe azide sources been increasing rapidly, mainly as a result of the role played (sometimes prepared in situ), that have the added benefit of by this heterocyclic functionality in medicinal chemistry as a being soluble in organic solvents. Unfortunately, with very metabolically stable surrogate for carboxylic acid function- few exceptions, all of these methods require long reaction alities.[1] Additional important applications for tetrazoles are times (several hours to days) in combination with high found in coordination chemistry, materials science, and as reaction temperatures. intermediates in a variety of synthetic transformations.[2] Based on atom economy and environmental impact, the The most common synthetic approach to prepare conceptually most straightforward approach to the tetrazole 5-substituted 1H-tetrazole derivatives involves the addition nucleus involves the direct addition of hydrazoic acid (HN3) of azide salts to organic nitriles in a temperature range of to organic nitriles, first attempted in 1932.[15] Unfortunately, [1,2] typically 100–1508C (Scheme 1). A plethora of synthetic HN3 is extremely toxic (comparable to HCN) and owing to the explosive nature and low boiling point (378C) of this high- [16] energy material procedures involving free HN3 have not found any practical application in tetrazole synthesis so far. -

Nitrosamines EMEA-H-A5(3)-1490

25 June 2020 EMA/369136/2020 Committee for Medicinal Products for Human Use (CHMP) Assessment report Procedure under Article 5(3) of Regulation EC (No) 726/2004 Nitrosamine impurities in human medicinal products Procedure number: EMEA/H/A-5(3)/1490 Note: Assessment report as adopted by the CHMP with all information of a commercially confidential nature deleted. Official address Domenico Scarlattilaan 6 ● 1083 HS Amsterdam ● The Netherlands Address for visits and deliveries Refer to www.ema.europa.eu/how-to-find-us Send us a question Go to www.ema.europa.eu/contact Telephone +31 (0)88 781 6000 An agency of the European Union © European Medicines Agency, 2020. Reproduction is authorised provided the source is acknowledged. Table of contents Table of contents ...................................................................................... 2 1. Information on the procedure ............................................................... 7 2. Scientific discussion .............................................................................. 7 2.1. Introduction......................................................................................................... 7 2.2. Quality and safety aspects ..................................................................................... 7 2.2.1. Root causes for presence of N-nitrosamines in medicinal products and measures to mitigate them............................................................................................................. 8 2.2.2. Presence and formation of N-nitrosamines -

Nitrous Acid)

5. Nitrogen Group Content 5.1 Occurrence 5.2 Group Properties Group 5.3 Physical Properties 15 or VA 5.4 Syntheses 7 1772 5.5 Chemical Behaviour N 15 5.6 Applications 1669 5.7 Chemistry of Elemental Nitrogen P 33 5.8 Compounds Made of Nitrogen and Hydrogen Antique 5.9 Nitrogen Compounds with Oxygen As 51 5.10 Nitrogen Compounds with Halides Antique Sb 5.11 Phosphorus/Hydrogen Compounds 83 1753 5.12 Phosphorus Oxides Bi 5.13 Oxo Acids of Phosphorus 115 2003 5.14 Phosphorus Compounds with Halides Mc 5.15 Arsenic, Antimony and Bismuth 5.16 Biological Aspects „Penteles“ Inorganic Chemistry I Slide 1 Prof. Dr. T. Jüstel 5.1 Occurrence Außer Phosphor kommen alle Pentele auch elementar (gediegen) vor Nitrogen (nitrogenium) N2 (78.1% in the air) NaNO3 Chile saltpetre KNO3 Saltpetre Phosphorus (phosphoros) Ca5(PO4)3(OH,F) Apatite greek: lightbearer Ca3(PO4)2 Phosphorite . Fe3(PO4)2 8H2O Vivianite Arsenic (arsenikos) FeAsS Arsenopyrite greek: mineral name As4S4 Realgar As4S3 Antimony (antimonium) Sb native Stibium = greek mineral name Sb2S3 Bismuth (bismutum) Bi native german: Wismut = Mutung “in the meadows” Bi2S3 Inorganic Chemistry I Slide 2 Prof. Dr. T. Jüstel 5.2 Group Properties Whereas Nitrogen Exhibits the Typical Properties of A Non-Metal, Bismuth Is Solely Metallic N P As Sb Bi Atomic number 7 15 33 51 83 Electronic [He] [Ne] [Ar] [Kr] [Xe]4f14 configuration 2s22p3 3s23p3 3d104s24p3 4d105s25p3 5d106s26p3 Electronegativity 3.0 2.1 2.2 1.8 1.7 Ionisation energy [eV] 14.5 11.0 9.8 8.6 7.3 Electronic affinity [eV] -0.3 0.6 0.7 0.6 > 0.7 Character of oxides acidic acidic amphoteric amphoteric alkaline Oxidation states -3, ...…, +5 With increasing atomic number, the oxidation state +3 becomes more stable, whilst the oxidation state +5 becomes instable. -

United States Patent Office Patented Aug

3,832,364 United States Patent Office Patented Aug. 27, 1974. 2 zene, o-, m- and p-dichlorobenzene, anisole, methyl. 3,832,364 benzyl ether, n-propyl phenyl ether, m-ethyl-anisole, 4 AMINATION OF AROMATIC COMPOUNDS IN methyldiphenyl ether, di-p-tolyl ether, ethyl 2-cyclohexyl LIQUID HYDROGEN FLUORIDE Dale Robert Coulson, Wilmington, Del assignor to E. I. phenyl ether, n-heptyl phenyl ether, isobutyl phenyl ether, du Pont de Nemours and Company, Wilmington, Del. 5 cyclohexyl phenyl ether, n-octyl phenyl ether, n-octyl p No Drawing. Filed May 25, 1972, Ser. No. 256,770 tolyl ether, n-octyl m-tolyl ether, decyl phenyl ether, 1 Int. C. C07c87/50, 97/12 benzylethylheptyl ether, benzoic acid, p-toluic acid, p U.S. C. 260-378 26 Claims chlorobenzoic acid, phthalic acid, nitrobenzene, m-dinitro benzene, o-, m- and p-nitrotoluene, acetophenone, methyl O benzyl ketone, p-methylacetophenone, 3-phenyl-2-buta ABSTRACT OF THE DISCLOSURE none, propriophenone, 2-methyl-1-tetralone, phenyl. n Disclosed herein is a process for making aromatic butyl ketone, benzophenone, p-methylbenzophenone, di amines from benzene or substituted benzene and an o-tolyl ketone, phenyl isobutyl ketone, phenyl n-hexyl aminating agent via direct amination in liquid hydrogen ketone, phenyl n - undecyl ketone, anthraquinone, 2 - fluoride medium as solvent and catalyst. 15 methylanthraquinone, and 1-methyl-4-isopropylanthra quinone. Preferred aromatic compounds are those containing BACKGROUND OF THE INVENTION two or fewer substituents. Especially preferred com 1. Field of the Invention pounds are those containing two or fewer substituents 20 selected from halogen and alkyl of up to four carbons. -

Potentially Explosive Chemicals*

Potentially Explosive Chemicals* Chemical Name CAS # Not 1,1’-Diazoaminonaphthalene Assigned 1,1-Dinitroethane 000600-40-8 1,2,4-Butanetriol trinitrate 006659-60-5 1,2-Diazidoethane 000629-13-0 1,3,5-trimethyl-2,4,6-trinitrobenzene 000602-96-0 1,3-Diazopropane 005239-06-5 Not 1,3-Dinitro-4,5-dinitrosobenzene Assigned Not 1,3-dinitro-5,5-dimethyl hydantoin Assigned Not 1,4-Dinitro-1,1,4,4-tetramethylolbutanetetranitrate Assigned Not 1,7-Octadiene-3,5-Diyne-1,8-Dimethoxy-9-Octadecynoic acid Assigned 1,8 –dihydroxy 2,4,5,7-tetranitroanthraquinone 000517-92-0 Not 1,9-Dinitroxy pentamethylene-2,4,6,8-tetramine Assigned 1-Bromo-3-nitrobenzene 000585-79-5 Not 2,2',4,4',6,6'-Hexanitro-3,3'-dihydroxyazobenzene Assigned 2,2-di-(4,4,-di-tert-butylperoxycyclohexyl)propane 001705-60-8 2,2-Dinitrostilbene 006275-02-1 2,3,4,6- tetranitrophenol 000641-16-7 Not 2,3,4,6-tetranitrophenyl methyl nitramine Assigned Not 2,3,4,6-tetranitrophenyl nitramine Assigned Not 2,3,5,6- tetranitroso nitrobenzene Assigned Not 2,3,5,6- tetranitroso-1,4-dinitrobenzene Assigned 2,4,6-Trinitro-1,3,5-triazo benzene 029306-57-8 Not 2,4,6-trinitro-1,3-diazabenzene Assigned Not 2,4,6-Trinitrophenyl trimethylol methyl nitramine trinitrate Assigned Not 2,4,6-Trinitroso-3-methyl nitraminoanisole Assigned 2,4-Dinitro-1,3,5-trimethyl-benzene 000608-50-4 2,4-Dinitrophenylhydrazine 000119-26-6 2,4-Dinitroresorcinol 000519-44-8 2,5-dimethyl-2,5-diydroperoxy hexane 2-Nitro-2-methylpropanol nitrate 024884-69-3 3,5-Dinitrosalicylic acid 000609-99-4 Not 3-Azido-1,2-propylene glycol dinitrate -

Inorganic Seminar Abstracts

C 1 « « « • .... * . i - : \ ! -M. • ~ . • ' •» »» IB .< L I B RA FLY OF THE. UN IVERSITY Of 1LLI NOIS 546 1^52-53 Return this book on or before the Latest Date stamped below. University of Illinois Library «r L161— H41 Digitized by the Internet Archive in 2012 with funding from University of Illinois Urbana-Champaign http://archive.org/details/inorganicsemi195253univ INORGANIC SEMINARS 1952 - 1953 TABLE OF CONTENTS 1952 - 1953 Page COMPOUNDS CONTAINING THE SILICON-SULFUR LINKAGE 1 Stanley Kirschner ANALYTICAL PROCEDURES USING ACETIC ACID AS A SOLVENT 5 Donald H . Wilkins THE SOLVENT PHOSPHORYL CHLORIDE, POCl 3 12 S.J. Gill METHODS FOR PREPARATION OF PURE SILICON 17 Alex Beresniewicz IMIDODISULFINAMIDE 21 G.R. Johnston FORCE CONSTANTS IN POLYATOMIC MOLECILES 28 Donn D. Darsow METATHESIS IN LIQUID ARSENIC TRICHLORIDE 32 Harold H. Matsuguma THE RHENI DE OXIDATION STATE 40 Robert L. Rebertus HALOGEN CATIONS 45 L.H. Diamond REACTIONS OF THE NITROSYL ION 50 M.K. Snyder THE OCCURRENCE OF MAXIMUM OXIDATION STATES AMONG THE FLUOROCOMPLEXES OF THE FIRST TRANSITION SERIES 56 D.H. Busch POLY- and METAPHOSPHATES 62 V.D. Aftandilian PRODUCTION OF SILICON CHLORIDES BY ELECTRICAL DISCHARGE AND HIGH TEMPERATURE TECHNIQUES 67 VI. £, Cooley FLUORINE CONTAINING OXYHALIDES OF SULFUR 72 E.H. Grahn PREPARATION AND PROPERTIES OF URANYL CARBONATES 76 Richard *• Rowe THE NATURE OF IODINE SOLUTIONS 80 Ervin c olton SOME REACTIONS OF OZONE 84 Barbara H. Weil ' HYDRAZINE BY ELECTROLYSIS IN LIQUID AMMONIA 89 Robert N. Hammer NAPHTHAZARIN COMPLEXES OF THORIUM AND RARE EARTH METAL IONS 93 Melvin Tecotzky THESIS REPORT 97 Perry Kippur ION-PAIR FORMATION IN ACETIC ACID 101 M.M. -

Department of Homeland Security (Dhs) Appendix a Chemicals of Interest (Coi)

DEPARTMENT OF HOMELAND SECURITY (DHS) APPENDIX A CHEMICALS OF INTEREST (COI) Acetaldehyde Bromine trifluoride Acetone Cyanohydrin, stabilized Bromothrifluorethylene Acetyl bromide 1,3-Butadiene Acetyl chloride Butane Acetyl iodide Butene Acetylene 1-Butene Acrolein 2-Butene Acrylonitrile 2-Butene-cis Acrylyl chloride 2-Butene-trans Allyl alcohol Butyltrichlorosilane Allylamine Calcium hydrosulfite Allyltrichlorosilane, stabilized Calcium phosphide Aluminum (powder) Carbon disulfide Aluminum Bromide, anhydrous Carbon oxysulfide Aluminum Chloride, anhydrous Carbonyl fluoride Aluminum phosphide Carbonyl sulfide Ammonia (anhydrous) Chlorine Ammonia (conc 20% or greater) Chlorine dioxide Ammonium nitrate, note #1 Chlorine monoxide Ammonium nitrate, note #2 Chlorine pentafluoride Ammonium perchlorate Chlorine trifluoride Ammonium picrate Chloroacetyl chloride Amyltrichlorosilane 2-Chloroethylchloro-methylsulfide Antimony pentafluoride Chloroform Arsenic trichloride Chloromethyl ether Arsine Chloromethyl methyl ether Barium azide 1-Chloropropylene 1,4-Bis(2-chloroethylthio)-n-butane 2-Chloropropylene Bis(2-chloroethylthio) methane Chlorosarin Bis(2-chloroethylthiomethyl)ether Chlorosoman 1,5-Bis(2-chloroethylthio)-n-pentane Chlorosulfonic acid 1,3-Bis(2-chloroethylthio)-n-propane Chromium oxychloride Boron tribromide Crotonaldehyde Boron trichloride Crotonaldehyde, (E)- Boron trifluoride Cyanogen Boron trifluoride compound with methyl Cyanogen chloride ether (1:1) Cyclohexylamine Bromine Cyclohexyltrichlorosilane Bromine chloride Cyclopropane -

Chemical Names and CAS Numbers Final

Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number C3H8O 1‐propanol C4H7BrO2 2‐bromobutyric acid 80‐58‐0 GeH3COOH 2‐germaacetic acid C4H10 2‐methylpropane 75‐28‐5 C3H8O 2‐propanol 67‐63‐0 C6H10O3 4‐acetylbutyric acid 448671 C4H7BrO2 4‐bromobutyric acid 2623‐87‐2 CH3CHO acetaldehyde CH3CONH2 acetamide C8H9NO2 acetaminophen 103‐90‐2 − C2H3O2 acetate ion − CH3COO acetate ion C2H4O2 acetic acid 64‐19‐7 CH3COOH acetic acid (CH3)2CO acetone CH3COCl acetyl chloride C2H2 acetylene 74‐86‐2 HCCH acetylene C9H8O4 acetylsalicylic acid 50‐78‐2 H2C(CH)CN acrylonitrile C3H7NO2 Ala C3H7NO2 alanine 56‐41‐7 NaAlSi3O3 albite AlSb aluminium antimonide 25152‐52‐7 AlAs aluminium arsenide 22831‐42‐1 AlBO2 aluminium borate 61279‐70‐7 AlBO aluminium boron oxide 12041‐48‐4 AlBr3 aluminium bromide 7727‐15‐3 AlBr3•6H2O aluminium bromide hexahydrate 2149397 AlCl4Cs aluminium caesium tetrachloride 17992‐03‐9 AlCl3 aluminium chloride (anhydrous) 7446‐70‐0 AlCl3•6H2O aluminium chloride hexahydrate 7784‐13‐6 AlClO aluminium chloride oxide 13596‐11‐7 AlB2 aluminium diboride 12041‐50‐8 AlF2 aluminium difluoride 13569‐23‐8 AlF2O aluminium difluoride oxide 38344‐66‐0 AlB12 aluminium dodecaboride 12041‐54‐2 Al2F6 aluminium fluoride 17949‐86‐9 AlF3 aluminium fluoride 7784‐18‐1 Al(CHO2)3 aluminium formate 7360‐53‐4 1 of 75 Chemical Abstract Chemical Formula Chemical Name Service (CAS) Number Al(OH)3 aluminium hydroxide 21645‐51‐2 Al2I6 aluminium iodide 18898‐35‐6 AlI3 aluminium iodide 7784‐23‐8 AlBr aluminium monobromide 22359‐97‐3 AlCl aluminium monochloride -

An Efficient One-Pot Three-Component Synthesis of Novel Sulfanyl Tetrazoles Using Ionic Liquids

Hindawi Publishing Corporation Journal of Chemistry Volume 2013, Article ID 104690, 6 pages http://dx.doi.org/10.1155/2013/104690 Research Article An Efficient One-Pot Three-Component Synthesis of Novel Sulfanyl Tetrazoles Using Ionic Liquids Sankari Kanakaraju, Bethanamudi Prasanna, and G. V. P. Chandramouli Department of Chemistry, National Institute of Technology, Warangal 506 004, India Correspondence should be addressed to G. V. P. Chandramouli; [email protected] Received 13 June 2012; Accepted 11 August 2012 Academic Editor: Mohamed Afzal Pasha Copyright © 2013 Sankari Kanakaraju et al. is is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. An efficient, simple, and environmentally benign method for the synthesis of novel sulfanyl tetrazoles has been achieved by one- pot three-component reaction of phenacyl bromides/3-(2-bromoacetyl)coumarins with KSCN and NaN using [Bmim]BF ionic liquid. It could be reused and recycled for four runs without signi�cant loss of product yield. 3 4 1. Introduction synthesize the compounds containing coumarin-substituted sulfanyl tetrazoles. Over the years, multicomponent reactions (MCRs) have e most convenient method of synthesizing tetrazoles become increasingly popular tools to ensure sufficient molec- is the addition of azide ions to nitriles. Earlier reported ular diversity and complexity. ey have gained signi�cant methods for the synthesis of 5-substituted tetrazoles suffer popularity in recent years due to their atom-economy and from drawbacks such as the use of strong Lewis acids, straightforward reaction design due to substantial minimiza- or expensive and toxic metals, and the in situ generated tion of waste, labour, time, and cost [1, 2].