THE HISTORY of Printing

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Image Carrier Poster

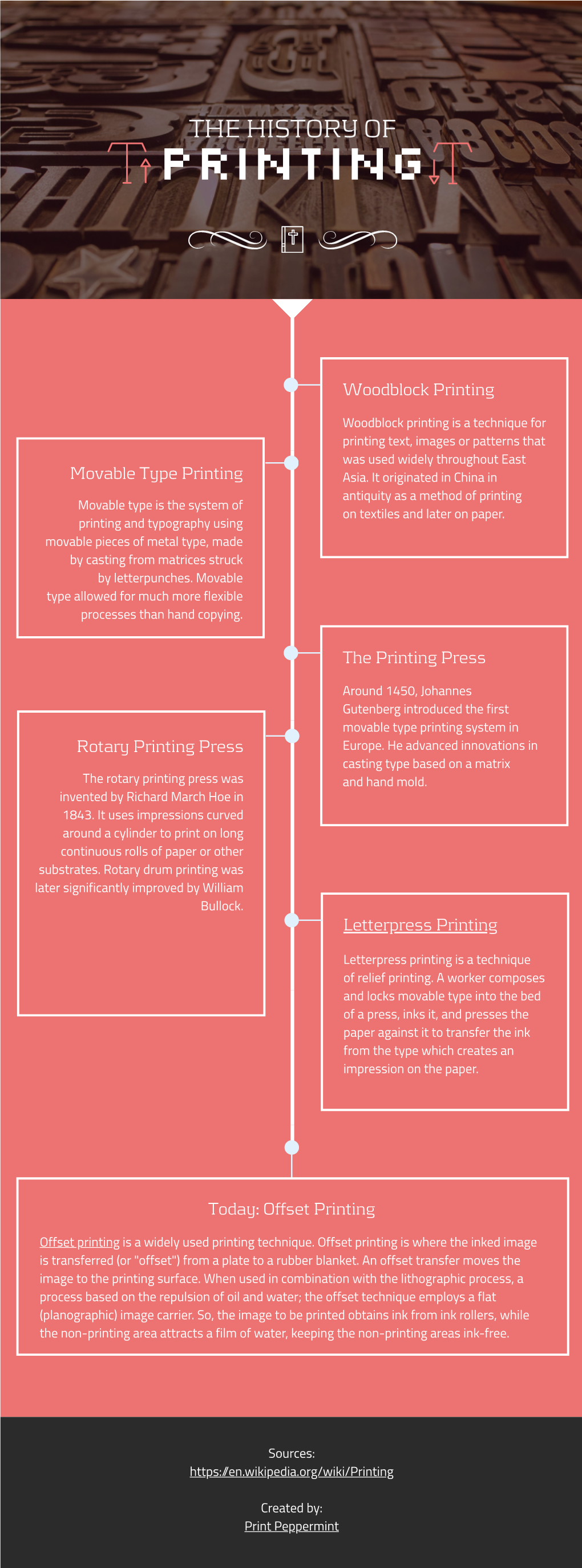

55899-11_MOP_nwsltr_poster_Winter11_v2_Layout 1 2/11/11 2:25 PM Page 1 The Museum of Printing, North Andover, MA and the Image Carrier www.museumofprinting.org Relief printing Wood cuts and wood engravings pre-dated moveable type. Called “xylographic printing,” it was used before Gutenberg for illustrations, playing cards, and small documents. Moveable type allowed corrections and editing. A wood engraving uses the end grain, where a wood cut uses the plank grain. Polymer plates are made from digital files which drive special engraving machines to produce relief plates. These plates are popular with many of today’s letterpress printers who produce invitations, and collectible prints. Metal relief cylinders were used to print repetitive designs, such as those on wrap - ping paper and wall paper. In the 1930s, the invention of cellophane led to the development of the anilox roller and flexographic printing. Today, flexography prints most of the flexible packaging film which accounts for about half of all packaged products. Hobbyists, artists, and printmakers cut away non-printing areas on sheets of linoleum to create relief surfaces. Wood cut Wood engraving and Metal plate Relief cylinder Flexographic plate Linoleum cut Foundry type began with Gutenberg and evolved through Jenson, Garamond, Moveable type Caslon and many others. Garamond was the first printer to cast type that was sold to other printers. By the 1880s there were almost 80 foundries in the U.S. One newspaper could keep one foundry in business. Machine typesetting changed the status quo and the Linotype had an almost immediate effect on type foundries. Twenty-three foundries formed American Type Founders in 1890. -

Relief Printing Letterpress Machines

DRAFT SYLLABUS FOR PRESS WORK - I Name of the Course: Diploma in Printing Technology Course Code: Semester: Third Duration: 16 Weeks Maximum Marks: 100 Teaching Scheme Examination Scheme Theory: 3 hrs/week Internal Examination: 20 Tutorial: 1 hr/week Assignment & Attendance: 10 Practical: 6 hrs/week End Semester Exam:70 Credit: 3 Aim: Getting the output through a printing machine is the most important operation for completing the print production. This subject known as Presswork - I is one of the key subject to make a clear and sound knowledge in some of the major print production systems and supplies. This will enable the students to make judgement about the aspect of printing, particularly the selection of a particular process to choose for a specific print production. Objective: The students will be able to (i) understand the basic and clear classification of all kinds of printing processes; (ii) understand the details divisions and subdivisions of letterpress printing machines, their applications and uses, characteristics and identifications of their products- merits and demerits of various letterpress machines; (iii) understand the principal mechanism of various letterpress and sheet-fed machines, their constructional differences in the printing unit and operational features; (iv) understanding the various feeding and delivery mechanism in printing machines; (v) appreciate the relational aspects of various materials used in presswork. Pre -Requisite: Elementary knowledge of Basic Printing & Production Contents: Group-A Hrs/unit Marks Unit 1 Relief Printing 10 10 1.1 Classifications of various relief printing machines, their applications and uses, characteristics of the products. 1.2 Details of divisions and subdivisions of letterpress printing machines, their applications and uses, characteristics and identifications of their products- merits and demerits of various letterpress machines General unit wise division of a printing machine. -

Introduction to Printing Technologies

Edited with the trial version of Foxit Advanced PDF Editor To remove this notice, visit: www.foxitsoftware.com/shopping Introduction to Printing Technologies Study Material for Students : Introduction to Printing Technologies CAREER OPPORTUNITIES IN MEDIA WORLD Mass communication and Journalism is institutionalized and source specific. Itfunctions through well-organized professionals and has an ever increasing interlace. Mass media has a global availability and it has converted the whole world in to a global village. A qualified journalism professional can take up a job of educating, entertaining, informing, persuading, interpreting, and guiding. Working in print media offers the opportunities to be a news reporter, news presenter, an editor, a feature writer, a photojournalist, etc. Electronic media offers great opportunities of being a news reporter, news editor, newsreader, programme host, interviewer, cameraman,Edited with theproducer, trial version of Foxit Advanced PDF Editor director, etc. To remove this notice, visit: www.foxitsoftware.com/shopping Other titles of Mass Communication and Journalism professionals are script writer, production assistant, technical director, floor manager, lighting director, scenic director, coordinator, creative director, advertiser, media planner, media consultant, public relation officer, counselor, front office executive, event manager and others. 2 : Introduction to Printing Technologies INTRODUCTION The book introduces the students to fundamentals of printing. Today printing technology is a part of our everyday life. It is all around us. T h e history and origin of printing technology are also discussed in the book. Students of mass communication will also learn about t h e different types of printing and typography in this book. The book will also make a comparison between Traditional Printing Vs Modern Typography. -

Graphic Communications. Progress Record, Theory Descriptions; High Schools; Industrial Arts; *Job ABSTRACT of the Shop Instructo

DOCUMENT RESUME ED 251 657 CE 040 262 TITLE Graphic Communications. Progress Record, Theory Outline. INSTITUTION Connecticut State Dept. of Education, Hartford. Div. of Vocational-Technical Schools. PUB DATE Sep 83 NOTE 64p.; For related documents see CE 040 261. PUB TYPE Guides Classroom Use - Guides (For Teachers) (052) EDRS PRICE MF01/PC03 Plus Postage. DESCRIPTORS Behavioral Objectives; Course Content; Course Descriptions; High Schools; Industrial Arts; *Job Performance; Job Skills; Photocomposition; *Printing; Recordkeeping; *Reprography; Safety; *School Shops; Secondary Education; Student Evaluation; *Student Records IDENTIFIERS *Graphic Communication ABSTRACT Intended to reduce unnecessary paper work on the part of the shop instructor in a graphic communicationE -ourse, this job assignment book offers a simplified method of keeping student records up-to-date. It first provides a record/form with areas for student name, tool check number, locker number, textbook number, and grades; broad course objectives; course objectives for grades 10, 11, and 12; and instructions for recording student progress on the shop progress records. The student progress records follow. These identify the operations/skills that the student in a graphic communications course is expacted to learn and provide a space in which the instructor records student progress as (1) instructed, (2) practiced, or (3) proficient. The theory outline appears next. Twenty-six topics are covered, including orientation, history, major printing processes, introduction to lithography, careers, layout, copy preparation, reproduction photography, the process camera, line photography, contacting, halftime photography, special effects, process color, quality control devices, proofing methods, gtripping, platemaking, offset duplicator, offset press, printing inks, printing papers, finishing and binding, job planning, and employer/employee relations. -

Graphic File Preparation for Letterpress Printing ©2016

GRAPHIC FILE PREPARATION FOR LETTERPRESS PRINTING ©2016, Smart Set, Inc. COMMON GRAPHIC FILE FORMATS Vector Formats .ai (Adobe Illustrator) Native Illustrator file format. Best format for importing into Adobe InDesign. Illustrators’s native code is pdf, so saving files in .ai contains the portability of pdf files, but retaining all the editing capabilities of Illustrator. (AI files must be opened in the version of Illustrator that they were created in (or higher). .pdf (Adobe Portable Document Format) A vector format which embeds font and raster graphics within a self-con- tained document that can be viewed and printed (but not edited) in Adobe’s Reader freeware. All pre-press systems are in the process of transitioning from PostScript workflows to PDF workflows. Because of the ability to em- bed all associated fonts and graphics, pdf documents can be generated from most graphics software packages and can be utilized cross-platform and without having all versions of different software packages. Many large printers will now only accept pdf files for output. .eps (Encapsulated PostScript) Before Adobe created the pdf format, PostScript allowed files to be created in a device-independent format, eps files printed on a 300 dpi laser printer came out 300 dpi, the same file printed to an imagesetter would come out at 2540 dpi. PostScript files are straight code files, an Encapsulated PostScript includes a 72 dpi raster preview so that you can see what you’re working with in a layout program such as Quark XPress or InDesign. COMMON GRAPHIC FILE FORMATS Raster Formats .tiff (Tagged Image File Format) Tiffs are binary images best for raster graphics. -

A Collection of Mildly Interesting Facts About the Little Symbols We Communicate With

Ty p o g raph i c Factettes A collection of mildly interesting facts about the little symbols we communicate with. Helvetica The horizontal bars of a letter are almost always thinner than the vertical bars. Minion The font size is approximately the measurement from the lowest appearance of any letter to the highest. Most of the time. Seventy-two points equals one inch. Fridge256 point Cochin most of 50the point Zaphino time Letters with rounded bottoms don’t sit on the baseline, but slightly below it. Visually, they would appear too high if they rested on the same base as the squared letters. liceAdobe Caslon Bold UNITED KINGDOM UNITED STATES LOLITA LOLITA In Ancient Rome, scribes would abbreviate et (the latin word for and) into one letter. We still use that abbreviation, called the ampersand. The et is still very visible in some italic ampersands. The word ampersand comes from and-per-se-and. Strange. Adobe Garamond Regular Adobe Garamond Italic Trump Mediaval Italic Helvetica Light hat two letters ss w it cam gue e f can rom u . I Yo t h d. as n b ha e rt en ho a s ro n u e n t d it r fo w r s h a u n w ) d r e e m d a s n o r f e y t e t a e r b s , a b s u d t e d e e n m t i a ( n l d o b s o m a y r S e - d t w A i e t h h t t , h d e n a a s d r v e e p n t m a o f e e h m t e a k i i l . -

Mechanization of the Printing Press Robin Roemer Western Oregon University, [email protected]

Western Oregon University Digital Commons@WOU History of the Book: Disrupting Society from Student Scholarship Tablet to Tablet 6-2015 Chapter 08 - Mechanization of the Printing Press Robin Roemer Western Oregon University, [email protected] Follow this and additional works at: https://digitalcommons.wou.edu/history_of_book Part of the Critical and Cultural Studies Commons, Cultural History Commons, and the History of Science, Technology, and Medicine Commons Recommended Citation Roemer, Robin. "Mechanization of the Printing Press." Disrupting Society from Tablet to Tablet. 2015. CC BY-NC. This is brought to you for free and open access by the Student Scholarship at Digital Commons@WOU. It has been accepted for inclusion in History of the Book: Disrupting Society from Tablet to Tablet by an authorized administrator of Digital Commons@WOU. For more information, please contact [email protected]. 8 Mechanization of the Printing Press - Robin Roemer - One of the important leaps in the technology of copying text was the mechanization of printing. The speed and efficiency of printing was greatly improved through mechanization. This took several forms including: replacing wooden parts with metal ones, cylindrical printing, and stereotyping. The innovations of printing during the 19th century affected the way images were reproduced for illustrations as well as for type. These innovations were so influential on society because they greatly increased the ability to produce large quantities of work quickly. This was very significant for printers of newspapers, who were limited by the amount their press could produce in a short amount of time. Iron Printing Press One major step in improving the printing press was changing the parts from wood to metal. -

Printmaking Through the Ages Utah Museum of Fine Arts • Lesson Plans for Educators • March 7, 2012

Printmaking through the Ages Utah Museum of Fine Arts • www.umfa.utah.edu Lesson Plans for Educators • March 7, 2012 Table of Contents Page Contents 2 Image List 3 Printmaking as Art 6 Glossary of Printing Terms 7 A Brief History of Printmaking Written by Jennifer Jensen 10 Self Portrait in a Velvet Cap , Rembrandt Written by Hailey Leek 11 Lesson Plan for Self Portrait in a Velvet Cap Written by Virginia Catherall 14 Kintai Bridge, Province of Suwo, Hokusai Written by Jennifer Jensen 16 Lesson Plan for Kintai Bridge, Province of Suwo Written by Jennifer Jensen 20 Lambing , Leighton Written by Kathryn Dennett 21 Lesson Plan for Lambing Written by Kathryn Dennett 32 Madame Louison, Rouault Written by Tiya Karaus 35 Lesson Plan for Madame Louison Written by Tiya Karaus 41 Prodigal Son , Benton Written by Joanna Walden 42 Lesson Plan for Prodigal Son Written by Joanna Walden 47 Flotsam, Gottlieb Written by Joanna Walden 48 Lesson Plan for Flotsam Written by Joanna Walden 55 Fourth of July Still Life, Flack Written by Susan Price 57 Lesson Plan for Fourth of July Still Life Written by Susan Price 59 Reverberations, Katz Written by Jennie LaFortune 60 Lesson Plan for Reverberations Written by Jennie LaFortune Evening for Educators is funded in part by the StateWide Art Partnership and the Professional Outreach Programs in the Schools (POPS) through the Utah State Office of Education 1 Printmaking through the Ages Utah Museum of Fine Arts • www.umfa.utah.edu Lesson Plans for Educators • March 7, 2012 Image List 1. Rembrandt Harmensz van Rijn (1606-1669), Dutch Self Portrait in a Velvet Cap with Plume , 1638 Etching Gift of Merrilee and Howard Douglas Clark 1996.47.1 2. -

Chinese Inventions - Paper & Movable Type Printing by Vickie

Name Date Chinese Inventions - Paper & Movable Type Printing By Vickie Invention is an interesting thing. Sometimes, an invention was developed to fulfill a specific need. Other times, it was simply a chance discovery. Looking back in history, there are two Chinese inventions that fell into the first category. They are paper and movable type printing. Long before paper was invented, the ancient Chinese carved characters to record their thoughts on tortoise shells, animal bones, and stones. Since those "writing boards" were heavy and not easy to carry around, they switched to writing on bamboo, wooden strips, and silk. The new alternatives were clearly better, but they were either still heavy or very costly. Then, during the Western Han dynasty (202 B.C. - 8 A.D.), paper made its debut. Its inventor is unknown. When paper first came out, it was not easy to produce in large quantities. And its quality was poor. Several decades later, a palace official named Tsai Lun (also spelled as Cai Lun) had a breakthrough in the papermaking process. He experimented with different materials and eventually settled on using tree bark, rags, and bits of rope to produce paper. He presented his first batch of paper to the emperor of the Eastern Han dynasty in 105 A.D. Tsai Lun's technique of making paper became an instant hit! It was quickly introduced to Korea and other countries nearby. In 751 A.D., Arabs learned the technique from the Chinese soldiers they captured in a war. They passed it on to Europe and, eventually, other parts of the world. -

Letterform Anatomy

Letterform Anatomy Guidelines: Baseline: a real or imaginary horizontal line upon which the base of each capital rests; Waistline (meanline): a real or imaginary line that marks the height of the body of a small lowercase letter (often is the same as the x-height); x; Capline (cap height): a real or imaginary horizontal line that runs along the tops of the capital letters; Ascender line: a real or imaginary line that marks the proper height for the tall lowercase letters of a typeface like b, d, f, h, k, and i; for some typefaces, this line is the same as the cap height; b, d, f, h, i, j, k, l, t Descender line: a real or imaginary line that marks the proper length for the lowercase g, j, p, q, and y of a typeface; g, j, p, q, y 2. Ascenders and Descenders Ascender: A stroke on a lowercase character that extends above the meanline; Descender: A stroke on a lowercase character that falls below the baseline; X-height: a real or imaginary line that shows how tall to make the lowercase letters of a typeface; the distance from the baseline to the meanline. It marks the proper optical height for the lowercase letter x. Typically, this is the height of lowercase letters and is most easily measured on the lowercase x; Although X-height is not a unit of measurement, it is significant because it conveys the visual impact of the type size. In other words, typefaces of the same point size may appear smaller or larger because of the difference in their x-heights. -

Flexible Packaging Printing Processes Overview Slide 2 2009 Consumer Packaging Solutions for Barrier Performance Course

2009 Consumer Packaging Solutions for Barrier Performance Course FlexibleFlexible PackagingPackaging PrintingPrinting ProcessesProcesses OverviewOverview Presented by: Warren E. Durling Associate Research Fellow The Clorox Company (GLAD) 2009 Consumer Packaging Solutions For Barrier Performance Course Flexible Packaging Printing Processes Overview Slide 2 2009 Consumer Packaging Solutions For Barrier Performance Course The Basics of Flexible Packaging Printing DEFINITION: Applying ink to a substrate to produce an image or text PRINTING METHODS: Flexography and Rotogravure the two most widely utilized methods for Flexible Packaging FOCUS: Design to Substrate; the “process” described Structures and Print location Understanding Ink Substrate Surface Preparation Methods and Equipment in detail Reproduction Basics; line and process printing Flexible Packaging Printing Processes Overview Slide 3 2009 Consumer Packaging Solutions For Barrier Performance Course Design to Substrate Preproduction Design Creation Ink Management Substrate Image Preparation Color Separation Management Press Make Ready Cylinder or Plate Making Press Cleaning and Maintenance PrintingPrinting Converting Flexible Packaging Printing Processes Overview Slide 4 2009 Consumer Packaging Solutions For Barrier Performance Course SURFACE Printing Flexible Packaging Printing Processes Overview Slide 5 2009 Consumer Packaging Solutions For Barrier Performance Course REVERSE Printing 2 Layer Structures Flexible Packaging Printing Processes Overview Slide 6 2009 Consumer Packaging -

Printing Press Operations

Property Risk Consulting Guidelines PRC.17.18.1 A Publication of AXA XL Risk Consulting PRINTING PRESS OPERATIONS INTRODUCTION Printing has progressed from the Gutenberg press, which required three minutes per impression, to today’s multicolor, two-sided, continuous presses that operate well in excess of 2000 ft/min (610 m/min). There are four major printing processes: lithography, letterpress, gravure and silk-screening. A lithography offset press prints from a level or plane surface; a letterpress prints from a raised surface; a gravure press prints from a depressed or sunken surface; and silk-screening prints by pushing ink through fabric. From the 6th Annual Report to the Congress of the United States: Printing Industry report, Figure 1 shows 1994 industry market share. PROCESSES AND HAZARDS The hazards of printing presses include the transfer and use of flammable inks; solvent recovery and pollution control devices; hydraulic and lubrication oil systems; gas or oil-fired dryers; electrostatic buildup from high press speeds; paper dust; and paper storage near presses. This section discusses common printing processes and their hazards. Loss prevention and control guidelines address construction features, flammable and combustible liquids handling, protection of the press area, electrical features, drying, and the disposal of solvent vapors. 50 47 45 40 35 30 28 25 19 20 Percent (%) Percent 15 10 5 3 3 0 Lithographic Letterpress Gravure Silk-screen Other Figure 1. Market share by process. 100 Constitution Plaza, Hartford, Connecticut 06103 Copyright 2020, AXA XL Risk Consulting Global Asset Protection Services, LLC, AXA Matrix Risk Consultants S.A. and their affiliates (“AXA XL Risk Consulting”) provide loss prevention and risk assessment reports and other risk consulting services, as requested.