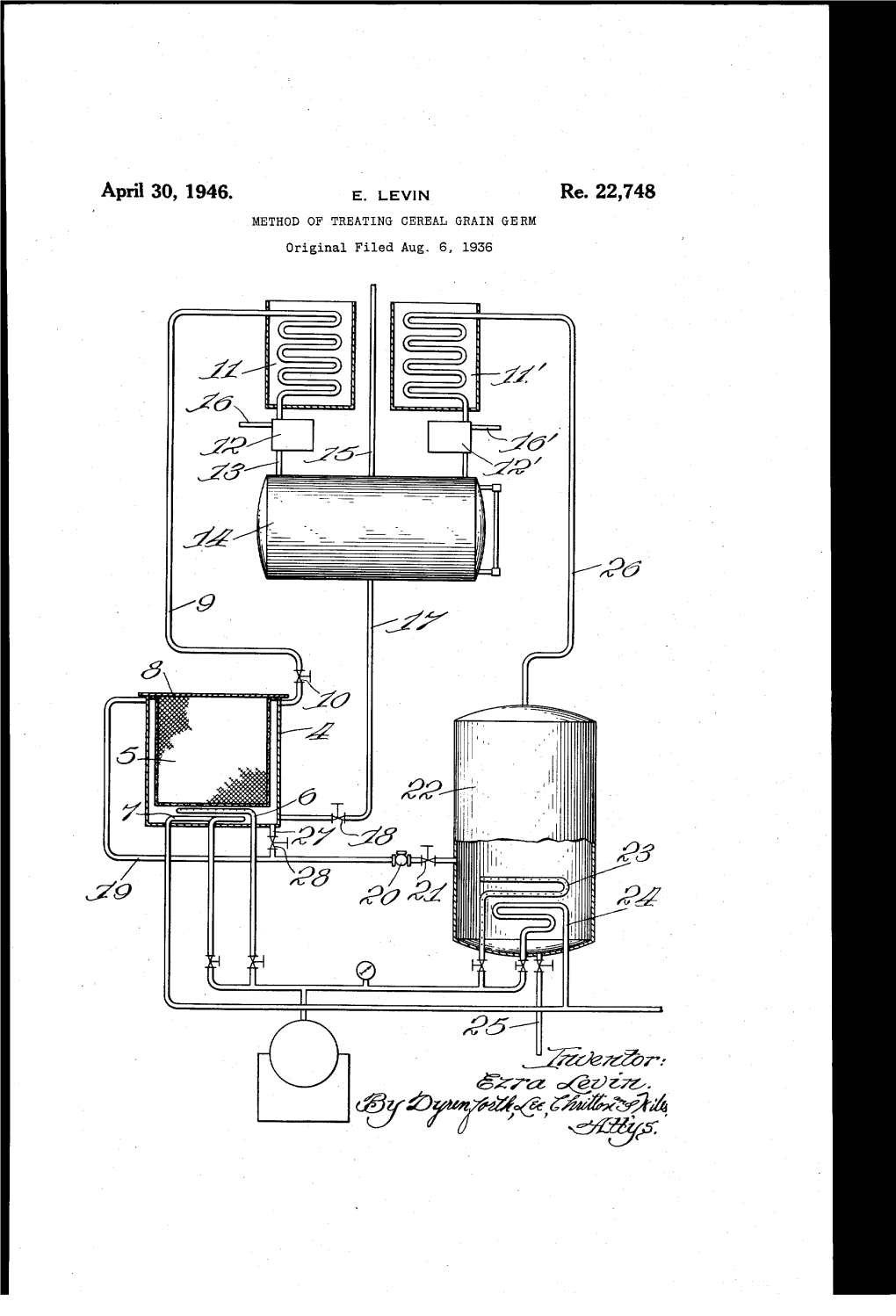

April 30, 1946. E. LEVIN Re. 22,748 METHOD of TREATING CEREAL GRAIN GERM Original Filed Aug

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Lipids and Fats [email protected]

The Biochemistry of Rice Human Metabolome Technologies America, Inc. 24 Denby Road, Suite 217, Boston, MA 02134 p. 617-987-0554 f. 617-902-2434 Lipids and Fats [email protected] THE STORY OF RICE LIPID CONTENT Rice (Oryza sativa L.) is one of the quality of rice. A number of studies have shown with a few exceptions, there is no Phosphatidylcholine most important cereal crops cul- that rice bran oil reduces the substantial difference in total lipid Oryza sativa, or Asian rice, con- CH2 tivated in the world; it feeds more tains two broad groups: indica harmful cholesterol (LDL) without content. − than half of the world’s popula- changing good cholesterol (HDL). R COO CH O (long-grain) and japonica − − − −OOCRˈ + tion. Metabolome analysis, the On the other hand, reports Phosphatidylethanolamine (short-grain). Other types of CH2 O P O CH2CH2N(CH3)3 investigation of all cellular me- Asian rice include glutinous rice showed that the hydrolysis and ox- ʺ − − tabolites, has become an import- idation of rice fat are responsible CH2 O and aromatic rice. All varieties of − − − − − for rice aging and deterioration of O ant strategy for gaining insight rice can be processed post-har- R COO CH Phosphatidyldimethylethanolamine − − into functional biology around vest as either white or brown grain flavor during storage, and − −OOCRˈ � low-oil rice cultivars are more suit- CH2 O P O CH2CH2NH2 CH understanding the flavor, health rice, affecting flavor, texture and 2 ʺ − − benefits, aroma and cultivation nutritive value. In short-grain rice able for grain storage The lipids of OH R COO CH− O these rice brans comprised mainly − − − − processes in rice production. -

I S S U E 1 J U N 2 0 2 0 N O T E S F R O M T H E E D I T O R 01 of Sowing

I S S U E 1 J U N 2 0 2 0 N O T E S F R O M T H E E D I T O R 01 OF SOWING: By EUGENE WAMBECK We started the year with jubilant topic last year. It should be a expectations for a new decade of recurring theme to guide our efforts change. In recent months though, to develop society even as we push an obscure virus has dominated through this decade. It is fitting the news and our thoughts, then that the United Nations has foreshadowing the joy of major declared 2020 as the International events around the World such Year of Plant Health. The UN as the Tokyo 2020 Olympics. General Assembly see this year as Despite the gloom, and desperate an opportunity to raise awareness measures most countries have on protecting plant health in been forced to take to contain the order to end hunger, protect the virus, the human spirit remains environment and sustain economic strong. We’ve seen great examples development. It is a clarion call for of neighbourliness and sacrifice measured stewardship! to help one another tide through this crisis. On the scientific front, In this maiden edition of there is a silver lining as well. Whilst ISawtheScience, we echo the conditions are tough for every one United Nations’ 2020 theme and and some fear prevails, there has cast the spotlight on plants. They been an unprecedented effort to inhabit the Earth with us, but we increase scientific communication. often take plants for granted. -

Page 1 MAILLARD P E R F E C T I N G

V O L . O N E MAILLARD PERFECTING RECIPES WITH SCIENCE The FoodSci Team THE FOODSCI TEAM President: William Hannon Vice President: Josephine Niu Secretary: Owen Hannon Director of Communications: Sienna Nimmer plus members and contributors MAILLARD MAILLARD PERFECTING RECIPES WITH SCIENCE The FoodSci Team LULU PUBLISHING DEDICATED TO THE READER: THAT YOU DO NOT FIND THIS BOOK BORING. Contents 64 Bread FoodSci's Favorite Baguettes • 67 Beginner's Sourdough Loaf • 71 Laugenbrötchen • 77 Cinnamon Swirl Bread • 81 Uber-Soft Dinner Rolls • 85 New York Bagels • 89 92 La Pizza Sourdough Pizza Dough • 95 Introduction • 10 FoodSci's Favorite Pizza Dough • 99 Basic Ingredients • 14 Neapolitan Pizza Sauce • 101 Basic Margherita Pizza • 103 Buffalo Chicken Pizza • 107 36 Frozen "Better-Than-The-Pizzeria" Garlic Knots • 109 Coconut Ice Cream • 39 Strawberry Honey Sorbet • 41 Spaghettieis • 43 112 Les pâtisseries Pain au Chocolat • 115 44 Brown Butter-Blueberry Pinwheel Cakes, Cookies, Pastries • 123 and Assorted Chaussons aux Pommes • 127 Desserts Browning Butter • 47 FoodSci's Favorite Chocolate Mousse • 132 Pies and Tarts 51 Chocolate Meringue Cookies • 55 FoodSci's Favorite Pie Crust • 135 Chocolate-Chunk Mousse Cake with Renaissance Apple Tart • 137 White Chocolate Whipped Cream • 57 FoodSci's Favorite Lemon Meringue FoodSci's Favorite Chocolate Chip Pie • 141 Cookies • 61 FoodSci's Favorite Coconut Cream Pie • 145 FoodSci's Favorite Key Lime Pie • 149 Resources • 150 Acknowledgments • 156 Introduction The Maillard reaction is perhaps the most predominant example of molecular gastronomy and culinary chemistry found in both cooking and baking. It refers to the process that gives brown food its distinctive flavor. -

Protection of Farm-Stored Grains, Oilseeds and Pulses from Insects, Mites and Moulds

Protection of farm-stored grains, oilseeds and pulses from insects, mites and moulds Publication 1851/E (Revised) 1 Protection of farm-stored grains, oilseeds and pulses from insects, mites and moulds Recommendations for pesticide use in this publication are intended as guide lines only. Any application of a pesticide must be in accordance with directions printed on the product label of that pesticide as prescribed under the Pest Control Products Act. Always read the label. A pesticide should also be recommended by provincial authorities. Because recommendations for use may vary from province to province, your provincial agricultural representatives should be consulted for specific advice. Covering Page Illustration (Top) Steel bins used for farm grain storage in Western Canada; (bottom left to right) Aspergillus mould on wheat, mould mites and rusty grain beetles. This document is available via the Internet at the Cereal Research Centre’s web page at http://www.agr.gc.ca/science/winnipeg/ Agriculture and Agri-Food Canada Publication 1851/E (Revised) © Cereal Research Centre. 2001. 195 Dafoe Road, Winnipeg, Manitoba R3T 2M9 Replaces 1851/E Également disponible en français sous le titre Protection des céréales, des oléagineux et des légumineuses à grain entreposés à la ferme contre les insectes, les acariens et les moisissures 2 Preface This publication describes pests of farm-stored grains, oilseeds and pulses and outlines methods for their prevention, detection and control. Prolonged storage of such crops occurs mainly on the farm, so pests are most likely to cause damage in farm bins. To avoid or control damage caused by pests, the producer needs to understand the problem and use current control practices. -

SCIENTIFIC REVIEWS Bread, Oldest Man-Made Staple Food in Human

WEBSITE: www.chem-tox-ecotox.org/ScientificReviews 15/11/2018 SCIENTIFIC REVIEWS Bread, Oldest Man-made Staple Food in Human Diet Bread intake is integral to good health and whole grain cereals beneficial against chronic diseases Athanasios Valavanidis Department of Chemistry, National and Kapodistrian University of Athens, University Campus Zografou, 15784 Athens, Greece ABSTRACT Bread is the most important staple food of humans from the prehistoric time. Baked bread is integral to human health with plenty of major nutrients, antioxidants and vitamins. After thousands of years, it remains the most regularly consumed food in the world, due to its convenience, portability, nutrition, and taste. Archaeological studies found that prehistoric human food hunter-gatherers started baking bread at least 30,000 years ago. Annual global wheat production is around 700 million tons. Over the same period the global average production of rice was 704 mt and for maize 874 mt. In the last decades a large number of scientific studies analysed wheat grain composition, protein content, essential amino acids, carbohydrates, mono- and oligo- saccharides, starch, vitamins, minerals, metals, dietary fibers, polyphenols, protenoids and carotenoids. All these components of wheat grain have direct relevance to human nutrition and health because they provide nutritional quality, energy and essential micro nutrients. Beneficial health effects from whole grain bread and other cereals have been studied by a large number of epidemiological and dietary studies. Most of the results found that consumption is associated with reduction of chronic diseases, such as coronary heart and cardiovascular diseases (CVDs), colon and breast cancers, obesity, type 2 diabetes and gastrointestinal diseases. -

(12) Patent Application Publication (10) Pub. No.: US 2005/0089602 A1 Kvist Et Al

US 2005.00896O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0089602 A1 Kvist et al. (43) Pub. Date: Apr. 28, 2005 (54) PROCESS FOR THE FRACTIONATION OF Publication Classification CEREAL BRANS (51) Int. Cl." ....................................................... A23K 1100 (76) Inventors: Sten Kvist, Odakra (SE); Tommie (52) U.S. Cl. ................................................................ 426/52 Carlsson, Hoganas (SE); John Mark Lawther, Roskilde (DK); Fernando (57) ABSTRACT Bastile DeCastro, Campinas/SP (BR) A process for the fractionation of valuable fractions from Correspondence Address: cereal brans (e.g. wheat, barley and oat brans, and rice Matthew E. Connors polish) is described. In particular, this invention describes a Gauthier & Connors LLP two step process, in which the Said bran is first Subjected to Suite 3300 a combination of enzymatic treatment and wet milling, 225 Franklin Street followed by Sequential centrifugation and ultrafiltration, Boston, MA 02110 (US) which aims at physically Separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich (21) Appl. No.: 10/643,402 fraction, residual endosperm fraction and Soluble Sugars. A Second Step consists of fractionating cereal brans Substan (22) Filed: Aug. 19, 2003 tially free of Soluble compounds, hence insoluble phase from the above-mentioned first Step, by enzymatic treatment Related U.S. Application Data with Xylanases and/or beta-glucanase and wet milling, fol (63) Continuation of application No. PCT/SE02/00309, lowed by Sequential centrifugation and ultrafiltration, which aims at physically Separating the main fractions, i.e. filed on Feb. 21, 2002. insoluble phase (remaining cell wall components), protein (30) Foreign Application Priority Data rich fraction, Soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall Feb. -

Public Health Reports Vol

Public Health Reports Vol. 55 o MARCH 29, 1940 * No. 13 ATTEMPTS TO PRODUCE TUMORS IN RATS BY FEEDING CRUDE WHEAT GERM OIL MADE BY PROLONGED ETHER EXTRACTION' By HAROLD BLUMBERG, Research Fellow, Aational Cancer Institute, United States Public Health Service In 1937 Rowntree, Lansbury, and Steinberg (8) reported the occurrence of malignant intra-abdominal tumors in albino rats that were fed a crude wheat germ oil prepared by ether extraction. This initeresting observation was confirmed in a simultaneous publication by Dorranice and Ciccone (4), who repeated the work with the use of materials from Rowntree's laboratory at the Philadelphia Institute for Medical Research. Rowntree and his collaborators (10) were able to produce these tumors, usually transplantable spindle-cell sarcomas, in more than 90 percent of the animals fed. Rats of the NVistar, Buffalo, and Yale albino strains were used. When daily doses of 1 cc. were administered, either poured over the diet or given directly by dropper, tumors were palpable in fronm 36 to 268 days. When larger doses were used, as approximately 21 percent of a diet niixture or as daily supplements of 3.5 to 4 cc., tumors were produced in as little as 13 days and in an average of about 54 days. The active fraction was apparently in that portion of the oil which settled out when kept in the refrigerator. Negative results were secured with refined wheat germ oil from ether extraction, expressed oil, naphtha extracted oil, and vitamin E concentrate. After further investigation, Rowntree, Steiniberg, and Browm (9) reported that the prinary site of tumor oiging seemed to be chiefly tbe intestinal wall in the 109 tumor-bearing animals which they had observed. -

Food Microbiology 79 (2019) 90–95

Food Microbiology 79 (2019) 90–95 Contents lists available at ScienceDirect Food Microbiology journal homepage: www.elsevier.com/locate/fm Potential reservoirs and routes of Cronobacter transmission during cereal growing, processing and consumption T Xiuqin Loua, Hua Yua, Xuchu Wanga, Jianjiang Qib, Wei Zhanga, Haoqiu Wanga, Guojing Sia, ∗ Shujuan Songa, Chuang Huangc, Tao Liua, Wei Zhenga, Zhiguo Fangc, a Hangzhou Center for Disease Control and Prevention, Hangzhou, 310021, China b Hangzhou Xixi Hospital, Hangzhou, 310023, China c College of Environmental Science and Engineering, Zhejiang Gongshang University, Hangzhou, 310018, China ARTICLE INFO ABSTRACT Keywords: Cronobacter are opportunistic bacterial pathogens of both infants and adults. We investigated the incidence and Cronobacter distribution of Cronobacter in 1245 samples of cereal and related environments. 39.1% (101/258) rice-related Reservoir and 46.9% (98/209) wheat-related samples tested positive for Cronobacter, and the positive rate differed notably Routes of transmission according to processing method. Cronobacter was found in rice and wheat plants at the tillering, filling and Domestic environment mature stages. Soil, water and swab samples from nearby milling plants were assayed, and results revealed that 6.3% (7/122) of water from paddy fields, 49.1% (28/57) and 62.1% (41/67) of swab samples from rice and wheat flour milling plants were Cronobacter positive. Pulsed-field gel electrophoresis (PFGE) subtyping indicated that some strains had a common profile, which suggested their persistence in the environment, potential transmission routes and cross-contamination in processing. Finally, we surveyed 18 families to evaluate potential risks. None of the families who primarily ate rice cooked with water tested positive for Cronobacter, though of 66.7% families (6/9) whose food staples were produced from wheat flour tested positive. -

Coriolis DAFWA Growing the North

GROWING THE NORTH Market opportunities for irrigated agricultural produce from northern Western Australia FINAL DISCUSSION DOCUMENT; under contract DAFWA244; November 2015 INHERENT LIMITATIONS ACCESSIBILITY This work was commissioned by the Department of Agriculture and e. any Coriolis Commentary accompanying the Coriolis document Coriolis seeks to support the widest possible audience for this Food Western Australia (DAFWA) and prepared by Coriolis. This is an integral part of interpreting the Coriolis document. research. This document has been designed to be as accessible to work is based on secondary market research, analysis of Consideration of the Coriolis document will be incomplete if it is as many users as possible. information available or provided to Coriolis by our client, and a reviewed in the absence of the Coriolis Commentary and Coriolis range of interviews with industry participants and industry experts. conclusions may be misinterpreted if the Coriolis document is Any person – with or without any form of disability – should feel Coriolis have not independently verified this information and make reviewed in absence of the Coriolis Commentary. free to call the authors if any of the material cannot be understood no representation or warranty, express or implied, that such or accessed. information is accurate or complete. Coriolis is not responsible or liable in any way for any loss or damage incurred by any person or entity relying on the information We welcome opportunities to discuss our research with our Projected market -

Functional Foods: Overview Functional Foods: Dietary Fibers, Prebiotics, Probiotics, and Synbiotics Nutrition: Soy-Based Foods

NUTRITION AND FOOD GRAINS Food Grains and Well-Being Contents Functional Foods: Overview Functional Foods: Dietary Fibers, Prebiotics, Probiotics, and Synbiotics Nutrition: Soy-Based Foods Functional Foods: Overview G Bultosa, Botswana College of Agriculture, Gaborone, Botswana; Haramaya University, Dire Dawa, Ethiopia ã 2016 Elsevier Ltd. All rights reserved. Topic Highlights Consumption of an adequately balanced diet is a means of body structure formation, energy generation, and health. More • Functional food concepts/definitions. than 2500 years ago, ‘Let foods be our medicine and medicine • Bioactive compounds. be our foods’ was stated by Hippocrates. This shows that • Chronic diseases and functional foods. consumption of diets with health-promoting effects is not • Gluten-free foods for celiac patients. new. But evidence on the relationship between dietary chem- ical component(s) and health is on evolutionary development as technology and human comprehension advance. Within Learning Objectives such evolution, the concept of functional foods was started in the 1980s as Foods for Specified Health Use (FOSHU) • To achieve understanding on the concepts/definitions of in Japan. Foods, when consumed as a regular diet that supplies functional foods. one or more bioactive components beyond basic nutrients and • To achieve understanding of bioactive compounds used in offer health-promoting effects, are today branded as functional functional foods, grain dietary sources, and potential effects foods. Functional foods are not prescribed drugs, dietary sup- on health. plements, medical foods of therapeutic effects, traditional • To impart processing principles on grain-based functional medicines, or nutraceuticals. Functional foods are distinct foods. from macronutrient and micronutrient supplements targeted to achieve balanced diets and to treat nutrient deficiency syn- dromes. -

Unite Statesp?T?Nt of "Ice Patented Mar

2,879,167 Unite Statesp?t?nt of "ice Patented Mar. 24, 1959 1 . 2 , di?iculties, on roller mills. The production of super?ne ?our from such ground and milled substantially de-oiled 2,879,167 cereal germs by sifting and sieving does not cause any dif?culty. PROCESS OF MAKING GERM FLAKES The resulting germ ?ours’ are comparatively stable, Felix Grandel, Inningeu, near Augsburg, Germany due to their low oil content. They can be stored in the samemanner as wheat ?our without becoming rancid. No Drawing. Application June 24, 1954 However, they still possess a bitter taste which limits Serial No. 439,125 their use as foodstuff. It has been found that the bitter , Claims priority, application Germany June 26, 1953 _ taste of such germ ?ours is dependent upon their de* gree of comminution. Flours which have been ground 1 Claim. (or. 99-80) only to a low degree of comminution and have as low a content of crude ?ber and bran particles as possible, have the best taste while highly comminuted ?ours which _ The present invention relates to a process of debitter contain large amounts of bran contain also large amounts ing germs and/or seedlings of cereals and more particu 16 of bitter components. larly to a process of producing debittered ?akes of germs This observation proves that the bitter components and/or seedlings of cereals, ‘and to products obtained of cereal germs are mainly enriched in bran and husk thereby. - components of said material. Therefore, only germ -. It-is known to debitter germs of cereals by roasting ?ours of low degree of comminution are suitable for the or‘by a treatment with alkali hydroxide solutions and to 20 production of a starting material which can be used in further'process such debittered germs of cereals to food the manufacture of cereal germ ?akes. -

Grains Bingo Myfreebingocards.Com

Grains Bingo myfreebingocards.com Safety First! Before you print all your bingo cards, please print a test page to check they come out the right size and color. Your bingo cards start on Page 3 of this PDF. If your bingo cards have words then please check the spelling carefully. If you need to make any changes go to mfbc.us/e/gqm99r Play Once you've checked they are printing correctly, print off your bingo cards and start playing! On the next page you will find the "Bingo Caller's Card" - this is used to call the bingo and keep track of which words have been called. Your bingo cards start on Page 3. Virtual Bingo Please do not try to split this PDF into individual bingo cards to send out to players. We have tools on our site to send out links to individual bingo cards. For help go to myfreebingocards.com/virtual-bingo. Help If you're having trouble printing your bingo cards or using the bingo card generator then please go to https://myfreebingocards.com/faq where you will find solutions to most common problems. Share Pin these bingo cards on Pinterest, share on Facebook, or post this link: mfbc.us/s/gqm99r Edit and Create To add more words or make changes to this set of bingo cards go to mfbc.us/e/gqm99r Go to myfreebingocards.com/bingo-card-generator to create a new set of bingo cards. Legal The terms of use for these printable bingo cards can be found at myfreebingocards.com/terms.