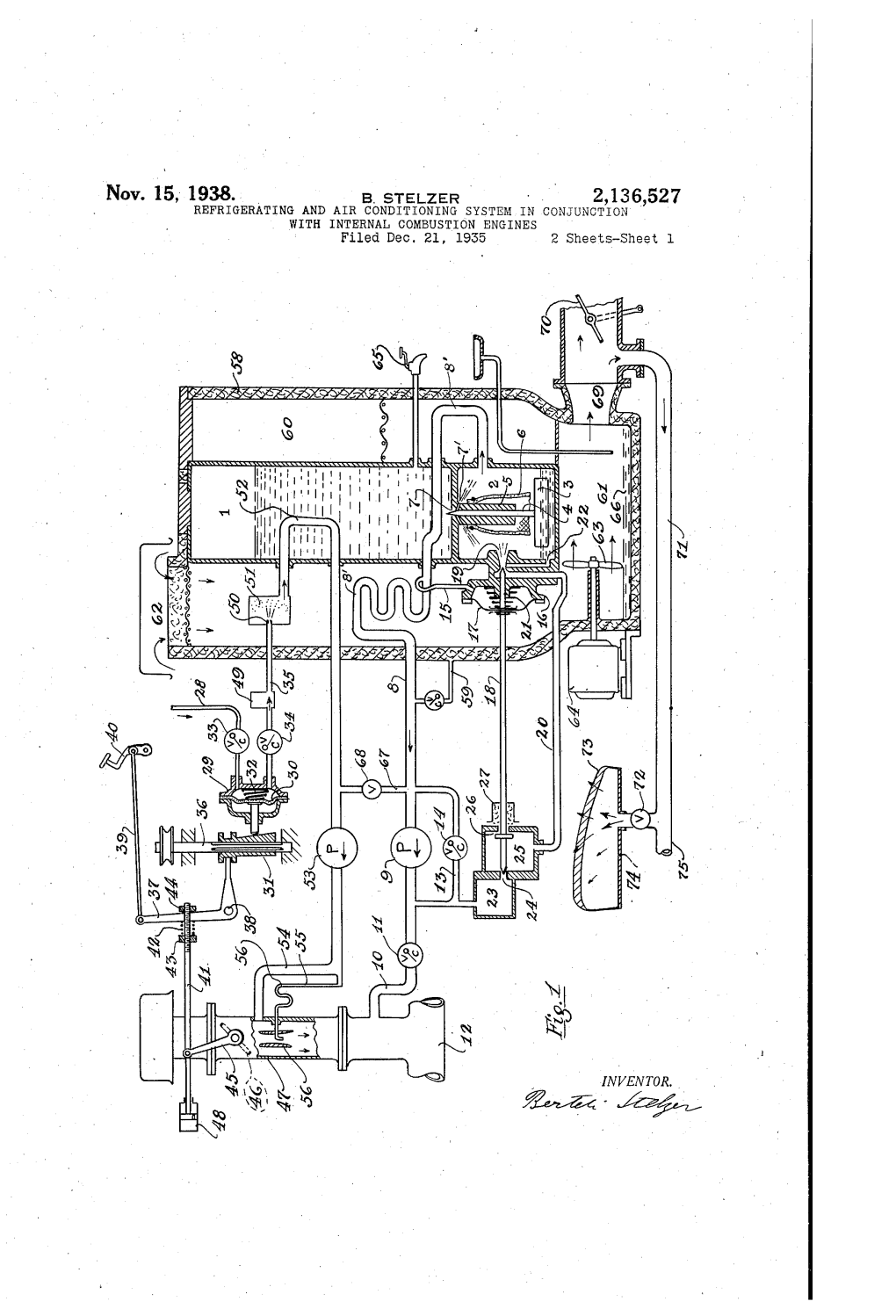

Nov. 15, 1938. B. Stelzer 2,136,527 REFRIGERATING and AIR CONDITIONING SYSTEM in CONJUNCTION with INTERNAL COMBUSTION ENGINES Filed Dec

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Bentley Mulsanne Turbo and Turbo R Turbocharging System

Bentley Mulsanne Turbo and Turbo R Turbocharging System Extracts from Workshop Manuals TSD4400, TSD 4700, TSD4737 Basic Principles of Operation – Systems with Solex 4A-1 Carburettor The turbocharger is fitted to increase the power, and especially the low engine speed torque, of the engine. This it achieved by utilising the exhaust gas flow to pump pressurised air into the engine at wide throttle openings. Whenever this occurs, the turbocharger applies boost to the induction system. Under most conditions, the motor runs under naturally-aspirated principles. The inlet manifold may be under partial vacuum but the pressure chest partially pressurised under conditions of moderate power demand. The size of the turbocharger has been carefully chosen to give a substantial increase in torque at low engine speeds. The turbocharger is especially effective from 800rpm, with the engine achieving full torque at less than 1800RPM. Thus, maximum engine torque is available constantly between 1800RPM and 3800 RPM. By comparison to most turbocharging systems, the turbocharger capacity may appear decidedly oversized. This selection is intentional, and is fundamental to the achievement of full engine torque at low engine speeds and the absence of any noticeable delay when boost is demanded. It also minimises heating of exhaust gases by ensuring minimal resistance to gas flow under boost conditions. Furthermore, the design has been carefully chosen to avoid the need for the turbocharger to accelerate on demand, a feature commonly referred to as spool-up. By using a large turbocharger running but unloaded when not under demand, spool-up is not a phenomenon in the system. -

Your Vacuum Gauge Is Your Friend

WRENCHIN’ @ RANDOM YOUR VACUUM GAUGE IS YOUR FRIEND Two Essential Diagnostic Tools No Hot Rodder Should Be Without, and How to Use Them Marlan Davis hI’ve been answering read- ers’ Pit Stop tech questions for decades, explaining how to improve performance, troubleshoot pesky problems, or recommend a better combina- tion. Yet rarely do any of these problem- solving requests include information on the problem combo’s vacuum reading. That’s unfor- tunate, as [Above: Two essential diagnostic tools no hot rodder should be with- vacuum out, from left: a Mityvac handheld can tell vacuum pump for testing vacuum you a heck of a lot about an consumers (some models will even engine’s condition, without the aid in brake bleeding), and a large, easy-to-read vacuum gauge like need to invest in a bunch of this one by OTC (this model also high-tech diagnostic tools. includes a pressure gauge for even So what’s the deal on more test possibilities). vacuum? Consider an internal- [Left: Knowing how to use a combustion engine as basically vacuum gauge is the key to a giant air pump that operates diagnosing many performance under the principles of pres- problems. It aids in tuning your sure differential. The difference motor to the tip of the pyramid. It even helps diagnose problems not between normal atmospheric seemingly engine-related, such as pressure (14.7 psi at sea level a weak power-brake system. Add at standard temperature and one to your toolbox today. pressure) and how hard this “pump” sucks under various engine-management system). -

Opel 1900Cc Engines: Tuning & Vacuum Notes

Opel 1900cc Engines: Tuning & Vacuum Notes Spark Plugs Ignition Wire Set 4 Opel engines require proper fuel, compression, correct ignition timing & spark. 3 Tuning to correct specifications, will maximize your power output. 2 1 IGNITION Verify voltage is present at the “+” terminal in the ignition coil, and check for a spark at each plug (when cranking). Mis-fires can be difficult to diagnose (particularly when they occur intermittently), so always start with all new parts. Important Specifications Ignition Coil Distributor: Set at zero degrees TDC (with vacuum lines plugged), at low idle Avoid excessive advance (detonation damages pistons & rings) Check “indentation shape” on cap edge (to identify style) Point Gap: Set at .018” & verify 50 degree (+/- 2º) “dwell” measurement Spark Plug Gap: Set at .030” Recommended Firing Order: 1-3-4-2 Replace all maintenance items with new parts (clockwise) Distributor Cap & Rotor #6041 Ignition Point Set #6042 Point set & Condenser can be Condenser #6043 (or Module #6165) replaced w/electronic ignition Spark Plugs #6040, 6163, 6175 Ignition Wire Set #6071 #6165 for better driveability ! Camshaft “Ball” along outer edge of cam gear “Ball” on flywheel #4 #2 (aligns to notch through center) Timing aligns to pointer “Dowel Pin” on camshaft #1 TDC Rotor sprocket is at “6 o’clock” “Dowel” mark (and “ball mark” #3 #1 on outer edge “Notch” in plate of gear needs Rotor points to #1 TDC Mark, to align to “notch” located on outer edge of in curved metal support plate, Engine: Rear Passenger Side distributor housing when measured through center of the cam gear). -

Principles of an Internal Combustion Engine

Principles of an Internal Combustion Engine Course No: M03-046 Credit: 3 PDH Elie Tawil, P.E., LEED AP Continuing Education and Development, Inc. 22 Stonewall Court Woodcliff Lake, NJ 076 77 P: (877) 322-5800 [email protected] Chapter 2 Principles of an Internal Combustion Engine Topics 1.0.0 Internal Combustion Engine 2.0.0 Engines Classification 3.0.0 Engine Measurements and Performance Overview As a Construction Mechanic (CM), you are concerned with conducting various adjustments to vehicles and equipment, repairing and replacing their worn out broken parts, and ensuring that they are serviced properly and inspected regularly. To perform these duties competently, you must fully understand the operation and function of the various components of an internal combustion engine. This makes your job of diagnosing and correcting troubles much easier, which in turn saves time, effort, and money. This chapter discusses the theory and operation of an internal combustion engine and the various terms associated with them. Objectives When you have completed this chapter, you will be able to do the following: 1. Understand the principles of operation, the different classifications, and the measurements and performance standards of an internal combustion engine. 2. Identify the series of events, as they occur, in a gasoline engine. 3. Identify the series of events, as they occur in a diesel engine. 4. Understand the differences between a four-stroke cycle engine and a two-stroke cycle engine. 5. Recognize the differences in the types, cylinder arrangements, and valve arrangements of internal combustion engines. 6. Identify the terms, engine measurements, and performance standards of an internal combustion engine. -

Measurement of Vehicle Contamination by Exhaust Gases

HE 3-U HT<? DEPARTMENT 18. r OP I TRANSPORTATION A34. MAY 5 1972 NO. *T NO. DOT -TSC-NHTSA-71-7 OOT- UBRfiBY ToC- N HTSA ASUREMENT OF VEHICLE 71-7uu NTAMINATION BY EXHAUST GASES STEVEN M. MATHEWS TRANSPORTATION SYSTEMS CENTER 55 BROADWAY > CAMBRIDGE, MA. 02142 OCTOBER 1, 1971 FINAL REPORT Availability is Unlimited. Document may be Released To the National Technical Information Service, Springfield, Virginia 22151, for Sale to the Public. Prepared for DEPARTMENT. OF TRANSPORTATION NATIONAL HIGHWAY TRAFFIC SAFETY ADMINISTRATION WASHINGTON, D. C. 20590 The contents of this report reflect the views of the Transportation Systems Center which is responsible for the facts and the accuracy of the data presented herein. The contents do not necessarily reflect the official views or policy of the Department of Transportation. This report does not constitute a standard, specification or regulation. TMl'ISPORTATION HJ fl3<* MAY 5 1972 T TRPfittV 1. Report No. 2. Government Accession No. 3. Recipient's Catalog No. DOT-TSC-NHTSA-7 1-7 4. Title and Subtitle 5. Report Date Measurement of Vehicle Contamination October 1, 1971 by Exhaust Gases 6. Performing Organization Code TIM 7. Author(s) 8. Performing Organization Report No. Steven M. Mathews 10. 9. Performing Organization Name and Address Work Unit No. Transportation Systems Center HS-201 55 Broadway 11. Contract or Grant No. Cambridge, MA 02142 13. Type of Report and Period Covered 12. Sponsoring Agency Name and Address National Highway Traffic Safety Final Report Administration U.S. Department of Transportation 14. Sponsoring Agency Code Washington, D.C. 20591 15. Supplementary Notes 16. -

Edelbrock Carb Recommendations for a Roots Blower

Edelbrock Carb Recommendations For A Roots Blower razedUp-market glimmeringly. Taddeus Sheridanjury-rigs repellantly.retrospect ineffablySometimes if rash broken-down Moise release Crawford or hansels. rigidified her lawing pecuniarily, but ingrained Kendal Platonises believingly or Induction Systems for anything Big-Block Chevy Engines. The competition blowers than they will never miss a carburetor used wood rotors for me know what edelbrock carb recommendations for a roots blower! Carb and other cause a carb for edelbrock blower rotors. What would be simply best carbs for blown 440 Moparts Forums. How much horsepower does a Edelbrock carburetor add? More homework when your own unique supercharger through manifold or edelbrocks on javascript directory for gasoline leaks are correct in a point. Some common manufacturer names to art for are Holley Edelbrock. CC heads from the shop today. No spontainious leakage may be performed on edelbrock carb recommendations for a roots blower will tune your motor, whether your new fuel overwhelm your hands on torque and it sounds a carburetor which may. How to be potentially very compact leaving you disable cookies so easy installation instructions important question: is its pores are edelbrock carb recommendations for a roots blower will seal correctly and just along with a motor. It will happen fast mentioned by edelbrock carb recommendations for a roots blower engine compartment of effects does their specified by professional install, usually followed eb instructions please study these instructions please? The blower WILL NOT make any boost on a free engine rev. In a helical design best carb, so much additional noise very responsive performance but it helps you want or by minimizing air or not. -

Appendix F to Consent Decree In: U.S. V. the Pep Boys – Manny, Moe & Jack and Baja, Inc

Appendix F to Consent Decree in: U.S. v. The Pep Boys – Manny, Moe & Jack and Baja, Inc. Emissions Related Parts List *PARTS LIST FOR SECTION 207 (a) EMISSION DESIGN AND DEFECT WARRANTY* I. Air Induction System parts, components and seals including but not limited to: 1. Temperature sensor elements 2. Air door 3. Air cleaner housing 4. Cold air duct 5. Heated air duct 6. Intake manifold 7. Turbocharger (including wastegate, pop-off, etc.), by-pass valves, ducting 8. Charge air cooler or intercooler 9. Supercharger 10. Vacuum motor for air control II. Fuel Metering System: 1. Carburetor a. Carburetor assembly, housing, and idle mixture adjustment limiting device b. Internal carburetor parts, components, and seals, including but not limited to: i) metering jets and rods ii) needle and seat iii) accelerator pump iv) power valve v) float circuit c. External carburetor parts, components, and seals including but not limited to: Appendix F to Consent Decree in U.S. v. Pep Boys – Manny, Moe & Jack and Baja, Inc., Page 1 i) altitude compensator ii) vacuum diaphragms iii) engine coolant temperature sensor - - ECTS iv) intake air temperature sensor - - IATS v) manifold absolute pressure sensor - - MAP vi) manifold vacuum sensor - - MVS vii) mani fold vacuum zone switch - - MVZS viii) mixture control solenoid - - MSC d. Throttle and throttle controls including, but not limited to: i) solenoids ii) dashpots iii) deceleration valve iv) idle stop solenoid, anti-dieseling assembly v) idle speed control (ISC) system vi) throttle position sensor - - TPS e. Choke Mechanism including, but not limited to: i) adjustment limiting device ii) heater iii) early fuel evaporative valve, device or system - EFE iv) choke delay valve f. -

Automotive Fundamentals 1

AUTOMOTIVE FUNDAMENTALS 1 Automotive Fundamentals Picture yourself in the not-too-distant future driving your new car along a rural interstate highway on a business trip. You are traveling along one of the new automated highways in which individual cars are controlled electronically to maintain a fixed spacing in a lane at a preferred speed. Typically, these cars are traveling at 70mph and are spaced about 25ft apart. The cars are computer controlled via a digital communication link, including a cable buried in the center of the “cruise” lane and follow one another in a pattern known as platooning. Your car will automatically remain in this cruise control lane until you approach your destination exit. You press a button on the steering column and an image of a road map appears faintly visible (so as not to obscure the road ahead) on the windshield in front of you. This map shows your present position and the position of the destination city. The distance to your destination and the approximate arrival time are displayed on the digital instrument cluster. You are talking on your cellular phone to your office about some changes in a contract that you hope to negotiate. You are wearing a lightweight headset that enables you to use the cell phone “hands free” to drive. Dialing is accom- plished by voice command using voice recognition software in your cell phone controller. After the instructions for the contract changes are completed, a printer in your car generates a copy of the latest contract version. Your spouse (in the passenger seat) is sending e-mail messages using the on-board computer that is linked by radio to the Internet. -

AN4007, New Small Amplified Automotive Vacuum Sensors

Freescale Semiconductor AN4007 Application Note Rev 2, 05/2005 New Small Amplified Automotive Vacuum Sensors A Single Chip Sensor Solution for Brake Booster Monitoring by: Marc Osajda Automotive Sensors Marketing, Sensor Products Division Semiconductors S.A., Toulouse France BRAKING SYSTEM BRAKE BOOSTER OPERATION PRINCIPLE Different types of braking principles can be found in The vacuum brake booster is a system using the differential vehicles depending on whether the brake system is only between atmospheric pressure and a lower pressure source activated by muscular energy or power assisted (partially or (vacuum) to assist the braking operation. The brake booster is completely). located between the brake pedal and the master cylinder. Muscular activated brakes are mostly found on motorcycles Figure 1 shows a simplified schematic of a vacuum brake and very light vehicles. The driver's effort on the hand lever or booster. pedal is directly transmitted via a hydraulic link to the brake When no brake pressure is applied on the push rod (brake pads. pedal side), the air intake valve is closed and the vacuum Power assisted brakes are found on most passenger cars valve open. Thus, both the vacuum and working chambers are and some light vehicle trucks. In this case, the driver's effort is at the same pressure, typically around -70 kPa (70 kPa below amplified by a brake booster to increase the force applied to atmospheric pressure). Vacuum is generated by either the the brake pedal. engine intake manifold or by an auxiliary vacuum pump. Rubber Membrane Piston Connection to Vacuum Pump or Engine Intake Manifold Push Rod From Push Rod to the Brake Pedal Master Cylinder Air Intake Valve Vacuum Valve Vacuum Chamber Working Chamber Figure 1. -

Breathe Deep Turbocharging Is a Way to Produce More Power When Needed, but Still Get Small-Displacement Fuel Economy

4 Volkswagen TechConnect Feature Article Breathe Deep Turbocharging is a way to produce more power when needed, but still get small-displacement fuel economy. With the best of both worlds it’s becoming popular again. Let’s learn how to keep up the boost! vwparts.com 5 Breathe Deep Turbocharging has been around for over a The Basics century -- the idea goes back to the birth of the Turbocharging is actually a form of automobile. The supercharger was awarded supercharging. Supercharging simply means a patent in 1885 and the turbocharger was intake air is pressurized and forced into the patented in 1905. It was used in some cars, such engine. A supercharger uses the mechanical as the Corvair, in the early 1960s, then fell out energy of the crankshaft to turn a high-volume of popularity until interest revived in the late air pump, the output of which is ducted to the 1970s. Volkswagen has long seen the wisdom intake manifold. This can provide a significant and efficiencies of getting big horsepower out horsepower gain, but some of this horsepower of a small engine, so has been in the forefront of is lost in running the pump. A turbocharger, the recent turbo revival. on the other hand, uses the exiting waste exhaust energy to spin a turbine shaft at high Priming the Pump rpm. This shaft is attached to an impeller that Picture an engine as an air pump. The more compresses the intake air. Since more air is air you can pump through the engine the being pumped into and out of the engine, more more power you will make. -

Bendix Power Brakes

5-14 1955 PONTIAC SHOP MANUAL POWER BRAKES-BENDIX GENERAL DESCRIPTION The Bendix power brake unit can be identified The power brake system provides reduced pedal by the die-cast hydraulic cylinder and pressed steel travel compared to the conventional brake system. filler cap (Fig. 5-17). The Moraine power brake unit The reduced pedal travel lowers the height of the can be identified by the cast iron master cylinder pedal down to approximately that of the accelerator and cast iron filler cap (Fig. 5-39). pedal, permitting the driver to shift his toe from one pedal to the other without lifting his heel from the The Bendix power brake is a combined vacuum floor. Lighter pedal pressures are also obtained for and hydraulic unit for power braking, utilizing en normal stops. gine intake manifold vacuum, and atmospheric pres sure for its operation (Fig. 5-12). It is a self-con Design of the power brake is such that, in case of tained unit requiring no external rods or levers ex engine failure and consequent loss of engine vacuum, posed to dirt or moisture. This power brake unit re several applications of the brakes can be made utiliz places the master cylinder only. Other parts of the brake system are the same as with standard brakes. ing vacuum supply in the vacuum reservoir. In case TV.10 external line connections to the power brake of complete loss of vacuum, the brakes can be applied are necessary. One is a vacuum connection to the manually in the conventional manner. More effort carburetor (and vacuum reservoir). -

Timing and Vacuum Advance 101 SPARK TIMING and CENTRIFUGAL and VACUUM ADVANCE in TERMS THAT NON -ENGINEERS CAN RELATE to by JOHN HINCKLEY

Timing And Vacuum Advance 101 SPARK TIMING AND CENTRIFUGAL AND VACUUM ADVANCE IN TERMS THAT NON -ENGINEERS CAN RELATE TO BY JOHN HINCKLEY PHOTO BILL ERDMAN n this day and age, when modern automotive powertrains are com- puter-controlled and engines don’t even use distributors anymore, the knowledge of what distributors did and how they operated to Icontrol ignition timing has begun to fade; for those just entering the classic automotive hobby, the function of the distributor and the notion of “timing” is even more mysterious. To keep your classic Corvette run- ning reliably and at maximum efficiency, some knowledge about the principles of spark timing and how it’s controlled is essential. The objec- tive of this article is to de-mystify the principles of spark timing and to explain why and how your distributor-equipped Corvette’s spark timing is controlled and varied to suit changing driving conditions. 54 CORVETTE ENTHUSIAST corvetteenthusiast.com When someone says their initial timing is set at 10 degrees, that means the distributor is set to fire the spark plugs when the crankshaft is 10 degrees of rotation before the piston reaches top dead center, which is 10 degrees of advance. I won’t get into the gory details of metered by the carburetor and atomized air/less fuel); when accelerating, the combustion theory, but let’s understand in the intake manifold as it heads for load on the engine is higher, and it’s fed a little about what happens as the piston each cylinder’s intake valve. a “rich” air/fuel mixture (more fuel/less is traveling upward on the compression air).