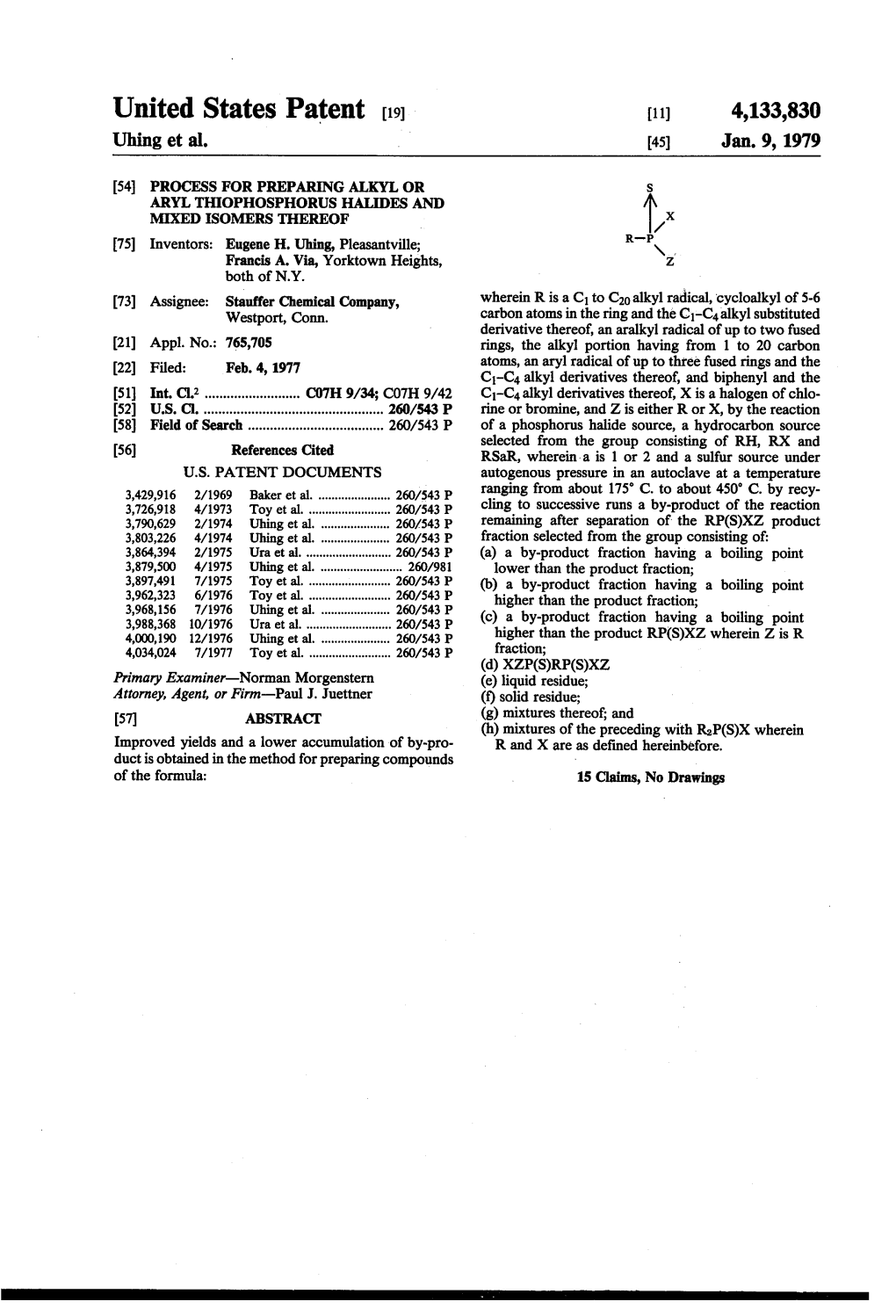

United States Patent (19) 11) 4,133,830 Uhing Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Durham E-Theses

Durham E-Theses Some reactions of phosphorus compounds as studied by 31p nmr techniques Nisbet, M. P. How to cite: Nisbet, M. P. (1976) Some reactions of phosphorus compounds as studied by 31p nmr techniques, Durham theses, Durham University. Available at Durham E-Theses Online: http://etheses.dur.ac.uk/8177/ Use policy The full-text may be used and/or reproduced, and given to third parties in any format or medium, without prior permission or charge, for personal research or study, educational, or not-for-prot purposes provided that: • a full bibliographic reference is made to the original source • a link is made to the metadata record in Durham E-Theses • the full-text is not changed in any way The full-text must not be sold in any format or medium without the formal permission of the copyright holders. Please consult the full Durham E-Theses policy for further details. Academic Support Oce, Durham University, University Oce, Old Elvet, Durham DH1 3HP e-mail: [email protected] Tel: +44 0191 334 6107 http://etheses.dur.ac.uk To Mum, Dad, and Steven Everything in this universe is made of one element which is a note, a single note. Atoms are really vibrations, you know, which are extensions of the BIG note. Everything is one note, even the ponies. Francis Vincent Zappa 1967 Declaration The work described in this thesis was carried out in the University of Durham between September 19 72 and July 1975. This work has not been submitted, either completely or in part, for a degree in this or any other university and is the original work of the author except where acknowledged by reference. -

United States Patent (19) 11) E Re

United States Patent (19) 11) E Re. 30,279 Toy et al. (45) Reissued May 20, 1980 54 PROCESS FOR PREPARING ALKYLOR 3,813,435 5/1974 Wood et al. ...................... 260/543 P ARYL PHOSPHORUS HALOES AND 3,847,979 1/1974 Richards .......................... 260/543 P MXED SOMERS THEREOF FOREIGN PATENT DOCUMENTS (75) Inventors: Arthur D. F. Toy, Stamford, Conn.; 1184767 3/1970 United Kingdom ................. 260/543 P Eugene H. Uhing, Ridgewood, N.J. OTHER PUBLICATIONS 73) Assignee: Stauffer Chemical Company, Westport, Conn. Ethyl Corp., Development Products Bulletin, Feb. 1969. 21 Appl. No.: 854 Richard et al., “J.A.C.S.", vol. 83 (1961), pp. 1722-1726. (22 Filed: Jan. 4, 1979 Kosolapoff, "Organo Phos. Comps.", pp. 152, 162 (1950). Related U.S. Patent Documents Sommer, "Zeit Anorg. Alleg. Chem.'", 1970,376(1), pp. Reissue of: 37-43. 64 Patent No.: 3,897,491 issued: Jul. 29, 1975 Primary Examiner-Norman Morgenstern Appl. No.: 151955 Attorney, Agent, or Firn-Paul J. Juettner Fied: Jun. 10, 1971 57 ABSTRACT 51) int.C. ................................................ COTF 9/42 Alkyl or aryl phosphonic or phosphonothioic dihalides 52) U.S. C. ........................... 260/543 P 260/45.7 P; and phosphinic or phosphinothioic monohalides are 260/45.7 PS prepared by reacting an alkyl halide or aryl halide re 58) Field of Search ......... 260/543 P, 45.7 P, 45.7 PS spectively with a tri-valent phosphorus compound hav (56) References Cited ing at least two halogens attached thereto, and prefera bly three two halogens such as phosphorus trihalide, in U.S. PATENT DOCUMENTS the presence of P4O10or P4S10 under at least autogenous 2,345,690 4/1944 Solmssen ......................... -

Low Oxidation State Group 15 Chemistry: New Synthetic Methods Towards Polymers

Low Oxidation State Group 15 Chemistry: New Synthetic Methods Towards Polymers By Erin L. Norton A Thesis Submitted to the Faculty of Graduate Studies and Research through the Department of Chemistry and Biochemistry in Partial Fulfillment of the Requirements for the Degree of Master of Science at the University of Windsor Windsor, Ontario, Canada 2008 Library and Bibliotheque et 1*1 Archives Canada Archives Canada Published Heritage Direction du Branch Patrimoine de I'edition 395 Wellington Street 395, rue Wellington Ottawa ON K1A0N4 Ottawa ON K1A0N4 Canada Canada Your file Votre reference ISBN: 978-0-494-42260-1 Our file Notre reference ISBN: 978-0-494-42260-1 NOTICE: AVIS: The author has granted a non L'auteur a accorde une licence non exclusive exclusive license allowing Library permettant a la Bibliotheque et Archives and Archives Canada to reproduce, Canada de reproduire, publier, archiver, publish, archive, preserve, conserve, sauvegarder, conserver, transmettre au public communicate to the public by par telecommunication ou par I'lnternet, prefer, telecommunication or on the Internet, distribuer et vendre des theses partout dans loan, distribute and sell theses le monde, a des fins commerciales ou autres, worldwide, for commercial or non sur support microforme, papier, electronique commercial purposes, in microform, et/ou autres formats. paper, electronic and/or any other formats. The author retains copyright L'auteur conserve la propriete du droit d'auteur ownership and moral rights in et des droits moraux qui protege cette these. this thesis. Neither the thesis Ni la these ni des extraits substantiels de nor substantial extracts from it celle-ci ne doivent etre imprimes ou autrement may be printed or otherwise reproduits sans son autorisation. -

Jacqueline Garland Phd Thesis

STUDIES IN PHOSPHORUS-SELENIUM CHEMISTRY Jacqueline Garland A Thesis Submitted for the Degree of PhD at the University of St Andrews 2013 Full metadata for this item is available in Research@StAndrews:FullText at: http://research-repository.st-andrews.ac.uk/ Please use this identifier to cite or link to this item: http://hdl.handle.net/10023/3688 This item is protected by original copyright Studies in Phosphorus-Selenium Chemistry Jacqueline Garland This thesis is submitted in partial fulfilment for the degree of Doctor of Philosophy (PhD.) at the University of St Andrews and Doctor rerum naturalium (Dr. rer. nat.) at the Universität Leipzig 21st February 2013 Supervisors: Prof. J. D. Woollins Prof. E Hey-Hawkins Declarations I, Jacqueline Garland, hereby certify that this thesis, which is approximately 53000 words in length, has been written by me, that it is the record of work carried out by me and that it has not been submitted in any previous application for a higher degree. I was admitted as a research student in September, 2008 and as a candidate for the degree of July 2009; in the higher study for which this is a record was carried out in the University of St Andrews and the Universität Leipzig between 2008 and 2013. Date: 21st February 2013 Signature of candidate: I hereby certify that the candidate has fulfilled the conditions of the Resolution and Regulations appropriate for the degree of PhD. in the University of St Andrews and that the candidate is qualified to submit this thesis in application for that degree. Date: 21st February 2013 Signature of supervisor: I hereby certify that the candidate has fulfilled the conditions of the Resolution and Regulations appropriate for the degree of Dr. -

CHAPTER 7 ALCOHOLS, THIOLS, PHENOLS, ETHERS 7.1 Alcohols

CHAPTER 7 ALCOHOLS, THIOLS, PHENOLS, ETHERS Several new functional groups are presented in this chapter. All of the functions are based on oxygen and sulfur in the sp2 hybridized state. The functional groups contain two pairs of non-bonding electrons and are the cornerstone of many organic processes. The structures for alcohols, phenols, thiols, ethers and thioethers are shown below. Alkyl-OH Ph-OH Alkyl-SH R-O-R R-S-R alcohol phenol thiol ether thioether 7.1 Alcohols 7.1a Nomenclature Priorities in nomenclature Several functional groups have been encountered as we have advanced through the chapters. When a new functional group is presented, its nomenclature is always based on the parent name with an ending that designates the functional group. When several functional groups are present in a molecule, priority rules must be used to determine which function is the parent system that determines the numbering of the system and the suffix used in the final name. The priority list is as follows: carboxylic acids > aldehydes> ketones> alcohols > amines > alkene > alkyne > alkyl, halogen, nitro Thus a compound that contained hydroxy, alkene and ketone functions would be named as a ketone with the ketone getting the lowest number possible, and substituents are numbered accordingly and named in alphabetical order. Below the compound on the left is named as an alcohol, but the one on the right is named as a ketone even though both compounds have the seven carbon backbone. 124 Ch 7 Alcohols, Thiols, Phenols, Ethers OH OH Cl Cl O 7-chloro-3-hepten-2-ol 1-chloro-6-hydroxy-4-hepten-3-one OH has priority ketone has priority Alcohol Nomenclature Hydroxy compounds are encountered frequently in organic chemistry and the OH function is of high priority with only acids, aldehydes and ketones having higher priority. -

The Par Infrared Spectra Op Several Pyramidal

THE PAR INFRARED SPECTRA OP SEVERAL PYRAMIDAL TRIHALIDES DISSERTATION Presented in Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy in the Gradxiate School of The Ohio State University By / PHILIP DAVIS, B. Sc. The Ohio State University 1954 Approved by: Adviser ACKNOWLEDGEMENT I 3hould. like to express my appreciation to Dr. Robert A. Oetjen and to Dr. Ely E. Bell for their guidance and patience during the course of this work. The ever present aid of the indefatigable Raymond L. Brown and Edward D. Palik of this laboratory was of great assistance to me throughout the time the work was in progress. I am indebted to The Ohio State University Research Foundation for allowing me a Fellowship for the year 1952- 53 and to the Wright Air Development Center for permitting me to use the far infrared spectrometer to carry out this investigation. Finally the excellent work of Mr. Carl McWhirt and the staff of the Physics Department shop is gratefully acknowledged. iii TABLE OB1 CONTENTS Introduction................. 1 H i s t o r y ............ 3 Experimental Procedure .............................. 6 Instrumentation ................... 6 Samples ................. 1 5 Cells ........... 1 6 Theory ............... .......... ......... 26 Group Theory ........... ........... 26 Normal Vibrations ..... ................. 43 Experimental Results ................................ 55 Phosphorus Trichloride ....................... 55 Arsenic Trichloride .......................... 62 Phosphorus Tribromide ....................... -

Green Chemistry

Green Chemistry View Article Online PAPER View Journal | View Issue Catalyst- and solvent-free hydrophosphination and multicomponent hydrothiophosphination of Cite this: Green Chem., 2016, 18, 4896 alkenes and alkynes† Yanina Moglie,‡a María José González-Soria,a Iris Martín-García,a Gabriel Radivoyb and Francisco Alonso*a The hydrophosphination of carbon–carbon multiple bonds has been generally performed under acid, base or metal catalysis in different solvents. Herein, alkyl and alkenyl tertiary phosphines are obtained by the addition of diphenylphosphine to alkenes and alkynes, respectively, in the absence of a solvent and a catalyst. In the presence of elemental sulfur, the corresponding alkyl and alkenyl tertiary phosphine Received 30th March 2016, sulfides are synthesized in a three-component process. These simple methods, which meet most of the Accepted 24th May 2016 principles of Green Chemistry, are highly regioselective towards the anti-Markovnikov products and DOI: 10.1039/c6gc00903d diastereoselective towards the Z alkenyl phosphines. The mechanistic aspects of the reactions are also Creative Commons Attribution-NonCommercial 3.0 Unported Licence. www.rsc.org/greenchem tackled and the efficiency of the latter is compared with that of the catalytic methods. Introduction The deployment of phosphorus compounds in industry has become widespread because of their manifold applications.1 Nowadays, many chemical, agrochemical and pharmaceutical This article is licensed under a substances containing phosphorus are routinely produced to control some natural or human-triggered processes and to upgrade the quality of our lives. Research laboratories also make extensive use of organophosphorus compounds, particu- Open Access Article. Published on 24 May 2016. Downloaded 9/28/2021 4:32:05 AM. -

The Synthesis of New Phenylhydroxyiodonium Phosphates from (Diacetoxyiodobenzene) and Dialkyl Phosphates and Their Use In

THE SYNTHESIS OF NEW PHENYLHYDROXYIODONIUM PHOSPHATES FROM (DIACETOXYIODOBENZENE) AND DIALKYL PHOSPHATES AND THEIR USE IN THE α−PHOSPHORYLATION OF KETONES TO MONO-KETOL PHOSPHATES A Thesis Presented to The Graduate Faculty of the University of Akron In Partial Fulfillment of the Requirements for the Degree Master of Science Ousainou A. Keita May, 2008 THE SYNTHESIS OF NEW PHENYLHYDROXYIODONIUM PHOSPHATES FROM (DIACETOXYIODOBENZENE) AND DIALKYL PHOSPHATES AND THEIR USE IN THE α−PHOSPHORYLATION OF KETONES TO MONO-KETOL PHOSPHATES Thesis Approved: Accepted: ________________________________ _______________________________ Advisor Dean of the College Dr. Kim C. Calvo Dr. Roger B. Creel ________________________________ _______________________________ Co-Advisor/Faculty Reader Dean of the Graduate School Dr. Gerald F. Koser Dr. George R. Newkome ________________________________ _______________________________ Department Chair Date Dr. Kim C. Calvo ii ABSTRACT The synthesis of new phenylhydroxyiodonium phosphates from (diacetoxyiodo) benzene and dialkyl phosphates, and their use in the α−phosphorylation of ketones was investigated. Reaction of diphenyl phosphate, (PhO)2P(O)OH, with (diacetoxyiodo) benzene, PhI(OAc)2, in the presence of water gave [hydroxy((bis(phenyl)phosphoryl)- oxy)iodo] benzene, (PhI(OH)OPO(OPh)2, HPIB) as a white solid in excellent yield. Similarly prepared are PhI(OH)OPO(OCH3) 2, PhI(OH)OPO (OCH2CH3) 2, PhI(OH)- OPO(OCH2CH2Cl) 2, PhI(OH)OPO(OCH2CCl3) 2, and PhI(OH)OPO(OCH2CF3)2 from the corresponding monobasic acid phosphates (RO)2P(O)OH (R= CH3, CH3CH2, CH2ClCH2, CCl3CH2, and CF3CH2 ) in 77-93 % yield . These ketones (acetophenone, 4-methoxyacetophenone, p-nitroacetophenone, acetone, and pinacolone) were directly phosphorylated at the α−carbon with the iodine (III) reagent, HPIB, or its alkyl derivatives to give the corresponding α-phosphoryloxy derivatives in 41-89 % yield. -

Preparation and Properties of Tetrachlorophosphonium

This dissertation has been microfilmed exactly as received 66-1851 WALTHER, James Fletcher, 1938- PREPARATION AND PROPERTIES OF T E TRAC HLOROPHOSPHONIUM TETRACHLORODIFLUOROPHOSPHATE. The Ohio State University, Ph.D., 1965 Chemistry, inorganic University Microfilms, Inc., Ann Arbor, Michigan PREPARATION AND PROPERTIES OP TETRACHLOROPHOSPHONIUH TKTRACHLORGDIFLUQROPHOSPHATE DISSERTATION Presented In Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy In the Graduate School of The Ohio State University BSP James Fletcher Walther, B.A.* M.Sc* The Ohio State University 1965 Department of Chemistry ACKHCMI2DGMENTS I wish to express ngr sincerest gratitude to my adviser* Or. Sheldon Q. Shore* Tor suggesting this very interesting and perplexing research problem. I am dearly grateful to ay wife* Kay* for her faithful assistance in preparing this dissertation and for her enduring interest and enthusiasm in my work. Also* I want to express my appreciation to the Chemistry Department of The Ohio State University for its financial assist ance through various teaching assistantships and summer fellow ships. ii VITA August *** 1 9 3 8 ........... Born* St* Louis* Missouri i960 ••••••••• ••• B*A** Central Methodist College* Fayette* Missouri 1960-1963 ....................... Teaching Assistant* Department of Chemistry* The Ohio State University* Columbus* Ohio 1963-196**................... Teaching Assistant* Graduate level* Inorganic Division* Department of Chemistry The Ohio State University* Columbus* (Alio 196*4—1965 .............. -

United States Patent 19 11) 4,081,445 Hermans 45) Mar

United States Patent 19 11) 4,081,445 Hermans 45) Mar. 28, 1978 54 CERTAIN BISPIPERAZIDO PHOSPHORUS 58) Field of Search ................... 260/268 K, 959, 958, COMPOUNDS 260/268 MK 75) Inventor: Johny C. Hermans, Wespelaar, (56) References Cited Belgium U.S. PATENT DOCUMENTS 73. Assignee: s.a. Texaco Belgium in.v., Brussels, 3,298,937 1/1967 Strauss et al. ........................ 260/959 Belgium 3,531,550 9/1970 Herber et al. ........................ 260/959 Primary Examiner-R. Gallagher 21 Appl. No.: 628,288 Attorney, Agent, or Firm-Thomas H. Whaley; Carl G. 22 Filed: Nov. 3, 1975 Ries; Carl G. Seutter (30) Foreign Application Priority Data 57 ABSTRACT Compounds useful as lube oil additives are prepared by May 21, 1975 United Kingdom ............... 21796/75 reaction of phosphorus halides and piperazine deriva 51 int. C.?................... C07D 295/16; CO7D 295/22 tives. 52 U.S. Cl. ............................... 260/268 K; 252/46.7; 252/49.9; 252/389 A; 544/121 5 Claims, No Drawings 4,081,445 1. 2 X represents an oxygen or sulphur atom or is absent, CERTAN BESPPERAZIDO PHOSPHORUS Y represents an (i) aliphatic, cycloalliphatic, or COMPOUNDS aromatic hydrocarbon group or a heterocyclic group; (ii) a group of the formula -NR in which FIELD OF THE INVENTION each group R represents a hydrogen atom, an ali This invention concerns bis-piperazido phosphorus phatic, cycloaliphatic, or aromatic hydrocarbon and trispiperazido phosphorus compounds, and meth group or a heterocyclic group, or the two groups ods for the preparation of these compounds. R, together with the nitrogen atom to which they Various of the compounds obtained according to the are attached, represent a N-containing heterocyclic invention are of interest as components of petroleum 10 ring; (iii) a group of the formula -OR in which R compositions, as additives for plastics materials, as com has the meaning given above; or (iv) a group of the ponents of flameresistant or flame-retardant polymers, formula: as pharmaceuticals or as intermediates in the production of pharmaceuticals. -

Chapter 7: Search for New Fire Suppressant Chemicals

Chapter 7: SEARCH FOR NEW FIRE J. Douglas Mather, Ph.D. SUPPRESSANT CHEMICALS Chemical Development Studies, Inc. Robert E. Tapscott, Ph.D. GlobeTech, Inc. TABLE OF CONTENTS 7.1 Fire Suppressant Replacement Knowledge Prior to the NGP .........................................612 7.1.1 Overview of Early Halon Replacement Efforts ....................................................612 7.1.2 Fire Suppressant Research – 1974 Through 1993.................................................613 7.1.3 DoD Technology Development Plan (1993 to 1997)............................................615 7.1.4 Advanced Agent Working Group (AAWG) .........................................................616 7.1.5 Summary: Alternative Agents and Selection Criteria Prior to the NGP ...............622 7.2 The NGP Approach to New Chemicals Screening..........................................................612 7.3 NGP Surveys of Inorganic Chemical Families................................................................612 7.3.1 Main Group Elements - Group I............................................................................626 7.3.2 Main Group Elements - Group II ..........................................................................627 7.3.3 Main Group Elements - Group III.........................................................................627 7.3.4 Main Group Elements - Group IV.........................................................................628 7.3.5 Main Group Elements - Group V..........................................................................634 -

United States Patent (19) (11) 3,884,997 Shook, Jr

United States Patent (19) (11) 3,884,997 Shook, Jr. (45) May 20, 1975 54 PROCESS FOR PREPARATION OF 2,880,223 3/1959 Coates et al.................... 260/976 X 3,287,449 l l (1966 Baranauckas et al............... 260/976 AROMATIC PHOSPHORUS COMPOUNDS 3,335,204 8/1967 Scherer et al....................... 260,976 75 Inventor: Howard E. Shook, Jr., Orange, Tex. 73 Assignee: E. I. du Pont de Nemours and Primary Examiner-Lorraine A. Weinberger Company, Wilmington, Del. Assistant Examiner-Richard L. Raymond Filed: May 2, 1973 22 57 ABSTRACT 21 ) Appl. No.: 356,444 An improved process is provided for the preparation of aromatic phosphorus compounds such as phosphite, (52) U.S. Cl.................. 260/973; 260/976; 260/990 phosphonite or phosphinite through reaction of a phe 51 Int. Cl. ......... C07f 9/08; CO7f 9/32; C07f 9/40 nol or phenolic compound with the appropriate phos 58) Field of Search..................... 260/973, 976, 990 phorus halide by incorporating a finely-divided metal in the reaction medium in the final stages of reaction 56) References Cited to produce an aromatic phosphorus compound free of UNITED STATES PATENTS by-product hydrogen halide. 2,220,845 1 1/1940 Moyle............................. 260/976 X 6 Claims, No Drawings 3,884,997 1 2 PROCESS FOR PREPARATION OF AROMATIC gen halide remaining in the reaction product. An ex PHOSPHORUS COMPOUNDS cess of metal will normally be used but in general a large excess would be avoided for economic reasons. After addition of the metal the reaction mixture is BACKGROUND OF THE INVENTION 5 maintained at a temperature in the range of 25°C.