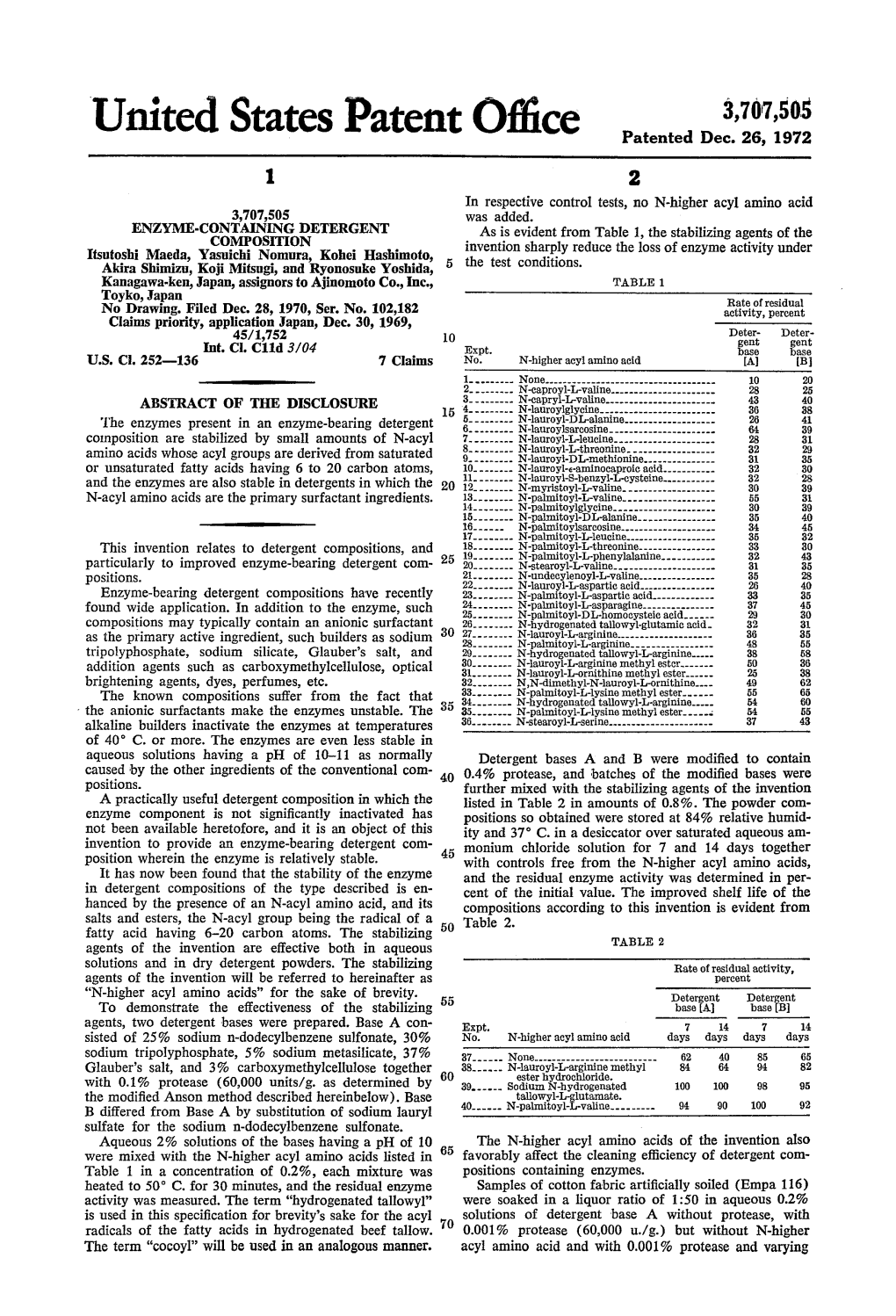

United States Patent Office Patented Dec

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Aspartic Acid Agonist, in the Mammalian Striatum

The Journal of Neuroscience August 1986, 6(8): 2226-2234 /II Vitro Release and Electrophysiological Effects In Situ of Homocysteic Acid, An Endogenous N-Methyl-(D)-aspartic Acid Agonist, in the Mammalian Striatum Kim Quang DO,* Paul L. Herrling,? Peter Streit,* Waldemar A. Turski,“fsl and Michel Cuenod* *Brain Research Institute, University of Zurich, Zurich, Switzerland, and j-Wander Research Institute, Bern, Switzerland A potassium-induced, calcium-dependent release of endogenous fects of microiontophoretically applied (L)-HCA on membrane homocysteic acid (HCA) from rat striatal slices was demonstrat- potential and cortically evoked EPSPsin cat caudate neurons, ed. A precolumn derivatization high-performance liquid chro- and the pharmacologicalspecificity of (L)-HCA in this structure. matography method was developed that allowed quantitative de- termination of sulfur-containing amino acids at the picomole level. Materials and Methods Intracellular recordings from cat caudate neurons during si- Materials multaneous microiontophoretic application of drugs and electri- cal stimulation of the corticocaudate pathway showed that (L> Release HCA evoked a depolarization pattern similar to that induced 4-N,N-Dimethylamino-azobenzene-4’-isotbiocyanate (DABITC) was ob- by %methyl-(D>aspartic acid (NMDA), and both these depo- tained from Fluka (Buchs, CH) and recrystallized in acetone (Merck, larizations could be selectively inhibited by a specific NMDA Darmstadt, FRG). All other solvents used were ofcommercial analytical antagonist, (D)-Z-amino-7-phosphonoheptanoicacid [(D)-AP-~]. grade from Merck or Fluka. The internal standard (D,L)-2-amino-7- A selective antagonismof (rJ-HCA-induced depolarizations by sulfonoheptanoic acid (AS-7) was a generous gift of Dr. J. C. Watkins. (L)-homocysteic acid [(L)-HCA], (L)-cysteine sulfinic acid [(L)-CSA], (L)- (D>AP-~ was confirmed in quantitative experiments with the cysteic acid [(L)-CA], and veratrine were purchased from Sigma (St. -

Treatment Protocol Copyright © 2018 Kostoff Et Al

Prevention and reversal of Alzheimer's disease: treatment protocol Copyright © 2018 Kostoff et al PREVENTION AND REVERSAL OF ALZHEIMER'S DISEASE: TREATMENT PROTOCOL by Ronald N. Kostoffa, Alan L. Porterb, Henry. A. Buchtelc (a) Research Affiliate, School of Public Policy, Georgia Institute of Technology, USA (b) Professor Emeritus, School of Public Policy, Georgia Institute of Technology, USA (c) Associate Professor, Department of Psychiatry, University of Michigan, USA KEYWORDS Alzheimer's Disease; Dementia; Text Mining; Literature-Based Discovery; Information Technology; Treatments Prevention and reversal of Alzheimer's disease: treatment protocol Copyright © 2018 Kostoff et al CITATION TO MONOGRAPH Kostoff RN, Porter AL, Buchtel HA. Prevention and reversal of Alzheimer's disease: treatment protocol. Georgia Institute of Technology. 2018. PDF. https://smartech.gatech.edu/handle/1853/59311 COPYRIGHT AND CREATIVE COMMONS LICENSE COPYRIGHT Copyright © 2018 by Ronald N. Kostoff, Alan L. Porter, Henry A. Buchtel Printed in the United States of America; First Printing, 2018 CREATIVE COMMONS LICENSE This work can be copied and redistributed in any medium or format provided that credit is given to the original author. For more details on the CC BY license, see: http://creativecommons.org/licenses/by/4.0/ This work is licensed under a Creative Commons Attribution 4.0 International License<http://creativecommons.org/licenses/by/4.0/>. DISCLAIMERS The views in this monograph are solely those of the authors, and do not represent the views of the Georgia Institute of Technology or the University of Michigan. This monograph is not intended as a substitute for the medical advice of physicians. The reader should regularly consult a physician in matters relating to his/her health and particularly with respect to any symptoms that may require diagnosis or medical attention. -

Endogenous Metabolites: JHU NIMH Center Page 1

S. No. Amino Acids (AA) 24 L-Homocysteic acid 1 Glutaric acid 25 L-Kynurenine 2 Glycine 26 N-Acetyl-Aspartic acid 3 L-arginine 27 N-Acetyl-L-alanine 4 L-Aspartic acid 28 N-Acetyl-L-phenylalanine 5 L-Glutamine 29 N-Acetylneuraminic acid 6 L-Histidine 30 N-Methyl-L-lysine 7 L-Isoleucine 31 N-Methyl-L-proline 8 L-Leucine 32 NN-Dimethyl Arginine 9 L-Lysine 33 Norepinephrine 10 L-Methionine 34 Phenylacetyl-L-glutamine 11 L-Phenylalanine 35 Pyroglutamic acid 12 L-Proline 36 Sarcosine 13 L-Serine 37 Serotonin 14 L-Tryptophan 38 Stachydrine 15 L-Tyrosine 39 Taurine 40 Urea S. No. AA Metabolites and Conjugates 1 1-Methyl-L-histidine S. No. Carnitine conjugates 2 2-Methyl-N-(4-Methylphenyl)alanine 1 Acetyl-L-carnitine 3 3-Methylindole 2 Butyrylcarnitine 4 3-Methyl-L-histidine 3 Decanoyl-L-carnitine 5 4-Aminohippuric acid 4 Isovalerylcarnitine 6 5-Hydroxylysine 5 Lauroyl-L-carnitine 7 5-Hydroxymethyluracil 6 L-Glutarylcarnitine 8 Alpha-Aspartyl-lysine 7 Linoleoylcarnitine 9 Argininosuccinic acid 8 L-Propionylcarnitine 10 Betaine 9 Myristoyl-L-carnitine 11 Betonicine 10 Octanoylcarnitine 12 Carnitine 11 Oleoyl-L-carnitine 13 Creatine 12 Palmitoyl-L-carnitine 14 Creatinine 13 Stearoyl-L-carnitine 15 Dimethylglycine 16 Dopamine S. No. Krebs Cycle 17 Epinephrine 1 Aconitate 18 Hippuric acid 2 Citrate 19 Homo-L-arginine 3 Ketoglutarate 20 Hydroxykynurenine 4 Malate 21 Indolelactic acid 5 Oxalo acetate 22 L-Alloisoleucine 6 Succinate 23 L-Citrulline 24 L-Cysteine-glutathione disulfide Semi-quantitative analysis of endogenous metabolites: JHU NIMH Center Page 1 25 L-Glutathione, reduced Table 1: Semi-quantitative analysis of endogenous molecules and their derivatives by Liquid Chromatography- Mass Spectrometry (LC-TripleTOF “or” LC-QTRAP). -

Involvements of Hyperhomocysteinemia in Neurological Disorders

H OH metabolites OH Review Involvements of Hyperhomocysteinemia in Neurological Disorders Marika Cordaro 1,† , Rosalba Siracusa 2,† , Roberta Fusco 2 , Salvatore Cuzzocrea 2,3,* , Rosanna Di Paola 2,* and Daniela Impellizzeri 2 1 Department of Biomedical, Dental and Morphological and Functional Imaging, University of Messina, Via Consolare Valeria, 98125 Messina, Italy; [email protected] 2 Department of Chemical, Biological, Pharmaceutical and Environmental Sciences, University of Messina, 98166 Messina, Italy; [email protected] (R.S.); [email protected] (R.F.); [email protected] (D.I.) 3 Department of Pharmacological and Physiological Science, Saint Louis University School of Medicine, Saint Louis, MO 63104, USA * Correspondence: [email protected] (S.C.); [email protected] (R.D.P.); Tel.: +39-090-6765208 (S.C. & R.D.P.) † The authors equally contributed to the review. Abstract: Homocysteine (HCY), a physiological amino acid formed when proteins break down, leads to a pathological condition called hyperhomocysteinemia (HHCY), when it is over a definite limit. It is well known that an increase in HCY levels in blood, can contribute to arterial damage and several cardiovascular disease, but the knowledge about the relationship between HCY and brain disorders is very poor. Recent studies demonstrated that an alteration in HCY metabolism or a deficiency in folate or vitamin B12 can cause altered methylation and/or redox potentials, that leads to a modification on calcium influx in cells, or into an accumulation in amyloid and/or tau protein involving a cascade of events that culminate in apoptosis, and, in the worst conditions, neuronal death. The present review will thus summarize how much is known about the possible role of HHCY in neurodegenerative disease. -

Primordial Synthesis of Amines and Amino Acids in a 1958 Miller H2 S

Primordial synthesis of amines and amino acids in a 1958 Miller H2S-rich spark discharge experiment Eric T. Parkera,1, Henderson J. Cleavesb, Jason P. Dworkinc, Daniel P. Glavinc, Michael Callahanc, Andrew Aubreyd, Antonio Lazcanoe, and Jeffrey L. Badaa,2 aGeosciences Research Division, Scripps Institution of Oceanography, University of California at San Diego, 8615 Kennel Way, La Jolla, CA 92093; bGeophysical Laboratory, Carnegie Institution of Washington, 5251 Broad Branch Road NW, Washington, DC 20015; cNational Aeronautics and Space Administration Goddard Space Flight Center, Solar System Exploration Division, Greenbelt, MD 20771; dNational Aeronautics and Space Administration Jet Propulsion Laboratory, California Institute of Technology, 4800 Oak Grove Drive, Pasadena, CA 91109; and eFacultad de Ciencias, Universidad Nacional Autónoma de México, Apdo. Postal 70-407 Ciudad Universitaria, 04510 Mexico D.F., Mexico Edited by Gerald F. Joyce, The Scripps Research Institute, La Jolla, CA, and approved February 14, 2011 (received for review December 22, 2010) Archived samples from a previously unreported 1958 Stanley Miller known volcanic apparatus were found to contain a wide variety of electric discharge experiment containing hydrogen sulfide (H2S) amino acids and amines, including ornithine, homoserine, methy- were recently discovered and analyzed using high-performance lamine, and ethylamine, many of which had not been reported liquid chromatography and time-of-flight mass spectrometry. We previously in spark discharge experiments (7). The volcanic report here the detection and quantification of primary amine- apparatus differed from Miller’s classic apparatus in that it uti- containing compounds in the original sample residues, which were lized an aspirator that injected steam into the electric discharge produced via spark discharge using a gaseous mixture of H2S, CH4, chamber, simulating a volcanic eruption (1). -

The Controversial Role of Homocysteine in Neurology: from Labs to Clinical Practice

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Archivio istituzionale della ricerca - Università di Trieste International Journal of Molecular Sciences Review The Controversial Role of Homocysteine in Neurology: From Labs to Clinical Practice Rita Moretti * and Paola Caruso Neurology Clinic, Department of Medical, Surgical, and Health Sciences, University of Trieste, 34149 Trieste, Italy; [email protected] * Correspondence: [email protected]; Tel.: +39-040-399-4572 Received: 29 November 2018; Accepted: 4 January 2019; Published: 8 January 2019 Abstract: Homocysteine (Hcy) is a sulfur-containing amino acid that is generated during methionine metabolism. Physiologic Hcy levels are determined primarily by dietary intake and vitamin status. Elevated plasma levels of Hcy can be caused by deficiency of either vitamin B12 or folate. Hyperhomocysteinemia (HHcy) can be responsible of different systemic and neurological disease. Actually, HHcy has been considered as a risk factor for systemic atherosclerosis and cardiovascular disease (CVD) and HHcy has been reported in many neurologic disorders including cognitive impairment and stroke, independent of long-recognized factors such as hyperlipidemia, hypertension, diabetes mellitus, and smoking. HHcy is typically defined as levels >15 micromol/L. Treatment of hyperhomocysteinemia with folic acid and B vitamins seems to be effective in the prevention of the development of atherosclerosis, CVD, and strokes. However, data from literature show controversial results regarding the significance of homocysteine as a risk factor for CVD and stroke and whether patients should be routinely screened for homocysteine. HHcy-induced oxidative stress, endothelial dysfunction, inflammation, smooth muscle cell proliferation, and endoplasmic reticulum (ER) stress have been considered to play an important role in the pathogenesis of several diseases including atherosclerosis and stroke. -

The Overlooked Modulating Role of Nitrous Oxide for Corrinoid-Dependent Microbial Processes

University of Tennessee, Knoxville TRACE: Tennessee Research and Creative Exchange Doctoral Dissertations Graduate School 12-2019 THE OVERLOOKED MODULATING ROLE OF NITROUS OXIDE FOR CORRINOID-DEPENDENT MICROBIAL PROCESSES Yongchao Yin University of Tennessee, [email protected] Follow this and additional works at: https://trace.tennessee.edu/utk_graddiss Recommended Citation Yin, Yongchao, "THE OVERLOOKED MODULATING ROLE OF NITROUS OXIDE FOR CORRINOID- DEPENDENT MICROBIAL PROCESSES. " PhD diss., University of Tennessee, 2019. https://trace.tennessee.edu/utk_graddiss/5761 This Dissertation is brought to you for free and open access by the Graduate School at TRACE: Tennessee Research and Creative Exchange. It has been accepted for inclusion in Doctoral Dissertations by an authorized administrator of TRACE: Tennessee Research and Creative Exchange. For more information, please contact [email protected]. To the Graduate Council: I am submitting herewith a dissertation written by Yongchao Yin entitled "THE OVERLOOKED MODULATING ROLE OF NITROUS OXIDE FOR CORRINOID-DEPENDENT MICROBIAL PROCESSES." I have examined the final electronic copy of this dissertation for form and content and recommend that it be accepted in partial fulfillment of the equirr ements for the degree of Doctor of Philosophy, with a major in Microbiology. Frank Löffler, Major Professor We have read this dissertation and recommend its acceptance: Gary Sayler, Alison Buchan, Qiang He Accepted for the Council: Dixie L. Thompson Vice Provost and Dean of the Graduate School (Original signatures are on file with official studentecor r ds.) THE OVERLOOKED MODULATING ROLE OF NITROUS OXIDE FOR CORRINOID-DEPENDENT MICROBIAL PROCESSES A Dissertation Presented for the Doctor of Philosophy Degree The University of Tennessee, Knoxville Yongchao Yin December 2019 Copyright © 2019 by Yongchao Yin. -

Lisa Strother Phd Thesis

INVESTIGATION OF MOLECULAR AND CELLULAR MECHANISMS UNDERPINNING THE NEUROTOXICITY OF HOMOCYSTEINE AND ITS METABOLITES IN MODELS OF NEURODEGENERATION Lisa Strother A Thesis Submitted for the Degree of PhD at the University of St Andrews 2018 Full metadata for this item is available in St Andrews Research Repository at: http://research-repository.st-andrews.ac.uk/ Please use this identifier to cite or link to this item: http://hdl.handle.net/10023/17067 This item is protected by original copyright Investigation of molecular and cellular mechanisms underpinning the neurotoxicity of homocysteine and its metabolites in models of neurodegeneration Lisa Strother CONTENTS LIST OF FIGURES ................................................................................................................. vii ACKNOWLEDGEMENTS ....................................................................................................... x ABSTRACT ............................................................................................................................. xii DECLARATIONS .................................................................................................................. xiv LIST OF ABBREVIATIONS ................................................................................................ xvii CHAPTER 1: INTRODUCTION AND BACKGROUND ....................................................... 1 1.1 INTRODUCTION ............................................................................................................ 2 1.1.1 Homocysteine -

Ageing Research Reviews 49 (2019) 144–164

Ageing Research Reviews 49 (2019) 144–164 Contents lists available at ScienceDirect Ageing Research Reviews journal homepage: www.elsevier.com/locate/arr Homocysteine and age-associated disorders T ⁎ E.A. Ostrakhovitch , S. Tabibzadeh Frontiers in Bioscience Research Institute in Aging and Cancer, Irvine, CA, USA ARTICLE INFO ABSTRACT Keywords: There are numerous theories of aging, a process which still seems inevitable. Aging leads to cancer and multi- Homocysteine systemic disorders as well as chronic diseases. Decline in age- associated cellular functions leads to neurode- Hyperhomocysteinemia generation and cognitive decline that affect the quality of life. Accumulation of damage, mutations, metabolic Metabolism changes, failure in cellular energy production and clearance of altered proteins over the lifetime, and hy- Aging perhomocysteinemia, ultimately result in tissue degeneration. The decline in renal functions, nutritional defi- Age associated diseases ciencies, deregulation of methionine cycle and deficiencies of homocysteine remethylation and transsulfuration cofactors cause elevation of homocysteine with advancing age. Abnormal accumulation of homocysteine is a risk factor of cardiovascular, neurodegenerative and chronic kidney disease. Moreover, approximately 50% of people, aged 65 years and older develop hypertension and are at a high risk of developing cardiovascular in- sufficiency and incurable neurodegenerative disorders. Increasing evidence suggests inverse relation between cognitive impairment, cerebrovascular and cardiovascular events and renal function. Oxidative stress, in- activation of nitric oxide synthase pathway and mitochondria dysfunction associated with impaired homo- cysteine metabolism lead to aging tissue degeneration. In this review, we examine impact of high homocysteine levels on changes observed with aging that contribute to development and progression of age associated dis- eases. -

Acetylcholine Release from the Rabbit Retina Mediated by Kainate Receptors

The Journal of Neuroscience, January 1991, 7 f(1): 11 l-l 22 Acetylcholine Release from the Rabbit Retina Mediated by Kainate Receptors David M. Linn,’ Christine Blazynski,* Dianna A. Redburn, and Stephen C. Massey’ Sensory Sciences Center, Graduate School of Biomedical Sciences, University of Texas Health Science Center, Houston, Texas 77030, 2Department of Biochemistry and Molecular Biophysics, Washington University School of Medicine, St. Louis, Missouri 63110, and 3Deoartment of Neurobiology and Anatomy, University of Texas Medical School, Houston,.Texas 77225 The cholinergic amacrine cells of the rabbit retina may be KA or QQ receptors (Slaughter and Miller, 1983a,b; Copen- labeled with 3H-choline (3H-Ch), and the activity of the cho- hagen and Jahr, 1989). In contrast, the sign-inverting input to linergic population may be monitored by following the re- ON bipolar cells is mediated by APB receptors (Shiells et al., lease of H-ACh. Glutamate analogs caused massive ACh 198 1; Slaughter and Miller, 1981, 1985). In fact, APB is a spe- release, up to 50 times the basal efflux, with the following cific agonist at this site, which underlies the separation of ON rank order of potency: a-amino-3-hydroxy-5-methyl-4-isox- and OFF responsesthroughout the visual system.Although KA, azolepropionic acid (AMPA) > quisqualate (QQ) = kainate QQ, and APB receptors have been found in the outer retina, (KA) z+ NMDA (in magnesium-free medium) B glutamate > NMDA receptors appear to be rare or absent. NMDA and aspartate. In contrast, the release of 3H-Ch was unchanged. NMDA antagonistshave little or no effect on second-orderneu- Submaximal doses of each agonist were used to establish rons of most species,including the rabbit (Shiells et al., 1981; the specifity of glutamate antagonists. -

COMPILATION of AMINO ACIDS, DRUGS, METABOLITES and OTHER COMPOUNDS in MASSTRAK AMINO ACID ANALYSIS SOLUTION Paula Hong, Kendon S

COMPILATION OF AMINO ACIDS, DRUGS, METABOLITES AND OTHER COMPOUNDS IN MASSTRAK AMINO ACID ANALYSIS SOLUTION Paula Hong, Kendon S. Graham, Alexandre Paccou, T homas E. Wheat and Diane M. Diehl INTRODUCTION LC conditions Physiological amino acid analysis is commonly performed to LC System: Waters ACQUITY UPLC® System with TUV monitor and study a wide variety of metabolic processes. A wide Column: MassTrak AAA Column 2.1 x 150 mm, 1.7 µm variety of drugs, foods, and metabolic intermediates that may Column Temp: 43 ˚C be present in biological fluids can appear as peaks in amino Flow Rate: 400 µL/min. acid analysis, therefore, it is important to be able to identify Mobile Phase A: MassTrak AAA Eluent A Concentrate, unknown compounds.1,2,3 The reproducibility and robustness of diluted 1:10 the MassTrak Amino Acid Analysis Solution make this method well Mobile Phase B: MassTrak AAA Eluent B suited to such a study as well.4 Weak Needle Wash: 5/95 Acetonitrile/Water Strong Needle Wash: 95/5 Acetonitrile/Water Gradient: MassTrak AAA Standard Gradient (as provided in kit) Detection: UV @ 260 nm Injection Volume: 1 µL EXPERIMENTAL Injection Mode: Partial Loop with Needle Overfill (PLNO) Compound sample preparation A library of compounds was assembled. Each compound was derivatized individually and spiked into the MassTrak™ AAA Solution Standard prior to chromatographic analysis. The elution RESULTS AND DISCUSSION position of each tested compound could be related to known amino acids. A wide variety of antibiotics, pharmaceutical compounds and metabolite by-products are found in biological fluids. The reten- 1. -

Memantine Protects Rats Treated with Intrathecal Methotrexate from Developing Spatial Memory Deficits

Author Manuscript Published OnlineFirst on July 5, 2013; DOI: 10.1158/1078-0432.CCR-13-1179 Author manuscripts have been peer reviewed and accepted for publication but have not yet been edited. Memantine protects rats treated with intrathecal methotrexate from developing spatial memory deficits Peter D. Cole1, Veena Vijayanathan1, Nafeeza F. Ali2, Mark E. Wagshul3, Eric J. Tanenbaum2, Jeremy Price2, Vidhi Dalal2, Maria E. Gulinello4 1Department of Pediatrics, Albert Einstein College of Medicine, Bronx, NY 2Albert Einstein College of Medicine, Bronx, NY 3Department of Radiology, Albert Einstein College of Medicine, Bronx, NY 4Department of Neuroscience, Albert Einstein College of Medicine, Bronx, NY Corresponding Author: Peter Cole, MD Albert Einstein College of Medicine 1300 Morris Park Avenue, Forchheimer 702 Bronx, NY 10461 email: [email protected] tel: 718-741-2342 fax: 718-920-6506 Acknowledgements: This work was supported in part by grant number P30HD071593 from the Eunice Kennedy Shriver National Institute of Child Health & Human Development (NICHD) at the National Institutes of Health. Its contents are solely the responsibility of the authors and do not necessarily represent the official views of NICHD. In addition, JP was supported in part by a Pediatric Oncology Student Training (POST) Program award from the Alex’s Lemonade Stand Foundation. There are no conflicts of interest to disclose Running Title: Memantine protects against MTX-induced memory deficits Key Words: Memory; Neuroprotection; Neurotoxicity; NMDA Receptor; Rat; Memantine; Methotrexate; Glutamate; Homocysteine; Homocysteic Acid Word Count (excluding references): Abstract 226; Total 3765. Total Number of figures (6) and tables (0) Downloaded from clincancerres.aacrjournals.org on September 26, 2021.