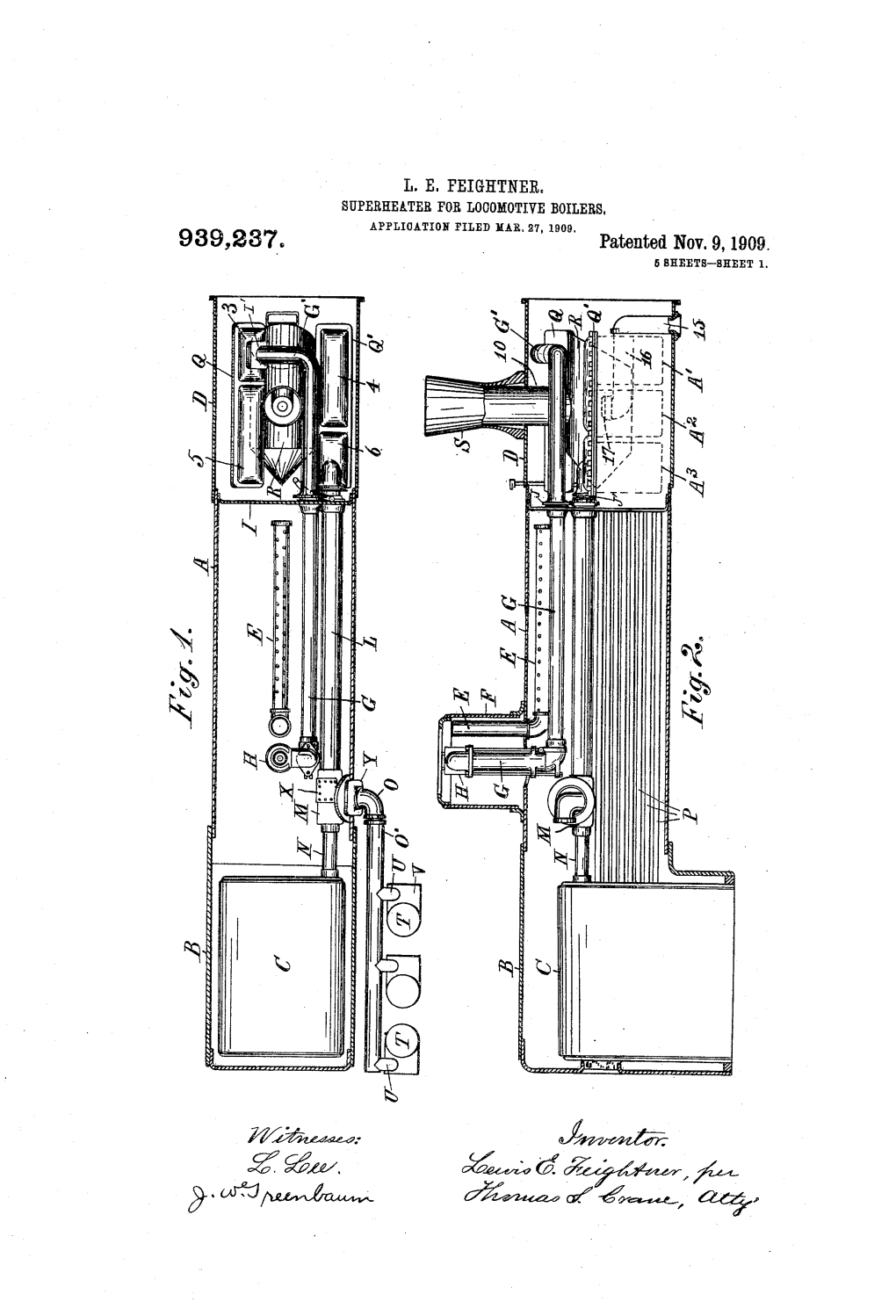

Patented Nov. 9, 1909. 5 SHEETS-SHEET

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Product Index for Print

Bull: ABS-CEJS-24SC-01 March 2009 AUXILIARY BOILER SYSTEMS ELECTRICELECTRIC STEAMSTEAM PACKAGEDPACKAGED Power generation projects require an For maximum flexibility of operation, quick auxiliary boiler system to provide steam on response, precise of control and avoidance start-up, during maintenance shut-downs, of environmental consequences, the electric for steam turbine gland systems, etc. solution is the best choice. For the past 45 years ACME-AEP has Pressure Vessels are built to ASME Code or manufactured the key components of auxiliary EU Pressure Vessels Directive. boiler systems, namely boilers, superheaters, Electrical Standards meet CSA or UL or CE. secondary pressure vessels and associated control systems. Quality control is according to ISO 9001 (2000). The Acme ABS Packages are up to date solutions to current problems. 1 Ref: 19-092038 P & I DIAGRAM FOR CEJS HIGH VOLTAGE ELECTRODE BOILER WITH 2 CIRCULATION PUMPS The two diagrams shown are built around the key boiler component availability: CEJS High Voltage Electrode Steam Boiler 24 SC Immersion Element type Boiler Power: 5 MW to 52 MW Power: 600 kW to 3.5 MW Voltages: 6.9 kV to 25 kV, 3 phase, 4 wires Voltages: 380 V, 400 V, 415 V, 480 V, 600 V. 3 phase, 50/60Hz Design Pressure: 150 PSI to 500 PSI Design Pressure: 100 PSI to 600 PSI Operating Pressure: 105 PSI to 450 PSI Operating Pressure: 30 PSI to 540 PSI VERTICAL BOILER HORIZONTAL or VERTICAL BOILER Metal: Carbon steel Metal: Carbon steel or Stainless Steel Heating Elements: Flanged, Incoloy 800 2 Ref: 23-092044 ELECTRIC ELEMENT BOILER - SUPERHEATER PACKAGE PIPING DIAGRAM The two diagrams shown are slightly different but complement each other. -

QUIZ: Boiler System Components

9707 Key West Avenue, Suite 100 Rockville, MD 20850 Phone: 301-740-1421 Fax: 301-990-9771 E-Mail: [email protected] Part of the recertification process is to obtain Continuing Education Units (CEUs). One way to do that is to review a technical article and complete a short quiz. Scoring an 80% or better will grant you 0.5 CEUs. You need 25 CEUs over a 5-year period to be recertified. The quiz and article are posted below. Completed tests can be faxed (301-990-9771) or mailed (9707 Key West Avenue, Suite 100, Rockville, MD 20850) to AWT. Quizzes will be scored within 2 weeks of their receipt and you will be notified of the results. Name: ______________________________________________ Company: ___________________________________________ Address: ____________________________________________ City: ______________________ State: _____ Zip: ________ Phone: ______________________ Fax: __________________ E-mail: _____________________________________________ Boiler Systems – Boiler Components By Irvin J. Cotton, Arthur Freedman Associates, Inc. and Orin Hollander, Holland Technologies, Inc. This is part two of a three-part series on boilers. In part one, the authors discussed boiler design and classification. Part two will discuss boiler components, and part three will describe the various chemistries used in boiler water treatment. Boiler Components The main components in a boiler system are the boiler feedwater heaters, deaerator, boiler, feed pump, economizer, boiler, superheater, attemperator, steam system, condenser and the condensate pump. In addition there are sets of controls to monitor water and steam flow, fuel flow, airflow and chemical treatment additions. Water sample points may exist at a number of places. Most typically the condensate, deaerator outlet, feedwater (often the economizer inlet), boiler, saturated steam and superheated steam will have sample points. -

Steam Locomotive Firebox Explosion on the Gettysburg Railroad Near Gardners, Pennsylvania

Steam Locomotive Firebox Explosion on the Gettysburg Railroad near Gardners, Pennsylvania Leadership ViTS Meeting 6 September 2005 Bryan O’Connor, Chief Office of Safety and Mission Assurance Accident Timeline Place: Gettysburg Railroad near Gardners, PA Accident Date: June 16, 1995 Gettysburg 1278 @ Gettysburg Oct 1988 The Accident: • Steam locomotive 1278 with six passenger cars had completed two excursions and was preparing for a third and final excursion for the day. • During slow climb up moderate grade, the boiler exploded, seriously burning the engineer and two firemen. • . (2) Events Associated with Proximate Cause • Operators began climb with too little water in boiler • Water-level continued to drop and by the time the locomotive had crested the grade the crownsheet of boiler was not covered by water and failed due to thermal overstress. • Failure of crownsheet opened boiler to the firebox (atmosphere) and the water in boiler flashed into high pressure steam. • Steam exploded through firebox door into the locomotive cab, seriously burning the engineer (third degree burns over 65% of body) and two firemen. (3) Events Associated with Proximate Cause Approx. 175 psi This figure is exaggerated to show low water conditions, in locomotive 1278 the lowest gage cock was 3.25 inches above the highest point of the crownsheet and the water glass was 3.125 inches above the highest point of the crownsheet (4) Contributing Factors • Prior to operation the feed pump gauge had been removed. • Preparing to ascend grade first fireman shut off the feed pump to the boiler because a leaking check valve between the feed-pump and the boiler could potentially cause slippage on driving wheels. -

Module BESTT MS1

Module BESTT MS1 Marine Steam Boiler Types, Construction and Maintenance. Aim This unit introduces learners to the wide variety of fuels which may be encountered in steam launches and small steam ships operating on inland waterways or sheltered coastal waters. The range of types of boilers is explained. In each case, the benefits of each fuel type or boiler type are explored. The reasons for caution when conducting external work on old boilers are explained. INTRODUCTION Boiler types considered Horizontal Fire Tube boilers (including locomotive type) Vertical Fire Tube boilers Horizontal Drum Water Tube boilers Vertical Drum Water Tube boilers Single coil (or Flash) boilers Construction, design and general arrangements Heat transfer Cleaning Considerations for boiler choice and design Options for materials and insulations Boiler cladding materials The sheer variety of boiler types used in marine applications is wider than anything we will encounter for railway locomotives or in road steam applications. Although fire tube boilers from earliest days have been the norm for railway locomotives, water tube boilers could also very occasionally be found in locomotives. The well-known Sentinel shunters had water tube boilers a little bigger but otherwise similar to the company’s steam wagon boilers, and Sir Nigel Gresley on the LNER experimented with a ‘Yarrow’ type boiler but dropped the idea and fitted Britain’s only 4-6-4 express engine with a traditional loco boiler. For shipping, various forms of the classic marine multi-furnace fire tube ‘Scotch’ boiler was a norm to the last, and vertical fire tube types were a standard for small steam launches, but alongside these a huge range of highly efficient water tube types was under constant development resulting in many different configurations. -

PATENT SPECIFICATION <N) 1421907

PATENT SPECIFICATION <n) 1421907 (21) Application No. 39315/72 (22) Filed 23 Aug. 1972 (19) O ON (23) Complete Specification filed 13 Aug. 1973 (44) Complete Specification published 21 Jan. 1976 H (51) INT. CL.8 F22G 5/18 F22B 1/06 (52) Index at acceptance H F4A 8C Gil G19 G20 (72) Inventors: ANTHONY RANDLE LUNT and THOMAS DAVID ROBERTS (54) STEAM GENERATING PLANTS (71) We, UNITED KINGDOM ATOMIC superheater 2 for heat exchange with liquid ENERGY AUTHORITY LONDON, a British sodium. The liquid sodium is supplied from a Authority do hereby declare the invention, sodium cooled nuclear reactor which also is 50 for which we pray that a patent may be not shown as it forms no part of the present 5 grantedjjto us, and the method by which it is to invention. Between the steam drum 1 and the be performed, to be particularly described superheater 2 there is an injector 3 which is in and by the following statement:— connected by a branch line 4 to the outlet 5 This invention relates to steam generating of the superheater. The outlet 5 is also con- 55 plants. nected to a turbine stop valve (not shown). 10 In one known construction of steam gen- The branch line includes a control valve 6. erating plant wet steam is separated from the Referring now to Figure 2 the injector 3 liquid phase in a steam drum and the wet comprises a housing 7 having a nozzle 8 and steam is fed to a superheater constructed from a diffuser 9. The nozzle 8 is connected to the 60 stainless steel and through which liquid metal steam drum 1 whilst the diffuser 9 is con- 15 is passed in heat exchange with the steam. -

The Case for the AMERICAN Steam Locomotive

• raIns. AUGUST 1967 • 60, T .. ... ----------------- ' f!,' lIelllelllh~'1' jhis al'jkle ill IIl'cf'lIIh~'1' I!'f;f; TIC,\INS? Xow "'I ('xllel'j ('Ollles THE CASE fOR THE fRENCH STEAM"' LOCOMOTIVE iOl'jh with •.. The case for the AMERICAN steam locomotive 21 Avgus! 1967 - VERNON l. SMITH illVllrolion AUTHOR'S COllECTION OR AS NOTED 1 IN htl ''The Case lor the F~nch trains to be bandied - In America background r($ultcd In fine, ('COnomi- Steam Loc:omoltv(''' in Decem· th~ arc !ugh and harsh. 1::al handhna; of compound engines, her 1966 TRAINS, author R. K. E ... tVl!> (3) MllK:ellancous conditIons - thc Many of the later (our-cylindcI' en_ stated, ", .. The fact ,'emains unques labol' market, the workIng clearances gines have the two r(l8ch I'ods cvn ti oned that nowhere in the world W3$ (loading gau,ge), the maIntenance ncctcd or 11ll1ned togcther to avoid the art of Sl~ locomotivt' design praclLcH, and the 1~'omoIlH: availa ImpI'opcr dIvision of the work by the developed as far and 1.$ clOSt' to per_ bility and utilization required. englneman b<>tween the hil1;h- and ft.oction as In France," MI'. Evans in his arucle Jit>okl> of lov.·-plcssul·c syste.ns, This suggeslS I question the claim put forth by compounding and mamtenance, draw that the labol market may be chonging Mr. Evans, because It 111 not supported bu horsepow(>r, fuel et.'(lnomy, valve Il\ France and that less refined loco by data and performance records gears. improved (ront ends, enlarged mouve dnving is taking place, And It gother(X{ during !.he high Iide of tteam and exhaust pa...sages, riding means that some of the original ('C;'01l- American locomolh,c design qualities and speed, and bOIler blow_ 01111(-'$ ar1! not beint, obtained. -

88 Series 2 Boiler Manual

88 Water & steam boilers – Series 2 for use with Gas, Light Oil, & Gas/Light Oil – Fired Burners Boiler Manual • Installation • Maintenance • Startup • Parts For additional information, refer to . Burner specifi cation and data sheets for burners pre-tested with model 88 boilers This manual must only be used by a qualifi ed INSTALLER Consider piping and installation when determining heating installer/service technician. Read all boiler location. instructions before installing. Follow all in- Any claims for damage or shortage in shipment must be structions in proper order. Failure to comply fi led immediately against the transportation company could result in severe personal injury, death by the consignee. or substantial property damage. USER . This manual is for use only by your qualifi ed heating When calling or writing about the boiler— installer/service technician. Boiler and burner must be Please have the boiler model number from the installed by a qualifi ed service technician. We recom- boiler rating label and the CP number from mend regular service by a qualifi ed service technician, the boiler jacket. at least annually. Part No. 550-100-068/1018 Weil-McLain 88 Water and steam boilers — Series 2 — for Gas, Light Oil, & Gas/Light Oil-Fired Burners Read before proceeding Hazard Definitions The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to important information concern- ing the life of the product. Indicates presence of hazards that will cause severe personal injury, death or substantial property damage if ignored. Indicates presence of hazards that can cause severe personal injury, death or substantial property damage if ignored. -

Hurst Boiler & Welding Company, Inc

Hurst Boiler & Welding Company, Inc. P.O. Drawer 530 - Highway 319 North Coolidge, Georgia 31738 877-99HURST – Toll Free 229-346-3545 – Local 229-346-3874 – Fax www.hurstboiler.com SERIES 45 STEAM BOILER (8.5- 813 HP, STEAM 15 psig) SAMPLE SPECIFICATIONS The following sample specifications are provided by Hurst Boiler & Welding Co., Inc. to assist you in meeting your customer's specific needs and application. The sample specifications are typically utilized as the base template for the complete boiler specification. Contact your local Hurst Boiler & Welding Co., Inc. authorized representative for information on special insurance requirements, special code requirements, optional equipment, or general assistance in completing the specification. 1.0 – General Boiler Specifications 1.1 - The Steam Boiler shall be Hurst Boiler & Welding Co., Inc. Series 45, hp designed for 15 psig. The maximum operating pressure shall be psig and the minimum operating pressure shall be psig. 1.2 - The boiler shall have a maximum output of Btu/hr, or horsepower when fired with oil and/or natural gas, Btu/cu-ft. Electrical power available shall be Volt Phase Cycle. 2.0 – Boiler Design 2.1 - The boiler shall be a three-pass wetback horizontal firebox type boiler with four (4) square feet of fireside heating surface per rated boiler horsepower. Furnace volume shall not be less than cubic feet. It shall be mounted on a heavy steel frame with integral forced draft burner and burner controls. The complete packaged boiler approved as a unit by Underwriters Laboratories and shall bear the UL label. 2.2 - The boiler shall be completely preassembled and tested at the factory. -

Steam Power Plant

www.getmyuni.com Steam Power Plant A power plant is assembly of systems or subsystems to generate electricity, i.e., power with economy and requirements. The power plant itself must be useful economically and environmental friendly to the society. The present book is oriented to conventional as well as non-conventional energy generation. While the stress is on energy efficient system regards conventional power systems viz., to increase the system conversion efficiency the supreme goal is to develop, design, and manufacturer the non-conventional power generating systems in coming decades preferably after 2050 AD which are conducive to society as well as having feasible energy conversion efficiency and non-friendly to pollution, keeping in view the pollution act. The subject as a whole can be also stated as modern power plants for power viz electricity generation in 21st century. The word modern means pertaining to time. At present due to energy crisis the first goal is to conserve energy for future while the second step is todevelop alternative energy systems including direct energy conversion devices, with the devotion, dedication and determination remembering the phrase, “Delve and Delve Again till wade into”. CLASSIFICATION OF POWER PLANTS Power Plant 1. Conventional - Steam Engines Power Plants - S team Turbine Power Plants - Diesel Power Plants - Gas Turbine Power Plants - Hydro-Electric Power Plants - Nuclear Power Plants Thermoelectric Generator 2. Non-conventional Thermoelectric generator Fuel-cells Power Plants Photovoltaic solar cells Power S ystem MHD Power Plants Fussion Reactor N PP Power S y stem Biogas, Biomass Energy Power sy stem Geothermal Energy Wind Energy Power System Ocean Thermal energy conversion (OTEC) Wave and Tidal Wave Energ y Plantation Scheme A power plant may be defined as a machine or assembly of equipment that generates and delivers a flow of mechanical or electrical energy. -

Steam Locomotive Firebox Explosion on the Gettysburg Railroad Near Gardners, Pennsylvania June 16, 1995

PB96-917008 NTSB/SIR-96/05 NATIONAL TRANSPORTATION SAFETY BOARD WASHINGTON, DC 20594 SPECIAL INVESTIGATION REPORT STEAM LOCOMOTIVE FIREBOX EXPLOSION ON THE GETTYSBURG RAILROAD NEAR GARDNERS, PENNSYLVANIA JUNE 16, 1995 . Illlr 6768 Abstract: On June 16, 1995, the firebox crownsheet of Gettysburg Passenger Services, Inc., steam locomotive 1278 failed while the locomotive was pulling a six-car excursion train about 15 mph near Gardners, Pennsylvania. The failure resulted in an instantaneous release (explosion) of steam through the firebox door and into the locomotive cab, seriously burning the engineer and the two firemen. This accident illustrates the hazards that are always present in the operation of steam locomotives. The Safety Board is concerned that these hazards may be becoming more significant because Federal regulatory controls are outdated and because expertise in operating and maintaining steam locomotives is diminishing steadily. As a result of its investigation, the National Transportation Safety Board issued safety recommendations to the Federal Railroad Administration, the National Board of Boiler and Pressure Vessel Inspectors, and the Tourist Railway Association, Inc. The National Transportation Safety Board is an independent Federal agency dedicated to promoting aviation, railroad, highway, marine, pipeline, and hazardous materials safety. Established in 1967, the agency is mandated by Congress through the Independent Safety Board Act of 1974 to investigate transportation accidents, determine the probable causes of the accidents, issue safety recommendations, study transportation safety issues, and evaluate the safety effectiveness of government agencies involved in transportation. The Safety Board makes public its actions and decisions through accident reports, safety studies, special investigation reports, safety recommendations, and statistical reviews. -

Firebox Design and Its Relation to Boiler Performance

ry C5-4 / FIREBOX DESIGN AND ITS RELATION TO BOILER PERFORMANCE BY CHARLES M. CLARK AND JAMES HERRON WESTBAY THESIS FOR THE DEGREE OF BACHELOR OF SCIENCE IN RAILWAY MECHANICAL ENGINEERING COLLEGE OF ENGINEERING UNIVERSITY OF ILLINOIS 1917 UNIVERSITY OF ILLINOIS 7 THIS IS TO CERTIFY THAT THE THESIS PREPARED UNDER MY SUPERVISION BY C HARLES M, . CLARK AND JAMES HERRON JffESTBAY . ENTITLED FIRgBOX DSSICT,,^ IS APPROVED BY ME AS FULFILLING THIS PART OF THE REQUIREMENTS FOR THE DEGREE OF MSHELGR.^ ..SC^EEC^^ Instructor in Charge Approved : HEAD OF DEPARTMENT OF RAILWAY ENGINEERING . 3 FIREBOX DESIGN AND ITS RELATION TO BOILER PERFORMANCE. Contents Page Introduction ------------------- 1 Purpose ------------------ 2 Part I. Theory of Combustion Definition -------------- - 2 The Combustion Process and Heat Distribution 2 Summary ------------------ 11 Part II. Heat Transmission in Locomotive Fireboxes Radiation ------------------ 1 Conduction ----------------- 14 Convection ----------------- 15 Graphical Representation of Heat Transfer - 19 Summary ------------------ 20 Part III. Heat Distribution and Firebox Efficiency Discussion of Articles by Mr. Anthony - - - - 21 Summary -------------------25 Part IV. Test Results and their Analysis The Brick Arch - Coatesville Tests ----- 27 The Brick Arch - P. R. R. Tests -------29 Grate Area - P. R. R. Tests -------- 34 Combustion Chamber - P. R. R. Tests ----- 36 Summary ------------------- Part V. General Conclusion - -- -- - -- -- -- 41 Acknowledgements -------------- 43 Digitized by the Internet Archive in 2013 http://archive.org/details/fireboxdesignitsOOclar . FIREBOX DESIGN AND ITS RELATION TO BOILER PERFORMANCE Introduction . The performance of a locomotive boiler is dependent to a very large extent upon the design of its firebox. A great deal of experimental work has been done in an effort to determine what steps should be taken to improve boiler performance and to increase boiler efficiency. -

Numerical Investigation of Superheater Tube Failure

This paper is part of the Proceedings of the 14th International Conference on Simulation and Experiments in Heat Transfer and its Applications (HT 2016) www.witconferences.com Numerical investigation of superheater tube failure H. H. Al-Kayiem & T. M. B. Albarody Mechanical Engineering Department, Universiti Teknologi PETRONAS, Perak, Malaysia Abstract Industrial superheaters in petrochemical plants possess leakages due to failure in many areas. This paper presents the results of investigations into identifying the failure causes. The investigations were carried out by simulating the heating process of a superheater. The simulation was carried out numerically using ANSYS mechanical commercial software. The simulation results indicated that the superheater tubes were subjected to direct radiation heat transfer as well as flame violence. The leakage spots were formed due to cracks in the material mainly at the joint points between the tubes and the header. It was also realized that the welding at the connection areas of the pipes and the header had weakened the material and formed low thermal resistance spots which could not stand the 510°C temperature and consequently, it had either melted or cracked. Keywords: boiler, superheater, thermal wave, thermal fatigue, thermal stress. 1 Introduction The basic failure mechanism, in the piping process, is fatigue due to vibration and/or thermal stresses caused by internal and/or external flows in pipes, junctions, and bends. When high temperature exists in the process, the possibility of thermal fatigue increases the possibilities of piping failure. In the industrial practice, such problem is commonly associated with boilers, risers, and pipes subjected to intermittent internal flow and periodic heat impact from internal or external sources.