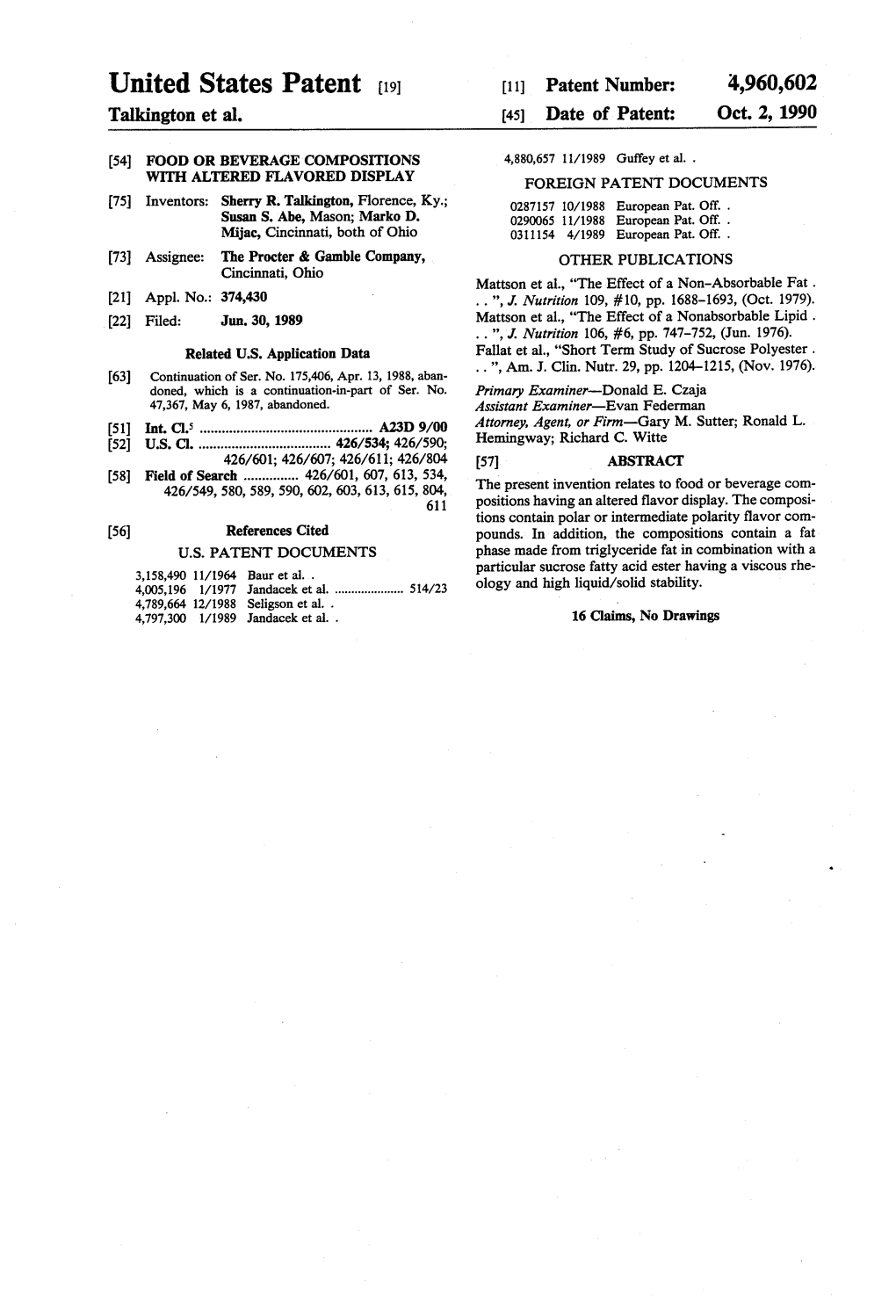

United States Patent (19) (11) Patent Number: 4,960,602 Talkington Et Al

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Safety Assessment of Sorbitan Esters As Used in Cosmetics

Safety Assessment of Sorbitan Esters as Used in Cosmetics Status: Re-Review for Panel Review Release Date: August 18, 2014 Panel Meeting Date: September 8-9, 2014 The 2014 Cosmetic Ingredient Review Expert Panel members are: Chairman, Wilma F. Bergfeld, M.D., F.A.C.P.; Donald V. Belsito, M.D.; Ronald A. Hill, Ph.D.; Curtis D. Klaassen, Ph.D.; Daniel C. Liebler, Ph.D.; James G. Marks, Jr., M.D., Ronald C. Shank, Ph.D.; Thomas J. Slaga, Ph.D.; and Paul W. Snyder, D.V.M., Ph.D. The CIR Director is Lillian J. Gill, D.P.A. This safety assessment was prepared by Monice M. Fiume, Assistant Director/Senior Scientific Analyst and Bart Heldreth, Ph.D., Chemist. © Cosmetic Ingredient Review 1620 L Street, NW, Suite 1200 ♢ Washington, DC 20036-4702 ♢ ph 202.331.0651 ♢ fax 202.331.0088 ♢ [email protected] Commitment & Credibility since 1976 Memorandum To: CIR Expert Panel Members and Liaisons From: Monice M. Fiume MMF Assistant Director/Senior Scientific Analyst Date: August 18, 2014 Subject: Safety Assessment of Sorbitan Esters as Used in Cosmetics Enclosed is the Re-Review of the Safety Assessment on Sorbitan Esters as Used in Cosmetics. (It is identified as sorbes092014rep_final for posting in the pdf document.) In 1985, the Panel determined that a group of seven sorbitan esters were safe as used in cosmetic ingredients. In 2002, the Panel reviewed the safety of an additional 10 sorbitan ester, and issued an addendum to that report, concluding that the sorbitan fatty acid esters were safe as used in cosmet- ic ingredients. -

Production and Characterization of Fish Oil Methyl Ester

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by International Journal of Innovative Technology and Research (IJITR) Deepak Tanwar* et al. / (IJITR) INTERNATIONAL JOURNAL OF INNOVATIVE TECHNOLOGY AND RESEARCH Volume No. 1, Issue No. 3, April - May 2013, 209 – 217. Production and Characterization of Fish Oil Methyl Ester DEEPAK TANWAR1 AJAYTA2 DILIP SHARMA3 Rajasthan State Pollution Control Board, Department of Mechanical Engineering, Department of Mechanical Engineering, RIICO Industrial area, Phase-III, Government Polytechnic College, Malaviya National Institute of Technology, Kishangarh 305801, India Ajmer 305001, India Jaipur 302004, India [email protected] YOGESH PRAKASH MATHUR4 KAMAL KISHORE KHATRI5 SHYAM LAL SONI6 Department of Civil Engineering, Department of Mechanical Engineering, Department of Mechanical Engineering, Malaviya National Institute of Technology, Malaviya National Institute of Technology, Malaviya National Institute of Technology, Jaipur 302004, India Jaipur 302004, India Jaipur 302004, India RAGINI GUPTA7 Department of Chemistry, Malaviya National Institute of Technology, Jaipur 302004, India Abstract: Limited availability of edible oils areas and are abundantly available in the country of prevents it from being used as viable source of testing. For example, soybean oil is of primary Biodiesel. Low cost and abundantly found fish oil interest source in the United States while many produced from soap stock could be a better option European countries are concentrating on Rapeseed oil for biodiesel processing. Such type of fish oil [2] and countries with tropical climates prefer to contains a higher amount of moisture and FFA utilize Coconut oil or Palm oil [3]. Other vegetable and requires a pre-treatment prior to biodiesel oils, including Sunflower, Safflower, Mahua, Neem, production. -

Characterization of the Fatty Acid Composition of Nannochloropsis

Characterization of the Fatty Acid Composition of Nannochloropsis salina as a Determinant of Biodiesel Properties Nagwa Gamal-ElDin Mohammady Department of Botany and Microbiology, Faculty of Science, Moharam Bey 21511, Alexandria University, Alexandria, Egypt. Fax: +203 3911 794. E-mail: [email protected] Z. Naturforsch. 66 c, 328 – 332 (2011); received November 21, 2010/March 27, 2011 Nannochloropsis salina was cultured batch-wise to evaluate the potential of the alga to produce biodiesel. The cells were harvested at the end of the exponential growth phase when the concentration was 18 · 106 cells/mL culture. The growth estimated as dry weight from this cell number was (3.8 0.7) mg/L. The lipid and triglyceride contents were 40% and 12% on a dry weight basis, respectively. The amount of the ratio triglycerides/total lipids was approximately 0.3. The composition of triglyceride fatty acid methyl esters (biodiesel) was analysed by gas- liquid chromatography and identifi ed as: C14:0, C16:0, C16:1, C18:0, C18:1, C18:2, C18:3, C20:1, and C20:5. The ratio of unsaturated to saturated fatty acid contents was approximate- ly 4.4. Additionally, the characterization of each individual fatty acid ester was discussed with regard to the fuel properties of biodiesel produced by the alga. Key words: Biodiesel, Lipids, Nannochloropsis salina Introduction Depending on species, many microalgae have been described as lipid-rich strains for their hy- The use of biofuels can play an important role drocarbons and other complex oils. However, not in avoiding excessive dependence on fossil fu- all algal oils are satisfactory for the production els and reducing pollution by greenhouse gases of biodiesel (Guschina and Harwood, 2006), due emission (Gouveia and Oliveira, 2009). -

Ethoxylation of Fatty Acids

S B N P Enzymatic Synthesis & Functional Characterization Fredrik Viklund Department of Biotechnology Stockholm Royal Institute of Technology Surfactants based on natural products — Enzymatic synthesis and functional characterization Copyright © by Fredrik Viklund ISBN --- is is the electronic version of the thesis. Compared to the printed version, it includes some minor typographical corrections. Royal Institute of Technology Printed in Stockholm AlbaNova University Center May Department of Biotechnology SE- Stockholm, Sweden Universitetsservice AB http://www.biotech.kth.se/ http://www.us-ab.se/ To Explorers Sammanfattning Tensider är molekyler som består av en vattenlöslig och en fettlöslig del. De spelar en viktig roll i produkter som rengöringsmedel, kosmetika, läkemedel och mat såväl som i många industriella processer. Tensider används i mycket stor skala vilket gör det viktigt att minska deras påverkan på miljön. Det kan åstadkommas genom att använda naturprodukter som råvaror, genom att förbättra tillverkningsmetoderna och genom att minska användningen av begränsade resurser som energi och lösningsmedel. Den här avhandlingen behandlar lipaskatalyserad syntes av naturprodukts- baserade tensider. Den omfattar också studier av de framställda tensiderna; dels som antioxidanter i oljor, dels som tensider för att öka lösligheten av läkemedel. Omättade fettsyraestrar av askorbinsyra framställdes genom katalys med Candida antarctica lipas B i t-amylalkohol och i joniska vätskor. Höga utbyten av askorbyloleat erhölls i en jonisk vätska som formgivits för att öka lösligheten av fettsyran, när reaktionen kördes under vakuum. Vi fann att askorbyloleat är amorft och att det är en bättre antioxidant än askorbylpalmitat i rapsolja. Polyetylenglykol (PEG)-stearat, PEG -hydroxystearat och en rad PEG -acyloxy-stearater framställdes i en vakuumdriven och lösningsmedels- fri uppställning med lipas B från C. -

Application of Simultaneous Oil Extraction and Transesterification in Biodiesel Fuel Synthesis: a Review

energies Review Application of Simultaneous Oil Extraction and Transesterification in Biodiesel Fuel Synthesis: A Review Violeta Makareviciene * , Egle Sendzikiene and Milda Gumbyte Faculty of Forest Sciences and Ecology, Agriculture Academy, Vytautas Magnus University, LT-44248 Kaunas, Lithuania; [email protected] (E.S.); [email protected] (M.G.) * Correspondence: [email protected] Received: 7 April 2020; Accepted: 28 April 2020; Published: 2 May 2020 Abstract: Increasing concentrations of greenhouse gases in the atmosphere are leading to increased production and use of biofuels. The industrial development of biodiesel production and the use of biodiesel in the EU transport sector have been ongoing for almost two decades. Compared to mineral diesel production, the process of producing biodiesel is quite complex and expensive, and the search for new raw materials and advanced technologies is needed to maintain production value and expand the industrial production of biodiesel. The purpose of this article is to review the application possibilities of one of the new technologies—simultaneous extraction of oil from oily feedstock and transesterification (in situ)—and to evaluate the effectiveness of the abovementioned process under various conditions. Keywords: biodiesel; in situ; simultaneous oil extraction and transesterification 1. Introduction With the increase in atmospheric pollution in the form of greenhouse gases, the development of the use of biofuels in the transport sector is receiving increasing attention. Biodiesel is a well-known type of biofuel that has been used for a relatively long time. It is produced from various oily raw materials. Recently, the possibilities of utilizing non-food raw materials and residual waste in the synthesis of biodiesel have been intensively studied. -

Reactive Distillation for Cosmetic Ingredients : an Alternative for the Production of Isopropyl Myristate?

Reactive distillation for cosmetic ingredients : an alternative for the production of isopropyl myristate? Citation for published version (APA): Jong, de, M. C. (2010). Reactive distillation for cosmetic ingredients : an alternative for the production of isopropyl myristate?. Technische Universiteit Eindhoven. https://doi.org/10.6100/IR674097 DOI: 10.6100/IR674097 Document status and date: Published: 01/01/2010 Document Version: Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers) Please check the document version of this publication: • A submitted manuscript is the version of the article upon submission and before peer-review. There can be important differences between the submitted version and the official published version of record. People interested in the research are advised to contact the author for the final version of the publication, or visit the DOI to the publisher's website. • The final author version and the galley proof are versions of the publication after peer review. • The final published version features the final layout of the paper including the volume, issue and page numbers. Link to publication General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. • Users may download and print one copy of any publication from the public portal for the purpose of private study or research. • You may not further distribute the material or use it for any profit-making activity or commercial gain • You may freely distribute the URL identifying the publication in the public portal. -

Characterization of Lactose Fatty Acid Esters for Their Microbial Growth Inhibitory Activity and Emulsification Properties

Utah State University DigitalCommons@USU All Graduate Theses and Dissertations Graduate Studies 5-2018 Characterization of Lactose Fatty Acid Esters for their Microbial Growth Inhibitory Activity and Emulsification Properties Seung-Min Lee Utah State University Follow this and additional works at: https://digitalcommons.usu.edu/etd Part of the Food Science Commons, and the Nutrition Commons Recommended Citation Lee, Seung-Min, "Characterization of Lactose Fatty Acid Esters for their Microbial Growth Inhibitory Activity and Emulsification Properties" (2018). All Graduate Theses and Dissertations. 7030. https://digitalcommons.usu.edu/etd/7030 This Dissertation is brought to you for free and open access by the Graduate Studies at DigitalCommons@USU. It has been accepted for inclusion in All Graduate Theses and Dissertations by an authorized administrator of DigitalCommons@USU. For more information, please contact [email protected]. i CHARACTERIZATION OF LACTOSE FATTY ACID ESTERS FOR THEIR MICROBIAL GROWTH INHIBITORY ACTIVITY AND EMULSIFICATION PROPERTIES by Seung-Min Lee A dissertation submitted in partial fulfillment of the requirement for the degree of DOCTOR OF PHILOSOPHY in Nutrition and Food Sciences Approved: ____________________________ ____________________________ Marie K. Walsh, Ph.D. Brian A. Nummer, Ph.D. Major Professor Committee Member ___________________________ ____________________________ Silvana Martini, Ph.D. Jon Y. Takemoto, Ph.D. Committee Member Committee Member ____________________________ ____________________________ Cheng-Wei Tom Chang, Ph.D. Mark R. McLellan, Ph.D. Committee Member Vice President for Research and Dean of the School of Graduate Studies UTAH STATE UNIVERSITY Logan, Utah 2018 ii Copyright © Seung-Min Lee 2018 All Rights Reserved iii ABSTRACT Characterization of Lactose Fatty Acid Esters for their Microbial Growth Inhibitory Activity and Emulsification Properties by Seung-Min Lee, Doctor of Philosophy Utah State University, 2018 Major Professor: Dr. -

Castor Oil Fatty Acid and Glycerol –– Oleic Acid Esters, As Emulsifier and Antibacterial Agent, Using Candida Rugosa Lipase

Synthesis of Glycerol –– Castor Oil Fatty Acid and Glycerol –– Oleic Acid Esters, as Emulsifier and Antibacterial Agent, Using Candida rugosa Lipase Elmira Vania Denada1, Sri Handayani1 Sumi Hudiyono1 and Siswati Setiasih1 1Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok 16424, West Java, Indonesia Keywords: Castor Oil, Glycerol, castor oil fatty acid, ester, oleic, emulsifier, antibacterial, Candida rugosa Abstract: The research’s objective is to synthesize glycerol – castor oil fatty acid and glycerol oleic acid esters using Candida rugosa lipase in n-hexane. Molar fatty acid to glycerol ratio that used in esterification varied from 1:1, 1:2, 1:3, and 1:4. The ester products then being analysed by using FTIR. The spectra for glycerol-castor oil fatty acid ester and glycerol-oleic acid absorption peak at wave number 1735.37 cm-1 and 1748.25 cm-1 respectively, which indicate the existence of C=O ester groups. Conversion percentage in esterification was conducted using titrimetric method. The highest conversion percentage was reached at the molar ratio 1:4 with the value of 92.4% respectively for glycerol-castor oil fatty acid and 86.2% for glycerol oleic ester. Emulsifier test was performed to observe the stability and the type of emulsion, using ester product as emulsifier. The properties of the emulsifier in both esters are obtained by type of water in oil. Antimicrobial assay were also conducted for both esterification product using disc diffusion method against Propionibacterium acne and Staphylococcus epidermidis. The antimicrobial assay showed that glycerol- castor oil fatty acid esters has antimicrobial activity, but glycerol-oleic esters did not show the antimicrobial activity. -

Research Progress in Glycerin Fatty Acid Ester Emulsifier

International Journal of Scientific & Engineering Research, Volume 4, Issue 5, May-2013 924 ISSN 2229-5518 Research progress in glycerin fatty acid ester emulsifier BAO Chengwei, An Shulin, Wang Wenli, WANG Fei, YANG Shuangchun, PAN Yi* Liaoning Shihua University, Fushun, Liaoning, China 113001 Abstract—Emulsifier is a stabilizing agent of the emulsion and a kind of surfactant. Food industry commonly uses emulsifier glycerol fatty acid esters of monoglycerides. This paper introduces the characteristics of three glycerin fatty acid ester emulsifier function, synthesis methods and application situation. Moreover, based on these details, some suggestions of the future development are indicated. Index Terms—glycerin fatty acid ester; stabilizer; emulsifier; surfactant —————————— —————————— 1 INTRODUCTION mulsifier rely on emulsification mechanism [ 1 ] can induce with glycerol , results show that the quality of the mono- E two immiscible liquid to form a stable emulsion of sub- glycerides Score can reach 62.6% , the production of the prod- stances , food emulsifier is one of the most important food uct quality and esterification considerable , but the experiment additive , since the 1980s , the people of emulsifier t0he multi- glycerol have self-polymerization reaction .In recent years function , high- purity , low stimulation , high - efficiency scholars more enzymatic studies , South China University of higher demands to develop more new emulsifier .Currently, Technology Zhuqi Si et al [ 5 ] in the reaction of tert-butyl alco- the most -

Thermal Performance Evaluation of Fatty Acid Ester and Paraffin

applied sciences Article Thermal Performance Evaluation of Fatty Acid Ester and Paraffin Based Mixed SSPCMs Using Exfoliated Graphite Nanoplatelets (xGnP) Hwayoung Lee, Su-Gwang Jeong, Seong Jin Chang, Yujin Kang, Seunghwan Wi and Sumin Kim * Building Environment & Materials Lab, School of Architecture, Soongsil University, Seoul 156-743, Korea; [email protected] (H.L.); [email protected] (S.-G.J.); [email protected] (S.J.C.); [email protected] (Y.K.); [email protected] (S.W.) * Correspondence: [email protected]; Tel.: +82-2-820-0665; Fax: +82-2-816-3354 Academic Editor: Mohammed Mehdi Farid Received: 22 February 2016; Accepted: 4 April 2016; Published: 12 April 2016 Abstract: Phase change materials (PCMs) have been used in various fields including the materials of buildings. In this research, mixed shape-stabilized PCMs (Mixed SSPCMs) were prepared by impregnating coconut oil and n-hexadecane into exfoliated graphite nanoplatelets (xGnP) through a vacuum impregnate method. Coconut oil is fatty acid ester PCM which is relatively economical in comparison to other PCMs, and n-hexadecane is paraffin PCM that has high latent heat capacity. Drawbacks include leakage in a liquid state and low thermal conductivity resolved by xGnP. When preparing Mixed SSPCMs, coconut oil and n-hexadecane were impregnated at different proportions, namely 70:30, 50:50, 30:70 wt %. Mixed SSPCMs were analyzed through SEM, FT-IR, DSC, TGA and TCi. As a result, we confirmed the microstructure, chemical stability, thermal properties, thermal stability and thermal conductivity of Mixed SSPCMs. Latent heat capacity of Mixed SSPCMs were 89.06, 104.30 and 124.50 J/g while those of SSPCMs containing single PCM were 82.34 and 96.40 J/g. -

Indentification and Localization of the Fatty Acids in Haemophilus Parainfluenzae

JOURNAL OF BACTERIOLOGY, Mar., 1967, p. 1079-1088 Vol. 93, No. 3 Copyright @ 1967 American Society for Microbiology Printed In U.S.A. Indentification and Localization of the Fatty Acids in Haemophilus parainfluenzae DAVID C. WHITE AND RICHARD H. COX Department ofBiochemistry and Department of Chemistry, University ofKentucky Medical Center, Lexington, Kentucky Received for publication 7 December 1966 Haemophilus parainfluenzae was capable of synthesizing 22 fatty acids. These fatty acids were equivalent to 4% of the bacterial dry weight. These fatty acids were localized in the membrane-wall complex, which contained the respiratory pigments, the quinone, and the phospholipids. The fatty acids which could be extracted with organic solvents comprised 86% of the total fatty acids of the cell. These fatty acids were distributed as 98% in the phospholipids and 1.9% in the neutral lipids, of which 0.5% were free fatty acids. Palmitic, palmitoleic, oleic, and vaccenic acids com- prised 72% of the total fatty acids and were found almost exclusively in the phos- pholipids. The phospholipids also contained the cyclopropane fatty acids. The neu- tral lipids contained significant proportions of the odd-numbered branched and straight-chain fatty acids. The principal free fatty acids were n-dodecanoic and penta- decenoic acids. The nonextractable wall complex contained 14% of the total fatty acids. These wall fatty acids were rendered soluble only after saponification. The wall fraction contained all of the f3-hydroxymyristic acid and most of the myristoleic and pentadecenoic acids. The significance of the distribution of fatty acids between non- esterified, neutral lipid, phospholipid, and nonextractible wall remains to be deter- mined. -

The Amendment of Standards for Specification, Scope, Application and Limitation of Food Additives MOHW Food No.1091301559, 11 August, 2020 Appendix 1: 07

The Amendment of Standards for Specification, Scope, Application and Limitation of Food Additives MOHW Food No.1091301559, 11 August, 2020 Appendix 1: 07. Food quality improvement, fermentation and food processing agents Code Food Additive Items Scope and Application Standards Limitations For manufacturing All foods: not more than 3 g/kg calculated as 07029 Sodium Dihydrogen Phosphate or processing phosphate. purpose. For manufacturing Sodium Phosphate, Monobasic All foods: not more than 3 g/kg calculated as 07030 or processing (Anhydrous) phosphate. purpose. For manufacturing All foods: not more than 10 g/kg calculated as 07075 Calcium Chloride, Anhydrous or processing Ca. purpose. 08. Nutritional additives Code Food Additive Items Scope and Application Standards Limitations 08194 Calcium Chloride Dehydrate Foods in capsule or tablet form and labeled For supplementing with daily dosage: not more than 1800 mg of purpose. total calcium in daily intake. 08195 Calcium Chloride Hexahydrate Foods in capsule or tablet form and labeled For supplementing with daily dosage: not more than 1800 mg of purpose. total calcium in daily intake. 08286 Sodium Dihydrogen Phosphate Foods in capsule or tablet form and labeled For supplementing with daily dosage: not more than 1200 mg of purpose. total phosphorus in daily intake. 09. Colors Code Food Additive Items Scope and Application Standards Limitations 09001 Ponceau 4R All foods: as practically needed. Not allowed in fresh raw meat, fish, shellfish, beans, vegetables, fruits, miso, soy 1 sauces, seaweeds, and tea. 11. Seasoning Agents Code Food Additive Items Scope and Application Standards Limitations 11005 Sodium Fumarate All foods: as practically needed. For manufacturing or processing purpose.