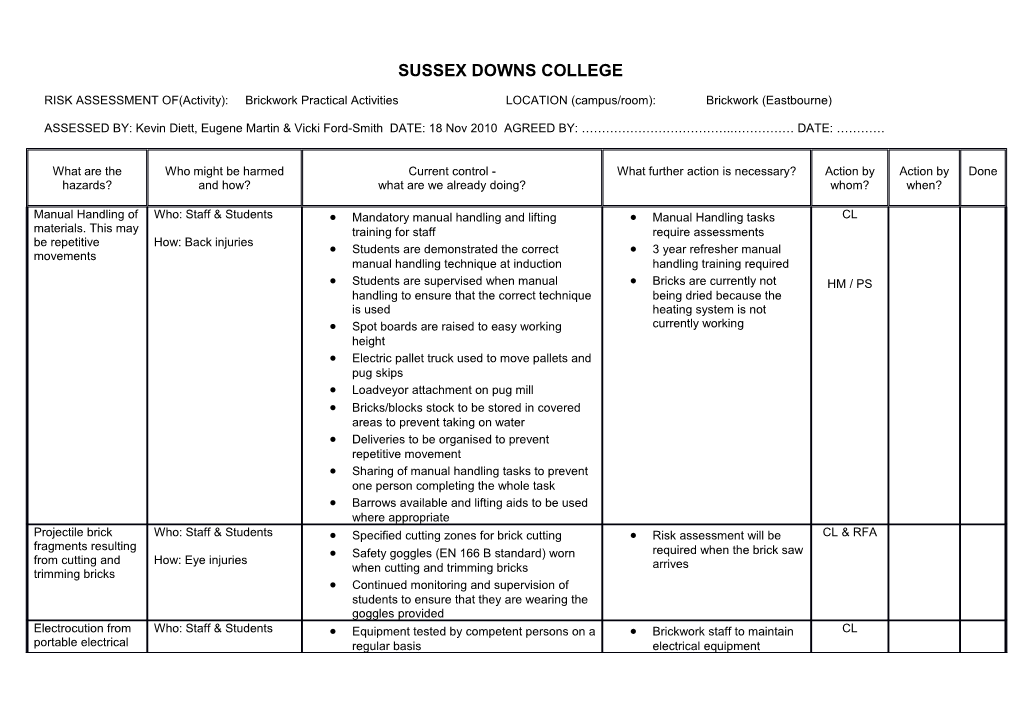

SUSSEX DOWNS COLLEGE

RISK ASSESSMENT OF(Activity): Brickwork Practical Activities LOCATION (campus/room): Brickwork (Eastbourne)

ASSESSED BY: Kevin Diett, Eugene Martin & Vicki Ford-Smith DATE: 18 Nov 2010 AGREED BY: ………………………………..…………… DATE: …………

What are the Who might be harmed Current control - What further action is necessary? Action by Action by Done hazards? and how? what are we already doing? whom? when?

Manual Handling of Who: Staff & Students Mandatory manual handling and lifting Manual Handling tasks CL materials. This may training for staff require assessments be repetitive How: Back injuries Students are demonstrated the correct 3 year refresher manual movements manual handling technique at induction handling training required Students are supervised when manual Bricks are currently not HM / PS handling to ensure that the correct technique being dried because the is used heating system is not Spot boards are raised to easy working currently working height Electric pallet truck used to move pallets and pug skips Loadveyor attachment on pug mill Bricks/blocks stock to be stored in covered areas to prevent taking on water Deliveries to be organised to prevent repetitive movement Sharing of manual handling tasks to prevent one person completing the whole task Barrows available and lifting aids to be used where appropriate Projectile brick Who: Staff & Students Specified cutting zones for brick cutting Risk assessment will be CL & RFA fragments resulting Safety goggles (EN 166 B standard) worn required when the brick saw from cutting and How: Eye injuries when cutting and trimming bricks arrives trimming bricks Continued monitoring and supervision of students to ensure that they are wearing the goggles provided Electrocution from Who: Staff & Students Equipment tested by competent persons on a Brickwork staff to maintain CL portable electrical regular basis electrical equipment equipment How: Burns or fatal 110v equipment in use inventory and ensure that injuries from faulty equipment is available equipment during testing period

What are the Who might be harmed Current control - What further action is necessary? Action by Action by Done hazards? and how? what are we already doing? whom? when?

Inexperienced Who: Students 1st Year under 16 year old student are students getting required to wear eye protection while working mortar in their eyes How: Irritation to eyes in workshops when laying bricks from contact Continued monitoring and supervision of or unloading onto students to ensure that they are wearing the the spot board goggles provided Students are advised at induction that throwing mortar will result in suspension from the course Operating pan Who: Staff Mill is fully guarded and guards in place Regular electrical inspection Estates mixer and during operation and testing loadveyor How: Crushing, Mill is only used by trained staff entrapment, entanglement in the conveyor Maintenance carried out by contractor annually Daily/weekly checks by staff to check for obvious damage If damage is observed, equipment is to be taken out of use immediately Risk assessment and method statement completed for the cleaning of the pan mixer and loadveyor Contact with Who: Students & Satff Risk of dermatitis or lime/cement burns and Training and information for CL to hazardous precaution explained to all students and staff staff on how to treat discuss substances eg. How: Contact dermatitis with Safety Washing facilities with hot and cold water, exposure mortar and burns. Team soap and basin large enough to wash forearms, available adjacent to workshop. COSHH risk assessments completed for all hazardous chemicals First aid kits contain emergency saline eyewash 20ml pods Students provided with gloves Barrier cream provided in welfare facilities

Dust from cutting Who: Students & Staff Dry sweeping not permitted Supervision and monitoring CL bricks or blocks and How: Dust exposure could Industrial vacuum cleaners are used of sweeping techniques dried mortar cause silicosis Workshop cleaning schedule and checklist being implemented

What are the Who might be harmed Current control - What further action is necessary? Action by Action by Done hazards? and how? what are we already doing? whom? when?

Slips and trips Who: Staff & Students Importance of housekeeping discussed with How: Sprains and students fractures if they trip over Staff and students wear safety footwear waste Designated walkways within workshop area Workshop cleaning schedule and checklist being implemented Good housekeeping is instilled at every lesson Noise from use of Who: Staff & Students Hearing defenders worn during specified Regular inspection checks CL equipment, eg activities to be introduced. angle grinder, pug How: Hearing loss. Continued monitoring and supervision of mill and cement students by staff to ensure that they are mixer using hearing protection. Pug mill and cement mixer is only used by staff Vehicle movement Who: Staff, Students & Speed limit on college campus Maintain pedestrian Estates in road to Brickwork Visitors Specified pedestrian walkways on approach walkways workshop (including CL road to workshop Hi vis jacket to be worn by deliveries) or How: Injuries resulting the pallet truck operator powered pallet from a collision with a Staff to act as “banksman” during unloading truck being vehicle or powered pallet and reversing activities operated in the truck Pallet truck only operated by staff that have workshop had a suitable level of training Electrocution from Who: Staff & Students Equipment tested by competent persons on a Brickwork staff to maintain CL portable electrical regular basis electrical equipment equipment How: Burns or fatal 110v equipment in use inventory and ensure that injuries from faulty equipment is available equipment during testing period Use of hand tools Who: Staff & Students Tools are visually inspected at the start of Tool inspection list being CL How: Injury resulting from each practical session implemented incorrect use of hand Students are trained before using hand tools tools or use of damaged and are instructed to carry out a visual check tools before use Any damaged tools are removed from use immediately

What are the Who might be harmed Current control - What further action is necessary? Action by Action by Done hazards? and how? what are we already doing? whom? when?

Demolition of Who: Staff & Students Students are instructed to take down models models How: Bricks falling onto in a careful manner feet All personnel to be wearing safety boots when in the workshop Appropriate staff to assist students when taking down models when required# Students provided with gloves for handling materials Falling objects Who: Staff & Students Workshop is designated as a Protective landing on feet How: crushing, cuts, Footwear (steels toe caps) zone bruises, fractures Students informed at induction that they must wear safety boots at all time when working in the workshop Brickwork department keep a small selection of boots for students that have forgotten their boots Students without boots will not be allowed into the practical areas Materials not stacked too hight Dusty environment Who: Staff & Students Dry sweeping is prohibited. Brooms may be Annual deep-clean CL used to push debris around but not be used Cleaning rota to be How: Spread of germs, to sweep implemented dust inhalation Industrial vacuum cleaners used Students or staff with breathing difficulties to be identified and to have personal risk assessment completed. Control measures from this risk assessment to be implemented where possible Debris from demolishing model to be scraped together into a heap using the trowel and disposed in the barrow Welfare and first Good facilities help to Hot and cold water, soap, towels, skin cream aid prevent dermatitis etc and full size wash basin Washroom provided to allow students to wash hands and forearms Toilet facilities provided in Park building