CFAS Enterprises Inc. After Market Utility Power Equipment Brokerage Mailto:[email protected] Turbine URL: http://CFASPower.com/Index.html Reciprocating URL: http://CFASPower.com/Recips.html

GTG_1377GR_RRAvons_60Hz.doc

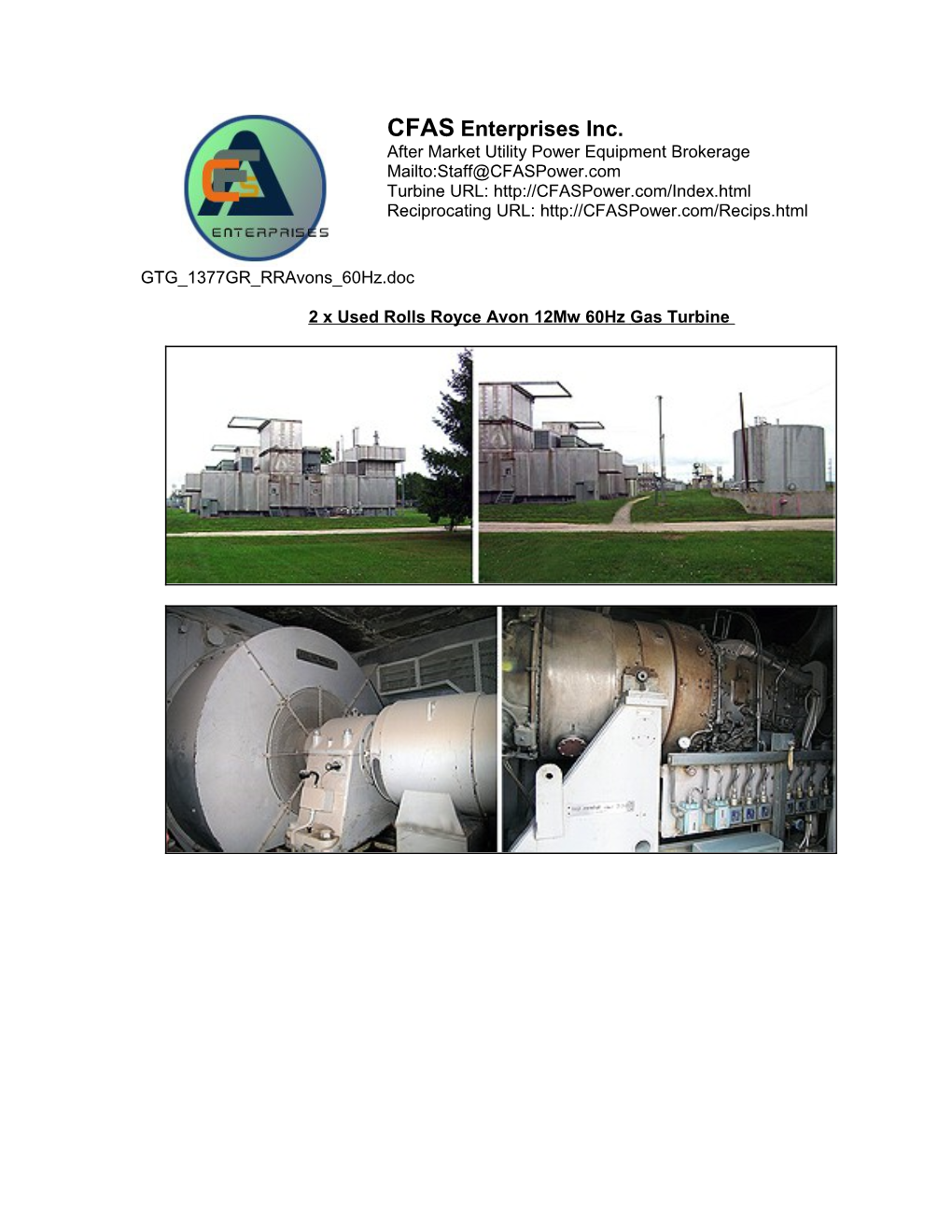

2 x Used Rolls Royce Avon 12Mw 60Hz Gas Turbine Asking Price: US $735,000 each

AVON INFORMATION Unit 7: Gas Generator: Model: 1533-76G/14 S/N: 37846 Hours Since Overhaul: 5380 Starts Since Last Overhaul: 2309

Power Turbine: Manufacturer: Cooper Bessemer Type: RT66 S/N: 314RT Lube Oil Type: Mineral Lube Oil Pressure Minimum: 20 PSIG Rated HP: 11000 / 12500 KW NEMA Normal RPM: 3600 Max Continuous RPM: 3600 Overspeed Trip Out RPM: 4040 / 4140 Gas Inlet Pressure: In Water 1.0 Max Temp Deg F: 1180

Generator: Manufacturer: Electric Products (EP) S/N: 170181201 Type: Turbo KVA: 14783 RPM: 3600 Cycle: 60 Volts: 13800 Amps: 618 Phase: 3 PF: 0.85

Unit 8: Gas Generator: Mark: 1533-76G/14 S/N: 37845 Hours Since Last Overhaul: 3,612.9 Starts Since Last Overhaul: 2075

Power Turbine: Manufacturer: Cooper Bessemer Type: RT66 S/N: 325RT Lube Oil type: Mineral Lube Oil Pressure Minimum: 20 PSIG Rated HP: 11000 / 12500 KW NEMA Normal RPM: 3600 Max Continuous RPM: 3600 Overspeed Trip out RPM: 4040 / 4140 Gas Inlet Pressure: In Water 1.0 Max Temp Deg F: 1180

Generator: Manufacturer: Electric Products (EP) S/N: 270181201 Type: Turbo KVA: 14783 RPM: 3600 Cycle: 60 Volts: 13800 Amps: 618 Phase: 3 PF: 0.85 SECTION 1

DESCRIPTION AND DATA Page 1-1

The Cooper-Bessemer Coberra Peak-Pakgas turbine-driven electric generator unit(Fig. 1-1) comprises a Rolls-Royce Avon 76Gas Generator, Cooper-BessemerRT66 PowerTurbine, Electric Machinery 12,500 KWGenerator with exciter, plus lubricating oilsystems, switchgear and controls to operatethe unit in attended or unattended service.The entire package is furnished complete withweatherproof enclosure to eliminate the needfor a separate building.

The Peak-Pak is designed to operate oneither natural gas or liquid fuel. The change- over from one fuel to the other can be madeeasily with an interchange of fuel manifoldsand eight burner assemblies.

Located at the inlet end of the gas generator is the air inlet plenum chamber. Thisplenum is provided with acoustic panels toattenuate the sound of inrushing air, facilitiesfor introducing a cleaning agent into the gasgenerator inlet air stream and an electricstarting motor. Entrance to the plenum isthrough a door in the end of the enclosure. Operation of the Peak-Pak is controlledby an automatic-sequential control system.Each step in the sequence must be proved be-fore the next step can be achieved. The unitcan be started, stopped and speed regulated,either up or down, by signals originating fromdevices on the control panel.

Automatic alarm and shutdown devicesare provided as protection against suchadverse operating conditions as overspeed,excessive vibration, high or low temperaturesand high or low oil pressures.

The gas generator, is started by an electricmotor in the plenum chamber which is coupledto the gas generator starter drive mechanismmounted on the front of the compressor shaft.This mechanism is a ratchet and pawl type arrangement that disengages by centrifugal forcewhen the gas generator speed exceeds the starting motor speed. As the starter turns the gasgenerator to a self-sustaining speed, combustionis initiated by two high-energy igniter plugs located in numbers 3 and 6 combustion flame tubes.The starting cycle is originated by the sequentialpanel in the control room.

The gas generator is an axial [low machinewith seventeen stages of compression to pro-vide approximately a 10 to I compression ratio.Air is drawn into the gas generator through theplenum chamber after having passed through asilencer. As the air exits from the compressor diffuser passage, fuel is mixed with asmall portion of the compressed air. Themixture of air and fuel then enters the combustion, or [lame, zone in each of the eightcombustor cans (flame tubes) where it isburned to produce high energy hot gas. Theremainder of the compressed air by-passesthe combustion zone and enters the combustorcans in such a manner as to cool the entiremetal surface of the can. The mixture ofcooling air and burned gases results in a hotgas that is suitable for expansion in the gasgenerator's turbines without imposing thermaldistress on the turbine nozzles and blades. Thecombustion gas is expanded through the turbineblades in the gas generator where a portion ofthe heat energy is converted to rotative powerto drive the gas generator's compressorstages. The turbine shaft and the compressorshaft are coupled together for the direct driveavailability. Only a small portion of the heatenergy is dissipated by the gas generatorturbines. The exhaust gas is still at a highenough (approximately 1111°F and 39 psia)energy level to drive the Cooper-Bessemerpower turbine. Refer to the Rolls-Royce Avon1533-76 Maintenance Manual for a moredetailed description of the gas generator.

The exhaust gases from the gas generatorpass through a cylindrical transition duct tothe power turbine inlet diffuser. Both flangesof the transition duct are sealed by a cast steelsealing ring o[ wedge-shaped section, pressur-ized by the exhaust gas. After passing throughthe power turbine, the exhaust gases are col-lected in an insulated hood and directed toatmosphere.

The Cooper-Bessemer Model RTG6 powerturbine is a single stage impulse reactionturbine. The rotor is overhung in two tilting-pad journal bearings mounted in the bearingcase which is an integral part of the turbinesupport. The bearing case also contains aKingsbury-type thrust bearing to absorb thrustand to limit rotor axial movement. The rotor shaft and turbine wheel isdynamically balanced as a unit before beinginstalled. A labyrinth seal separates the hotgas section of the power turbine from the bearing housing to protect the bearings from exposure to the hot exhaust gases. A Woodward governor, mounted on theupper turbine bearing case and an electronictripping device protect the power turbineagainst overspeeding.

Equipment Data

Gas Generator

Manufacturer: Rolls-Royce Ltd., Derby, England Model: Avon 1533-76G Direction of Rotation: Counterclockwise viewed from rear Compressor: 7 stage axial flow Turbine: 3 stage axial flow Fuel System: Natural gas/distillate oil Lubricating Oil: See Rolls-Royce Avon 1533- 76G Service Manual Lubricating Oil Temperature,: 140°F

Gas Generator Starter

Manufacturer; See Auxiliary Index C-B Part Number; See Auxiliary Index Horsepower and Speed: 50/25 hp © 1750/875 rpm

Power Turbine

Manufacturer: Cooper-Bessemer Company Model: RT66 Stages: 1 Type: Reaction Direction of Rotation: Clockwise viewed from bearing housing end Design Operating Speed: 3600 rpm Normal Operating Speed: ±2% Overspeed Tripout: 4140 rpm Axial Thrust Clearance: 011-.017" Journal Bearing Running Clearance: Impeller End .0150-,0175 Coupling End: ,0100-.0125" Lubricating Oil: See Engineering Standard SE-114-4 in Appendix I Lube Oil Temperature in, °F: 130 Lube Oil Pressure in psi: 20 Turbine Inlet Temperature, Normal °F; 1111 Shutdown ° F: 1180 Turbine Inlet Pressure psi: 39

Main and Auxiliary Lube Oil Pumps (Gas Generator)

Manufacturer: Commercial Shearing and Stamping Cooper-Bessemer Part Number: See Auxiliary Index Model See Auxiliary Index Rating: 9 gpm at 500 psi and 1200 rpm Pump Motor: Manufacturer: General Electric Cooper-Bessemer Part Number: See Auxiliary Index Horsepower: .5 RPM: 1200 Volts: 230/460 Cycle: 60Hz Phase: 3

Main and Auxiliary Lube Oil Pump (Power Turbine and Electric Generator)

Manufacturer: Dean Cooper-Bessemer Part Number: See Auxiliary Index Model: See Auxiliary Index Rating: 60 gpm at 50 psig and 3500 rpm Pump Motor: Manufacturer: General Electric Cooper-Bessemer Part Number: See Auxiliary Index Horsepower: 7.5 RPM: 3500 Volts: 230/480 Cycle: 60Hz Phase: 3

Emergency Lube Oil Pump (Power Turbine and Electric Generator)

Manufacturer: Dean Cooper-Bessemer Part Number: See Auxiliary Index Model: See Auxiliary Index Rating: 20 gpm at 12 psig and 1750 rpm Pump Motor: Manufacturer: Reliance Cooper-Bessemer Part Number: See Auxiliary Index Horsepower: .5 Volts D.C.: 28

Capacities

Gas Generator Oil Reservoir: 60 U.S. Gal. Power Turbine and Electric Generator Oil Reservoir: 430 U.S. Gal.

Fuel Oil Specifications

Refer to Rolls-Royce Avon 1533-76G Maintenance Manual. Fuel Oil Pumps (2)

Manufacturer: Roper Cooper-Bessemer Part Number: See Auxiliary Index Model: See Auxiliary Index Rating: 1500 psi @ 1750 rpm Pump Motor: Manufacturer: Reliance Cooper-Bessemer Part Number: See Auxiliary Index Horsepower: 40 Volts: 240/480 Cycle: 60 Phase: 3

A-C Generator

Manufacturer: Electric Machinery Speed, rpm: 3600 KVA: 14,783 Cycle: 60 Volts: 13,800 Phase: 3 Wire: 6

Estimated Weights as Shipped Lbs

Main Skid (includes intake plenum1 power turbine exhaust hood and supports and power turbine exhaust transition & expansion sect): 67,420 GG Main Intake Air Hood (no filter): 2,700 GG Main Intake Air Silencer: 3,050 GG & PTEnclosure (plenum roof, GG & RT encl) side and roof panels and support I beams): 10,160 GG Compartment Cooling Air Fan, Duct & Silencer: 1,600 GG & Power Turbine Generator Lube Oil Radiator: 5,000 GG on Stand (3630 without stand): 4,300 Power Turbine to Generator Coupling : 420 Generator Skid (including generator): 114,450 Generator Terminal Junction Box: 550 Generator Exhaust Air Silencer: 1,400 Generator Intake Air Filters and Frames: 120 Generator Bus Duct (100#/Ft. Length): 2,000 Control House with Contents: 35,000

(Total Estimated) 248,170

Main skid without gas fuel accessories weighs 2500# less.Optional hood with filter weighs 3850# more.

Vibration Limits (Mils) Turbine Shaft: 2.0 Coupling Hub: 2.5 Coupling Spacer: 4.0 Generator Shaft: 1.0

Torque Specifications RT66 Power turbine (see Assembly drawing in Parts List) Gas Generator (See Rolls-Royce Avon 1533-76G Maintenance Manual)