Background Statement for SEMI Draft Document 4792 (Yellow Ballot) NEW STANDARD: GUIDE FOR HIGH PURITY WATER USED IN PHOTOVOLTAIC CELL PROCESSING

Note: This background statement is not part of the balloted item. It is provided solely to assist the recipient in reaching an informed decision based on the rationale of the activity that preceded the creation of this document.

Note: Recipients of this document are invited to submit, with their comments, notification of any relevant patented technology or copyrighted items of which they are aware and to provide supporting documentation. In this context, “patented technology” is defined as technology for which a patent has been issued or a patent application has been submitted. In the latter case, only publicly available information on the contents of the patent application is to be provided.

Background This document provides the Reviewer with background information, describing the process of how this specification was developed.

The needs of Photovoltaic (PV) end-users’ requirements differ from those in semiconductor when it comes to high purity water used during production. This is driven by different (lower) sensitivity to water quality parameters and higher sensitivity to facility system cost. Our taskforce took the existing SEMI F063 document as a template and converted it into a high purity water standard for use in photovoltaic applications, specifically cell processing.

The taskforce is comprised of members from PV manufacturing, suppliers, consulting and engineering.

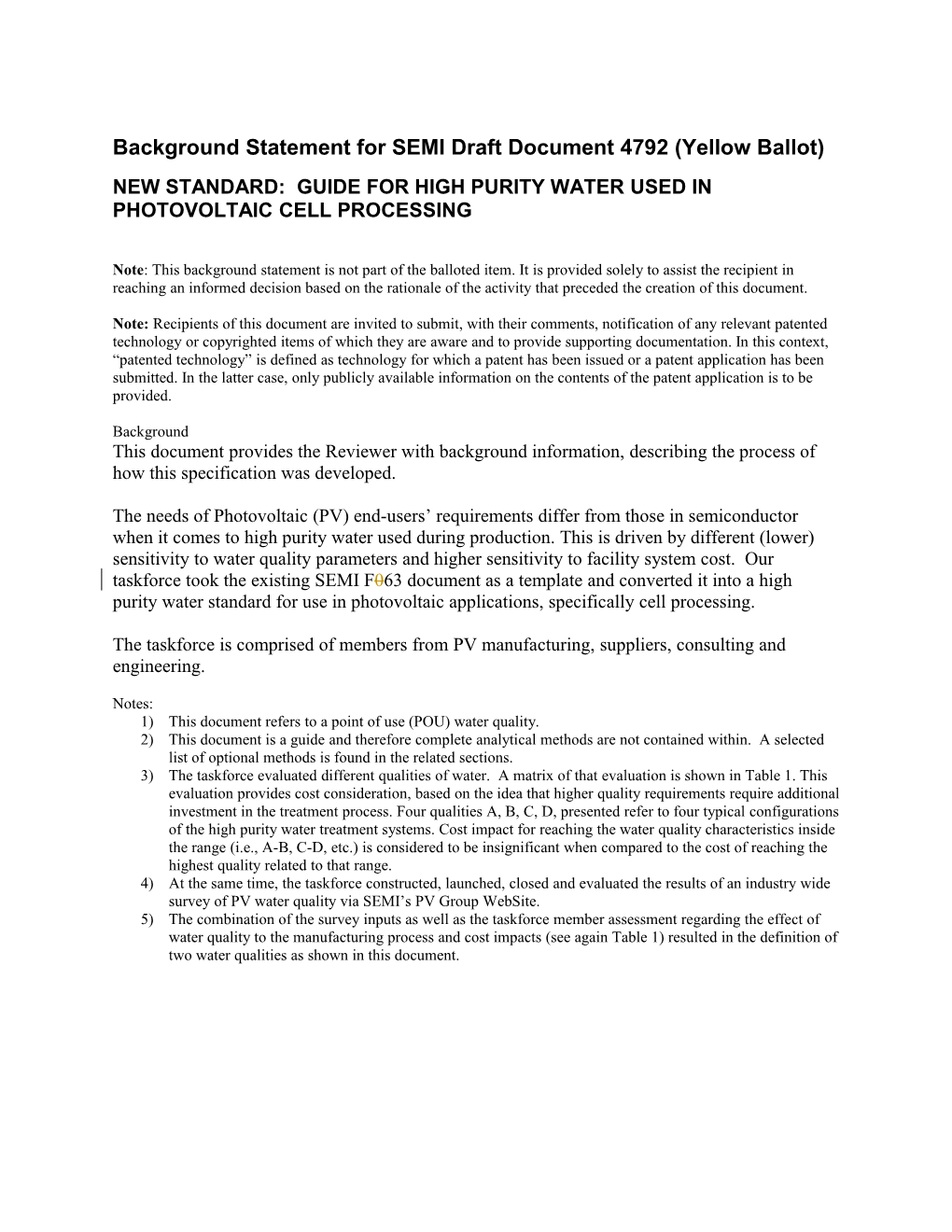

Notes: 1) This document refers to a point of use (POU) water quality. 2) This document is a guide and therefore complete analytical methods are not contained within. A selected list of optional methods is found in the related sections. 3) The taskforce evaluated different qualities of water. A matrix of that evaluation is shown in Table 1. This evaluation provides cost consideration, based on the idea that higher quality requirements require additional investment in the treatment process. Four qualities A, B, C, D, presented refer to four typical configurations of the high purity water treatment systems. Cost impact for reaching the water quality characteristics inside the range (i.e., A-B, C-D, etc.) is considered to be insignificant when compared to the cost of reaching the highest quality related to that range. 4) At the same time, the taskforce constructed, launched, closed and evaluated the results of an industry wide survey of PV water quality via SEMI’s PV Group WebSite. 5) The combination of the survey inputs as well as the taskforce member assessment regarding the effect of water quality to the manufacturing process and cost impacts (see again Table 1) resulted in the definition of two water qualities as shown in this document. Table 1 – Matrix of evaluated water qualities

UPW Quality Level A Level B Level C Level D Ultra-high purity High Purity High Quality Standard Re, MΩ·cm >18.2 >18.2 >17 >10 TOC, ppb < 1 < 5 <20 < 100 Critical metals, <0.01 < 0.05 < 0.1 < 0.5 ppb Particles, #/L <500 < 3,000 < 10,000 < 10,000 Size of the 0.05 0.05 0.2 0.3 critical particle, μm Bacteria, #/L 0 (excl. sample 0 (excl. sample 10 100 contamination) contamination) Total Si, ppb 0.3 3 20 50 B, ppb NA NA NA NA DO, ppb NA NA NA NA Typical UPW System Configuration Pretreatment RO, RO-RO; IX- RO, IX; RO-RO; RO; RO-RO; IX-RO IX; RO, RO-RO; (~1 MΩ·cm) RO; IX-RO IX-RO Make-up UV- MB; or UV- UV- MB; or UV- CEDI-MB, UV- CEDI-MB EDI- Polish (O3)-UV-MB-UF UV-MB- MF MB-MF(0.1 or 0.2 AB-CB- MF(0.2 (0.05 μm) μm) , or CEDI-MB- μm); or CEDI MF (0.1 or 0.2 μm) MF(0.2 μm) Distribution material Supply PVDF PVDF, PP PP, PVC PP, PVC Return PP PP, PVC PP, PVC PP, PVC

The results of this ballot will be reviewed by PV Gas and Liquid Chemicals Purity TF and adjudicated by NA PV Committee during their meetings in the Fall, November 3-4, 2009 at SEMI HQ in San Jose, California. Please check www.semi.org/standards for the latest meeting schedule. Informational (Blue) Ballot1000A (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 3 3 the determine and practices health and safety appropriate other ofprior limitations use.applicability regulatoryor to establish to standard this of users the of responsibility NOTICE: 2 1 PROCESSING CELL PHOTOVOLTAIC HIGH STANDARD: WATERIN GUIDEUSED FOR NEW PURITY DRAFT Document SEMI 4792 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 4 Performance requirements should be determined based on the sensitivity of the manufacturing process to the monitoring theparameters. watersystem and to process manufacturing maintenance, installation, with the associated costs the and of instrumentation, the of sensitivity sensitivity the water, the the of purity on based determined be should requirements Performance 3.1 yield. device impacts water the of quality The technologies. bed photovoltaicover in with time. the cell forwatermay purity increase changes higher Requirements resin Osmosis/Deionized Reverse purpose this for produced using typically is HPW panels. and wafers substrate of rinsing the as such steps processing 2.1 process by used be may guide This systems. HPW their of supplied of aboutoperation the toquality the expectations HPWby them facilities. being to establishreasonable engineers the for parameters control process set to engineers facility by internally used be also may It equipment. (HPW) Water Purity High new of purchases for 1.1 4.1 absolute valuesas observedin values. meaningful may be as Consequently, trends the 3.7 onthe HPW thedistribution manufacturingtool lateral. (POC) of 3.6 technologies. future 3.5 tools. of 3.4 testing analytical for laboratory a in needed water grade reagent and chemicals. process materials photovoltaic of purity the for specifications setting in equipment system 3.3 water from specifications (3) set to system HPW andresources. owner’savailable needs waterbased theof purity for its onthe specifications a of industry; owner individual each to up is PV it photovoltaic However, SEMI process. balloting during the through HPW and the of meetings users and producers for from input and water (4) manufacturers; purity high that laboratories independent test by measured as systems, HPW photovoltaic of selection large a from levels HPW PV SEMI that survey 3.2 Limitations Scope Purpose Referenced Standards Referenced Documents and hs gie i o nedd t e n aslt ubr fr promne o atclr HW system. HPW particular a of performance for number absolute an set to intended not is guide This wet all for manufacturing association and cells photovoltaic of production the in extensively used is Water criteria performance establishing for basis a as used be may It purposes. multiple for provided is guide This SEMI Standard SEMI used. are techniques calibration and method testing which on depend will measured data the of quality The Connection of Point a is which (POU), Point-of-Use at defined is specification quality water for Location enabling account into take not do and manufacturing PV state-of-the-art current on based are guidelines The manufacturing critical as well as facilities manufacturing photovoltaic general both consider guidelines The considered is D5127 ASTM manufacturing. photovoltaic for produced HPW for targeted are guidelines The industry an (1) including; inputs and sources of variety a from established been has guidelines of set This purposes only.purposes 1: NOTE This standard does not purport to address safety issues, if any, associated with its use. It is the is It use. its with associated any, if issues, safety address to purport not does standard This

These suggested guidelines are published as technical information and are intended for informational for intended are and information technical as published are guidelines suggested These ru Group s adrstandards c miteommittee Page provided to members of its standards activities; (2) typical (2) activities; standards its of members to provided 3 ru Group Document Number:4792 Document standards committee standards Doc. 4792 Doc. 4792 Date: DRAFT 6/5/2018 SEMI

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000A (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 5 5 NOTICE: and Bacteria for Method Count Direct SEM 3. UltrapureWater Samples Enumeration of Particle Appendix Components System Distribution UPW by Retention #92010949B Transfer Technology and Electron Processing for Used Water of Monitoring Microbiological for Method Plastic Sampling and byValve BagMethod Devices Direct-the PressureTap Pre-sterilized Microelectronic Test — F1094 ASTM Measurement Colorimetric of On-Line Silica Test Method for D7126ASTM —Standard and Carbon Inorganic Carbon, Total of Determination Level Low Conductivity Detection Waterand byUltraviolet,Oxidation, in Persulfate Membrane Organic Carbon for Method Test Standard — D6317 ASTM Sample Water Purity High Flowing a of Resistivity and Conductivity Electrical for Method Test Standard — D5391 ASTM Conductivity by Electrolytic Chemical by Water in Compounds or NDIR Carbon Phase Gas by Followed Combustion Temperature of High by or Both, by Oxidation, Monitoring Light UV by Oxidation, On-Line for Method Test Standard — D5173 ASTM ElectronicsSemiconductor in WaterIndustry GuideUltraUsed and D5127for the ASTM Pure —Standard SuppressedChromatography byChemically Anionsin Test MethodIon for D4327ASTM —Standard Water of On-line Test MethodSodium for Water D2791Determination ASTM in —Standard Silica Test Method for D859Water ASTM —Standard in —Guidethe Analysis ofChemicals SEMI C1 for Liquid reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 2 Fax: 610.832.9555; 610.832.9585; 1 other from plant source. awatersourceor drinking a municipal enters the feedwaterthat treated to refer 5.2.2 been exchange. by polished ion has waterthat RO 5.2.1 is users watertreatment use semiconductor manufacturing. system,which the sentend for in to produced by a process. (DI) Deionization 5.1.3 5.1.2 5.1.1.2 5.1.1.1 on needs: dependinguser end by chosen be to choices two quality There are particles. and bacteria TOC, ions,gases, dissolved 5.1.1 1 American Society for Testing and Materials,Drive, 100Barr forHarbor West Society Pennsylvania and Conshohocken, Testing USA. Telephone: 1 American 19428-2959, 2

4.3 4.2 5.2 5.1 Terminology SEMATECH, 2706 Montopolis Drive, Austin,78741, TX SEMATECH, 2706Montopolis Drive, Raw water Raw water (deionized) DI UPW TOC HPW SEMATECH SEMATECH ASTM Standards Definitions Abbreviations andAcronyms Standard Purity quality — quality ofsensitivity Purity processes PV —quality HPWlower requiredStandard quality for higher required qualityfor High ofsensitivity Purity processes —quality HPW PV Unless otherwise indicated, all documents cited shall be theversions. latestpublished otherwise documents all cited be shall Unless indicated, — total organic carbon, also Total Oxidizable Carbon. Refers to organic compounds. organic alsoOxidizableto Total Refers —total Carbon. carbon, organic — Ultrapure Water System consisting of multiple components including a Reverse Osmosis (RO) and a and (RO) Osmosis Reverse a including components multiple of consisting System Water Ultrapure — — High Purity Water System, but with a lower grade than UPW, due to lower requirements for requirements lower to due UPW, than grade lower a with but System, Water Purity High — — any untreated natural water like river water, lake water, ground water, or seawater. May also May seawater. or water, ground water, lake water, river like water natural untreated any — Standards 1 — generally refers to water that has passed through a full-train ion exchange system or system exchange ion full-train a through passed has that water to refers generally — http://www.astm.org P sis UPW document

SEMATECH Provisional Test Method for Determining Particle Contribution and Particle Determining for Test MethodProvisional SEMATECH a higher purity of water that exceeds all the requirements of HPW and is and HPW of requirements the all exceeds that water of purity higher a 2 http://www.sematech.org Page 4 Document Number:4792 Document Doc. 4792 Doc. 4792 Date: DRAFT 6/5/2018 SEMI

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000A (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and by conductivity or infrared photometry and reported as carbon(C). photometryand orby reported conductivity infrared 7.2.1 25°C. for limit water at upper pure theoretical 7.1.1 7 6 modify dissolved orderto solids the in water. suspended injections content the of and/or 5.2.4 (permeate) water to refers Generally osmosis passed reverse (RO) through has that a membrane. solids. dissolved all of majority vast the and solids suspended all essentially 5.2.3 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 1. listed Table in guide are 7.6.2 nitrate, sulfate. phosphate, fluoride, nitrite, and chloride, 7.6.1 7.5.2 Coupled Inductively MassPlasma (ICP-MS). Spectroscopy Resolution High or (ICP-AES) Spectroscopy Emission Atomic Plasma Inductively-Coupled 7.5.1 7.4.1 Technology described#92010949B. bein Transfer can used, Microscopy as Electron 7.3.2 7.3.1 7.2 7.1 6.4 6.3 6.2 6.1 7.6 7.5 7.4 7.3 Description ofDescriptionParameter Tests Units Involves oxidation of organic materials and detection of carbon dioxide produced by the reaction, as measuredas the reaction, by dioxideproduced of carbon detection and materials organic of oxidation Involves the is MOhm-cm 18.25 instrumentation. on-line with accurately measured only is (conductivity) Resistivity water Treated (RO) osmosis Reverse Up to 68 elements may be determined by GFAAS, ICP-AES, or ICP-MS. The 20 elements included in this in included elements 20 The ICP-MS. or ICP-AES, GFAAS, by determined be may elements 68 to Up bromide, ammonium, including Chromatography Ion using determined be may cations and anions Many SiO (ppbDissolved Silica as (GFAAS), Spectrophotometry Absorption Atomic Furnace Graphite by measured be may (ppb) Silica Total ontheF1094 ASTM based of a samples using sample 1L. arecultured minimum size Triplicate Scanning with counting by followed membrane, etch track a on particles of collection alternative, an As trend accurate recommendedanalysis. for using methods technologyOn-line laser are Total Organic CarbonTotal Organic (TOC) (ppb) orMohm–cm) (megohm-centimeters Resistivity bacteria Forming organisms. (CFU)aColony Units is of measurement millimeter. meter,one islengthequal unitof oneofthousandth to a Micron millionth a or of a at 1g/mL whereassumed. (ppm) million theofis equivalentdensity Parts mg/L per is water to is density ng/mLμg/L waterat isto 1g/mL billion (ppb) whereassumed.Parts or per the of equivalent Ions andMetals (ppb)Ions Silica (CFU/L)Bacteria MatterParticulate (Particles/L) to capture to excursion events. 4: NOTE at levels.positives low false avoid to appropriate be should techniques sampling and containers Sample specified. levels the at parameters listed 3: NOTE for C1 analytical methodology).validation SEMI (see applicable be also may methods Alternative purposes. informational for only are methods analytical specific 2: NOTE

This method will not provide a real time analysis. Therefore, the frequency of sample collection might fail might collection sample of frequency the Therefore, analysis. time real a provide not will method This Since SEMI Guidelines do not require analytical data or methods to support them, the recommendations of recommendations the them, support to methods or data analytical require not do Guidelines SEMI Since Sampling methods and contamination control are of paramount importance when attempting to measure the measure to attempting when importance paramount of are control contamination and methods Sampling ae ht hs pse hog ae ramn qimn n/r rcie chemical received and/or equipment treatment water through passed has that water — itain tcnlg ht uiie eiprebe mmrn o remove to membrane semi-permeable a utilizes that technology filtration a — 2 ) may be measured by heteropoly blue photometry or byIon may Chromatography. be blue photometryor measured by) heteropoly

Page 5 Document Number:4792 Document Doc. 4792 Doc. 4792 Date: DRAFT 6/5/2018 SEMI

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000A (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and 8 8 reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This 8.1 Parametersand Typical Concentrations Table 1 lists each parameter with itsperformance. with 1lists range eachparameter of Table Table 1 ParametersandRangeofPerformance Table 1 Resistivity on-line @ 25°C on-line Resistivity (Mohm–cm)@ Silica dissolved as — (ppb SiO On-line (micron Particles/L range) Dissolved Oxygen (ppb) Dissolved on-line Ions Metals & (ppb) Silica total — (ppb) TOC (ppb) on-line Bacteria (CFU/L) PARAMETER Ammonium Magnesium Manganese Aluminum Chromium Phosphate Antimony Cadmium Potassium Chloride Bromide Titanium Calcium Fluoride Lithium Arsenic Barium 0.3–0.5 0.2–0.3 0.1–0.2 Sodium Copper Sulfate Nitrate Nitrite Nickel Silica Lead >0.5 Iron Tin 2 ) Note

# 1 Page 6 High Purity High RANGE PERFORMANCE OF <1000 >17.5 <100 <20 <10 <10 <20 <20 NA <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 <1 Standard Purity <10,000 <1000 <100 <100 <200 Document Number:4792 Document <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <10 <50 >10 <10 <10 <10 <10 <10 <10 <50 NA NA Doc. 4792 Doc. 4792 Date: DRAFT 6/5/2018 SEMI

LETTER (YELLOW) BALLOT Informational (Blue) Ballot1000A (Blue) Informational Phone:408.943.6900 Fax: 408.943.7943Phone:408.943.6900 Fax: CASan 95134-2127Jose, 3081 Zanker Road Equipment Semiconductor InternationalMaterials and the risk of infringement of such rights are entirely their own suchresponsibility. infringementareentirely rights their the of risk of this in mentioned item any with connection and copyrights, or rights patent such any of in determination that advised expressly are standard this of Users asserted standard. copyrights or rights position patent no any of takes validity (SEMI) the International respecting Materials and Equipment Semiconductor standard, this of publication By other and change to sheets, subject notice.without are data standards These product herein. mentioned labels, equipment product or materials instructions, any respecting manufacturer’s literature relevant to refer to cautioned are theUsers of responsibility user. the solely is standard(s) the of suitability the of determination The application. particular any NOTICE: reproduce and/or distribute this document, in whole or in part, only within the scope of SEMI International Standards committee (document development) activity. All other All activity. development) (document committee Standards International SEMI of scope the within reproduction without distribution and/or SEMIwritten the ofprior isprohibited.consent only part, in or whole in document, this distribute and/or reproduce to granted is Permission standard. adopted or official an as construed be to is page this on material No program. Standards International SEMI the of document draft a is This in the specin defined #1 SEMI makes no warranties or representations as to the suitability of the standard(s) set forth herein for herein forth set standard(s) the of suitability the to as representations or warranties no makes SEMI Total Si is defined as the leading specification parameter. Typically dissolved Si presents the majority of the total Si total the of majority the presents Si dissolved Typically parameter. specification leading the as defined is Si Total . range. Measuring be Si for dissolved chosen may convinience for optimization or cost reasons. Vanadium Zinc Page 7 <1 <1 Document Number:4792 Document <10 <10 Doc. 4792 Doc. 4792 Date: DRAFT 6/5/2018 SEMI

LETTER (YELLOW) BALLOT