Name: Program:

PROD 2100 Production and Operations Management Exam: September 2004

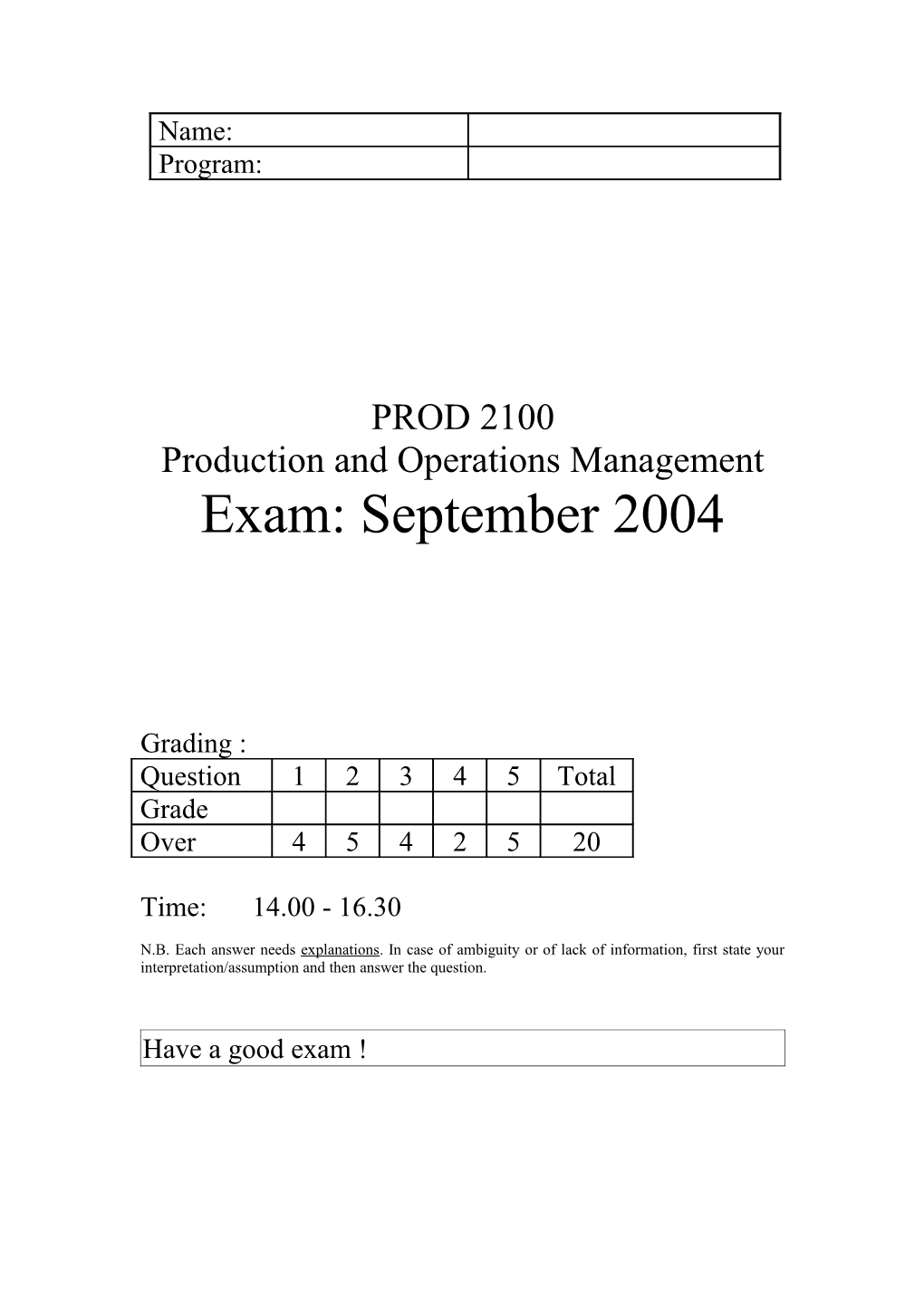

Grading : Question 1 2 3 4 5 Total Grade Over 4 5 4 2 5 20

Time: 14.00 - 16.30

N.B. Each answer needs explanations. In case of ambiguity or of lack of information, first state your interpretation/assumption and then answer the question.

Have a good exam ! The company The company is called “ Belgian AUTOWASH”. It basically offers standard car-wash services. The company owns shops in several cities. Here we are interested in the shop in Ottignies.

The products and services The company uses revolutionary cleaning products, which have been developed to ensure effective cleaning without causing harm or corrosion to the protective surface polish of the automobile. This is ensured through a powerful combination of special soak agents that improve penetration and help loosen stubborn dust film without leaving unsightly traces.

The company offers a classical wash service that is highly standardized. The service is made of a sequence of operations performed by one cleaner, by one shop seller and by various machines. The following table lists: the successive operations, the man or machine in charge of each operation and the average duration of each operation.

Sequence Welcome Pre-Washing Washing Polishing Drying Driving to Payment of operations Parking Goodbye

Distribution Deterministic Deterministic Uniform Deterministic Deterministic Deterministic Deterministic Duration 1 4 [4-8] 3 3 1 4 in minutes Man/ Cleaner Cleaner Washing Wax Drying Customer Shop seller Machine machine machine machine in charge

After the manual pre-washing, customer drives his car inside a bay. Once his car is in the correct position, a signal informs him to stop. Then, an automated system moves over his car on a track, composed of car-wash equipment performing specific functions, such as washing, polishing and drying. These three functions are independent. It means that different machines can simultaneously work on different cars. Polishing is a facultative option. Moreover, some exterior services are available. Namely, clients can use a coin operated vacuum cleaner at the end of these processes for customer self use. After payment, the vacuum cleaner works during 10 minutes. A large parking allows customers to wait for the vacuum cleaner if it is busy. Finally, the company provides complete detailing services in a shop adjacent to the car wash. The shop sells various washing products: shampoo, vacuum cleaner, wax, towels, … . Payment for the car wash service is done in this shop. This ensures that each car-wash client will go to the shop.

The Staff The staff of the car wash of Ottignies is composed of one manager, one cleaner and one shop seller.

Maintenance Every day, the vacuum cleaner requires 2 maintenances. One maintenance lasts 20 minutes and is carried out by the manager of the shop. One vacuum cleaner is currently available at the shop of Ottignies. The operations

The company is open six days a week, 48 weeks a year. A day is made of 7 hours.

The demand In this market, the demand fluctuates with the seasons (One season = 12 weeks). The following table and figure give historical demand for the car wash services (with and without polishing). Half of the customers require the polishing option and 4/5 of the customers require the vacuum cleaner.

Season Periods Number of required services (including without polishing and with polishing) Summer 2001 1 2010 Autumn 2001 2 2056 Winter 2002 3 2295 Spring 2002 4 1944 Summer 2002 5 2187 Autumn 2002 6 2257 Winter 2003 7 2511 Spring 2003 8 2159 Summer 2003 9 2395 Autumn 2003 10 2445 Winter 2004 11 2708 Spring 2004 12 2339

Past demand for the car wash services 2750 2700 Past demand 2650 2600 2550 2500 2450 2400 2350 2300 2250 2200 2150 2100 2050 2000 1950 1900 0 1 2 3 4 5 6 7 8 9 10 11 12 13 Seasons The cleaning product The company is very careful about the inventory management for the cleaning product that is used in the pre-washing and washing machines. For this critical raw material, the company has a specific supplier. The cleaning product costs 1 euro by liter. Washing one car requires one liter of cleaning products.

For the cleaning product, the car wash has a limited capacity of storage of 2000 liters.

The manager of the car wash can order at any time to the supplier. 3 days are required to deliver the products. Transport cost for an order (independent of the quantity) is 7 euros. The administration cost (paper work, reception and control of the goods) is 3 euros per order. The yearly storage cost (warehouse, insurance, ...) is 20 % of the stored value and the yearly opportunity cost of the money is 20 %. Question 1

1) What are the maximum daily productivity and the average daily productivity of the car wash system? 2) Might a buffer be useful? a. If yes, where should it be placed? b. What do you save?

1) Max daily production = 1 car every 5 minutes Average daily production = 1 car every 6,125 min.=5*(1/4)+ ((5+8)/2)*(3/4) During ¼ of the time, the cleaner is the slowest one, during ¾ of the time, the washing machine is the slowest one. 2) Yes between the cleaner and the washing machine. It eliminates the starved time of the washing machine when the cleaner is slower. The production rate would be equal to 1 car every 6 minutes. Question 2 1) Which forecasting model is the most appropriate for the demand of the car- wash services? 2) Assuming the regression method, calculate approximately the parameters of the model. 3) How accurate is your model? 4) Using this model, give an estimation of the demand for summer 2004.

1) Additive and seasonal model with increasing trend. 2) Ft = a+bt+ctmodT With a = 1950, b = 50, csummer = 0, cautumn = 0, cwinter = 200, cSpring = -200

Season Period Past Demand Model et |et| t Dt Ft Summer 2001 1 2010 2000 10 10 Autumn 2001 2 2056 2050 6 6 Winter 2002 3 2295 2300 -5 -5 Spring 2002 4 1944 1950 -6 -6 Summer 2002 5 2187 2200 -13 -13 Autumn 2002 6 2257 2250 7 7 Winter 2003 7 2511 2500 11 11 Spring 2003 8 2159 2150 1 1 Summer 2003 9 2395 2400 -5 -5 Autumn 2003 10 2445 2450 -5 -5 Winter 2004 11 2708 2700 8 8 Spring 2004 12 2339 2350 -11 -11

3) et = Dt-Ft

MAD = |et|/n = 96/12 = 8

TSE = et/MAD = 6/8 = 0,71 The model seems to be accurate.

4) F13(summer2004) = a+b*13+csummer = 1950 + 50*13 + 0 = 2600 Question 3 The manager of the car wash makes these following propositions in order to improve the customer service: 1) First, he proposes that the cleaner will be responsible for collecting the payment. Henceforth, customer will pay at the cleaner at the beginning of the car-wash process. Thus, the shop seller will not intervene in the car-wash process and customer has not to go to the shop. 2) Second, he proposes to buy one extra vacuum cleaner.

How do you evaluate these propositions? What are the consequences of these changes?

1) This first proposition reduces the production rate (1 car every 9 minutes). This reduces the available capacity of the car wash. Now, the available capacity is = 420 min*12weeks*6days/6,125 = 4937 cars a day With this proposition : 420*12*6 / 9 = 3360 cars a day (very close to the real demand).

Moreover, the shop might be less visited (customers have not to go to the shop). It might reduce the sales.

2) This second proposition increases the available capacity of the vacuum cleaner service : Now, the available capacity in minutes for one day is (7h*60 min)-40 min = 380 min/day the available capacity in minutes for one season is 380min*12weeks*6 = 27360 min/season the available capacity in cars for one season is 27360 min/10 min = 2736 cars/season The demand of the vacuum cleaner for summer 2004 is 4/5 *2600 = 2080 cars So, in terms of capacity, we have enough capacity with one vacuum cleaner.

Nevertheless, in term of service quality, this strategy may be useful in term of customer waiting time: - We can reduce the waiting time in the parking for the vacuum cleaner - More particularly, during the maintenance, customers should no more wait for the vacuum cleaner, they can use the new one. Question 4

Currently, customers go to the car wash without reservation. Would you suggest that the company works with an appointment system? Explain. (An appointment system means that customers need to call to make a reservation)

Demand may fluctuate during the day. So this suggestion could reduce the customer waiting time. Moreover, this system may be useful in order to better regulate the arrivals of customers and to better organize the customer service. Nevertheless, it assumes that customers agree to call the car wash in order to make a reservation. Question 5

Currently (summer 2004), the manager of the car wash orders 1000 liters of cleaning products when the available capacity of products is 1000 liters (to replenish the inventory to 2000 liters). The manager does not wish to have more than one stockout every 5 years.

1) Are the values of the parameters, which are selected for the ordering policy by the manager, optimal in terms of management costs? If these values are not optimal, give the parameters (when and how many to order) of an optimal management. 2) To which fill rate does the above-calculated optimal ordering policy lead? 3) Default of delivery: Due to technical reasons, the supplier delivers less cleaning product than expected. If this problem turns out to be frequent, what impact would that have on annual stockout frequency and on the fill rate? Please comment/explain your answer.

F13(summer2004) = µ 1season = 2600 µ 3`days=LT = 2600*3/(12*6) = 108

MAD12= 8 1season =1,25*MAD = 10 3`days = 10*sqrt(3/(12*6)) = 2 1) O = 10, H = 0,2+0,2 (for one year) Q = Sqrt(2*10*2600/(0,4/4)) = 721 Litre. F = 2600*4/721 = 15 orders/year

P(X>R) = x = 1/5 = 1/5/15 = 0;0133 z = 2,2 SS = 2,2*2 = 4,4 R =µ LT + SS = 108+ 4,4 = 112,4

The current strategy of the car wash manager is not optimal. The inventory cost is too high.

2) E(z) = Q(1-)/ LT

E(z) = 0,0049, LT = 2,2, Q = 721 1- = 0,0049 * 2/721 = 0, 0000…% = 99,9999%

3) The number of orders during one year will be higher (F increases) the annual stockout frequency increases and the fill rate increases. Distribution normale N(0,1) z = nombre d'écarts types P(z) = Prob [ x ³ z ] = p (x) dx z N (0,1) E(z) = nombre moyen de manquants = (x z) p (x) dx z N (0,1) z P(z) E(z) E(-z) 0,0000 0,5000 0,3989 0,3989 0,1000 0,4602 0,3509 0,4509 0,2000 0,4207 0,3069 0,5069 0,3000 0,3821 0,2668 0,5668 0,4000 0,3446 0,2304 0,6304 0,5000 0,3085 0,1978 0,6978 0,6000 0,2743 0,1687 0,7687 0,7000 0,2420 0,1429 0,8429 0,8000 0,2119 0,1202 0,9202 0,9000 0,1841 0,1004 1,0004 1,0000 0,1587 0,0833 1,0833 1,1000 0,1357 0,0686 1,1686 1,2000 0,1151 0,0561 1,2561 1,3000 0,0968 0,0455 1,3455 1,4000 0,0808 0,0367 1,4367 1,5000 0,0668 0,0293 1,5293 1,6000 0,0548 0,0232 1,6232 1,7000 0,0446 0,0183 1,7183 1,8000 0,0359 0,0143 1,8143 1,9000 0,0287 0,0111 1,9111 2,0000 0,0228 0,0085 2,0085 2,1000 0,0179 0,0065 2,1065 2,2000 0,0139 0,0049 2,2049 2,3000 0,0107 0,0037 2,3037 2,4000 0,0082 0,0027 2,4027 2,5000 0,0062 0,0020 2,5020 2,6000 0,0047 0,0015 2,6015 2,7000 0,0035 0,0011 2,7011 2,8000 0,0026 0,0008 2,8008 2,9000 0,0019 0,0005 2,9005 3,0000 0,0014 0,0004 3,0004 3,1000 0,0010 0,0003 3,1003 3,2000 0,0007 0,0002 3,2002 3,3000 0,0005 0,0001 3,3001 3,4000 0,0003 0,0001 3,4001 3,5000 0,0002 0,0001 3,5001 3,6000 0,0002 0,0000 3,6000 3,7000 0,0001 0,0000 3,7000 3,8000 0,0001 0,0000 3,8000 3,9000 0,0001 0,0000 3,9000 4,0000 0,0000 0,0000 4,0000