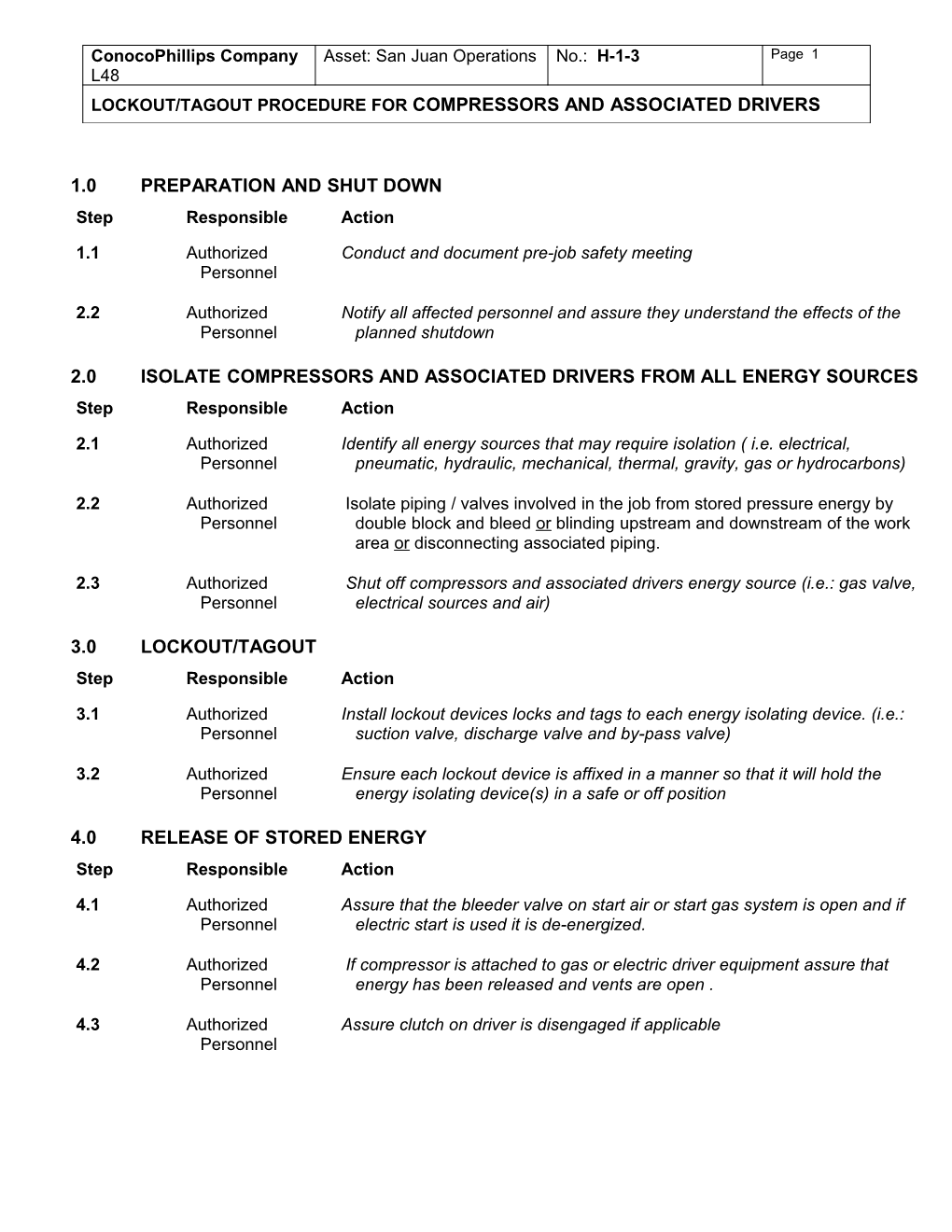

ConocoPhillips Company Asset: San Juan Operations No.: H-1-3 Page 1 L48 LOCKOUT/TAGOUT PROCEDURE FOR COMPRESSORS AND ASSOCIATED DRIVERS

1.0 PREPARATION AND SHUT DOWN Step Responsible Action

1.1 Authorized Conduct and document pre-job safety meeting Personnel

2.2 Authorized Notify all affected personnel and assure they understand the effects of the Personnel planned shutdown

2.0 ISOLATE COMPRESSORS AND ASSOCIATED DRIVERS FROM ALL ENERGY SOURCES Step Responsible Action

2.1 Authorized Identify all energy sources that may require isolation ( i.e. electrical, Personnel pneumatic, hydraulic, mechanical, thermal, gravity, gas or hydrocarbons)

2.2 Authorized Isolate piping / valves involved in the job from stored pressure energy by Personnel double block and bleed or blinding upstream and downstream of the work area or disconnecting associated piping.

2.3 Authorized Shut off compressors and associated drivers energy source (i.e.: gas valve, Personnel electrical sources and air)

3.0 LOCKOUT/TAGOUT Step Responsible Action

3.1 Authorized Install lockout devices locks and tags to each energy isolating device. (i.e.: Personnel suction valve, discharge valve and by-pass valve)

3.2 Authorized Ensure each lockout device is affixed in a manner so that it will hold the Personnel energy isolating device(s) in a safe or off position

4.0 RELEASE OF STORED ENERGY Step Responsible Action

4.1 Authorized Assure that the bleeder valve on start air or start gas system is open and if Personnel electric start is used it is de-energized.

4.2 Authorized If compressor is attached to gas or electric driver equipment assure that Personnel energy has been released and vents are open .

4.3 Authorized Assure clutch on driver is disengaged if applicable Personnel ConocoPhillips Company Asset: San Juan Operations No.: H-1-3 Page 2 L48 LOCKOUT/TAGOUT PROCEDURE FOR COMPRESSORS AND ASSOCIATED DRIVERS

5.0 VERIFICATION OF ISOLATION AND TRY Step Responsible Action

5.1 Authorized Ensure that there is no re-accumulation of stored energy Personnel

5.2 Authorized Try starting unit Personnel

6.0 RELEASE FROM LOCKOUT/TAGOUT

Step Responsible Action 6.1 Authorized Ensure that equipment has been appropriately serviced or repaired Personnel 6.2 Authorized Remove all non-essential items from the work area Personnel 6.3 Authorized Ensure compressor and associated driver components are operationally Personnel intact 6.4 Authorized Assure all personnel are safely positioned or clear from the area Personnel 6.5 Authorized Remove lockout devices locks and tags Personnel

6.6 Authorized Notify all affected personnel that the lockout and tagout devices have been Personnel removed

6.7 Authorized Re-energize compressor and associated driver Personnel

6.8 Authorized Start up compressor and associated driver Personnel

6.9 Authorized Notify affected personnel and put equipment back in service Personnel

7.0 VERIFICATION OF ISOLATION 7.1 Authorized Refer to attached checklist for verification of isolation. Personnel ConocoPhillips Company Asset: San Juan Operations No.: H-1-3 Page 3 L48 LOCKOUT/TAGOUT CHECKLIST FOR COMPRESSORS AND ASSOCIATED DRIVERS

EQUIPMENT DESCRIPTION: COMPRESSORS & ASSOCIATED LOCATION: DRIVERS/ENGINES CHECKLIST AUTHORIZED Employee(s): AFFECTED Employee(s): Each AUTHORIZED employee shall: 1) Make a survey to locate and identify all energy isolating devices; 2) Notify all AFFECTED employees of the planned shutdown; 3) Understand the effects of the planned shutdown; 4) Verify the equipment is isolated; 5) Verify isolation and de-energization; and 6) Affix their own lockout device(s) to each energy isolating device. Sequence of Energy Isolation: (Types of Energy Sources and Hazards that may require isolation: electrical, pneumatic, hydraulic, mechanical, thermal, chemical, gravity, hydrocarbons, toxic vapors, etc.) 1. Preparation and Shutdown: Yes No n/a All energy isolating devices identified? All AFFECTED employees notified and understand the effects of the planned shutdown? 2. Isolate Equipment From All Energy Sources by the Appropriate Method: Potential Energy Sources and Hazards: Sequence and Methods of Energy Isolation: Hydrocarbons/Gas Compressor: Isolate block valves for all inlet and discharge compressor stages? Verify local gauges are at zero energy state? Blind and tag piping for all inlet and discharge compressor stages if Hot work is required? By-pass valve open? Isolate make-up gas block valve? Gas supply block valve closed? Gas supply block valve closed, disconnected or tagged and blinded if Hot Work is required? Drain lines block valve closed? Drain lines block valve closed, disconnected or tagged and blinded if Hot Work is required? Driver: Gas supply fuel/starting block valve closed? Verify local gauges are at zero energy state? Gas supply fuel/starting block valve closed, disconnected or tagged and blinded if Hot Work is required? Drain lines block valve closed? Drain lines block valve closed, disconnected or blinded if Hot Work is required? Electrical Compressor: Circuit breaker to external oil/sump/pre-lube pumps locked and tagged out? Verify with voltage meter that energy state is at zero? Cathodic turned off? Heat trace turned off? Driver: Circuit breaker to electric driver locked and tagged out? Starting battery terminals disconnected tagged and locked together. Circuit breaker to external oil/sump/pre-lube pumps locked out? Magneto disconnected? Mechanical Flywheel locked or blocked in place on integral engine or on a unit with potential for movement? ConocoPhillips Company Asset: San Juan Operations No.: H-1-3 Page 3 L48 LOCKOUT/TAGOUT CHECKLIST FOR COMPRESSORS AND ASSOCIATED DRIVERS

Thermal Driver/Compressor: Jacket water heat dissipated? Piping/equipment under insulation heat dissipated? Pneumatic Driver: Block valve closed to start air/gas system? Toxic Vapors Area checked for flammable and toxic vapors? 3. Lockout and Tag out: Lockout and tag-out device(s) affixed to each energy isolating device or to the lockbox (if the group lockout procedure is used) by each Authorized employee?

Each lockout and tag-out device affixed in a manner so that it will hold the energy isolating device(s) in a "safe" or "off" position. 4. Relieve, Disconnect, Restrain, or Otherwise Render Safe Stored Energy: Compressor vent valve opened and residual pressure blown down? Bleeder on start air/gas system opened and residual pressure blown down and if electric start system is used it is de-energized? 5. Verify Isolation Prior to Starting Work on the Equipment: Look and listen for residual pressure dissipating through vents and bleeder? Start air/gas valve on control panel opened? Pull/push button on control panel opened? Isolation of equipment verified by Authorized employee(s)? (If there is a possibility of a re-accumulation of stored energy to a hazardous level, verification of isolation shall be continued until the servicing or maintenance is complete.) 6. Release from Lockout and Tag out: Equipment components operationally intact? Equipment checked to determine if it has been appropriately serviced or repaired? Non-essential items removed? All employees safely positioned or clear from the area? Affected employees notified that the lockout or tagout devices are to be removed? Each lockout and tagout device removed from each energy isolating device by the employee who applied the device? Equipment startup or system re-energized? Equipment put back in service? Affected employees notified that the equipment is returned to service?