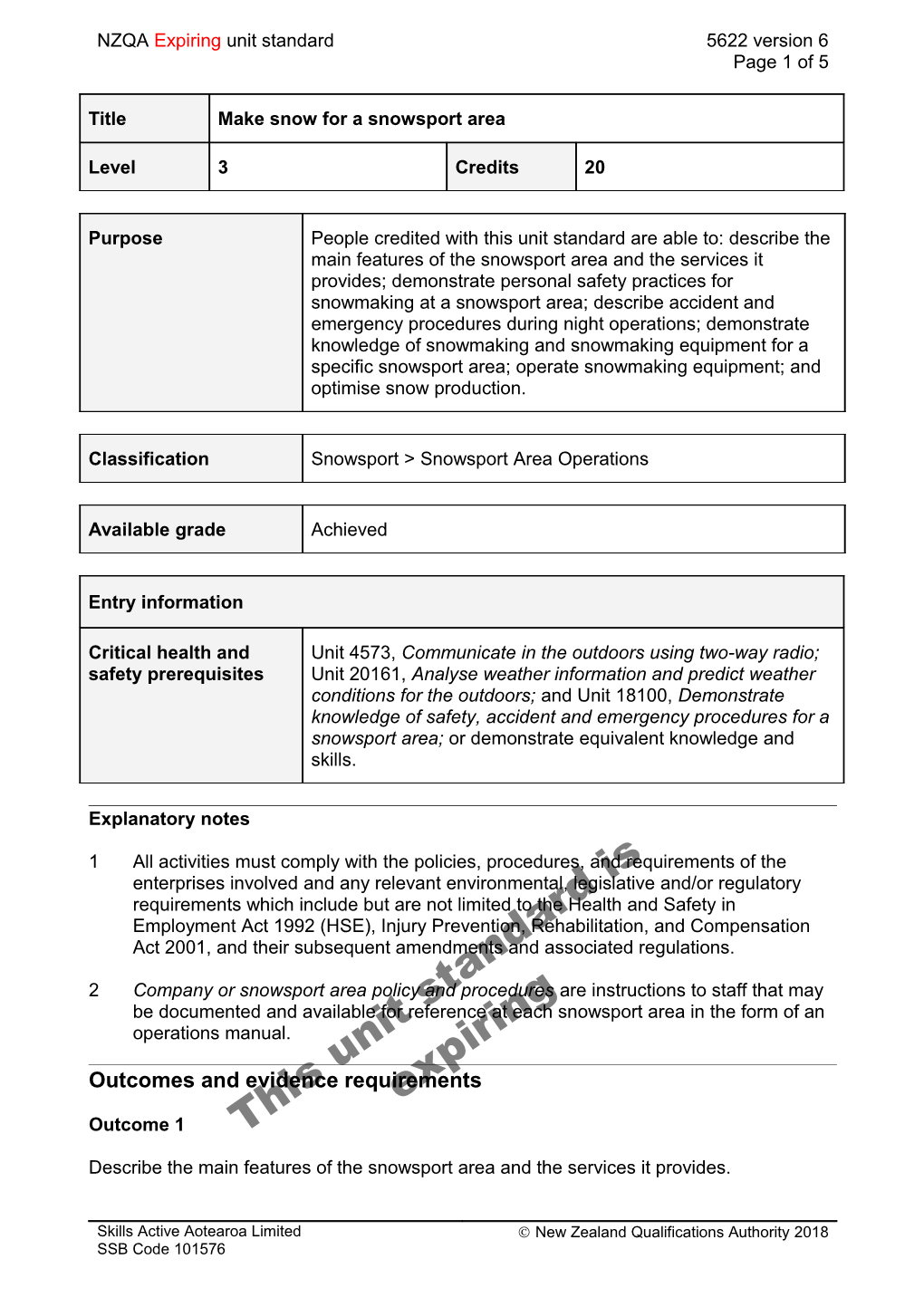

NZQA Expiring unit standard 5622 version 6 Page 1 of 5

Title Make snow for a snowsport area

Level 3 Credits 20

Purpose People credited with this unit standard are able to: describe the main features of the snowsport area and the services it provides; demonstrate personal safety practices for snowmaking at a snowsport area; describe accident and emergency procedures during night operations; demonstrate knowledge of snowmaking and snowmaking equipment for a specific snowsport area; operate snowmaking equipment; and optimise snow production.

Classification Snowsport > Snowsport Area Operations

Available grade Achieved

Entry information

Critical health and Unit 4573, Communicate in the outdoors using two-way radio; safety prerequisites Unit 20161, Analyse weather information and predict weather conditions for the outdoors; and Unit 18100, Demonstrate knowledge of safety, accident and emergency procedures for a snowsport area; or demonstrate equivalent knowledge and skills.

Explanatory notes

1 All activities must comply with the policies, procedures, and srequirements of the enterprises involved and any relevant environmental, legislative i and/or regulatory requirements which include but are not limited to ther Healthd and Safety in Employment Act 1992 (HSE), Injury Prevention, Rehabilitation,a and Compensation Act 2001, and their subsequent amendments andd associated regulations. an 2 Company or snowsport area policy andst proceduresg are instructions to staff that may be documented and available fort reference at neach snowsport area in the form of an operations manual. i ri un pi Outcomes and evidences requirementsx hi e Outcome 1 T Describe the main features of the snowsport area and the services it provides.

Skills Active Aotearoa Limited Ó New Zealand Qualifications Authority 2018 SSB Code 101576 NZQA Expiring unit standard 5622 version 6 Page 2 of 5

Evidence requirements

1.1 Services provided by the company or snowsport area are explained in terms of how the snowmaking operation impacts on other operations within the company or snowsport area.

Range other operations may include – lift operation, patrol, racing, maintenance, snowgrooming department.

1.2 Major natural and artificial features of the snowsport area, including identification of access routes to each feature, are described.

Range natural features may include but are not limited to – peaks, valleys, gullies, bluffs, streams, tarns; artificial features may include but are not limited to – runs, boundaries, lift lines, buildings, snowmaking hydrants, water reservoir.

1.3 Hazardous areas and/or conditions, and operating procedures in or near such areas within the snowsport area, are described and comply with snowsport area or company policy.

Range hazards may include but are not limited to – potential avalanche start zones and paths, waterlogged snow, icy snow, soft snow, steep slopes, machinery, restricted areas.

Outcome 2

Demonstrate personal safety practices for snowmaking at a snowsport area.

Evidence requirements

2.1 Safe work practices are followed during snowmaking operation, and comply with company or snowsport area policy and procedures. Range during operation of snowmaking – workings near snowgroomers, lifts, other slope users, in the workshop, i while working with vehicles or machinery, while workingd at night, while working with pressurised air and water, anda electricity;r practices may include but ared not limited to – use of mountain clothing, footwear, buddyn system. ta 2.2 During snowmaking operations s communicationsg are maintained with relevant staff, using two-way radio, andt practice icompliesn with company procedures. ni ir Range may includeu but is notp limited to – supervisor, base personnel, others workers. x hi e 2.3 Steps areT created, and provide secure footing for climbing, descending, or traversing a snow-slope.

Range may include – crampons, ice axe.

Skills Active Aotearoa Limited Ó New Zealand Qualifications Authority 2018 SSB Code 101576 NZQA Expiring unit standard 5622 version 6 Page 3 of 5

Outcome 3

Describe accident and emergency procedures during night operations.

Evidence requirements

3.1 Actions of snowmaking personnel in the event of an accident or injury are described according to company or snowsport area procedures.

Range may include but is not limited to – personal injury, fire, power or equipment failure, avalanche event, electrical cable failure.

3.2 Actions of snowmaking personnel are described in the event of an emergency according to company or snowsport area procedures.

Range emergencies may include but is not limited to – slide, avalanche, lahar.

3.3 Key company or snowsport area personnel, to whom a report would be made in the event of an accident or injury, are identified.

3.4 Key points and details for inclusion in an accident report are identified according to company or snowsport area requirements.

Outcome 4

Demonstrate knowledge of snowmaking and snowmaking equipment for a specific snowsport area.

Evidence requirements

4.1 An overview of the snowmaking process is outlined with reference to how machine snow is made.

4.2 The components and capacity of the snowsport area's snowmaking system are described using technical terms, with reference to the function of each component. is d Range water supply, pump system, snowguns,r air compressors. da 4.3 The location of snowmaking hydrants,n and their use, are described using recognised terminology. ta s g 4.4 Main factors that affect thei ttype and qualityin of snow are identified, with options identified for snowmakingn in a rangei ofr situations. u xp Range wetis bulb temperature,e ambient air temperature, wind speed, wind hdirection, humidity and evaporation, water temperature, air T temperature and pressure, water volume and droplet size, hang time; may also include – compressed air temperature, additives.

Skills Active Aotearoa Limited Ó New Zealand Qualifications Authority 2018 SSB Code 101576 NZQA Expiring unit standard 5622 version 6 Page 4 of 5

Outcome 5

Operate snowmaking equipment.

Evidence requirements

5.1 Snowmaking equipment is transported, set-up, and secured according to company procedures, with safety fencing and/or signs erected to advise customers, workers, and groomers, in accordance with company policy and procedures.

5.2 A routine maintenance check of the snowmaking components is completed prior to operation, in accordance with manufacturer's recommendations and company or snowsport area policy and procedures.

Range routine maintenance check may include – oil levels, electrical connections, air compressor and/or fan, water hoses and nozzles, valves, hydrants, meters, gauges, brakes, tow-bar, wheels and tyres, frame, nucleator.

5.3 Snowmaking equipment is cleared of ice where required, and started up in sequence, according to manufacturer's operating instructions and company procedures.

5.4 Snowmaking equipment is shutdown in sequence, according to manufacturer's operating instructions and company procedures.

5.5 Operational and maintenance logs are completed according to company or snowsport area requirements.

5.6 Snowmaking equipment is operated to ensure personal safety in a variety of conditions and according to snowsport area policy and procedures and manufacturer’s operating instructions.

Range conditions may include but are not limited to – steep slopes; icy, windy, slippery conditions; electrical hazards. is Outcome 6 d ar Optimise snow production. nd Evidence requirements ta s g 6.1 Weather data is collected ilocallyt beforei andn during snowmaking, and the information is analysedn for snowmaking.ir u xp Range humidity,is temperatures,e wind strength, wind direction, local Thclimatic conditions.

Skills Active Aotearoa Limited Ó New Zealand Qualifications Authority 2018 SSB Code 101576 NZQA Expiring unit standard 5622 version 6 Page 5 of 5

6.2 Adjustments made to the snowgun match the analysis of weather information and snow quality.

Range temperature, wind strength, wind direction, humidity.

6.3 Snow quality is controlled using operating adjustments, to the standard required by the company or snowsport area.

Range adjustments may include but are not limited to – size of nozzles, water pressure, nucleator adjustment, gun direction, gun position.

This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below.

Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 23 November 1995 31 December 2019 Revision 2 24 July 1996 31 December 2019 Revision 3 19 February 1998 31 December 2019 Review 4 28 March 2001 31 December 2019 Review 5 29 June 2005 31 December 2019 Review 6 20 April 2017 31 December 2019

Consent and Moderation Requirements (CMR) reference 0099 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. is Industry Training Organisations must be granted consent tod assess against standards by NZQA before they can register credits from assessment againstr unit standards. da Providers and Industry Training Organisations, whichn have been granted consent and which are assessing against unit standards tmusta engage with the moderation system that applies to those standards. s g it in Requirements for consent to assessn and an outlineir of the moderation system that applies to this standard are outlined in uthe Consentx pand Moderation Requirements (CMR). The CMR also includes usefuli informations eabout special requirements for organisations wishing to develop education andh training programmes, such as minimum qualifications for tutors and assessors, andT special resource requirements.

Skills Active Aotearoa Limited Ó New Zealand Qualifications Authority 2018 SSB Code 101576