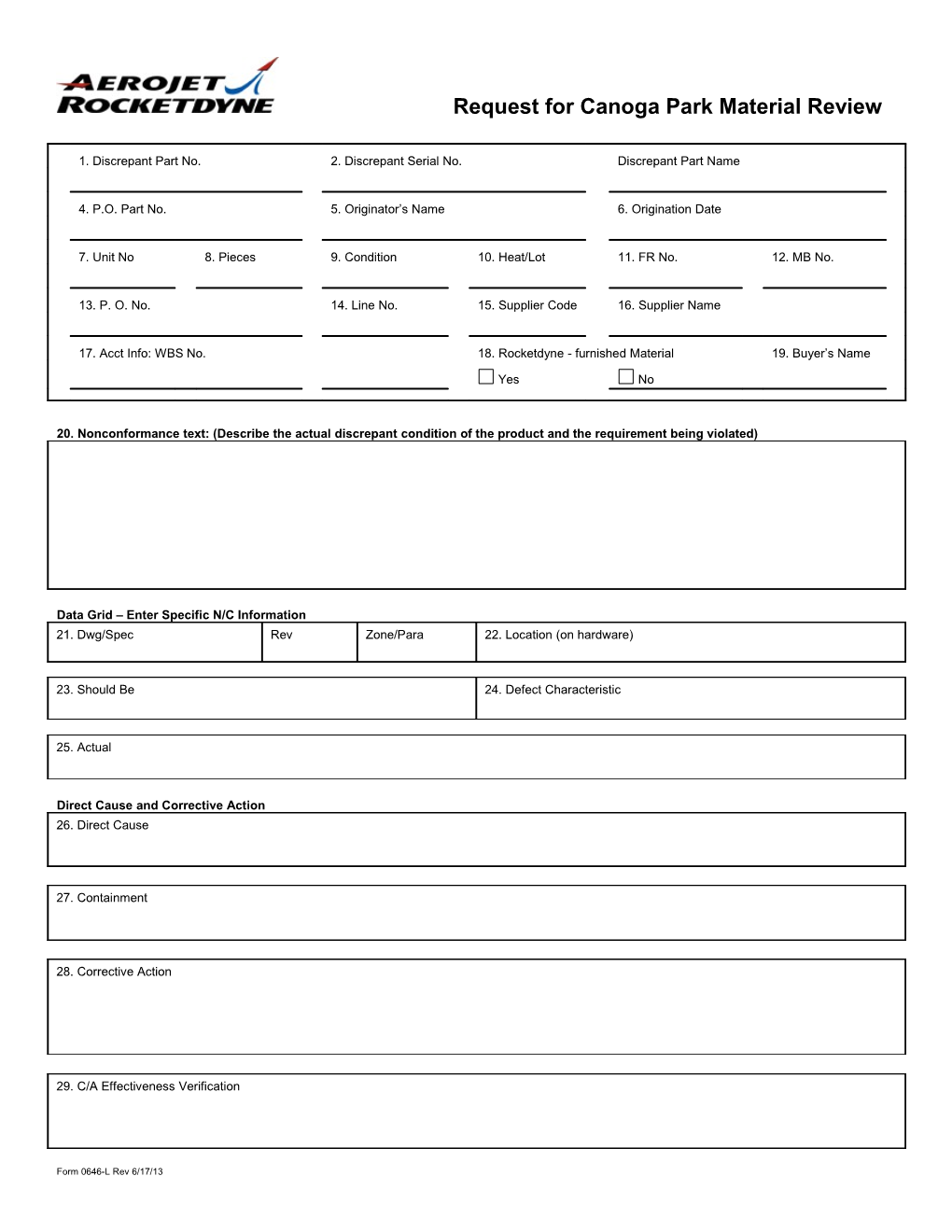

Request for Canoga Park Material Review

1. Discrepant Part No. 2. Discrepant Serial No. Discrepant Part Name

4. P.O. Part No. 5. Originator’s Name 6. Origination Date

7. Unit No 8. Pieces 9. Condition 10. Heat/Lot 11. FR No. 12. MB No.

13. P. O. No. 14. Line No. 15. Supplier Code 16. Supplier Name

17. Acct Info: WBS No. 18. Rocketdyne - furnished Material 19. Buyer’s Name

Yes No

20. Nonconformance text: (Describe the actual discrepant condition of the product and the requirement being violated)

Data Grid – Enter Specific N/C Information 21. Dwg/Spec Rev Zone/Para 22. Location (on hardware)

23. Should Be 24. Defect Characteristic

25. Actual

Direct Cause and Corrective Action 26. Direct Cause

27. Containment

28. Corrective Action

29. C/A Effectiveness Verification

Form 0646-L Rev 6/17/13 Request for Canoga Park Material Review Instructions This entry clarifies the discrepant part number. It may or may not be the same as an assembly part number on the purchase order. It will be different when the 1 Discrepant Part No. nonconforming part is an unattached component issued to an assembly. When a detail is welded or otherwise attached; the discrepant part is the assembly. This entry may have only one discrepant part number. This entry is for the discrepant serial number. Record all nonconforming serial 2 Discrepant Serial No. numbers. Use Rocketdyne unique serial numbers if provided. 3 Discrepant Part Name Record this name from the Engineering drawing or purchase order. This entry is the part number that is being procured by Rocketdyne. It may or may 4 P.O. Part No. not be the same as Block No 1. 5 Originator’s Name This entry records the name of the person initiating this request. 6 Origination Date Record the date this request was initiated. When designated by the purchase order, record the unit number assigned to this 7 Unit No. hardware. 8 Pieces Enter the number of discrepant pieces. 9 Condition Record New unless the purchase order indicates hardware is being refurbished. 10 Heat/Lot Record as applicable. Enter NA if not applicable. 11 FR No. Record the forging number as applicable. Enter NA if not applicable. 12 MB No. Record the “Make from” or raw material as applicable. Enter NA if not applicable. 13 P.O. No. Record the purchase order number. 14 Line No. Record the Line Item number from the purchase order. 15 Supplier Code Record the Supplier code from the purchase order. Record the Supplier name from the purchase order. Do not record sub-tier 16 Supplier Name sources. 17 Acct Info: WBS No. Record account information “WBS number” from the purchase order. 18 Rocketdyne Furnished Material Check Yes or No if material provided by Rocketdyne. 19 Buyer’s name Record the name of the Rocketdyne buyer from the purchase order. Describe what condition does not comply with the Rocketdyne drawing or specification. Include the requirement, the feature callout, location (I.D., O.D., 20 Nonconformance text Radius, Profile, etc) actual measurements (size and/or dimension) and any tolerance specified.

Data Grid Information (for Rocketdyne Data Tracking)

21 Dwg/Spec Record the drawing or specification of the requirement being violated. Rev Record the revision letter of the drawing or specification of the requirement. Zone/Para Record the drawing zone or paragraph which imposes the requirement. Enter the feature affected (I.D., O.D., Radius, Profile, etc). 22 Location Enter NA if not applicable. Enter the condition that complies with the drawing. Example: 1.500 max, 23 Should be No Dents allowed, Clean per RL100001, etc. 24 Defect Characteristic Enter the type of defect. Example: Dim, Damage, Materail Defect, etc. Enter the existing condition and measurement Example: Oversize, Undersize, Not 25 Actual Inspected, etc.

Cause and Corrective Action

Enter a brief description that resulted in the nonconformance. Example: Planning 26 Direct Cause Statement error, Operator inattention, Material not available, etc. Enter containment actions, extent of other parts affected, rationale for bounding of 27 Containment affected product by this cause of nonconformance. Enter corrective action taken to prevent recurrence. Ex: Planning master changed, Tool repaired, Sub tier has been notified of nonconformance, etc. Also indicate which level (1, 2, or 3) of “mistake proofing” you consider your corrective action is. 28 Corrective Action Level 1= Prevent an error from occurring at the source (e.g. one-way assemblies, automatic calculations), Level 2: Detect the error as it is being made (e.g. alarms sound), Level 3: Stop the defect from reaching the next operation providing the mistake proof solution is used (e.g. checklist, inspection point) Enter brief description of plan to verify that corrective actions will prevent 29 C/A Effectiveness Verification recurrence. Ex: ran test parts to verify improvement changes, will monitor next 3 parts, will perform added inspection at affected operation upon next order, etc.

E-mail (encrypted only), mail or fax this request to Rocketdyne buyer

Form 0646-L Rev 6/17/13