UNIVERSITY OF CENTRAL LANCASHIRE

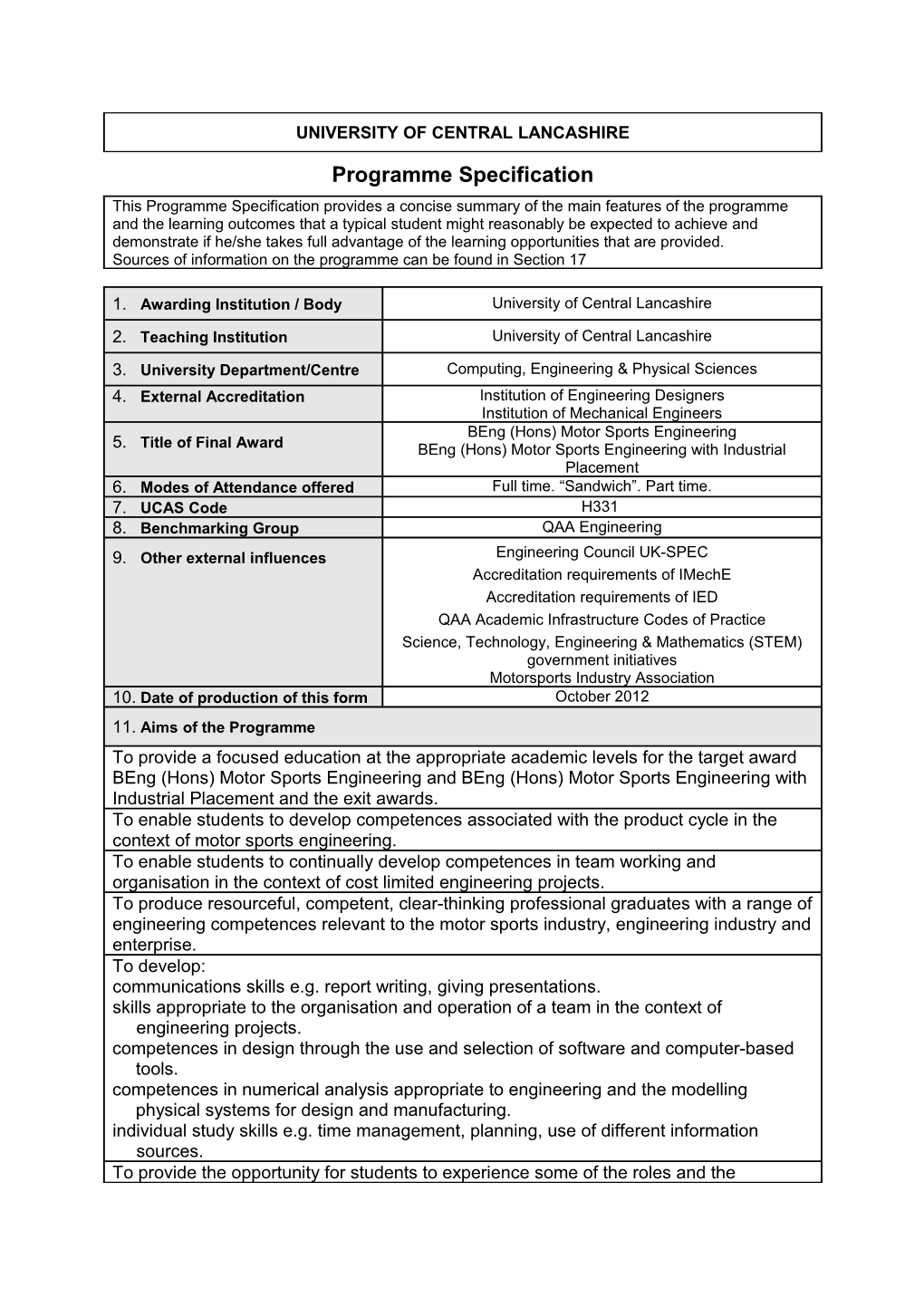

Programme Specification This Programme Specification provides a concise summary of the main features of the programme and the learning outcomes that a typical student might reasonably be expected to achieve and demonstrate if he/she takes full advantage of the learning opportunities that are provided. Sources of information on the programme can be found in Section 17

1. Awarding Institution / Body University of Central Lancashire

2. Teaching Institution University of Central Lancashire

3. University Department/Centre Computing, Engineering & Physical Sciences 4. External Accreditation Institution of Engineering Designers Institution of Mechanical Engineers BEng (Hons) Motor Sports Engineering 5. Title of Final Award BEng (Hons) Motor Sports Engineering with Industrial Placement 6. Modes of Attendance offered Full time. “Sandwich”. Part time. 7. UCAS Code H331 8. Benchmarking Group QAA Engineering 9. Other external influences Engineering Council UK-SPEC Accreditation requirements of IMechE Accreditation requirements of IED QAA Academic Infrastructure Codes of Practice Science, Technology, Engineering & Mathematics (STEM) government initiatives Motorsports Industry Association 10. Date of production of this form October 2012 11. Aims of the Programme To provide a focused education at the appropriate academic levels for the target award BEng (Hons) Motor Sports Engineering and BEng (Hons) Motor Sports Engineering with Industrial Placement and the exit awards. To enable students to develop competences associated with the product cycle in the context of motor sports engineering. To enable students to continually develop competences in team working and organisation in the context of cost limited engineering projects. To produce resourceful, competent, clear-thinking professional graduates with a range of engineering competences relevant to the motor sports industry, engineering industry and enterprise. To develop: communications skills e.g. report writing, giving presentations. skills appropriate to the organisation and operation of a team in the context of engineering projects. competences in design through the use and selection of software and computer-based tools. competences in numerical analysis appropriate to engineering and the modelling physical systems for design and manufacturing. individual study skills e.g. time management, planning, use of different information sources. To provide the opportunity for students to experience some of the roles and the responsibilities within a professional race team. To satisfy the Engineering Council requirements for a BEng (Hons) for CEng.

VSMSEN101 BEMSE FT VSMSEN102 MEMSE FT 12. Learning Outcomes, Teaching, Learning and Assessment Methods

UK Standard for Professional Engineering Competence (UK-SPEC) UK-SPEC is the standard for recognition of professional engineers and professional engineering technicians in the UK. The standard is published by ECUK on behalf of the engineering profession. UK-SPEC recommends general learning outcomes (GLO) and specific learning outcomes (SLO) for degree courses that are consistent with the learning outcomes that exist for UCLAN courses. The following sections A,B, C, and D are written in the UCLAN format with reference made to the corresponding GLOs AND SLOs in UK-SPEC. The GLOs are embodied within the various SLOs – the GLOs listed below are those that are given greatest emphasis. A. Knowledge and Understanding includes A1. Engineering science (shape, materials properties, loads, deformation) (UK-SPEC:GLO: K&U1, K&U2, K&U2, IA1i, IA1, IA2, IA3, TS1, TS2 UK-SPEC:SLO US1, E1,E2, E3, E4, P4) A2. Engineering design and manufacturing (processes and technology) (UK-SPEC:GLO: PS1, PS1i, TS1, TS2, SLO: US3, P1, P2, P4) A3. The principles, implications and limitations of ITC and of developing technologies in ICT (UK-SPEC: K&U3, GLO: SLO: US2) A4. Management and organisation of the commercial and economic resources for design and manufacturing within the product cycle (UK-SPEC:GLO: IA3, TS2, TS3, UK-SPEC:SLO D3, S1, S2, P3, P5, P6, P7) A5. Evaluate the basis and effects of commercial risks (UK-SPEC:GLO:K&U3, IA3, UK-SPEC:SLO D1, D2) Teaching and Learning Methods Stage 1 includes lectures, seminars, individual assignments with a small number of group assignments. There are three hours per week in the student workshops with workbooks and a design and make project to develop experience of taking a product through a number of manufacturing processes. Use is made of specialist equipment within Wharf Building to introduce engineering principles. Stage 2 includes individual and team assignments and projects of increasing complexity some involving the use of software such as SolidWorks, Arena, CosmosWorks and CFD. Use is made of the specialist equipment within Wharf Building to further develop competences and expertise around the product cycle and a belief in the fundamental relationships in engineering science, design, manufacture, management and organisation. Assessment methods Stage 1 includes three formal end of year examinations, practical assignments and report, workbooks, presentations, small assignments. Stage 2 includes reports, group work, individual working, designing, manufacturing, viva voce, portfolios and associated commentaries, major project research and decomposition, planning, assessing individual and group profiles and use of technology associated with design and manufacture such as CAD and operations software. There are two formal examinations at level five and one formal examination at level six. One third of the final year is concerned with developing a car for the Formula Student competition. This requires considerable development of individual and group learning competences, critical appraisal and reflection of organisational and technical aspects of a major project. There is also a major individual project that is also one third of the final year. B. Subject-specific skills include B1. To specify, plan and manage motor sports engineering designing and projects (individual and team working) (UK-SPEC:GLO: PS2,TS2, UK-SPEC: SLO D1,D5,D6) B2. To design and manufacture components for motor sports (UK-SPEC: GLO: PS1 UK-SPEC: SLO {D5, D6) B3. To consider and prioritise relevant factors, including health, safety, environmental issues and risk, in the context of motor sports engineering and the product cycle (UK-SPEC: GLO K&U3, IA3: SLO {D1, D2, D6) B4. To have the capacity and confidence to independently develop technical proficiencies to solve motor sports engineering problems (UK-SPEC:GLO: TS1, TS3, UK-SPEC:SLO US1) B5. To evaluate and prioritise factors in the context of motor sports engineering and the product cycle (UK-SPEC:GLO: K&U2, K&U3 SLO US1, US2, US3) B6. To apply analytical design techniques to synthesise components and vehicle systems for motor sports (UK-SPEC:GLO: K&U1, K&U2, K&U3 PS1 SLO US2) Teaching and Learning Methods Stage 1 involves the introduction of engineering principles, design activity and technology to be related to a range of applications through formal lectures, seminars, tutorials, workshop and technical activities. In stage 2 there is an increasing emphasis on integrating the aspects within design from physical laws to manufacturing organisation and methods through the direct introduction of work associated with the processes within the product cycle. Formal lectures, seminars, individual and team assignments and projects are used together with work based around the design and development and use of components and systems, manufacturing plant and technical equipment within Wharf Building. MP3598 has a two hour student-centred formal meeting every week and a two hour master class for personal development on technical, organisational and commercial aspects of projects engineering. The major project is seminar based and requires the student to demonstrate a professional approach to a realistic engineering problem and identify and reflect on the project and subject specific and cognitive and transferable skills that are developed. Assessment methods Stage 1 includes workbooks, reports, presentations and small assignments and three formal examinations. Stage 2 includes reports, group and individual working. There are two examinations at level five and one at level six. Both individual and group presentations and viva voce are used for the major project and Formula Student work. Formula Student is used within MP3598 and requires the critical appraisal of engineering work in the context of the product cycle, group work and the integration of IT across a group in the soft building of a car currently on SolidWorks and the hard build in Wharf Building.

C. Thinking Skills (Cognitive) In the context of the product cycle: C1. Analysis & decomposition associated with engineering design & manufacture (UK-SPEC:GLO: IA1i, IA1, IA2 SLO {US3, E1, E2, E3, D1, P3, P8) C2. Synthesis including effective use of CAE technology (UK-SPEC:GLO: IA1i, IA1, IA2 K&U1 SLO E1, E2, E3, D1, D4, D5, P3, P8} C3. Application and analysis of the limitations and context of engineering principles (UK-SPEC:GLO K&U1i, K&U1, IA1i, IA1, IA3 SLO E1, E3, E4, P3, P8) C4. Decomposition, evaluation and solution of problems of increasing complexity (UK-SPEC:GLO: IA1i, IA1, IA2, IA3, K%U1i, K&U1, K&U2, K&U1m, UK-SPEC SLO (E1, E2, E3, E4, D1, D2, D3, D4, D5, D6, P1, P3, P8)) C5. Recognise the broader aspects of engineering in the business and industrial environment (UK-SPEC: GLO: K&U2, K&U3, SLO: S1, S2, S3, S4, S5) Teaching and Learning Methods Stage 1 introduces engineering concepts and the use of learning outcomes in the curriculum. The approach is relatively direct and requires students to decompose engineering problems. Formal lectures supported with seminars and practical tests are used with a ‘hands-on’ approach in the workshops and drawing rooms as appropriate. There is initial use of CAD facilities, and presentations from students and external speakers. Stage 2 requires students to demonstrate and increasingly reflect on integration across modules. This requires developing and increasing depth and level of engineering competences. The assignments increasingly use of case studies based around engineering problems of growing complexity. This can be illustrated with the introductory project in MP2570 which is followed by a second more substantial piece of work. This continues with a major piece of group work and individual development for the design of a race car for Formula Student within MP3598. Assessment methods Stage 1 Assessment includes reports on practical tests, a design and make project, formal examinations and workbooks and drawings. Stage 2 uses more marked developing assessment methods to require students to demonstrate integration across modules and disciplines and problems. These include formal reports with reflections on practical tests and designs, generating CAD models, reporting on computer based calculations around engineering software, generating and analysing simulation models for manufacture. The assessment is generally based around the learning outcomes in order to indicate the direction and the requirements. In most modules at level 6 the extensive use of case studies is used. D. Other skills relevant to employability and personal development include

D1. Inter-personal skills, mechanics and organisation of team working (UK-SPEC:GLO: PS2, TS2, TS3, SLO D6, S2) D2. Communicate effectively: (presentation, IT, written) (UK-SPEC:GLO:K&U1 SLO: US4m) D3. Searching, summarising and effectively using information (UK-SPEC:GLO: TS1, TS2, TS3, UK-SPEC SLO US2, E1, E3, E4) D4. Numeracy (UK-SPEC:GLO: K&U1i, K&U1 SLO: US2, E1, E3, E4) D5. Synthesise within a framework of relevant legal requirements (UK-SPEC:GLO: K&U3 SLO S4) D6. To demonstrate a high level of professional and ethical conduct (UK-SPEC:GLO: K&U2, K&U3, IA3, UK-SPEC SLO US2,US2m, S3,S5) Teaching and Learning Methods Teaching and learning methods include traditional lectures, tutorials, laboratory work, directed self-study, and project work. As the course progresses there is greater emphasis on independent learning and resource and time management. At stage 3 the emphasis is on developing an approach to problem solving through the solution of open ended problems, unfamiliar problems and the limitations and implications with solutions to problems. Assessment methods The assessment methods develop as students progress through the course with a change in the balance from the testing of specific leaning outcomes in a direct manner to requiring students to also develop the material used for reflection and commentary. The changing emphasis enables and requires students to develop life long learning skills through the development of the relating of competences to the work requirements. 13. Programme Structures* Level Module Code Module Title 14. Awards and Credits* MP3592 Motor Sports Systems MP3604 Advanced CAD 6 MP3598 MS Design & Devel’ment (C) MP3999 Project (C) MP2899 Industrial Placement (O) MP2714 CAD & Manufacture Level 5 Stage 2.1 MP2721 Operations Management A MP2570 Engineering Design & Manufacture MP2578 Engineering Mechanics MP2576 Thermo-fluids with CFD MS1062 Engineering Analysis A MS1063 Engineering Analysis B MP1515 Drawing & CAD MP1532 Manufacturing Engineering MP1784 Introduction to Mechanics EL1785 Electronics & Instrumentation Level 4 MP1790 Race Car Anatomy Stage 1

Study of one of the Engineering Analysis modules below MS1060 Engineering Analysis A MS1063 Engineering Analysis B 15. Personal Development Planning Personal Development Planning (PDP) is: Reflection on learning, performance, and achievement Planning for personal, educational, and career development. PDP involves review and reflection involving academic study, extra-curricular activities and career planning. It results in an understanding and ownership of learning. The student will be introduced to PDP during tutorial sessions which should be seen as an opportunity to develop a plan for the whole of the student's time at University. Since learning is a lifelong process the work in PDP is not assessed. There are many similarities to work-based learning, and Continued Professional Development (CPD) - which is required for membership of professional societies. The skills in PDP are key components of employability - self- reflection, recording, target setting, action planning and monitoring. Web based materials relevant to PDP are found at: Personal Development Planning www.uclan.ac.uk/ldu/resources/pdp/intro1.htm Skills Learning Resources www.uclan.ac.uk/lskills/TLTP3/entersite.html There is also information available which can be located using a web search engine. At Induction the student takes part in a session involving a range of self-assessment exercises. This is followed by early in Semester 1 the student being recommended to access the Personal Development Planning web page (above), where there are a range of activities and exercises. The results of the activity or exercise are kept together in an A4 folder. A paper based system is suggested, due to concerns about the security, privacy, and long-term accessibility of records. This activity is reinforced by all first year students taking part in an event organised by 'Frontier Education' and based on the Mongolian 'Yurts' form of accommodation. This encourages communication and team working between students and fellow students, and between students and staff. Subsequently during tutorial sessions there will be discussion around PDP elements and in particular anything the student may have found difficult, or in which he/she needs assistance. Alternative approaches may be considered and discussed, if the student has particular issues. By the end of their University studies, the student is advised to have completed and reviewed all the activities and exercises 16. Admissions criteria Programme Specifications include minimum entry requirements, including academic qualifications, together with appropriate experience and skills required for entry to study. These criteria may be expressed as a range rather than a specific grade. Amendments to entry requirements may have been made after these documents were published and you should consult the University’s website for the most up to date information. Students will be informed of their personal minimum entry criteria in their offer letter.

Minimum entry requirements for degree level study for students of Curriculum 2000 will be a 12 unit profile, which must be made up from one of the following configurations: Three A2 level subjects. Two A2 level subjects plus one single award Advanced VCE. One A2 level subject plus one double award Advanced VCE. One A2 level subject plus two single award Advanced VCE. Plus evidence of Key Skills. Although Year 12 (AS) qualifications will be a useful indicator of potential, offers of places will only be made against total achievement at the end of Year 13. For guidance entry requirements for BEng (Hons) Motor Sports Engineering should be 280 points including Mathematics and Science and a third such as Technology at A2 level and at least five GCSEs at Grade B or above including Maths and English. Other acceptable qualifications include: Scottish Certificate of Education Higher Grade passes (AAAA) Irish Leaving Certificate Higher Grade passes (AAABB) International Baccalaureate (32 points) An appropriate BTEC Certificate or Diploma - an average of distinction grade must have been achieved. Kitemarked Access Course. Applications from individuals with non-standard qualifications, relevant work or life experience and who can demonstrate the ability to cope with and benefit from degree-level studies are considered. If an applicant has gained a BTEC HND in Engineering it may be possible to achieved entry with advanced standing. Applicants should note that a minimum period of study may apply.

Applicants seeking entry with advanced standing should note that the maximum entry point is to the second year of study.

17. Key sources of information about the programme

Factsheet; Prospectus; University website uclan.ac.uk; Motor Sports information sheet 18. Curriculum Skills Map Please tick in the relevant boxes where individual Programme Learning Outcomes are being assessed. The Core Skills relevant to employability and personal development (C) or Kno Subj Thin Optio wled ect- king n (O) ge spec Skill ECTV and ific s Modu unde Skill LevelModulele rstan s Code Title ding A1 A2 A3 A4 A5 A6 B1 B2 B3 B4 B5 B6 C1 C2 C3 C4 6 Proje MP3999ct 6 Adva nced MP3604CAD 6 MS C Des & MP3598Dev 6 MS Syste MP3592ms 5 Eng Mech MP2578anics 5 O Engin eerin g Desig n & MP2570Man 5 Ops Man MP2721A 5 CAD C & Manu MP2714f 5 Ther ECTV mo+C MP2576FD 4 Manu f E n MP153 g 2 g 4 Intro to M e MP178 c 4 h 4 Engg A n al y MS106 si 3 s 4 Electr o ni cs +I ns EL1785 t 4 Drawi C n g & C MP151 A 5 D 4 Race MP179Car 0Anat ECTV UK-SPEC Learning Outcomes 2. Degree Output Standards The Output statements set out below are the interpretation by the IMechE of those published by ECuk in its document “The Accreditation of Higher Educations Programmes – May 2004”. Within this document the following terms are used with the meanings stated: “Understanding” is the capacity to use concepts creatively, for example, in problem solving, in design, in explanations and in diagnosis “Knowledge” is information that can be recalled. “Know-how” is the ability to apply learned knowledge and skills to perform operations intuitively, efficiently and correctly. “Skills” are acquired and learned attributes which can be applied almost automatically. “Awareness” is general familiarity, albeit bounded by the needs of the specific discipline.

2.1 General Learning Outcomes Graduates with the exemplifying qualifications, irrespective of registration category or qualification level, must satisfy the following criteria:

IEng degree BEng(Hons) for CEng

Place an emphasis on the application of developed To be accredited, engineering programmes must BEng degrees differ from CEng Bachelors degrees in technology and the attainment of know-how, provide two different categories of learning outcomes. having a greater range of project work, including a sometimes within a multidisciplinary engineering One category will be general in nature, and will apply group project. They also provide a greater range and environment. The breadth and depth of underpinning to all types of programme. The second category will depth of specialist knowledge, within a research and scientific and mathematical knowledge, understanding be more specific. These two categories of outcome industrial environment, as well as a broader and more and skills is provided in the most appropriate manner will be inter-related, with the general learning outcomes general educational base, to provide both a foundation to enable the application of engineering principles being embodied to a greater or lesser extend within the for leadership, and a wider appreciation of the within existing technology to future engineering various engineering learning outcomes. economic, social and environmental context of problems and processes. engineering.

A programme accredited for IEng will have the general The range of general learning outcomes described for learning outcomes described earlier in this document. graduates from Bachelors programmes will also apply IEng programmes will have an emphasis on to graduates from BEng programmes. Graduates from developing and supporting the know-how necessary to an accredited integrated BEng degree will have the apply technology to engineering problems and ability to integrate their knowledge and understanding processes, and to maintain and manage current of mathematics, science, ICT, design, the economic, technology at peak efficiency. social and environmental context and engineering practice to solve a substantial range of engineering problems, some of a complex nature. They will have acquired much of this ability through involvement in individual and group design projects, which have a greater degree of industrial involvement than those in Bachelors degree programmes. Knowledge and Understanding

IEng degree BEng(Hons) for CEng

underpinning scientific and mathematical must be able to demonstrate their knowledge and the ability to learn new theories, concepts, knowledge and understanding to enable the understanding of essential facts, concepts, methods etc in unfamiliar situations application of engineering principles within theories and principles of their engineering existing technology to future engineering discipline, and its underpinning science and problems and processes mathematics

must have an appreciation of the wider multidisciplinary engineering context and its underlying principles

must appreciate the social, environmental, ethical, economic and commercial considerations affecting the exercise of their engineering judgement

Intellectual Abilities

IEng degree BEng(Hons) for CEng

to support know-how when applying technology must be able to apply appropriate quantitative the ability to develop, monitor and update a plan, to future engineering problems and processes science and engineering tools to the analysis of to reflect a changing operating environment problems

must be able to demonstrate creative and innovative ability in the synthesis of solutions and in formulating design

must be able to comprehend the broad picture and thus work with an appropriate level of detail

Practical Skills

IEng degree BEng(Hons) for CEng

application of engineering principles within must possess practical engineering skills existing technology to future engineering acquired through, for example, work carried out in problems and processes laboratories and workshops, in industry through supervised work experience, in individual and group project work, in design work and in the development and use of computer software in design, analysis and control

evidence of group working and participation in a an understanding of different roles within a team, major project are expected and the ability to exercise leadership General Transferable Skills

IEng degree BEng(Hons) for CEng

must have developed transferable skills that will be of value in a wide range of situations

exemplified by the QCA Higher Level Key Skills and include problem solving, communication, and working with others, as well as the effective use of general IT facilities and information retrieval skills

also include planning self-learning and improving the ability to monitor and adjust a personal performance, as the foundation for lifelong programme of work on an ongoing basis, and to learning/CPD learn independently 2.2 Specific Learning Outcomes Graduates from accredited programmes must achieve the following five learning outcomes, defined by broad areas of learning. The learning outcomes are expressed in terms of underpinning science and mathematics, engineering analysis, design, economic, social and environmental context and engineering practice In the table below, the central column related to the BEng (Hons) for CEng, is the reference column and the ones to the left and right show enhancements or limitations to it. Where no enhancement or limitation is shown the statement in the central column applies. IEng degree as enhancement or Integrated BEng degree as, BEng (Hons) for CEng limitation to BEng (Hons) for CEng enhancement of BEng Hons

Underpinning science and mathematics, and associated engineering disciplines (US) • Knowledge and understanding of the • Knowledge and • A comprehensive understanding of the scientific principles underpinning relevant understanding of scientific scientific principles of mechanical and technologies. principles and methodology related engineering disciplines necessary to underpin their education in mechanical and related engineering US1i US1 disciplines, to enable US1m appreciation of its scientific and engineering context, and to support their understanding of future developments and technologies. US2i • Knowledge and understanding of US2 • Knowledge and US2m • A comprehensive knowledge and mathematics necessary to support understanding of understanding of mathematical models application of key engineering principles mathematical principles relevant to the mechanical and related necessary to underpin their engineering disciplines, and an education in mechanical appreciation of their limitations; and related engineering disciplines and to enable them to apply mathematical methods, tools and notations proficiently in the analysis and solution of engineering problems

Ability to apply and • An understanding of concepts from a integrate knowledge and range of areas including some outside understanding of other engineering, and the ability to apply US3 US3 engineering disciplines to US3m them effectively in engineering projects support study mechanical and related engineering disciplines • A comprehensive knowledge and understanding of the role and limitations US4m of ICT, and an awareness of developing technologies in ICT; 1.1 1.2 IEng degree BEng (Hons) for CEng Integrated BEng degree Engineering Analysis (E) • Ability to monitor, interpret and apply the • Understanding of • Ability to use fundamental knowledge results of analyses and modelling in order engineering principles and to investigate new and emerging E1i to bring about continuous improvement E1 the ability to apply them to E1m technologies analyse key engineering processes • Ability to use the results of analysis to • Ability to identify, classify • Ability to extract data pertinent to an solve engineering problems, apply and describe the unfamiliar problem, and apply in its technology and implement engineering performance of systems solution using computer based E2i processes. E2 and components through E2m engineering tools when appropriate; the use of analytical methods and modelling techniques • Ability to apply quantitative methods and • Ability to apply • An understanding of the capabilities of computer software relevant to mechanical quantitative methods and computer based models for solving engineering technology, frequently within a computer software relevant problems in engineering, and the ability E3i E3 E3m multidisciplinary context. to mechanical and related to assess the limitations of particular engineering disciplines, to cases; solve engineering problems • Ability to apply a systems approach to • Understanding of and engineering problems through know-how ability to apply a systems E4i of the application of the relevant E4 approach to engineering E4 technologies. problems Design (D) • Define a problem and identify constraints. • Investigate and define a • Wide knowledge and comprehensive problem and identify understanding of design processes and constraints including methodologies and the ability to apply environmental and and adapt them in unfamiliar situations D1i D1 D1m sustainability limitations, health and safety and risk assessment issues

• Design solutions according to customer • Understand customer and and user needs. user needs and the D2i D2 importance of D2 considerations such as aesthetics • Identify and manage cost D3 D3 drivers D3

IEng degree BEng (Hons) for CEng Integrated BEng degree

• Use practical creativity and innovation • Use creativity to establish • Ability to generate an innovative design innovative solutions. for systems, components or processes D4i D4 D4m to fulfil new needs

• Ensure fitness for purpose (including • Ensure fitness for purpose • Ability to generate ideas for new operation, maintenance, reliability etc). for all aspects of the products and develop and evaluate a problem including range of new solutions D5i D5 D5m production, operation, maintenance and disposal

• Adapt designs to meet their new • Manage the design D6i purposes or applications. D6 process and evaluate D6 outcomes Economic, social and environmental context (S) • Knowledge and understanding of • Knowledge and • The ability to make general evaluations commercial and economic context of understanding of of commercial risks through some S1i engineering processes. S1 commercial and economic S1m understanding of the basis of such risks context of engineering processes. • Knowledge of management techniques • Knowledge of • Extensive knowledge and which may be used to achieve engineering management techniques understanding of management and objectives within that context which may be used to business practices, and their limitations, S2i S2 S2m achieve engineering and how these may be applied objectives within that appropriately to strategic and tactical context issues. • Understanding of the requirement for • Understanding of the engineering activities to promote requirement for engineering S3i sustainable development S3 activities to promote S3 sustainable development

• Awareness of the framework of relevant • Awareness of the legal requirements governing engineering framework of relevant legal activities, including personnel, health, requirements governing S4i safety, and risk (including environmental S4 engineering activities, S4 risk) issues including personnel, health, safety, and risk (including environmental risk) issues • Understanding of the need for a high • Understanding of the level of professional and ethical conduct in need for a high level of S5i S5 S5 engineering professional and ethical conduct in engineering IEng degree BEng (Hons) for CEng Integrated BEng degree

Engineering Practice (P)

P1i • Understanding of and ability to use P1 • Knowledge of characteristics of particular P1m • A thorough relevant equipment, tools, processes, or equipment, processes, or products understanding of current products. practice and its limitations, and some appreciation of likely new developments P2i • Knowledge and understanding of P2 • Engineering workshop and laboratory skills P2m • Extensive knowledge engineering workshop and laboratory and understanding of a practice wide range of engineering materials and components P3i • Knowledge of contexts in which P3 • Understanding of contexts in which P3 engineering knowledge can be applied engineering knowledge can be applied (e.g. (e.g. operations and management, operations and management, technology technology development, technology development, etc) application etc). P4i • Ability to use and apply information from P4 • Understanding use of technical literature and P4 technical literature. other information sources P5 P5 • Awareness of nature of intellectual property P5 and contractual issues P6i • Ability to use appropriate codes of P6 • Understanding of appropriate codes of P6 practice and industry standards. practice and industry standards P7i • Awareness of quality issues and their P7 • Awareness of quality issues P7 application to continuous improvement. P8i • Understanding of the principles of P8 • Ability to work with technical uncertainty P8m • Ability to apply managing engineering processes. engineering techniques taking account of a range of commercial and industrial constraints

1.3