2018 年 6 月 5 日

MOORETRONIX Switch Cream

We have been using this product for about 2 1/2 years with extremely good results. In some cases the treated switch assemblies work better than brand new switches.

A little history is in order. The basic wiping action switch contact goes back to the early days of vacuum tube receivers. These switches were used for band switching, tone control, automatic tuning and audio control. The switches were produced in rotary and push-push types. The ITT Shadow model became a refined assembly with low pressure contacts and a sealing system to keep most contaminates from the internal switch parts.

E-switch was another company that further enhanced this design. Both companies produced silver and gold contact switch assemblies.

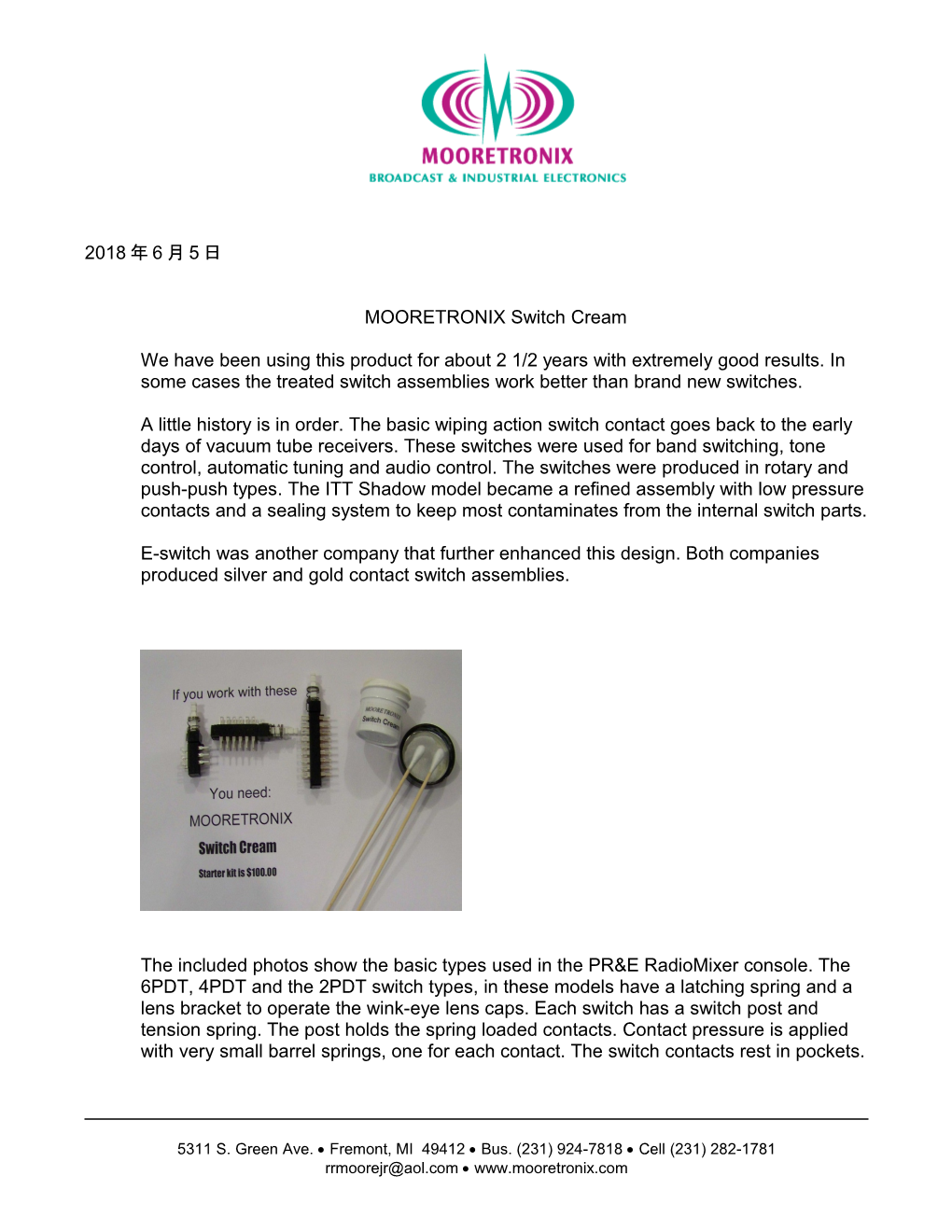

The included photos show the basic types used in the PR&E RadioMixer console. The 6PDT, 4PDT and the 2PDT switch types, in these models have a latching spring and a lens bracket to operate the wink-eye lens caps. Each switch has a switch post and tension spring. The post holds the spring loaded contacts. Contact pressure is applied with very small barrel springs, one for each contact. The switch contacts rest in pockets.

5311 S. Green Ave. Fremont, MI 49412 Bus. (231) 924-7818 Cell (231) 282-1781 [email protected] www.mooretronix.com The barrel spring has its own pocket centered between the two ends of each switch contact.

The switch body houses the switch post and holds the switch leg terminals that connect to the PC board. Internally groups of 3 terminals form the switch contacts on both sides of the switch body. The switch post, with its spring loaded contacts, slide against these legs forming the contact. This wiping action makes these switches ideal for low level audio signal currents.

The RadioMixer 8 station switch assemblies are used for the Control Room module, Studio module and the Remote Line selectors. The switches are mounted onto a switch chassis with an interlocking bar and tension spring. The latching spring is removed in this type of assembly with the interlocking bar and tension spring forming the latch. When a button is pressed the interlocking bar is released and allowed to latch the new position when the button is released. I mention this because removing the switch post from this type of switch is a bit tricky.

If you don't like working with very small and delicate parts, reworking these switches is not for you. If you have patience and a steady hand, then by all means use our MOORETRONIX Switch Cream to rejuvenate your audio switches. The results are truly amazing.

The reason this treatment is necessary is due to the chemical barrier formed between the switch post contacts and the switch body legs. These elements form the electrical switch circuit. All PR&E radio consoles are convection cooled. Air is drawn through the frame supplied by the stations HVAC system. Heat from electronic components and vapors from the electrolytic capacitors rise to the top of the console module switch assemblies. This contaminated air impregnates a thin film to the internal parts of the switch. The added electrical current flowing between the contacts enhances this barrier. Because the switches see very little movement in the day to day operation of the console, these thin chemical barriers form causing low resistance contacts to go intermittent.

Our MOORETRONIX Switch Cream breaks down this barrier and the binder applies a light lubrication to help seal out barrier build up. The Switch Cream is applied with a cotton swab.

- 2 - Refer to the close-up photos of the 2PDT switch and follow the steps required to treat a switch.

The switch body has a plastic tab lift point. This tab locks the switch post inside the switch body. See the photo with the small screw driver tip inserted at the lift point. Do not over lift this tab or you will de-form the plastic tab. You will need to lift the tab about 1/32 of an inch to get the switch post to release. Gently pull the switch post from the switch body.

Be very careful at this point because the switch contacts rest in the small pockets held in place with the small barrel springs. Apply a small amount of MOORTRONIX Switch Cream to a cotton swab. Now apply a thin coat of the Switch Cream to the exposed switch contact surface. Wipe the material across the switch contact from front to back. Do not apply any side or up down pressure or you will remove the contact from the post and the small barrel spring will fly away. This will of course make the switch worthless. Apply the Switch Cream to the opposite side of the post for the other contact. Re-insert the switch post into the switch body until the post locks in.

To get the Switch Cream to work, push the switch post in and then release about 20 times to work the material between the switch contacts and legs within the switch body. Now re-attach the latch spring. The switch is now ready for service. A switch with 4 or 6 sets of contacts is just repetition of the above steps. Remember when the switch post is removed from the switch body the contacts within the pockets are very fragile.

Good luck and I hope you have the same success we have had using this product. We are going to sell this product to everyone who is comfortable with the process. Please E-mail us with your results. You should find that the treated switches work the way they were intended with long service life in low level audio applications.

The MOORETRONIX Switch Cream is priced at $100.00 per kit.

Thank-You,

Bob Moore

- 3 - MOORETRONIX

- 4 -