Many car manufacturers are adopting electronically controlled systems that improve handling. We're not talking about electronically controlled shock absorbers or even ABS, but systems that actually reduce understeer or oversteer by braking just a single wheel when the car is sliding. It's a bit like driving a car which has four brake pedals - one per wheel - and having an electronic robot available to automatically operate them!

How They Do It

When a vehicle is understeering (the front sliding wide), braking of the inside rear wheel will reduce the amount of understeer that occurs. For example, if the car is understeering around a right-hand bend, braking the right-hand rear wheel (while the other wheels continue to turn at their normal rate), causes the car to pivot around to the right. That's where you want the car to go when you're going around a right-hand bend, so the understeer has been reduced.

The Lexus system brakes both rear wheels to control understeer. Other systems brake just the inside rear wheel, creating a correcting turning motion of the car.

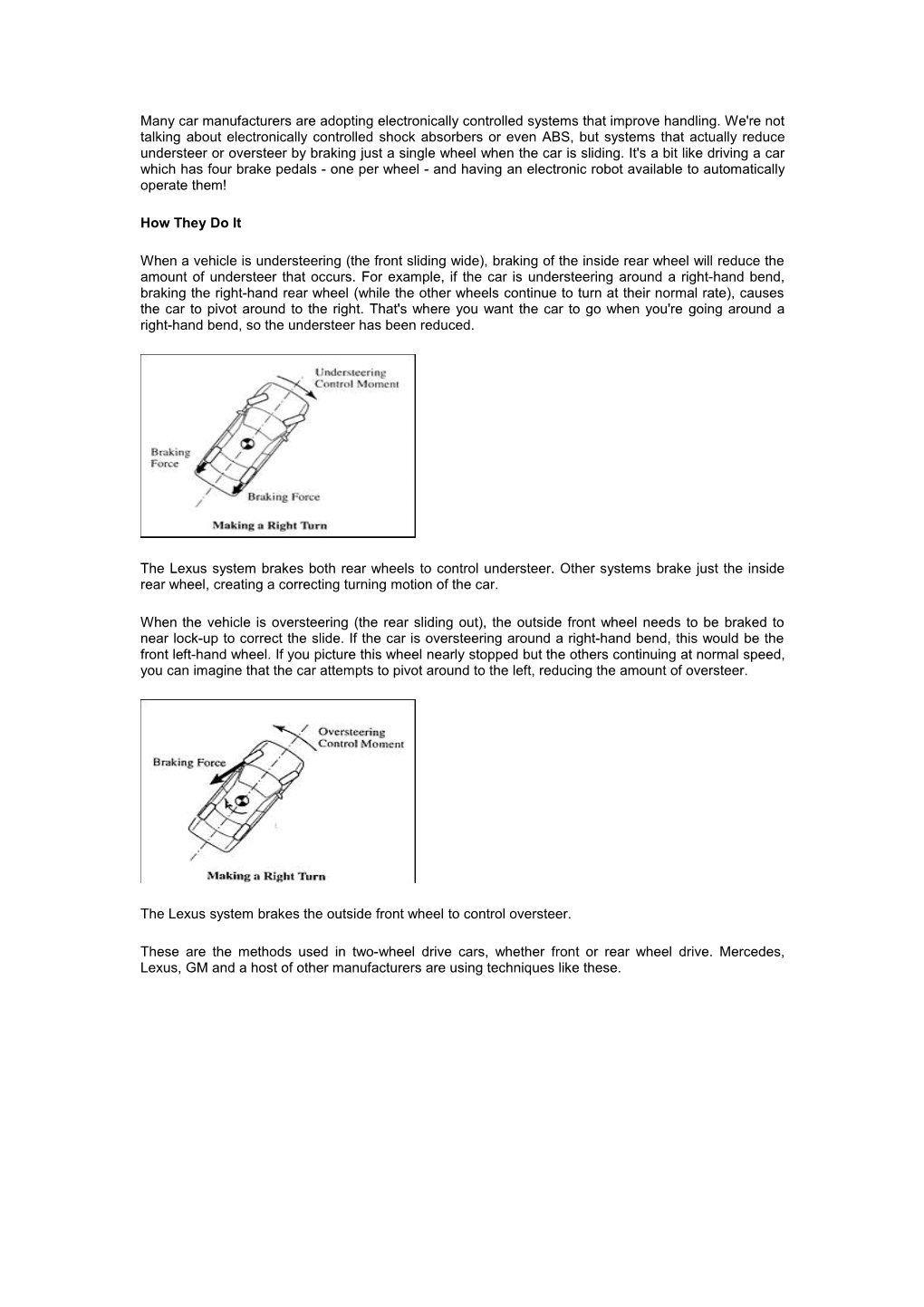

When the vehicle is oversteering (the rear sliding out), the outside front wheel needs to be braked to near lock-up to correct the slide. If the car is oversteering around a right-hand bend, this would be the front left-hand wheel. If you picture this wheel nearly stopped but the others continuing at normal speed, you can imagine that the car attempts to pivot around to the left, reducing the amount of oversteer.

The Lexus system brakes the outside front wheel to control oversteer.

These are the methods used in two-wheel drive cars, whether front or rear wheel drive. Mercedes, Lexus, GM and a host of other manufacturers are using techniques like these. The top Mercedes is using a Bosch stability control system while the bottom car is not. Note how the understeer is controlled, even though the front tyre is sliding so much that it is smoking!

The Electronics

For these systems to work, the electronic controller needs to know exactly what the car is doing.

Since all cars being fitted with Automatic Stability Control systems are equipped with ABS (Anti-lock Braking System), there are already wheel speed sensors fitted.

Speed sensors are integrated into the hub of the car. Here the cable going to the sensor can be seen just to the left of the drive shaft.

In addition to speed sensing, Stability Control Systems also require a means of detecting the steering angle, vehicle yaw rate and vehicle acceleration. A steering angle sensor is used to detect the amount and direction of steering lock being applied.

The Lexus steering angle sensor uses an optical design. Three sensors are used in conjunction with a slotted disc.

The yaw rate is the speed with which the vehicle is turning around a vertical axis. In other words, how quickly the car is changing direction. Yaw rate sensors are usually positioned in the middle of the car. The Lexus GS300 yaw sensor. It is located beneath the centre console in the cabin.

Vehicles also use an accelerometer (g-sensor) which - as you'd expect - detects acceleration. This includes braking and cornering forces as well as straight-line acceleration.

The Lexus accelerometer used two sensing elements mounted at 90° to each other.

Depending on how the Stability Control System is integrated with the rest of the electronic systems in the car, additional sensors may be fitted to detect brake fluid pressure and throttle opening. In most cars these sensors are already present, meaning that a Stability Control System can be added by the manufacturer for very little additional cost.

The Mechanicals

Most Stability Control Systems apply individual wheel brakes and reduce engine torque. The individual wheels are braked by the ABS hydraulic unit under the instructions of the electronic control unit (ECU). Some cars like the Lexus GS300 integrate the hydraulic aspects of the Stability Control System, ABS and conventional braking systems into one package. Rather than having a separate hydraulic master cylinder, vacuum booster and ABS hydraulic control unit, all of these are in one firewall-mounted assembly.

This is the amazing Lexus GS300 hydraulic assembly. It integrates the ABS hydraulic control unit, the brake booster, and the control valves for the stability control system.

The compact unit contains: the pump and pump motor; a nitrogen-charged pressure accumulator; three pressure switches; a relief valve; the brake fluid reservoir; the master cylinder; the brake booster which applies accumulator pressure; four switching solenoid valves to direct fluid pressure to any or all of the wheels; and finally, four pressure control solenoid valves that regulate the hydraulic pressure being applied to each wheel's brake.

Reduction of engine torque (which occurs in some systems when the brakes are being applied) can be carried out in a number of ways. These include reducing the throttle opening or retarding camshaft timing (when variable cam timing system is used), reducing ignition advance or even cutting out individual injectors.