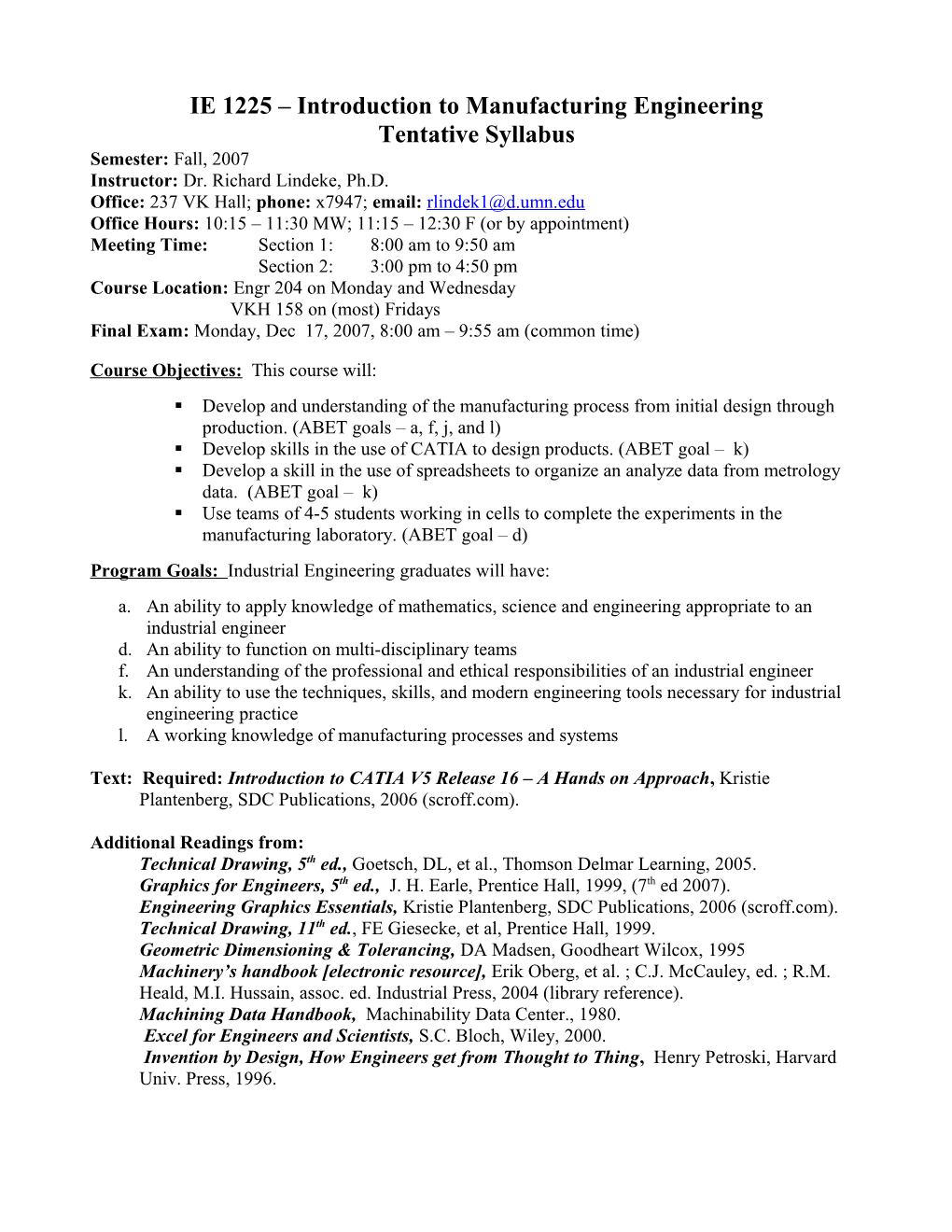

IE 1225 – Introduction to Manufacturing Engineering Tentative Syllabus Semester: Fall, 2007 Instructor: Dr. Richard Lindeke, Ph.D. Office: 237 VK Hall; phone: x7947; email: [email protected] Office Hours: 10:15 – 11:30 MW; 11:15 – 12:30 F (or by appointment) Meeting Time: Section 1: 8:00 am to 9:50 am Section 2: 3:00 pm to 4:50 pm Course Location: Engr 204 on Monday and Wednesday VKH 158 on (most) Fridays Final Exam: Monday, Dec 17, 2007, 8:00 am – 9:55 am (common time)

Course Objectives: This course will: . Develop and understanding of the manufacturing process from initial design through production. (ABET goals – a, f, j, and l) . Develop skills in the use of CATIA to design products. (ABET goal – k) . Develop a skill in the use of spreadsheets to organize an analyze data from metrology data. (ABET goal – k) . Use teams of 4-5 students working in cells to complete the experiments in the manufacturing laboratory. (ABET goal – d) Program Goals: Industrial Engineering graduates will have: a. An ability to apply knowledge of mathematics, science and engineering appropriate to an industrial engineer d. An ability to function on multi-disciplinary teams f. An understanding of the professional and ethical responsibilities of an industrial engineer k. An ability to use the techniques, skills, and modern engineering tools necessary for industrial engineering practice l. A working knowledge of manufacturing processes and systems

Text: Required: Introduction to CATIA V5 Release 16 – A Hands on Approach, Kristie Plantenberg, SDC Publications, 2006 (scroff.com).

Additional Readings from: Technical Drawing, 5th ed., Goetsch, DL, et al., Thomson Delmar Learning, 2005. Graphics for Engineers, 5th ed., J. H. Earle, Prentice Hall, 1999, (7th ed 2007). Engineering Graphics Essentials, Kristie Plantenberg, SDC Publications, 2006 (scroff.com). Technical Drawing, 11th ed., FE Giesecke, et al, Prentice Hall, 1999. Geometric Dimensioning & Tolerancing, DA Madsen, Goodheart Wilcox, 1995 Machinery’s handbook [electronic resource], Erik Oberg, et al. ; C.J. McCauley, ed. ; R.M. Heald, M.I. Hussain, assoc. ed. Industrial Press, 2004 (library reference). Machining Data Handbook, Machinability Data Center., 1980. Excel for Engineers and Scientists, S.C. Bloch, Wiley, 2000. Invention by Design, How Engineers get from Thought to Thing, Henry Petroski, Harvard Univ. Press, 1996. Grading: Points will be assigned as follows: 25 drawings @ 5 points 125 7 Lab Reports @ 15 105 2 midterms @ 75 150 Final Transmission drawing/Report 75 Reverse Eng. Part Report 75 Course participation 70 Final Exam (lab/lecture) 150 Total 750 Your number of points will be totaled and compared to the maximum. Although it may vary somewhat, 90 - 80 - 70 - 60 percent represent the usual indicated break points in grading.

Weekly Schedule Week Test/Lecture Material Lab Assignment HW Assignment (due following Mon. 1 Section 1.1, 1.2, 6.1 Drafting Ch. 6 - complete 1.2 Demo/Drafted 2 Drawing Const. Sec. 2.1, Basic Measurements Ex 2.1 b, c, d, f 2.2, 2.3 3 Process Capability (Excel Measuring Holes – size & Ex 2.2b; Ex 2.3 a, d Study) position 4 Tol/Allowance Fits, Machine Plate and Make Draft of Dimensioned Plate Machining Processes Holes (Friday for Lab) 5 Sec 2.4, 2.5 Setup, Machine and Inspect Inspection Report; Ex 2.5 a, b Midterm 1 (WED) Plate Angle and Dimensions 6 Sec 2.6, 2.7 Intro to CMM Ex 2.6 a, b 7 Sec 3.1, 3.2; Pads & Machine Steel Step Ex 3.1a; Ex 3.2a Pockets Cylinder Steel Part (Friday for Lab) 8 Threads; Sec 3.3, 3.4, 3.5, Cutting Internal and Ex 3.3b; Ex 3.4a Threaded 3.6 External Threads Part (Friday for Lab) 9 Sec. 3.6, 3.7 Design, Machine and Ex 3.5 a, b Inspect Milled Gage 10 Chapter 5 Assembly Compute/Design TBA Design Midterm II (Wed) Transmission 11 Sec 3.9; Operations Machine/Inspect Cylinders Operation sheets 12 Sec 3.8,Work on Mach/Inspect End and Base Assembly Package Drawings Component & Assb’ly Plates/ Ass’ble/Test Drawings Transmission 13 Sec 4.1; 4.2 Disassembly and Final Transmission Report measurement of Product 14 Component & Assb’ly No Formal Lab Meeting – Continue with Part Sketches Drawings (Rev. Continue building for Component Engineered product) Assembly Package 15 Component & Assb’ly No Formal Lab Meeting – Final Reverse. Engineering Drawings (Rev. Continue building Product report (Dec 14) Engineered product) Assembly Package Exam Schedule: Mid term I - Wednesday, Oct. 3rd, Class time Mid term II: Wednesday, Nov. 7th, Class time Final Exam: Monday, Dec 17 – 8:00 am to 9:55 am*****

Attendance. Attendance will be taken. Excessive absenteeism (4 or more times) will result in a lower grade! Furthermore: The Instructor views class attendance as a mandatory part of any professional behavior. It is expected that each student view their education as “Their Job” during this portion of their career. As engineers, each and every one of us strives to be the “Best we can Be,” thus it is imperative that we attend and participate fully in each classroom and lab experience. This, then, implies that reading assignment be completed before class time, reports and homework be prepared in advance of due dates and each student be prepared to discuss topics of interest to this class subject within the classroom and lab. Assignment Policy: All assignments will receive a point reduction for every class day they are late. Note: Most assignments are due on Monday! Make-up and Incomplete Policies: Any make-up will be considered late and have points deducted accordingly unless extenuating circumstances are evident. Incompletes can be arranged if the student is unable to complete a major assignment or test due to these circumstances. Cheating: I consider the copying or use of another’s electronic files to be cheating. If two or more people turn in identical drawings (even if slightly rearranged), all involved will receive a 0 for the assignment and be subject to the UMD policy on academic misconduct (See below). Furthermore: Academic Dishonesty: In the case of writing or drawing, this means you are trying to pass off someone else's work as your own. To prevent this, don't plagiarize material and be sure to make liberal use of references (which means you have substantial references and bibliography!). In the case of exams, it is cheating. The penalty for cheating or plagiarism will be an "F" in the class! Exam are Open Book/Open Notes, however, if any old examinations are brought to the classroom or any questions are copied during the exam, a severe point reduction will be taken for that exam. Academic dishonesty tarnishes UMD's reputation and discredits the accomplishments of students. UMD is committed to providing students every possible opportunity to grow in mind and spirit. This pledge can only be redeemed in an environment of trust, honesty, and fairness. As a result, academic dishonesty is regarded as a serious offense by all members of the academic community. In keeping with this ideal, this course will adhere to UMD's Student Academic Integrity Policy, which can be found at www.d.umn.edu/assl/conduct/integrity. This policy sanctions students engaging in academic dishonesty with penalties up to and including expulsion from the university for repeat offenders.

University's Student Conduct Code (http://www.d.umn.edu/assl/conduct/code). Appropriate classroom conduct promotes an environment of academic achievement and integrity. Disruptive classroom behavior that substantially or repeatedly interrupts either the instructor's ability to teach, or student learning, is prohibited. Disruptive behavior includes inappropriate use of technology in the classroom. Examples include ringing cell phones, text- messaging, watching videos, playing computer games, doing email, or surfing the Internet on your computer instead of note-taking or other instructor-sanctioned activities." Student Participation: Teams will complete the laboratory work in the production portion of the course. All successful teams need work together, with everyone contributing, to complete a given task. Students should be aware that a number of points toward the final grade are awarded by reviewing your performance in the lab. Disabilities. Individuals who have any disability, either permanent or temporary, which might affect their ability to perform in this class are encouraged to inform the instructor at the start of the semester. Adaptation of methods, materials, or testing may be made as required to provide for equitable participation.