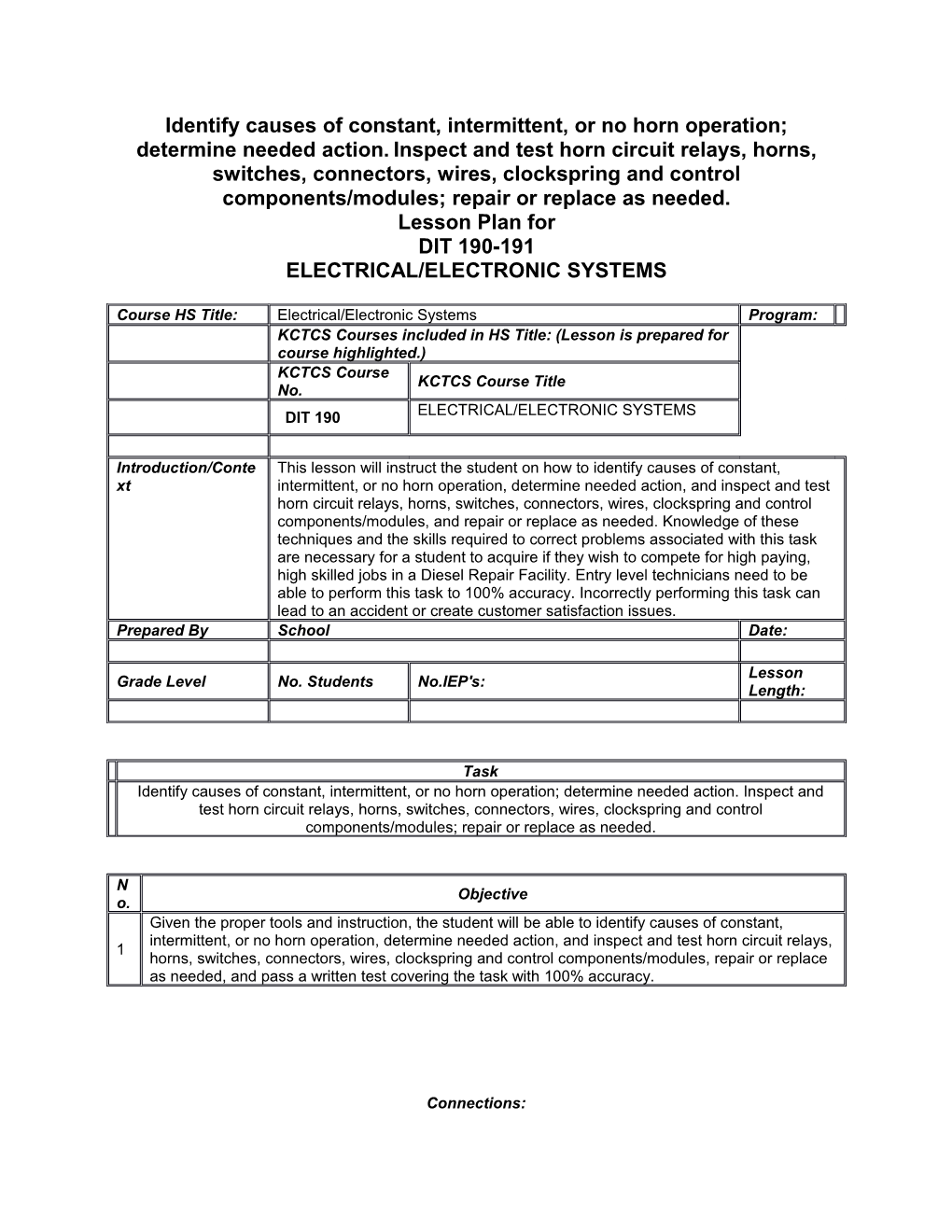

Identify causes of constant, intermittent, or no horn operation; determine needed action. Inspect and test horn circuit relays, horns, switches, connectors, wires, clockspring and control components/modules; repair or replace as needed. Lesson Plan for DIT 190-191 ELECTRICAL/ELECTRONIC SYSTEMS

Course HS Title: Electrical/Electronic Systems Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course KCTCS Course Title No. DIT 190 ELECTRICAL/ELECTRONIC SYSTEMS

Introduction/Conte This lesson will instruct the student on how to identify causes of constant, xt intermittent, or no horn operation, determine needed action, and inspect and test horn circuit relays, horns, switches, connectors, wires, clockspring and control components/modules, and repair or replace as needed. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Diesel Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Identify causes of constant, intermittent, or no horn operation; determine needed action. Inspect and test horn circuit relays, horns, switches, connectors, wires, clockspring and control components/modules; repair or replace as needed.

N Objective o. Given the proper tools and instruction, the student will be able to identify causes of constant, intermittent, or no horn operation, determine needed action, and inspect and test horn circuit relays, 1 horns, switches, connectors, wires, clockspring and control components/modules, repair or replace as needed, and pass a written test covering the task with 100% accuracy.

Connections: Skills Standards: OH 001 OH 002 OH 003 OD 002 OD 003 OD 005 New Common Core Standards: RST 11-12 3 A-CED-4 N-Q.1 Common Core Technical Standards: TD-OPS 2 TD-SYS 2 New Generation Science Standards: HS-PS2-5. HS-PS3-3. HS-PS3-5.

INSTRUCTIONAL MATERIALS/TECHNOLOGY

Teacher Designed Materials and Other Handouts

Textbooks and Workbooks

Author Title/ISBN No. Edition Publisher Pages Stockel Stockel Auto Diagnosis, Service, and repair / 1-56637- Goodheart 239 Johanson 910-5 Wilcox Electrical/Electronic Systems ASE Test Prep Various Fifth Delmar 35 T6

Equipment Quantity Item Source As Needed Continuity / Test Light Various As Needed DVOM Various As Needed Wiring Terminal Repair Various

Content/Presentation/Demonstration Outline Instruct students that the horn system has not changed much since it was developed. The horn assembly has a diaphragm with a make and break circuit. When energized the diaphragm vibrates, creating sound. As the diaphragm vibrates the circuit is opens, or breaks, allowing the diaphragm to return to its original position where it is re-energized. This flexing of the diaphragm occurs many times per second, causing a continuous sound. Inform students that horns are energized by a switch usually located in the center of the steering wheel. This switch controls a relay that supplies a heavier current to the horn assembly. Some horn systems don’t use a relay, but supply a ground directly through the steering column. Discuss with students the safety concerns of working on a vehicle that incorporates the horn switch in the air bag inflator module. Most problems with the horn system occur over time. Wear in the contact switch or slip ring causes an open circuit that won’t allow the horn to blow. Sticking contacts will cause the horn to sound continuously. While pressing on the horn, listen for the relay to click. If you here the relay click the problem is most likely in the horn, the horn ground, or relay contact. Instruct students that an electric horn uses high current so the circuit almost always includes a relay. If the horn does not work at all, tell students to first check for power going to the horn itself. If the unit is properly grounded and does not operate, the unit is defective and should be replaced. Have them check both the control and power circuits at the relay. When testing a horn relay circuit, tell students to first check for fused power at the positive side of the horn relay. Next, have them check for a signal from the steering wheel switch. This may be either positive or ground-side switching, depending on the manufacturer. Assuming the use of a 5-pin mini-relay, the circuit should function exactly Instruct students to follow the following suggestions. Symptom: Horn(s) are inoperative. Possible Causes: Poor ground on horn(s), Defective relay (if used), Open circuit in the steering column, Defective horn (use a jumper wire connected between the positive terminal of the battery and the horn [horn wire disconnected] to check for proper operation of the horn Symptom: Horns produce low volume or wrong sound: Possible Causes: Poor ground at horn, Incorrect frequency of horn Symptom: Horn blows all the time. Possible causes: Stuck horn relay (if used), Short to ground in the wire to the horn button

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)