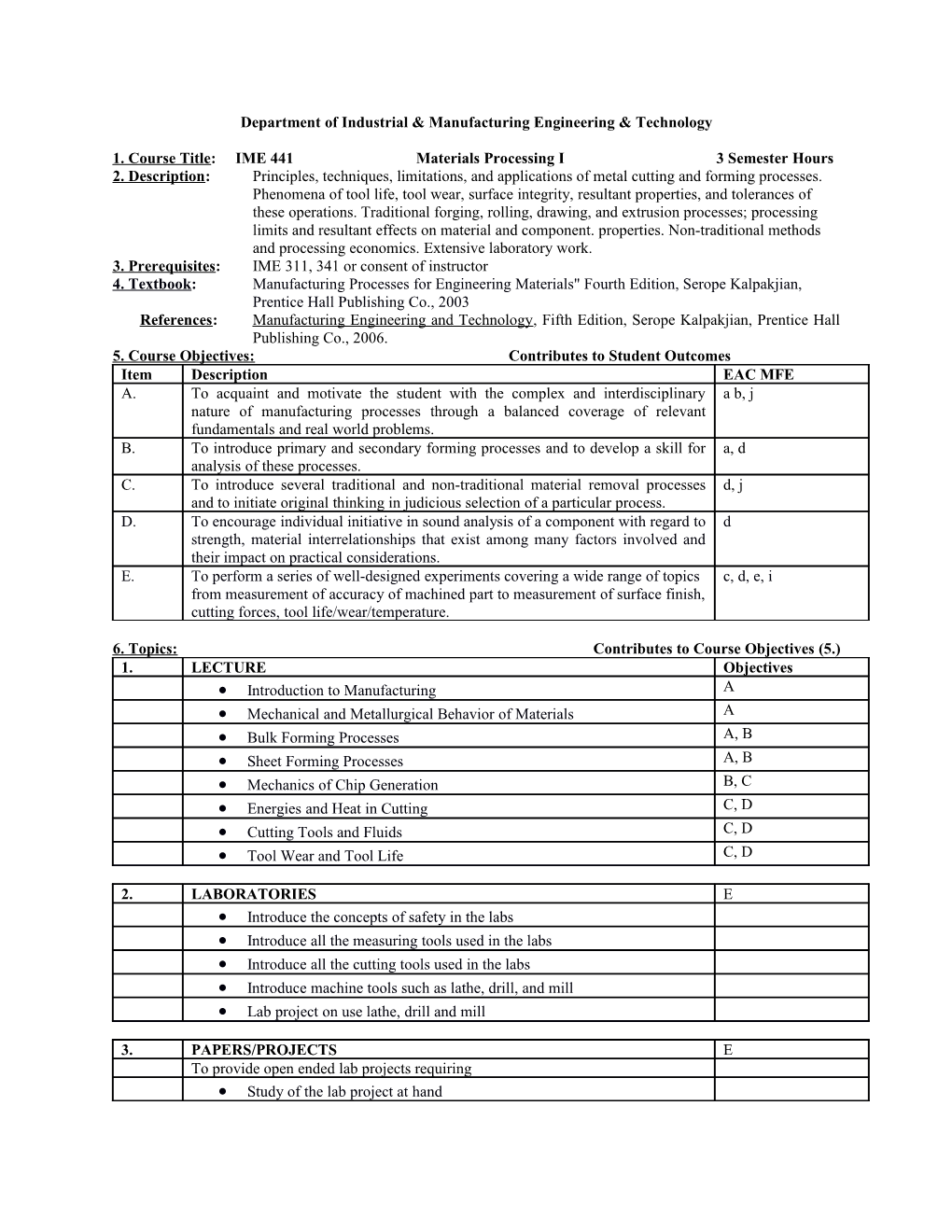

Department of Industrial & Manufacturing Engineering & Technology

1. Course Title: IME 441 Materials Processing I 3 Semester Hours 2. Description: Principles, techniques, limitations, and applications of metal cutting and forming processes. Phenomena of tool life, tool wear, surface integrity, resultant properties, and tolerances of these operations. Traditional forging, rolling, drawing, and extrusion processes; processing limits and resultant effects on material and component. properties. Non-traditional methods and processing economics. Extensive laboratory work. 3. Prerequisites: IME 311, 341 or consent of instructor 4. Textbook: Manufacturing Processes for Engineering Materials" Fourth Edition, Serope Kalpakjian, Prentice Hall Publishing Co., 2003 References: Manufacturing Engineering and Technology, Fifth Edition, Serope Kalpakjian, Prentice Hall Publishing Co., 2006. 5. Course Objectives: Contributes to Student Outcomes Item Description EAC MFE A. To acquaint and motivate the student with the complex and interdisciplinary a b, j nature of manufacturing processes through a balanced coverage of relevant fundamentals and real world problems. B. To introduce primary and secondary forming processes and to develop a skill for a, d analysis of these processes. C. To introduce several traditional and non-traditional material removal processes d, j and to initiate original thinking in judicious selection of a particular process. D. To encourage individual initiative in sound analysis of a component with regard to d strength, material interrelationships that exist among many factors involved and their impact on practical considerations. E. To perform a series of well-designed experiments covering a wide range of topics c, d, e, i from measurement of accuracy of machined part to measurement of surface finish, cutting forces, tool life/wear/temperature.

6. Topics: Contributes to Course Objectives (5.) 1. LECTURE Objectives Introduction to Manufacturing A Mechanical and Metallurgical Behavior of Materials A Bulk Forming Processes A, B Sheet Forming Processes A, B Mechanics of Chip Generation B, C Energies and Heat in Cutting C, D Cutting Tools and Fluids C, D Tool Wear and Tool Life C, D

2. LABORATORIES E Introduce the concepts of safety in the labs Introduce all the measuring tools used in the labs Introduce all the cutting tools used in the labs Introduce machine tools such as lathe, drill, and mill Lab project on use lathe, drill and mill

3. PAPERS/PROJECTS E To provide open ended lab projects requiring Study of the lab project at hand Brainstorming the various alternatives Getting good feel for the available resources, equipment and time Designing experiments Conducting experiments Recording appropriate responses using both strip chart recorder and data acquisition system Charting the data collected from experiments Critical examination of the effect of process parameters on the measured responses Making inferences and making recommendations

7. Class Schedule: Two lecture sessions of 50 minutes and one lab session of 100 minutes per week 8. Contribution of Course to Meeting the Professional Component: Communications 0.0 hrs Mathematics 0.0 hrs Physical and Natural Science 0.0 hrs Social Sciences and Humanities 0.0 hrs Technical Content 3.0 hrs

9. Relationship of Course to MFE Student Outcomes: (based on 1 to 5 scales, 5 denotes very strong continuation to the student outcome and blank cell denotes that the course does not continue the related student outcome) Cod Student Outcomes, A Graduate from the Program Will Have: Contribution e Manufacturing Engineering graduates will have an ability to apply knowledge of mathematics and science to manufacturing processes, materials, and design of 3.2 a manufacturing systems Manufacturing Engineering graduates will have an ability to design and conduct experiments, and to analyze and interpret data related to manufacturing processes, 3.71 b materials evaluation, and manufacturing systems Manufacturing Engineering graduates will have an ability to design, select, implement, and control a manufacturing system and its components or processes to meet desired 3.25 c needs Manufacturing Engineering graduates will have an ability to function on multi- disciplinary teams and the ability to apply a concurrent approach and project 3.71 d management to process and product development Manufacturing Engineering graduates will have an ability to identify, formulate, and solve manufacturing engineering problems through a hands-on approach that considers — e constraints, costs, benefits, and comparative processes and materials Manufacturing Engineering graduates will have an understanding of the professional f and ethical responsibilities of a manufacturing engineer 3 Manufacturing Engineering graduates will have an ability to effectively communicate g technical concepts through appropriate methods 3 Manufacturing Engineering graduates will have an understanding of the impact of manufacturing engineering solutions in a global, economic, environmental, and societal 3.75 h context Manufacturing Engineering graduates will have a recognition of the need to engage in i lifelong learning — Manufacturing Engineering graduates will have a knowledge of contemporary issues j facing manufacturing engineers 2.5 Manufacturing Engineering graduates will have an ability to use the proper techniques, skills, and modern engineering tools necessary for manufacturing engineering practice 3.25 k utilizing supporting technologies

10. Prepared by: Iqbal Shareef 10/2013 Reviewed by: Curriculum Committee