College of Engineering Shop Procedure

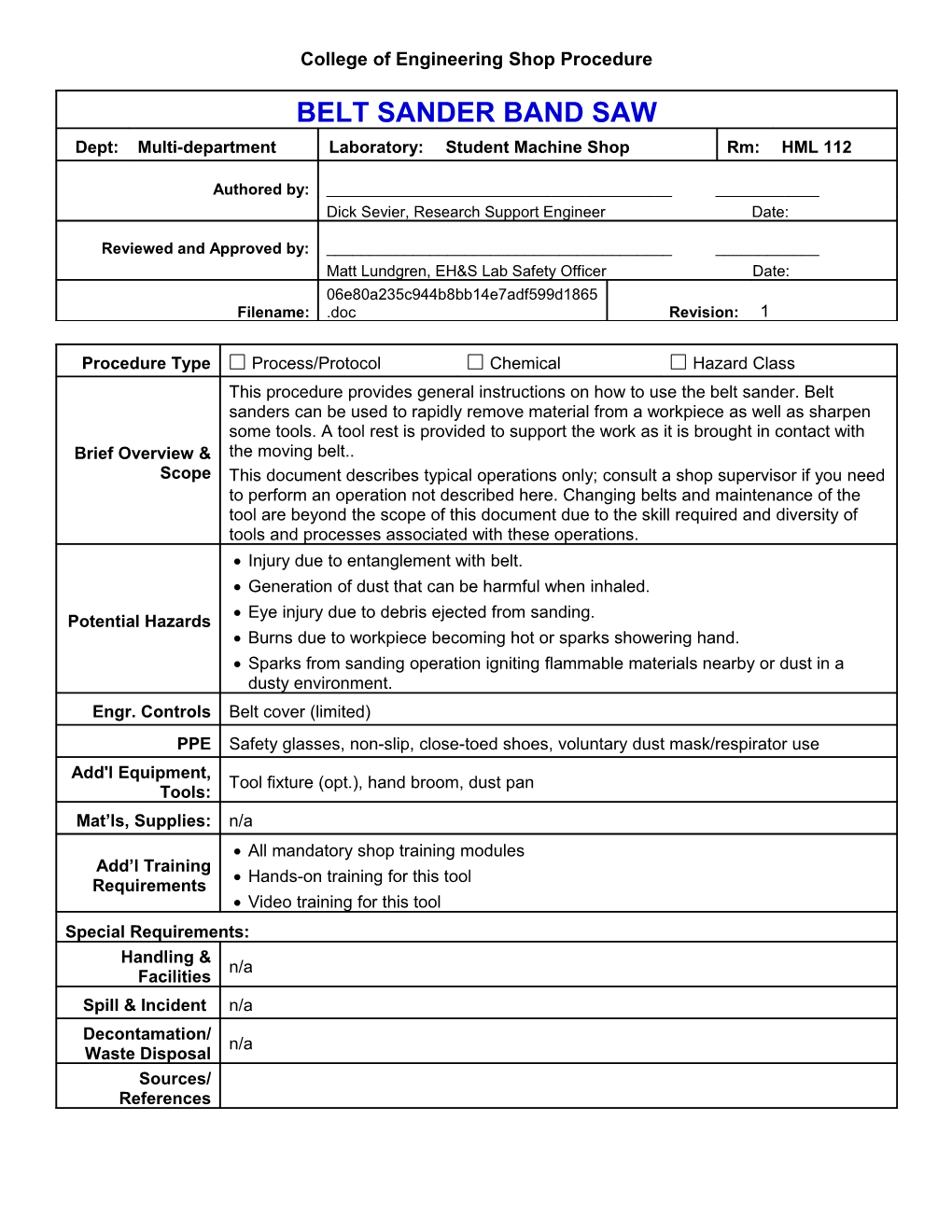

BELT SANDER BAND SAW Dept: Multi-department Laboratory: Student Machine Shop Rm: HML 112

Authored by: ______Dick Sevier, Research Support Engineer Date:

Reviewed and Approved by: ______Matt Lundgren, EH&S Lab Safety Officer Date: 06e80a235c944b8bb14e7adf599d1865 Filename: .doc Revision: 1

Procedure Type Process/Protocol Chemical Hazard Class This procedure provides general instructions on how to use the belt sander. Belt sanders can be used to rapidly remove material from a workpiece as well as sharpen some tools. A tool rest is provided to support the work as it is brought in contact with Brief Overview & the moving belt.. Scope This document describes typical operations only; consult a shop supervisor if you need to perform an operation not described here. Changing belts and maintenance of the tool are beyond the scope of this document due to the skill required and diversity of tools and processes associated with these operations. Injury due to entanglement with belt. Generation of dust that can be harmful when inhaled. Eye injury due to debris ejected from sanding. Potential Hazards Burns due to workpiece becoming hot or sparks showering hand. Sparks from sanding operation igniting flammable materials nearby or dust in a dusty environment. Engr. Controls Belt cover (limited) PPE Safety glasses, non-slip, close-toed shoes, voluntary dust mask/respirator use Add'l Equipment, Tool fixture (opt.), hand broom, dust pan Tools: Mat’ls, Supplies: n/a All mandatory shop training modules Add’l Training Hands-on training for this tool Requirements Video training for this tool Special Requirements: Handling & n/a Facilities Spill & Incident n/a Decontamation/ n/a Waste Disposal Sources/ References BELT SANDER

TABLE OF CONTENTS

TOOL COMPONENTS...... 2 GENERAL TOOL SAFETY RULES...... 3 COMMON TASKS...... 4 1. Stopping the Grinding Wheel...... 4 2. Setting Up to Sharpen Tools...... 4 3. Setting Up for General Sanding...... 5 4. Grinding/Sanding a Cutting Tool or Workpiece...... 5 5. Cleanup...... 5

TOOL COMPONENTS

Belt `Cover Motor

On/Off Switch Wheel Cover

Tool Rest

03-Oct-11 Page 2 of 5 BELT SANDER

GENERAL TOOL SAFETY RULES a. Safety glasses are required to use this tool. b. WARNING: To prevent entanglement with the belt: - Tie back long hair and tuck under shirt, roll up long sleeves, remove gloves or loose clothing. - Remove any gloves, rings, or other jewelry. Note: Tight fitting latex or nitrile gloves are permissable. - Keep hands away from belt. c. Know the location of On/Off switch. d. Do not use any machine in which a guard or cover has been removed. Contact the shop supervisor immediately. e. WARNING: Sanding some materials could generate dust that is harmful to breathe. Consult with shop supervisor if sanding anything that is non-metallic. f. WARNING: Sanding magnesium could generate dust that could be ignited. Consult with shop supervisor if sanding magnesium. g. Avoid accidental starting. Make sure switch is in “OFF” position before connecting to power source. h. Stop the machine immediately if odd noises or excessive vibration occurs. i. Steel, Aluminum and wood can be sanded on this machine. j. Take care to not allow the workpiece to become so hot it burns your fingers if it is handheld. k. WARNING: This tool may generate sparks. Clear the area of any material that could be ignited from a stray spark from the sanding operation. Do not use this tool in a dusty environment that could be ignited by sparks. l. Wear slip-resistant shoes to maintain a secure footing and balance. m. If you have any questions about this tool or its use, stop what you are doing and ask a shop supervisor.

03-Oct-11 Page 3 of 5 BELT SANDER

COMMON TASKS

1. Stopping the Grinding Wheel

a. In the course of normal operation or in the event of an emergency, turn off the pedestal grinder by flipping the power switch to the left in the OFF position as shown.

OFF position s

2. Setting Up to Sharpen Tools

a. Power off machine before making any adjustments. b. If the desired belt is not mounted to the sander, have the shop supervisor mount the correct one. c. Adjust angle of tool rest on support to desired position and tighten nut securely. Adjust tool rest so that there is 1/8" or less clearance between tool rest and belt and tighten nut securely.. Cutting If sharpening a cutting tool edge, be sure to set rest so that the Belt Tool tool will be ground at the desired angle. See figure to right. Direction

Tool Rest

Workpiece 03-Oct-11 Page 4 of 5 Belt Direction BELT SANDER Tool Rest

3. Setting Up for General Sanding

b. Power off machine before making any adjustments. d. If the desired belt is not mounted to the sander, have the shop supervisor mount the correct one. e. Adjust angle of tool rest on support to desired position and tighten nut securely. Adjust tool rest so that there is 1/8" or less clearance between tool rest and belt and tighten nut securely.. See figure to right.

4. Grinding/Sanding a Cutting Tool or Workpiece

a. Flip the On/Off switch to ON. WARNING: Be sure there are no flammable or combustible vapors or dust near the grinder. Sparks could result in fire or explosion if combustible materials, vapors have not been removed. b. Carefully bring the tool in contact with the belt. Do not apply excessive force; let the belt do the sanding/grinding. c. WARNING: Care must be taken to avoid breathing dust generated when sanding some materials such as wood. Consult with the shop supervisor on the voluntary use of a dust mask or respirator. d. WARNING: If there is an abundant shower of sparks, stop the operation and put on tight-fitting nitrile or latex gloves. Do not put on loose fitting gloves, as they may become entangled in the grinding wheel. e. Every few seconds, cool the tool or workpiece in the water bath. WARNING: Failure to cool the tool could result in burns to the fingers or hands or inability to hold workpiece. CAUTION: Excessive heat can make reduce its hardness. Be sure when grinding to quench the tool tip frequently. f. WARNING: If you are working with magnesium, be aware that magnesium dust can catch fire if allowed to accumulate. Wipe away any magnesium dust that may accumulate on the floor or nearby surfaces. g. Turn the switch to the OFF position when sanding/grinding is completed.

5. Cleanup

a. When done, brush or wipe down the area to remove any accumulation of dust. b. Sweep the floor around the tool.

03-Oct-11 Page 5 of 5