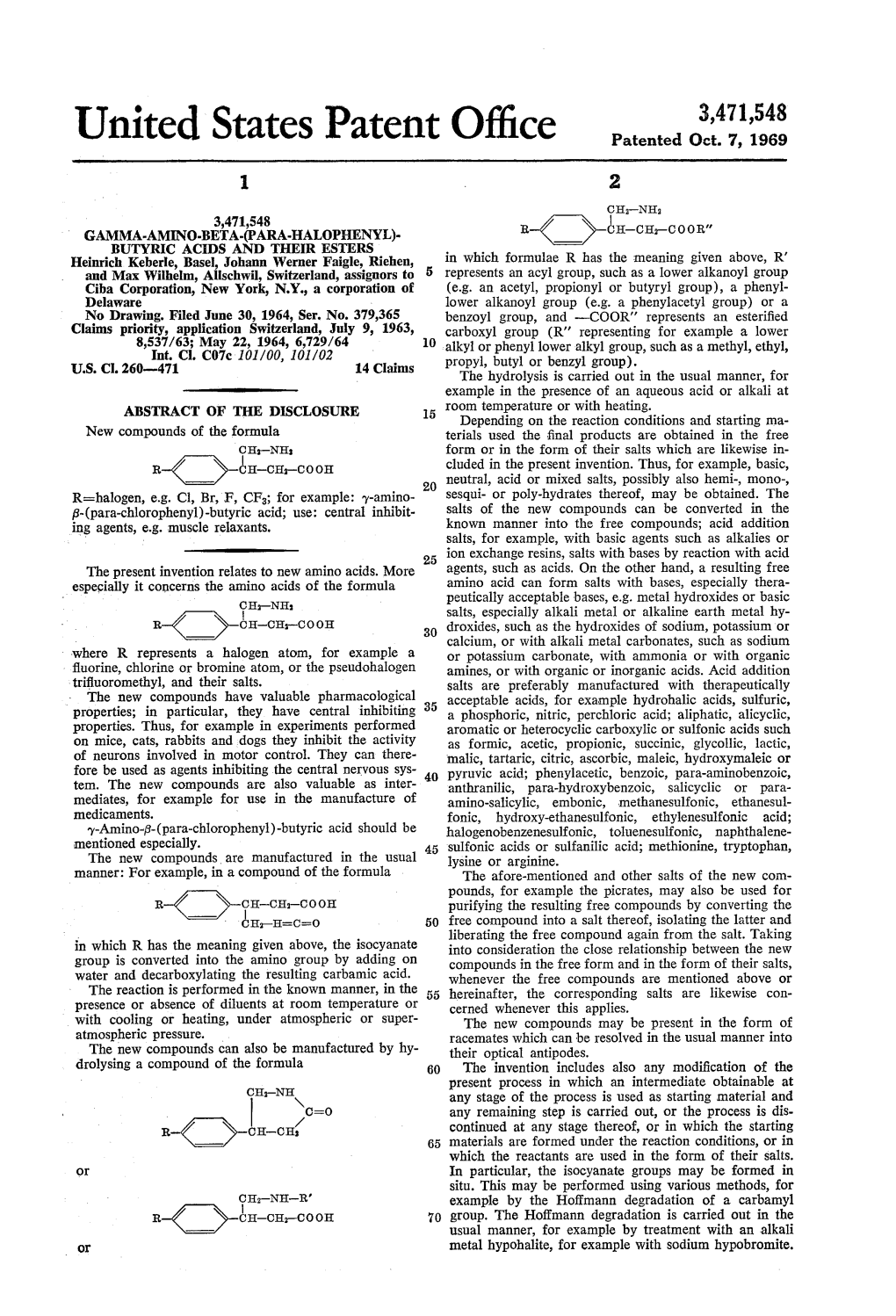

United States Patent Office Patented Oct

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Toxicological Basis Data for the Derivation of EU-LCI Values For

TEXTE 223/2020 Toxicological basis data for the derivation of EU- LCI values for neopentyl glycol, diisobutyl succinate, diisobutyl glutarate, 1,2- dimethoxyethane and 1,2-diethoxyethane Final report German Environment Agency TEXTE 223/2020 Ressortforschungsplan of the Federal Ministry for the Enviroment, Nature Conservation and Nuclear Safety Project No. (FKZ) 3719 62 205 0 Report No. FB000359/ENG Toxicological basis data for the derivation of EU-LCI values for neopentyl glycol, diisobutyl succinate, diisobutyl glutarate, 1,2- dimethoxyethane and 1,2-diethoxyethane Final report by Dr. Barbara Werschkun Wissenschaftsbüro, Berlin On behalf of the German Environment Agency Imprint Publisher Umweltbundesamt Wörlitzer Platz 1 06844 Dessau-Roßlau Tel: +49 340-2103-0 Fax: +49 340-2103-2285 [email protected] Internet: www.umweltbundesamt.de /umweltbundesamt.de /umweltbundesamt Report performed by: Wissenschaftsbüro Dr. Barbara Werschkun Monumentenstr. 31a 10829 Berlin Germany Report completed in: May 2020 Edited by: Section II 1.3 Indoor Hygiene, Health-related Environmental Impacts Dr. Ana Maria Scutaru Publication as pdf: http://www.umweltbundesamt.de/publikationen ISSN 1862-4804 Dessau-Roßlau, December 2020 The responsibility for the content of this publication lies with the author(s). TEXTE Toxicological basis data for the derivation of EU-LCI values for neopentyl glycol, diisobutyl succinate, diisobutyl glutarate, 1,2-dimethoxyethane and 1,2-diethoxyethane – Final report Abstract: Toxicological basis data for the derivation of EU-LCI values for neopentyl glycol, diisobutyl succinate, diisobutyl glutarate, 1,2-dimethoxyethane and 1,2-diethoxyethane The objective of this study was the evaluation of toxicological data for five substances as basis for the derivation of EU-LCI values. -

Glutaric Aciduria Lactic Acidosis Glutaryl-Coa Dehydrogenase Deficiency Short-Chain Monocarboxylic Acids

Pediat. Res. 13: 977-981 (1979) C6-C l~-dicarboxylicacid ketosis glutaric aciduria lactic acidosis glutaryl-CoA dehydrogenase deficiency short-chain monocarboxylic acids Ketotic Episodes in Glutaryl-CoA Dehydrogenase Deficiency (Glutaric Aciduria) NIELS GREGERSEN AND NIELS JACOB BRANDT Research Laboratory for Metabolic Disorders, University Department of Clinical Chemistry, Aarhus Kommunehospital, Aarhus, and Section of Clinical Genetics, University Department of Paediatrics, Obstetrics, and Gynaecology, Rigshospitalet, Copenhagen, Denmark Summaw the ketoacidosis, a pronounced lactic acidosis and lactic aciduria is seen in most cases. The present report, together with a recent A 7-yr-old boy with glutaryl-CoA dehydrogenase deficiency (glu- report of Goodman et al. (7), indicates that glutaryl-CoA dehy- taric aciduria), presenting periodic episodes of lethargy and keto- drogenase deficiency (glutaric aciduria) may present ketotic epi- sis, was studied during two such episodes. The urinary excretions sodes, similar to those of the other organic acidurias. of glutaric and 3-OH-glutaric acids were 3100-7900 and 460-660 The patient described by Goodman et al. (7) died in a Reye's &mg creatinine, respectively, during these episodes. Urine sam- syndromelike state. Our patient has had two episodes of ketosis ples collected before and after the attacks contained 100-5300 and and lethargy. During these episodes, the urinary metabolic profiles 230-370 &mg creatinine of glutaric acid and 3-OH-glutaric of organic acids were studied in detail, in an attempt to elucidate acids, respectively. During the episodes, glutaconic acid excretion the pathogenic mechanism leading to the severe clinical and rose from 14-89 to 93-630 pg/mg creatinine. -

Microwave-Assisted Low-Temperature Dehydration Polycondensation of Dicarboxylic Acids and Diols

Polymer Journal (2011) 43, 1003–1007 & The Society of Polymer Science, Japan (SPSJ) All rights reserved 0032-3896/11 $32.00 www.nature.com/pj RAPID COMMUNICATION Microwave-assisted low-temperature dehydration polycondensation of dicarboxylic acids and diols Polymer Journal (2011) 43, 1003–1007; doi:10.1038/pj.2011.107; published online 26 October 2011 INTRODUCTION time (4100 h). Therefore, we next focused on has been no report concerning a Currently, because of increasing concerns identifying more active catalysts and found that non-thermal effect in microwave-assisted about damage to the environment, the devel- scandium and thulium bis(nonafluorobutane- polycondensation reactions,33,34 although opment of new, eco-friendly (industrially sulfonyl)imide ((Sc(NNf2)3) and (Tm(NNf2)3)) there has been a report that non-thermal relevant) chemical reactions and materials is were more efficient catalysts and allowed us microwaves have a role in the chain polymer- crucial. Aliphatic polyesters have attracted to obtain high-molecular-weight polyesters ization of a lactone.32 Therefore, we studied 4 much interest as environmentally benign, (Mn42.0Â10 ) from adipic acid (AdA) and microwave-assisted syntheses of polyesters at biodegradable polymers.1,2 In general, alipha- 3-methyl-1,5-pentanediol (MPD) at 60 1Cina a relatively low temperature (80 1C) using a tic polyesters are commercially produced by shortperiodoftime(24h)andwithasmaller microwave chamber equipped with a tem- polycondensation of a dicarboxylic acid and a amount of catalyst (0.1 mol%) than had pre- perature control, and the results are reported 1.1–1.5 mol excess of a diol at a temperature viously been possible.26 herein. -

Glutaric Acid Production by Systems Metabolic Engineering of an L-Lysine–Overproducing Corynebacterium Glutamicum

Glutaric acid production by systems metabolic engineering of an L-lysine–overproducing Corynebacterium glutamicum Taehee Hana, Gi Bae Kima, and Sang Yup Leea,b,c,1 aMetabolic and Biomolecular Engineering National Research Laboratory, Systems Metabolic Engineering and Systems Healthcare Cross-Generation Collaborative Laboratory, Department of Chemical and Biomolecular Engineering (BK21 Plus Program), Institute for the BioCentury, Korea Advanced Institute of Science and Technology, Yuseong-gu, 34141 Daejeon, Republic of Korea; bBioInformatics Research Center, Korea Advanced Institute of Science and Technology, Yuseong-gu, 34141 Daejeon, Republic of Korea; and cBioProcess Engineering Research Center, Korea Advanced Institute of Science and Technology, Yuseong-gu, 34141, Daejeon, Republic of Korea Contributed by Sang Yup Lee, October 6, 2020 (sent for review August 18, 2020; reviewed by Tae Seok Moon and Blake A. Simmons) There is increasing industrial demand for five-carbon platform processes rely on nonrenewable and toxic starting materials, chemicals, particularly glutaric acid, a widely used building block however. Thus, various approaches have been taken to biologi- chemical for the synthesis of polyesters and polyamides. Here we cally produce glutaric acid from renewable resources (13–19). report the development of an efficient glutaric acid microbial pro- Naturally, glutaric acid is a metabolite of L-lysine catabolism in ducer by systems metabolic engineering of an L-lysine–overproducing Pseudomonas species, in which L-lysine is converted to glutaric Corynebacterium glutamicum BE strain. Based on our previous study, acid by the 5-aminovaleric acid (AVA) pathway (20, 21). We an optimal synthetic metabolic pathway comprising Pseudomonas previously reported the development of the first glutaric acid- putida L-lysine monooxygenase (davB) and 5-aminovaleramide amido- producing Escherichia coli by introducing this pathway compris- hydrolase (davA) genes and C. -

APPENDIX G Acid Dissociation Constants

harxxxxx_App-G.qxd 3/8/10 1:34 PM Page AP11 APPENDIX G Acid Dissociation Constants § ϭ 0.1 M 0 ؍ (Ionic strength ( † ‡ † Name Structure* pKa Ka pKa ϫ Ϫ5 Acetic acid CH3CO2H 4.756 1.75 10 4.56 (ethanoic acid) N ϩ H3 ϫ Ϫ3 Alanine CHCH3 2.344 (CO2H) 4.53 10 2.33 ϫ Ϫ10 9.868 (NH3) 1.36 10 9.71 CO2H ϩ Ϫ5 Aminobenzene NH3 4.601 2.51 ϫ 10 4.64 (aniline) ϪO SNϩ Ϫ4 4-Aminobenzenesulfonic acid 3 H3 3.232 5.86 ϫ 10 3.01 (sulfanilic acid) ϩ NH3 ϫ Ϫ3 2-Aminobenzoic acid 2.08 (CO2H) 8.3 10 2.01 ϫ Ϫ5 (anthranilic acid) 4.96 (NH3) 1.10 10 4.78 CO2H ϩ 2-Aminoethanethiol HSCH2CH2NH3 —— 8.21 (SH) (2-mercaptoethylamine) —— 10.73 (NH3) ϩ ϫ Ϫ10 2-Aminoethanol HOCH2CH2NH3 9.498 3.18 10 9.52 (ethanolamine) O H ϫ Ϫ5 4.70 (NH3) (20°) 2.0 10 4.74 2-Aminophenol Ϫ 9.97 (OH) (20°) 1.05 ϫ 10 10 9.87 ϩ NH3 ϩ ϫ Ϫ10 Ammonia NH4 9.245 5.69 10 9.26 N ϩ H3 N ϩ H2 ϫ Ϫ2 1.823 (CO2H) 1.50 10 2.03 CHCH CH CH NHC ϫ Ϫ9 Arginine 2 2 2 8.991 (NH3) 1.02 10 9.00 NH —— (NH2) —— (12.1) CO2H 2 O Ϫ 2.24 5.8 ϫ 10 3 2.15 Ϫ Arsenic acid HO As OH 6.96 1.10 ϫ 10 7 6.65 Ϫ (hydrogen arsenate) (11.50) 3.2 ϫ 10 12 (11.18) OH ϫ Ϫ10 Arsenious acid As(OH)3 9.29 5.1 10 9.14 (hydrogen arsenite) N ϩ O H3 Asparagine CHCH2CNH2 —— —— 2.16 (CO2H) —— —— 8.73 (NH3) CO2H *Each acid is written in its protonated form. -

Inconsistencies in the Nutrition Management of Glutaric Aciduria Type 1: an International Survey

nutrients Article Inconsistencies in the Nutrition Management of Glutaric Aciduria Type 1: An International Survey Laurie Bernstein 1,*, Curtis R. Coughlin 1, Morgan Drumm 1, Steven Yannicelli 2 and Fran Rohr 3 1 Department of Pediatrics, Section of Medical Genetics, University of Colorado Anschutz Medical Campus, Aurora, CO 80045, USA; [email protected] (C.R.C.); [email protected] (M.D.) 2 Nutricia North America, Rockville, MD 20850, USA; [email protected] 3 Met Ed Co, Boulder, CO 80302, USA; [email protected] * Correspondence: [email protected] Received: 16 September 2020; Accepted: 12 October 2020; Published: 16 October 2020 Abstract: Glutaric aciduria type 1 (GA-1) is a cerebral organic aciduria characterized by striatal injury and progressive movement disorder. Nutrition management shifted from a general restriction of intact protein to targeted restriction of lysine and tryptophan. Recent guidelines advocate for a low-lysine diet using lysine-free, tryptophan-reduced medical foods. GA-1 guideline recommendations for dietary management of patients over the age of six are unclear, ranging from avoiding excessive intake of intact protein to counting milligrams of lysine intake. A 22–question survey on the nutrition management of GA-1 was developed with the goal of understanding approaches to diet management for patients identified by newborn screening under age six years compared to management after diet liberalization, as well as to gain insight into how clinicians define diet liberalization. Seventy-six responses (25% of possible responses) to the survey were received. Nutrition management with GA-1 is divergent among surveyed clinicians. There was congruency among survey responses to the guidelines, but there is still uncertainty about how to counsel patients on diet optimization and when diet liberalization should occur. -

Inhibitory Effects of Green Tea Polyphenols on Microbial

H OH metabolites OH Article Inhibitory Effects of Green Tea Polyphenols on Microbial Metabolism of Aromatic Amino Acids in Humans Revealed by Metabolomic Analysis Yuyin Zhou 1, Ningning Zhang 1 , Andrea Y. Arikawa 2 and Chi Chen 1,* 1 Department of Food Science and Nutrition, University of Minnesota, St. Paul, MN 55108, USA; [email protected] (Y.Z.); [email protected] (N.Z.) 2 Department of Nutrition & Dietetics, University of North Florida, Jacksonville, FL 32224, USA; [email protected] * Correspondence: [email protected]; Tel.: +1-612-624-7704; Fax: +1-612-625-5272 Received: 7 April 2019; Accepted: 9 May 2019; Published: 11 May 2019 Abstract: The bioactivities and potential health benefits of green tea polyphenols (GTP) have been extensively investigated, but the metabolic impact of chronic GTP intake on humans is not well defined. In this study, fecal and urine samples from postmenopausal female subjects taking a GTP supplement or placebo for 12 months were compared by liquid chromatography-mass spectrometry-based metabolomic analysis. The GTP-derived and GTP-responsive metabolites were identified and characterized by structural elucidation and quantitative analysis of the metabolites contributing to the separation of control and treatment samples in the multivariate models. Major GTP and their direct sulfate and glucuronide metabolites were absent in feces and urine. In contrast, GTP-derived phenyl-γ-valerlactone and phenylvaleric acid metabolites were identified as the most abundant GTP-derived metabolites in feces and urine, suggesting extensive microbial biotransformation of GTP in humans. Interestingly, GTP decreased the levels of microbial metabolites of aromatic amino acids (AAA), including indoxyl sulfate, phenylacetylglutamine, and hippuric acid, in urine. -

Certificate of Analysis

National Institute of Standards and Technology Certificate of Analysis Standard Reference Material® 2277 Organic Acids in Methanol:Methylene Chloride This Standard Reference Material (SRM) is a solution of 24 organic acids in methanol:methylene chloride. This SRM is intended primarily for use in the calibration of chromatographic instrumentation used for the determination of organic acids. A unit of SRM 2277 consists of five 2 mL ampoules, each containing approximately 1.2 mL of solution. Certified Concentrations of Constituents: The certified concentration values and estimated uncertainties for the 24 constituents, expressed as mass fractions, are given in Table 1 along with the Chemical Abstract Service (CAS) Registry Numbers. The certified concentration values are based on results obtained from the gravimetric preparation of this solution and from the analytical results determined by using gas chromatography. A NIST certified value is a value for which NIST has the highest confidence in its accuracy in that all known or suspected sources of bias have been investigated or accounted for by NIST. Expiration of Certification: The certification of SRM 2277 is valid, within the measurement uncertainties specified, until 31 December 2017, provided the SRM is handled and stored in accordance with the instructions given in this certificate (see “Instructions for Use”). The certification is nullified if the SRM is damaged, contaminated, or otherwise modified. Maintenance of SRM Certification: NIST will monitor this SRM over the period of its certification. If substantive technical changes occur that affect the certification before the expiration of this certificate, NIST will notify the purchaser. Registration (see attached sheet) will facilitate notification. -

Supplement of Fog Composition at Baengnyeong Island in the Eastern Yellow Sea: Detecting Markers of Aqueous Atmospheric Oxidations

Supplement of Atmos. Chem. Phys., 16, 437–453, 2016 http://www.atmos-chem-phys.net/16/437/2016/ doi:10.5194/acp-16-437-2016-supplement © Author(s) 2016. CC Attribution 3.0 License. Supplement of Fog composition at Baengnyeong Island in the eastern Yellow Sea: detecting markers of aqueous atmospheric oxidations A. J. Boris et al. Correspondence to: J. L. Collett Jr. ([email protected]) The copyright of individual parts of the supplement might differ from the CC-BY 3.0 licence. 1 Supplementary Material 2 Methods: Chemicals 3 Chemical standards and solvents were purchased as follows: malonic acid (99%), 4-nitrophenol 4 (98%), and 2,4-dinitrophenol (98%) were purchased from Acros organics. Glutaric acid (99%), 5 oxalic acid (99.999%), benzoic acid (99%), succinic acid (99+%), pyruvic acid (98%), propionic 6 acid (99+%), 2-methyl-4-nitrophenol (97%), maleic acid (99%), cis-pinonic acid (98%), and 2,4- 7 pentanedione (99+%) were purchased from Aldrich. Inorganic salt standards (Six Cation-II and 8 Seven Anion Standards) were purchased from Dionex and diluted. Formaldehyde (37% 9 aqueous/methanol), sodium hydroxide pellets, potassium iodide (KI; 99.6%), iodine (100.0%), 10 potassium hydrogen phthalate (99.95%), sodium carbonate (HPLC grade), and sodium 11 bicarbonate (certified ACS) were purchased from Fischer. Ammonium acetate (≥99.0%), para- 12 hydroxy-phenylacetic acid (POPHA; ≥98.0%), Na4EDTA4H2O (≥99%), CDTA (≥98%), 13 parafuchsin (containing pararosaniline), methanesulfonic acid (MSA; ≥99.0%), acetic acid (99%), 14 formic acid (~98%), adipic acid (≥99%), n-valeric acid (≥99%), azelaic acid (98%), and 4,6- 15 dinitro-o-cresol (2-methyl-4,6-dinitrophenol; ≥98%) were purchased from Fluka. -

(CDR) by CASRN Or Accession Number

List of Chemicals Reported for the 2012 Chemical Data Reporting (CDR) by CASRN or Accession Number For the 2012 CDR, 7,674 unique chemicals were reported by manufacturers (including importers). Chemicals are listed by CAS Registry Number (for non-confidential chemicals) or by TSCA Accession Number (for chemicals listed on the confidential portion of the TSCA Inventory). CASRN or CASRN or ACCESSION ACCESSION NUMBER CA INDEX NAME or GENERIC NAME NUMBER CA INDEX NAME or GENERIC NAME 100016 Benzenamine, 4-nitro- 10042769 Nitric acid, strontium salt (2:1) 10006287 Silicic acid (H2SiO3), potassium salt (1:2) 10043013 Sulfuric acid, aluminum salt (3:2) 1000824 Urea, N-(hydroxymethyl)- 10043115 Boron nitride (BN) 100107 Benzaldehyde, 4-(dimethylamino)- 10043353 Boric acid (H3BO3) 1001354728 4-Octanol, 3-amino- 10043524 Calcium chloride (CaCl2) 100174 Benzene, 1-methoxy-4-nitro- 100436 Pyridine, 4-ethenyl- 10017568 Ethanol, 2,2',2''-nitrilotris-, phosphate (1:?) 10043842 Phosphinic acid, manganese(2+) salt (2:1) 2,7-Anthracenedisulfonic acid, 9,10-dihydro- 100447 Benzene, (chloromethyl)- 10017591 9,10-dioxo-, sodium salt (1:?) 10045951 Nitric acid, neodymium(3+) salt (3:1) 100185 Benzene, 1,4-bis(1-methylethyl)- 100469 Benzenemethanamine 100209 1,4-Benzenedicarbonyl dichloride 100470 Benzonitrile 100210 1,4-Benzenedicarboxylic acid 100481 4-Pyridinecarbonitrile 10022318 Nitric acid, barium salt (2:1) 10048983 Phosphoric acid, barium salt (1:1) 9-Octadecenoic acid (9Z)-, 2-methylpropyl 10049044 Chlorine oxide (ClO2) 10024472 ester Phosphoric acid, -

Ketoadipic Aciduria: a Description of a New Metabolic Error in Lysine - Tryptophan Degradation

Pediat. Res 9: 522-526 (1975) a-Aminoadipic acid tryptophan a-ketoadipic acid urine lysine -Ketoadipic Aciduria: A Description of a New Metabolic Error in Lysine - Tryptophan Degradation R. W. WILSON,'31' C. M. WILSON, S. C. GATES, AND J. V. HIGGINS Departments of Natural Science. Zoologv. Biochemistrv, and Human Development, Michigan State Universitv, East Lahsing. Michigan USA Extract Lysine Tryptophan , , Our studies of a mentally retarded male with extremely elevated levels of a-aminoadipic acid and a-ketoadipic acid in his urine have I Y' led to the description of a new metabolic defect, a-ketoadipic a-Aminoadipic acid a-Aminomuconic acid aciduria. Analysis of the urine and serum from the patient's family revealed that the patient (KW) had a mentally and physically a-Aminoadipate a-Aminornuconate normal sister (CW) with the same metabolites elevated, but the rest transferase of the family appeared normal. reductase \a-Ketoadipic /' acid I Speculation a-Ketoadipate dehydrogenase (a-ketoglutarate dehydrogenase?) The presence of elevated levels of a-ketoadipate in the urine of the plus cofactors reported sibs suggests a reduced level of a-ketoadipic acid dehydro- Glutaryl-CoA1 plus CO, genase. This enzyme has not been purified in humans, but is considered to be a-ketoglutaric acid dehydrogenase in several I nonhuman animals. We are presenting evidence that would suggest * that in humans these may be separate enzymes, or that more than Acetoacetyl-CoA one form of the a-ketoglutaric acid dehydrogenase exists. Scheme 1. Steps in degradation pathway. MATERIALS AND METHODS During the routine testing for amino acid anomalies in Michigan PATIENT state hospitals for the mentally retarded, an unidentified ninhy- drin-positive compound was found in the urine of a 14-year-old The subject (XW) is a Caucasian male and was born in July 1960 male. -

Fluorescent Probes for the Labelling of Cardiomyocyte and Mitochondrial Proteins. Thomas D. Z. Pearson

Fluorescent Probes for the Labelling of Cardiomyocyte and Mitochondrial Proteins. A thesis submitted in partial fulfilment of the requirements for the degree of Doctor of Philosophy. By Thomas D. Z. Pearson 2017 School of Science and Technology Nottingham Trent University Clifton Lane Nottingham NG11 8NS United Kingdom i Declaration I hereby certify that the work embodied in this thesis is the result of my own investigations except where reference has been made to published literature. ii Abstract Organophosphates are a known danger to human health with an array of biochemical targets and complex toxic effects. Phenyl saligenin phosphate (PSP) is an organophosphate and related phenoxy substituted organophosphates irreversibly bind to a variety of important enzymes causing the condition known as organophosphate induced delayed neuropathy (OPIDN). These compounds also potentially cause cardiac muscle damage but little is known about how this class of compounds effect cardiomyocytes. The identification of proteins targeted by these toxins is of interest. This study investigates the synthesis and application of novel fluorescently labelled organophosphates to investigate organophosphate interaction with H9c2 cardiomyoblasts. The synthesis of probes with BODIPY, pyrene and rhodamine fluorescent component is explored with success in preparation of pyrene and rhodamine probes. The fluorescent behaviour of three rhodamine labelled phenyl saligenin phosphates probes with alkyl and PEG linkers is examined and the cytotoxicity of the probes assessed by monitoring MTT reduction, and LDH release from exposed H9c2 cardiomyoblasts. All three analogues showed cytotoxicity (4 h exposure; 100 µM). These probes were found to bind to proteins within mitochondria and spots from 2D-gel electrophoresis experiments, visualised at 532 nm, which are undergoing MS analysis.