United States Patent Office Patented Dec

Total Page:16

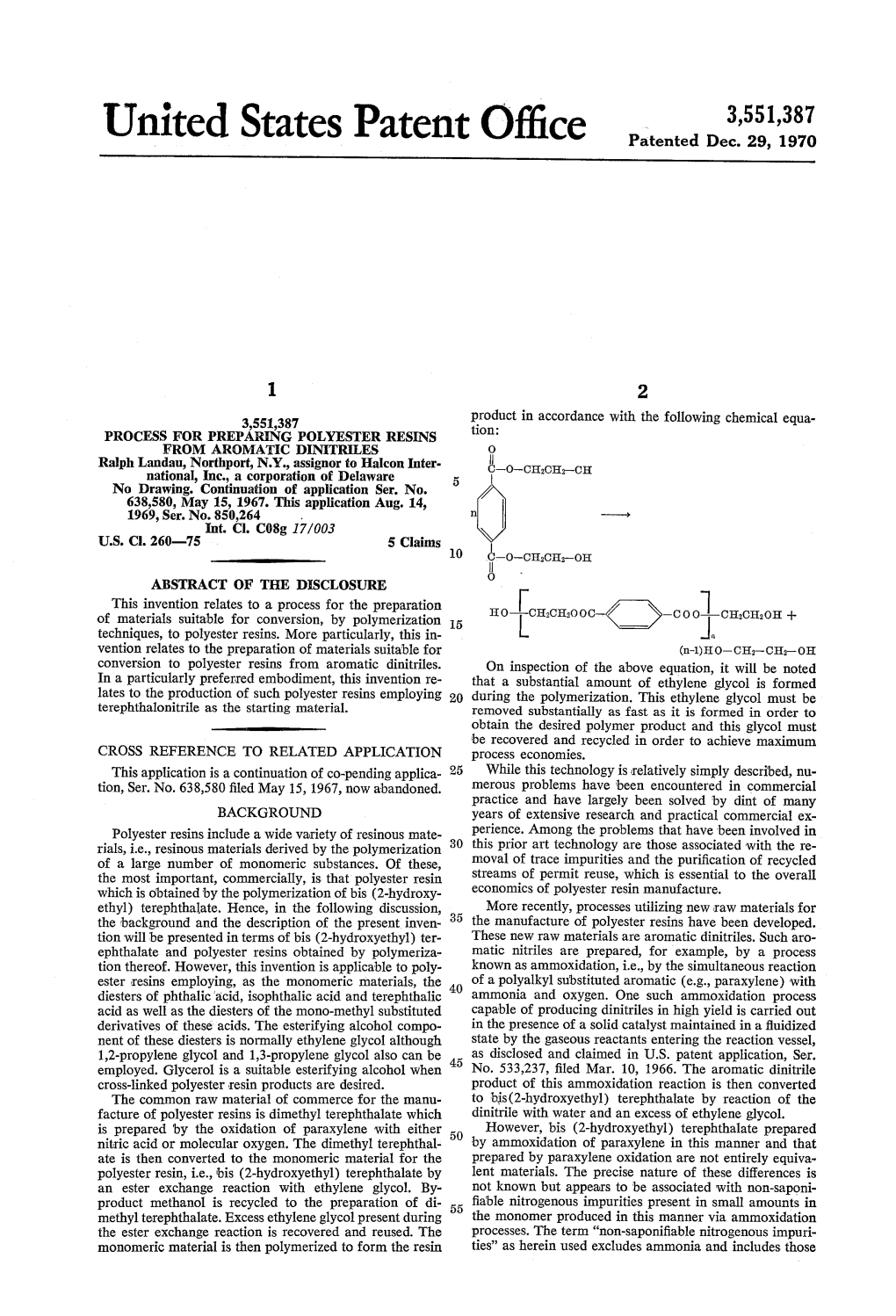

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

475528 1 En Bookfrontmatter 1..21

Primed for Success: The Story of Scientific Design Company “More than a company history, Primed for Success is the story of the chemical industry in the United States. It is comprehensive in scope and detailed in its treatment—an essential read for anyone who studies the chemical industry or has been part of it.” —Thomas M. Connelly, Chief Executive Officer, ACS “Peter Spitz’ detailed and engrossing account of the rise of the petrochemical industry—which set in motion the building blocks of the modern industrial economy—captures how transformative the industry has been to not just economic development, but to so many aspects of modern life.” —Andrew N. Liveris, Former Chairman and CEO, Dow Chemical “Peter Spitz is opening up a new chapter in the history of the petrochemical industry that provides a lasting platform and remembrance of the great entrepreneurs of the industry. The new book should be very valuable for the new generation of chemical engineers as they recognize the vision and creativity of many courageous scientists and engineers.” —Werner Praetorius, President Petrochemicals (ret.), BASF Group “Peter Spitz delivers an essential history with Primed for Success. He details the inside story of a disruptive startup that invented the breakthrough technologies that would help usher in the petrochemical age. The book’s insights on entrepreneurship, successful innovation and the risks of overreach and hubris offer enduring lessons for today’s engineers and professionals as well.” —Robert Westervelt, Editor-in-Chief, Chemical Week “Ralph Landau was one of the giants of the chemical engineering profession. Both experienced and early-stage chemical engineers can appreciate how Ralph created a new business model as well as learn many lessons from his technical and business leadership.” —June C. -

Department of Chemical Engineering, Report to the President 2014-2015

Department of Chemical Engineering Overview The Department of Chemical Engineering (ChemE) continues to be ranked as the world’s number-one chemical engineering program, a position it has held for the past 26 years. Many of our faculty received major honors and awards this year. Despite this continuity, there have been some significant changes in the physical space that the department has occupied for almost 40 years and a recent change in leadership. Research volume in the department continues to be strong, increasing by 7% this year to $57.6 million. Of these funds, $23.6 million were handled directly through the department, and the rest was handled by different cost centers at MIT, including the Koch Institute for Integrative Cancer Research, the MIT Energy Initiative, the Institute for Soldier Nanotechnologies, and the Ragon Institute. The strong engagement with these interdisciplinary centers continues to provide a robust basis for innovation, and provides our students with experience solving important and difficult real-world problems. Professor Klavs F. Jensen stepped down as department head in July 2015, after leading the department for eight years. Among his many accomplishments are significant space renovations, including the modernization of Building 66 and new faculty laboratories in buildings E17 and E18; successful recruiting 10 new faculty members; and exemplary leadership. His many years of service are greatly appreciated by the faculty and staff of the Department of Chemical Engineering. Paula T. Hammond, the David H. Koch professor in engineering, became the new head of the Department of Chemical Engineering, effective July 13, 2015. Professor Hammond is an accomplished researcher with a strong record of service to MIT and the department. -

JUN 2 41996 Science

POLYMER-BASED SOLVENTS FOR MINIMIZING POLLUTION DURING THE SYNTHESIS OF FINE CHEMICALS by Linda K. Molnar B.S., Chemistry University of Pittsburgh, 1991 Submitted to the Department of Materials Science and Engineering Program in Polymer Science and Technology in Partial Fulfillment of the Requirements for the Degree of Doctor of Philosophy at the Massachusetts Institute of Technology June 1996 © 1996 Massachusetts Institute of Technology All rights reserved Signature of A uthor ....................... ............ Department of Materials Science anidEngineering Program in Polymer Science and Technology May 3, 1996 Certified by ........................................................... .............. T. Alan Hatton Ralph Landau Professor of Chemical Engineering Practice Thesis Supervisor Certified by.... ......................... Stephen L. Buchwald Professor of Chemistry T~esis Supervisor Accepted by ............. Michael F. Rubner TDK Professor of Materials Science and Engineering Chair, Departmental Committee of Graduate Students SOF TECHNOLOGY OF TECýNNLOC~ JUN 2 41996 Science UBRARiES Polymer-Based Solvents for Minimizing Pollution During the Synthesis of Fine Chemicals by Linda K. Molnar Submitted to the Department of MaterialsScience and Engineering Program in Polymer Science and Technology on May 3, 1996 in PartialFulfillment of the Requirementsfor the Degree of Doctorof Philosophy ABSTRACT Most processes used in the pharmaceutical industry are, by necessity, carried out in organic solvents. In many cases these solvents are volatile and sufficiently water-soluble to contaminate air emission and aqueous discharge streams, adding to the environmental burden and the cost of downstream processing and recovery operations. One example is the use of tetrahydrofuran (THF) as the solvent for Grignard reactions which must be carried out under anhydrous conditions. The desired product is often obtained by aqueous precipitation. -

The Department of Chemical Engineering at MIT Maintained Its Usual High Productivity and Visibility in Teaching and Research

Department of Chemical Engineering In academic year 2004, the Department of Chemical Engineering at MIT maintained its usual high productivity and visibility in teaching and research. For the 15th consecutive year, both our graduate and undergraduate programs garnered the number‐one ranking among the nation’s chemical engineering departments by US News and World Report. The department also had a tremendous year fiscally, with research expenditures of $23.3 million. During the academic year, 28 doctoral degrees (PhD and ScD) were awarded, along with 36 SM and/or master’s‐level degrees, yielding a total of 64 advanced degrees conferred. Forty‐one SB degrees were conferred as of June 2004, with 70 percent awarded to women. The department’s undergraduate enrollment stands at 140 students. The graduate student enrollment is stable at 258 students, with 232 in the doctoral program and 26 master’s‐level degree candidates. The graduate programs include 91 foreign, 75 female, 28 Asian American, and 10 self‐identified minority students. This year, we received 335 applications for our doctoral program and offered admissions to 75 individuals, of which 53 accepted our admissions. Among the incoming class for 2004, 14 are female and 8 are minority or Asian American graduate students. Renovation of the Edwin R. Gilliland Auditorium, on the first floor of the Ralph Landau Building, has added updated audiovisual, networking, and digital media technology to the lecture hall. This has substantially improved both the teaching environment for several key departmental undergraduate and graduate courses and the functionality of the space for various lectures events. Modernized lighting and finishes in the first floor corridor effectively link the renovated auditorium to an Edwin R. -

Catalysis Looks to the Future

o.... °a CATALYSISLOOTOKTHESFUTURE -i Panel on New Directions in Catalytic Science and Technology Board on Chemical Sciences and Technology National Research Council DISCLAIMER This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsi- bility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Refer- ence herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recom- mendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof. NATIONAL ACADEMY PRESS Washington, D.C. 1992 DISTRIBUTION OF THIS DOCUMENT IS UNLIMITED ....... i f p -_ PANEL ON NEW DIRECTIONS IN CATALYTIC SCIENCE AND TECHNOLOGY Alexis T. Bell, University of California, Berkeley, Chair Michel Boudart, Stanford University Burt D. Ensley, Envirogen David Estell, Genencor Robert H. Grubbs, California Institute of Technology L. Louis Hegedus, W. R. Grace & Co. Leo E. Manzer, E. I. Du Pont de Nemours & Co., Inc. Jule A. Rabo, UOP Tarrytown Technical Center Julius Rebek, Jr., Massachusetts Institute of Technology James F. Roth, Air Products and Chemicals, Inc. Gabor A. Somorjai, University of California, Berkeley Vern W..Weekman, Mobil Research & Development Company William Spindel, Study Director o.o Ill COMMISSION ON PHYSICAL SCIENCES, MATHEMATICS, AND APPLICATIONS Norman Hackerman, Robert A. -

Implications for Energy Innovation from the Chemical Industry Ashish

Implications for Energy Innovation from the chemical industry Ashish Arora, Duke University and NBER, & Alfonso Gambardella, Bocconi University September, 2009. Abstract: The history of innovation in the chemical industry offers many insights for accelerating energy innovation. In this chapter, we begin by laying out the early history of the chemical industry for an overview of the role innovation has played in its development. We then explore three noteworthy historical experiences. We describe the switch in feedstocks from coal to oil, and briefly analyze two government programs that have attempted to promote innovation: synthetic rubber and synfuels. We take a close look at the role that specialized engineering firms have played in the diffusion of important innovations, and we detail the effect that government policies have had on fostering innovation. In particular, we highlight the role of anti-trust policies, and of policies for protecting intellectual property rights. We are grateful to Linda Cohen, Rebecca Henderson, Richard Newell and other participants at the NBER meeting, April 2009, Boston for helpful comments, and to Bonnie Nevel and Susan Schaffer for assistance in the preparation of this manuscript. We remain responsible for all remaining errors. Once a leader in industrial innovation, the chemical industry has changed countless aspects of modern life. From the plastic in the toothbrush we use in the morning, to the tires we drive to work on and the fuel that powers them, to the clothes that keep us warm, chemical innovations are so infused in our daily lives that we generally take them for granted. It is hard to imagine life without the myriad chemical breakthroughs that shape today’s world. -

Chemical Weapons Convention Implementation in Pakistan

SAFETY AND SECURITY OF CHEMICAL INDUSTRY: CHEMICAL WEAPONS CONVENTION IMPLEMENTATION IN PAKISTAN A thesis submitted to the Department of Defence and Strategic Studies Quaid-i-Azam University, Islamabad in partial fulfillment of the requirements for the award of DOCTOR OF PHILOSOPHY IN DEFENCE AND STRATEGIC STUDIES by Naeem Haider DEPARTMENT OF DEFENCE AND STRATEGIC STUDIES QUAID-I-AZAM UNIVERSITY ISLAMABAD, PAKISTAN MAY 2014 DECLARATION I hereby declare that this thesis is the result of my individual research and that it has not been submitted concurrently to any other university for any other degree. Naeem Haider May 2014 APPROVAL The Ph.D. thesis Safety and Security of Chemical Industry: Chemical Weapons Convention Implementation in Pakistan by Naeem Haider has been written to my satisfaction, which meets the required standards of research for the award of Ph.D. degree. Therefore, the thesis is approved for external evaluation. Dr. Zafar Nawaz Jaspal Associate Professor Director (SPIR)/ Supervisor May 2014 CONTENTS Page ABSTRACT viii ACKNOWLEDGEMENTS x ABBREVIATIONS xi LIST OF TABLES xiii INTRODUCTION 1 Objective of the Study 9 Definition of the Problem 9 Review of Literature 10 Research Framework 29 Research Methodology 29 Limitations of the Study 31 Organization of the Study 32 CHAPTER 1 THEORETICAL FRAMEWORK: LEARNING FROM REGIME THEORY 37 PART- I: REGIME THEORY 39 1.1 Conceptualizing Regime Theory 39 1.2 Evolution of International Regimes 42 1.3 Determinants for the Efficacy of Regime 44 1.4 Efficacy of Regime: An Appraisal 49 1.5 -

Michael D. Grubb

Michael D. Grubb Boston College phone: 617-552-1569 140 Commonwealth Ave. e-mail: [email protected] Maloney Hall, Office 341 web: https://sites.google.com/bc.edu/michael-grubb/ Chestnut Hill, MA 02467 ACADEMIC EXPERIENCE BOSTON COLLEGE ECONOMICS DEPARTMENT, Chestnut Hill, MA 2013 – present Associate Professor of Economics (with tenure) 2016 – present Assistant Professor of Economics 2013 – 2016 MIT SLOAN SCHOOL OF MANAGEMENT, Cambridge, MA Assistant Professor of Applied Economics 2007 – 2013 HARVARD DEPARTMENT OF ECONOMICS, Cambridge, MA Visiting Scholar 2009 – 2010 EDUCATION STANFORD GRADUATE SCHOOL OF BUSINESS, Stanford CA Ph.D. in Business Administration (Field: Economics) 2007 UNIVERSITY OF OXFORD - NUFFIELD COLLEGE, Oxford UK M. Phil. in Economics 2002 UNIVERSITY OF PENNSYLVANIA, Philadelphia PA Management and Technology Joint Degree Summa Cum Laude The Wharton School, B.S. in Economics 2000 School of Engineering and Applied Science, B.S. in Engineering 2000 FIELDS OF INTEREST Behavioral Industrial Organization, Industrial Organization, Applied Microeconomic Theory PUBLICATIONS “Selling to Overconfident Consumers”, American Economic Review, 2009, 99(5), pp. 1770-1807. Doi:10.1257/aer.99.5.1770. (Winner of The Claire and Ralph Landau Prize 2007) “Developing a Reputation for Reticence”, Journal of Economics & Management Strategy, 2011, 20(1) pp. 225-268. Doi:10.1111/j.1530-9134.2010.00288.x. “Dynamic Nonlinear Pricing: biased expectations, inattention, and bill shock”, International Journal of Industrial Organization, 2012, 30(3), pp. 287-290. Doi:10.1016/j.ijindorg.2011.12.007. “Consumer Inattention and Bill-Shock Regulation”, Review of Economic Studies, 2015, 82(1), pp. 219- 257. Doi:10.1093/restud/rdu024. “Cellular Service Demand: Biased Beliefs, Learning, and Bill Shock” (with Matthew Osborne), American Economic Review, 2015, 105(1), pp. -

CHEMICAL HERITAGE FOUNDATION MANSON BENEDICT Transcript Of

CHEMICAL HERITAGE FOUNDATION MANSON BENEDICT Transcript of an Interview Conducted by James J. Bohning at Naples, Florida on 24 January 1991 (With Subsequent Additions and Corrections) This interview has been designated as Free Access. One may view, quote from, cite, or reproduce the oral history with the permission of CHF. Please note: Users citing this interview for purposes of publication are obliged under the terms of the Chemical Heritage Foundation Oral History Program to credit CHF using the format below: Manson Benedict, interview by James J. Bohning at Naples, Florida, 24 January 1991 (Philadelphia: Chemical Heritage Foundation, Oral History Transcript # 0088). Chemical Heritage Foundation Oral History Program 315 Chestnut Street Philadelphia, Pennsylvania 19106 The Chemical Heritage Foundation (CHF) serves the community of the chemical and molecular sciences, and the wider public, by treasuring the past, educating the present, and inspiring the future. CHF maintains a world-class collection of materials that document the history and heritage of the chemical and molecular sciences, technologies, and industries; encourages research in CHF collections; and carries out a program of outreach and interpretation in order to advance an understanding of the role of the chemical and molecular sciences, technologies, and industries in shaping society. MANSON BENEDICT 1907 Born in Lake Linden, Michigan on 9 October Education 1928 B. Chem., Cornell University 1930-1931 University of Chicago 1932 M.S., physical chemistry, MIT 1935 Ph.D., physical chemistry, MIT Professional Experience 1929-1930 Research Chemist, National Aniline and Chemical Co. 1935-1936 National Research Council Fellow, Harvard University 1936-1937 Research Associate in Geophysics, Harvard University 1937-1938 Research Chemist, National Aniline and Chemical Co. -

For Policy Peform

FORIVSTITUTE " POLICY PEFORM The objective of the Institute for Policy Reform is to enhance the foundation for broad based economic growth in developing countrics. Through its research, education and training activities the Institute encourages activ,, participation in the dialogue on policy reform, l)cs in oil changCes that stimu late and s'stain cco.-mlic development. At the core of these activities is the search for creative ideas thal an be used to design const itutIjonal, institutional aad policy reforms. Research fellows and poticy practitioners are engag(ed by IPR to expand the analytical core of the reform process. This incIuIdes all elements of comlprehensive and customized reform packages, recognizing cultuII ral, political, economic and en vi ronnIental elements as crucial dimensions of societies. 1400 16th Street, NW / Suite 350 Washington, DC 20036 (202) 939 - 3450 U.S. Agency for International Development This publication was made possible through support provided by the Office of Education and Institutional Development, Bureau for Research and Development, U.S. Agency for International Development, under the terms of Grant No. PDC# 0095-A-00- 1126-00. The opinions expressed herein are those of the author(s) and do not necessarily reflect .he views of the U.S. Agency for International Development or the Institute for Policy Reform. INSTITUTE FOR POLICY REFORM IPR95 Implementing Environmental Taxes on Intermediate Goods in Open Economies James M. Poterba1 & Julio J. Rotemberg 2 Massachusetts Institute of Technology&1 2 and Senior Research Fellow' Institutefor Policy Reform June, 1994 Many proposed and actual environmental taxes are taxes on intermediate goods. These goods, such as fossil fucls, are typically tradable, and they are also used in the production of many tradable final goods. -

Lake County Emissions Tied to Cancer Public Not Warned About Ethylene Oxide Released by Waukegan, Gurnee Facilities

Nov. 4, 2018 Nov. 4, 2018 Lake County emissions tied to cancer Public not warned about ethylene oxide released by Waukegan, Gurnee facilities By Michael Hawthorne Communities facing abnormally high cancer risks from toxic air pollution stand out on a color-coded map created by the U.S. Environmental Protection Agency. Only a few dozen residential areas nationwide are shaded dark blue like neighborhoods surrounding the Sterigenics facility in west suburban Willowbrook in DuPage County, where potent ethylene oxide gas escapes from fumigation chambers used to sterilize medical instruments, pharmaceutical drugs and food. Pull back from a tight focus on Willowbrook and another dark blue cluster comes into view about 40 miles northeast in Lake County. More than 19,000 people live within areas at risk from ethylene oxide emitted by a Medline Industries facility near Interstate 94 in the southwest corner of Waukegan, the interactive map shows. Another facility in Lake County could pose even greater risks than Sterigenics or Medline. Federal and state officials confirmed the only reason it isn't on the map is that someone at the state level failed to provide the facility's ethylene oxide emissions for the U.S. EPA's latest estimate of cancer risks, known as the National Air Toxics Assessment. Vantage Specialty Chemicals in Gurnee reported to another office at the EPA that during 2014 it released 6,412 pounds of ethylene oxide -- more than either Sterigenics or Medline did during the same period. The federal agency estimated cancer risks based on 5,566 pounds of the toxic gas emitted by Sterigenics that year and 3,058 pounds released by Medline. -

Advances in Chemical Engineering-Volume 38, (2010) Ii

ADVANCES IN CHEMICAL ENGINEERING Editor-in-Chief GUY B. MARIN Department of Chemical Engineering Ghent University Ghent, Belgium Editorial Board DAVID H. WEST Research and Development The Dow Chemical Company Freeport, Texas, U.S.A. JINGHAI LI Institute of Process Engineering Chinese Academy of Sciences Beijing, P.R. China SHANKAR NARASIMHAN Department of Chemical Engineering Indian Institute of Technology Chennai, India Advances in CHEMICAL ENGINEERING MICROSYSTEMS AND DEVICES FOR (BIO)CHEMICAL PROCESSES VOLUME 38 Edited by J C SCHOUTEN Eindhoven University of Technology Eindhoven, The Netherlands Amsterdam • Boston • Heidelberg • London • New York • Oxford Paris • San Diego • San Francisco • Singapore • Sydney • Tokyo Academic Press is an imprint of Elsevier Academic Press is an imprint of Elsevier Linacre House, Jordan Hill, Oxford OX2 8DP, UK 32 Jamestown Road, London NW1 7BY, UK Radarweg 29, PO Box 211, 1000 AE Amsterdam, The Netherlands 30 Corporate Drive, Suite 400, Burlington, MA 01803, USA 525 B Street, Suite 1900, San Diego, CA 92101-4495, USA First edition 2010 Copyright � 2010, Elsevier Inc. All rights reserved No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic, mechanical, photocopying, recording or otherwise without the prior written permission of the publisher Permissions may be sought directly from Elsevier's Science & Technology Rights Department in Oxford, UK: phone (+44) (0) 1865 843830; fax (+44) (0) 1865 853333; email: [email protected].