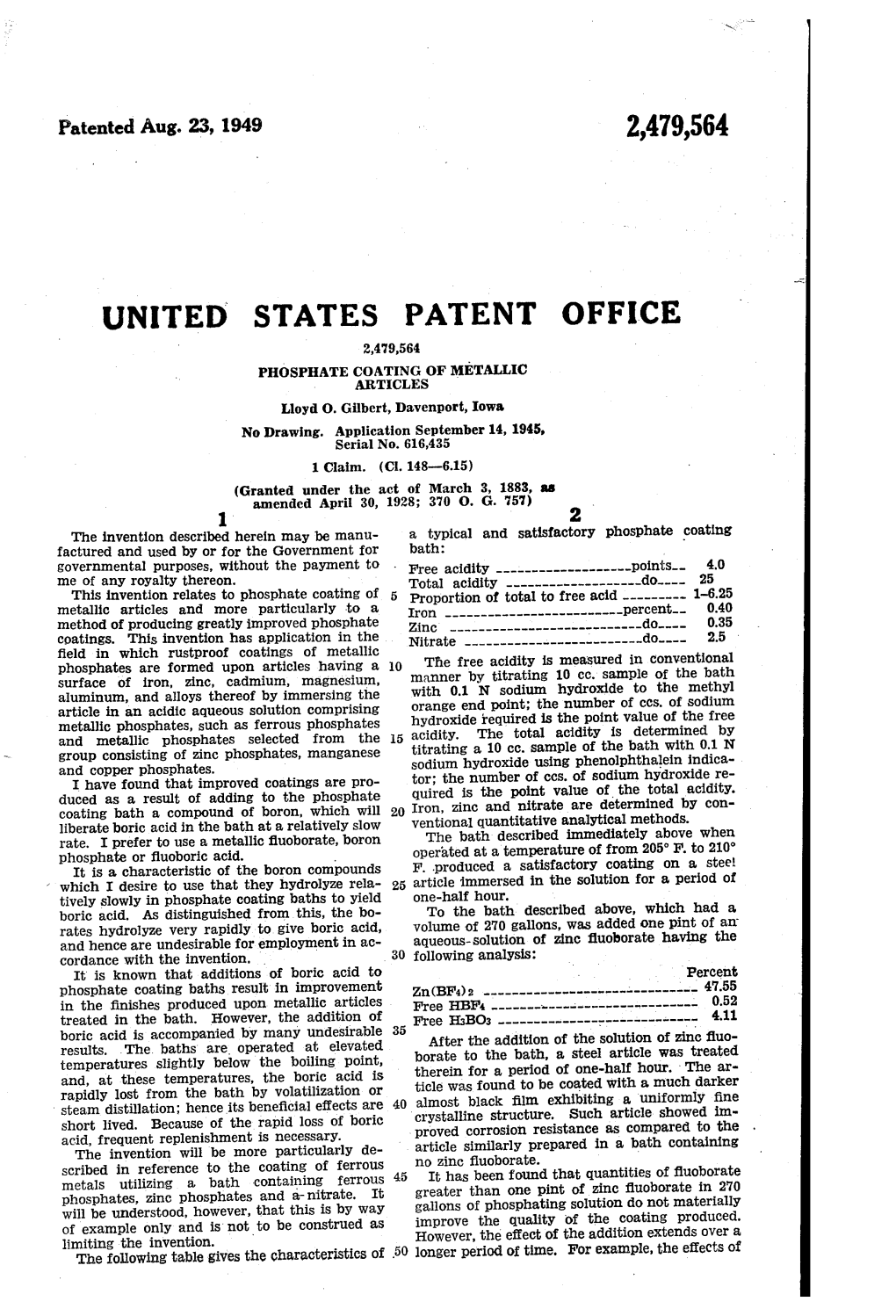

UNITED STATES PATENT OFFICE 2,479,564 PHOSPHATE COATING 0F METALLIC ARTICLES Lloyd 0

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

United States Patent Office 368)

Patented May 8, 1945 2,375,638 UNITED STATES PATENT OFFICE 368). OSPORCAC) AND METHOD OF PSEPARNG SE SAE Leonard H. Egguani, Winona, illinn. No Drawing. App3.cation May 17, 1942, Seria Ne, 393,938 6 Claims. (C. 23-166) This invention relates to the provision and pro phosphorus pentoxide P2O5, to about four molec diction of phosphorus pentoxide derivatives and ular equivalents of the boric acid B(OH) are has as a general object the provision and prepa employed in the reaction which is represented by ration of a novel boro-phosphoric acid and a the following equation: . method of preparing various salts thereof. A more specific object of the invention is the provision of a novel powdery non-hygroscopic While do not wish the invention imited to acid comprising acid oxide groups of boron and any theory of the reactions which may be in phosphorus together with certain molecular pro voived, in view of the generai belief stated above, portions of water. C it Enight toe we to point out by way of possible Another object of the invention is the pro explanation that i believe the two molecular vision of a novel boro-phosphoric acid which has equivalents of the phosphorus pentoxide, 2Paos, a relatively great capacity for neutralizing bases abstract from the four noiecular equivalents of and which can be readily stored and handled as the horic acid, 43(OH)3, three Eholecular equiva other non-corrosive powders without requiring lents of Water. Tiki as the boron oxide groups experasive subber-coated or rubber-lined equip ray be C33 'feite it one notects r equivalent ment and containers. -

Boron Compounds As Additives to Lubricants

ISSN: 1402-1544 ISBN 978-91-86233-XX-X Se i listan och fyll i siffror där kryssen är LICENTIATE T H E SIS Faiz Ullah to Shah Lubricants Additives Compounds Boron as Division of Chemical Engineering Division of Machine Elements Boron Compounds as Additives to Lubricants ISSN: 1402-1757 ISBN 978-91-7439-027-8 Synthesis, Characterization and Tribological Luleå University of Technology 2009 Optimization Synthesis, Characterization and Tribological Optimization Tribological Characterization and Synthesis, Faiz Ullah Shah Boron Compounds as Additives to Lubricants: Synthesis, Characterization and Tribological Optimization Faiz Ullah Shah Division of Chemical Engineering & Division of Machine Elements Luleå University of Technology SE- 971 87 Luleå SWEDEN November 2009 Printed by Universitetstryckeriet, Luleå 2009 ISSN: 1402-1757 ISBN 978-91-7439-027-8 Luleå www.ltu.se The most fundamental and lasting objective of synthesis is NOT production of new compounds but PRODUCTION OF NEW PROPERTIES George S. Hammond. Norris Award lecture, 1968 SUMMARY Developing new technological solutions, such as use of lightweight materials, less harmful fuels, controlled fuel combustion processes or more efficient exhaust gas after-treatment, are possible ways to reduce the environmental impact of machines. Both the reduction of wear and the friction control are key issues for decreasing of energy losses, improving efficiency and increasing of the life-span of an engine. Dialkyldithiophosphates (DTPs) of different metals have been extensively used as multifunctional additives in lubricants to control friction and reduce wear in mechanical systems. Among these DTP-compounds, zinc dialkyldithiophosphates (ZnDTPs) are the most common additives used for more than 60 years. These additives form protective films on steel surfaces and, thus, control friction and reduce wear. -

Treaty Series

Treaty Series Treaties and internationalagreements registered or filed and recorded with the Secretariat of the United Nations VOLUME 446 Recueil des Traites Traites et accords internationaux enregistres ou classes et inscrits au repertoire au Secrtariat de l'Organisationdes Nations Unies United Nations * Nations Unies New York, 1963 Treaties and international agreements registered or filed and recorded with the Secretariat of the United Nations VOLUME 446 1962 I. Nos. 6397-6409 TABLE OF CONTENTS Treaties and internationalagreements registered /rom 29 November 1962,to 4 December 1962 Page No. 6397. Denmark and People's Republic of China: Exchange of notes constituting an agreement relating to mutual exemption from taxation of residents of either State who are temporarily staying in the other State for educational purposes. Copenhagen, 7 and 23 Septem- ber 1961 .............. .............. ........ 3 No. 6398. United States of America and Denmark: Interim Agreement relating to the General Agreement on Tariffs and Trade (with schedules). Signed at Geneva, on 5 March 1962 ............ 9 No. 6399. United States of America and Finland: Interim Agreement relating to the General Agreement on Tariffs and Trade (with schedules). Signed at Geneva, on 5 March 1962 ......... ... 19 No. 6400. United States of America and Israel: Interim Agreement relating to the General Agreement on Tariffs and Trade (with schedules). Signed at Geneva, on 5 March 1962 ......... ... 29 No. 6401. United States of America and New Zealand: Interim Agreement relating to the General Agreement on Tariffs and Trade (with schedules). Signed at Geneva, on 5 March 1962 ......... ... 39 No. 6402. United States of America and Norway: Interim Agreement relating to the General Agreement on Tariffs and Trade (with schedules). -

Download and Execute the Full Code for These Examples Themselves and Modify Them for Their Own Applications

Lawrence Berkeley National Laboratory Recent Work Title Benchmarking Coordination Number Prediction Algorithms on Inorganic Crystal Structures Permalink https://escholarship.org/uc/item/0sj353dg Journal Inorganic Chemistry: including bioinorganic chemistry, 60(3) ISSN 0020-1669 Authors Pan, Hillary Ganose, Alex Horton, Matthew et al. Publication Date 2021-02-01 DOI 10.1021/acs.inorgchem.0c02996 Peer reviewed eScholarship.org Powered by the California Digital Library University of California Benchmarking Coordination Number Prediction Algorithms on Inorganic Crystal Structures Hillary Pan,y,{ Alex M. Ganose,y,{ Matthew Horton,y,z Muratahan Aykol,y Kristin Persson,y,z Nils E.R. Zimmermann,∗,y and Anubhav Jain∗,y yLawrence Berkeley National Laboratory, Energy Technologies Area, 1 Cyclotron Road, Berkeley, CA 94720, United States zDepartment of Materials Science & Engineering, University of California, Berkeley, United States {Equal contribution E-mail: [email protected]; [email protected] Abstract Coordination numbers and geometries form a theoretical framework for understand- ing and predicting materials properties. Algorithms to determine coordination num- bers automatically are increasingly used for machine learning and automatic structural analysis. In this work, we introduce MaterialsCoord, a benchmark suite containing 56 experimentally-derived crystal structures (spanning elements, binaries, and ternary compounds) and their corresponding coordination environments as described in the research literature. We also describe CrystalNN, a novel algorithm for determining near neighbors. We compare CrystalNN against 7 existing near-neighbor algorithms on the MaterialsCoord benchmark, finding CrystalNN to perform similarly to several well-established algorithms. For each algorithm, we also assess computational demand and sensitivity towards small perturbations that mimic thermal motion. Finally, we 1 investigate the similarity between bonding algorithms when applied to the Materials Project database. -

Patented July 21, 1953 2,646,344

Patented July 21, 1953 2,646,344 Jonas Kamlet, Easton, Conn, assignor to Amer ican Potash & Chemical Corporation, Trona, Calif., a corporation of Delaware No Drawing. Application September 27, 1952, serial No. 311,943 s. 1. Claim. (C1.23-203) 1 : 2 : . This invention relates to a process for the with ammonia in the Vapor phase to form adipo manufacture of boron phosphate (BPO4). More dinitrile for the nylon process (Arnold and partietary, it relates to a simple process where Iazier-U.S. Patent : 2,200,734); . by-boron phosphate:may be manufactured in a (e). As a catalyst in the dehydration of ethyl single step from cheap and readily available raw senic and cycloaliphatic alcohols (Usines. de . Melle-British Patent. 589,709); materials.Boron phosphate has heretofore been s manu (f) As a catalyst in the vapor phase methyl factured by the following methods: . ation of benzene with dimethyl ether to form (a) By the reaction of boric anhydride with toluene . (Given and Hammick, Journ. Chem. phosphorus oxychloride or phosphorus penta () Soc. 1947,928-935); chloride, according to the equations: (g) As a catalyst in the vapor phase nitration of aromatic hydrocarbons in petroleum with NO2 (Rout, U. S. Patent 2,431,585); (h) As a catalyst in the desulfurization of at 150°-170° C. for 8-10 hours, or by the reaction hydrocarbons in petroleum refining (Krug, U. S. of phosphorus pentoxide with boron trichloride Patent 2,441,493); at 200° C. for 2-3 days (Gustavson, Berichte 3, (i) As a catalyst in the dehydration of hy 426 (1871), Zeit. -

Standard X-Ray Diffraction Powder Patterns

PUBLICATIONS OF o Q NBS MONOGRAPH 25-SECTION 20 00 Q ar U.S. DEPARTMENT OF COMMERCE/National Bureau of Standards Standard X-ray Diffraction Powder Patterns 100 .U556 Mo. 25 Sect. 20" 1934 NATIONAL BUREAU OF STANDARDS The National Bureau of Standards' was established by an act ot Congress on March 3, 1901. The Bureau's overall goal is to strengthen and advance the Nation's science and technology and facilitate their effective application for public benefit. To this end, the Bureau conducts research and provides: (1) a basis for the Nation's physical measurement system, (2) scientific and technological services for industry and government, (3) a technical basis for equity in trade, and (4) technical services to promote public safety. The Bureau's technical work is per- formed by the National Measurement Laboratory, the National Engineering Laboratory, and the Institute for Computer Sciences and Technology. THE NATIONAL MEASUREMENT LABORATORY provides the national system of physical and chemical and materials measurement; coordinates the system with measurement systems of other nations and furnishes essential services leading to accurate and uniform physical and chemical measurement throughout the Nation's scientific community, industry, and commerce; conducts materials research leading to improved methods of measurement, standards, and data on the properties of materials needed by industry, commerce, educational institutions, and Government; provides advisory and research services to other Government agencies; develops, produces, and distributes -

(CDR) by CASRN Or Accession Number

List of Chemicals Reported for the 2012 Chemical Data Reporting (CDR) by CASRN or Accession Number For the 2012 CDR, 7,674 unique chemicals were reported by manufacturers (including importers). Chemicals are listed by CAS Registry Number (for non-confidential chemicals) or by TSCA Accession Number (for chemicals listed on the confidential portion of the TSCA Inventory). CASRN or CASRN or ACCESSION ACCESSION NUMBER CA INDEX NAME or GENERIC NAME NUMBER CA INDEX NAME or GENERIC NAME 100016 Benzenamine, 4-nitro- 10042769 Nitric acid, strontium salt (2:1) 10006287 Silicic acid (H2SiO3), potassium salt (1:2) 10043013 Sulfuric acid, aluminum salt (3:2) 1000824 Urea, N-(hydroxymethyl)- 10043115 Boron nitride (BN) 100107 Benzaldehyde, 4-(dimethylamino)- 10043353 Boric acid (H3BO3) 1001354728 4-Octanol, 3-amino- 10043524 Calcium chloride (CaCl2) 100174 Benzene, 1-methoxy-4-nitro- 100436 Pyridine, 4-ethenyl- 10017568 Ethanol, 2,2',2''-nitrilotris-, phosphate (1:?) 10043842 Phosphinic acid, manganese(2+) salt (2:1) 2,7-Anthracenedisulfonic acid, 9,10-dihydro- 100447 Benzene, (chloromethyl)- 10017591 9,10-dioxo-, sodium salt (1:?) 10045951 Nitric acid, neodymium(3+) salt (3:1) 100185 Benzene, 1,4-bis(1-methylethyl)- 100469 Benzenemethanamine 100209 1,4-Benzenedicarbonyl dichloride 100470 Benzonitrile 100210 1,4-Benzenedicarboxylic acid 100481 4-Pyridinecarbonitrile 10022318 Nitric acid, barium salt (2:1) 10048983 Phosphoric acid, barium salt (1:1) 9-Octadecenoic acid (9Z)-, 2-methylpropyl 10049044 Chlorine oxide (ClO2) 10024472 ester Phosphoric acid, -

Boron Delivery Agents for Neutron Capture Therapy of Cancer Rolf F

Barth et al. Cancer Commun (2018) 38:35 https://doi.org/10.1186/s40880-018-0299-7 Cancer Communications REVIEW Open Access Boron delivery agents for neutron capture therapy of cancer Rolf F. Barth1*, Peng Mi2 and Weilian Yang1,3 Abstract Boron neutron capture therapy (BNCT) is a binary radiotherapeutic modality based on the nuclear capture and fssion reactions that occur when the stable isotope, boron-10, is irradiated with neutrons to produce high energy alpha particles. This review will focus on tumor-targeting boron delivery agents that are an essential component of this binary system. Two low molecular weight boron-containing drugs currently are being used clinically, boronopheny- lalanine (BPA) and sodium borocaptate (BSH). Although they are far from being ideal, their therapeutic efcacy has been demonstrated in patients with high grade gliomas, recurrent tumors of the head and neck region, and a much smaller number with cutaneous and extra-cutaneous melanomas. Because of their limitations, great efort has been expended over the past 40 years to develop new boron delivery agents that have more favorable biodistribution and uptake for clinical use. These include boron-containing porphyrins, amino acids, polyamines, nucleosides, peptides, monoclonal antibodies, liposomes, nanoparticles of various types, boron cluster compounds and co-polymers. Cur- rently, however, none of these have reached the stage where there is enough convincing data to warrant clinical biodistribution studies. Therefore, at present the best way to further improve the clinical efcacy of BNCT would be to optimize the dosing paradigms and delivery of BPA and BSH, either alone or in combination, with the hope that future research will identify new and better boron delivery agents for clinical use. -

Shurflo Chemical Chart

Chemical Resistance Information: The Shurflo "Chemical Compatibility Chart" is based on a variety of information, comprised from our material suppliers' information, Engineering Lab Test Data, actual Field Test results and some generally published engineering data. This guide is believed to be accurate, but due to the many variables which may affect the compatibility of materials, this information should be considered as a guide only. Actual decisions on material selection need to be thoroughly tested and evaluated by the customer for each specific application. It is the full responsibility of the customer to perform and evaluate the compatibility of materials for their requirements. Non-chemical compatibility is excluded from the standard Shurflo Limited Warranty. All recommendations are based on ambient temperatures unless otherwise noted. RATINGS GUIDE A- EXCELLENT (No effect) B - GOOD - - - - - (Little to no effect) C - FAIR - - - - - - (Moderate effect) D - NOT RECOMMENDED (Severe effect) To help assist you with the proper selection of a pump for your application Shurflo has also included an "Application Specification Guide", Form MS-020-005 (Rev. 2/03). This guide will provide us with the system information we will need to properly spec the right pump for your applications. Please try to complete all sections of this form in as much detail as possible. If you need assistance or have any questions regarding this form, please give us a call at (800) 854-3218 and ask for one of our Application Engineers. They will be happy to assist -

Preparation of Conjugated Dienes

Europa,schesP_ MM M II M M MINI II Ml M M Ml J European Patent Office -i An n i © Publication number: 0 463 748 B1 Office europeen des brevets © EUROPEAN PATENT SPECIFICATION © Date of publication of patent specification: 21.06.95 © Int. CI.6: C07C 11/12, C07C 1/24, C07C 11/173, B01J 27/18 © Application number: 91304959.9 @ Date of filing: 31.05.91 © Preparation of conjugated dlenes. ® Priority: 04.06.90 GB 9012429 © Proprietor: ENICHEM ELASTOMERS LIMITED Charleston Road @ Date of publication of application: Hardley, Hythe 02.01.92 Bulletin 92/01 Southampton S04 6YY (GB) © Publication of the grant of the patent: @ Inventor: Hudson, Ian David 21.06.95 Bulletin 95/25 19 Marsh Drive, Freckleton © Designated Contracting States: Preston, PR4 1HJ (GB) BE DE ES FR IT NL Inventor: Hutchlngs, Graham John 17 North End © References cited: Osmotherley, EP-A- 0 162 385 N. Yorks. DL6 3BA (GB) EP-A- 0 174 898 EP-A- 0 272 663 © Representative: Jones, Alan John et al US-A 4 310 440 CARPMAELS & RANSFORD 43 Bloomsbury Square London, WC1A 2RA (GB) 00 00 00 CO Note: Within nine months from the publication of the mention of the grant of the European patent, any person ® may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition CL shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee LU has been paid (Art. 99(1) European patent convention). Rank Xerox (UK) Business Services (3. -

Dissolution Kinetics of Ulexite in Borax Pentahydrate Solutions Saturated with Carbon Dioxide

1st International Syposium on Sustainable Development, June 9-10 2009, Sarajevo Dissolution Kinetics of Ulexite in Borax Pentahydrate Solutions Saturated with Carbon Dioxide Soner Ku şlu Atatürk University, Faculty of Engineering, Chemical Engineering Dept. Erzurum, Turkey [email protected] Feyza Çavu ş Atatürk University, Faculty of Engineering, Chemical Engineering Dept. Erzurum, Turkey [email protected] Sabri Çolak Atatürk University, Faculty of Engineering, Chemical Engineering Dept. Erzurum, Turkey [email protected] Abstract: The aim of the study was to investigate the dissolution kinetics of ulexite in borax pentahydrate solutions saturated with carbon dioxide in a mechanical agitation system. The effects of reaction temperature, stirring speed, CO 2 flow rate, solid/liquid ratio and particle size on the rate of dissolution of ulexite were examined. It was observed that increase in the reaction temperature and decrease in the solid/liquid ratio causes an increase the dissolution rate of ulexite. The dissolution extent is not affected by the stirring speed rate in experimental conditions. The activation energy was found to be 58.7 kJ/mol. This value indicates the dissolution rate of ulexite is a chemically controlled reaction. The rate expression associated with the dissolution rate of ulexite depending on the parameters chosen may be summarized as: 1-(1-X) 1/3 = 7.4x10 5. D -0.8 . (S/L) -0.6 . W0.1 . e (-58700 /R T) .t Keywords: Ulexite, Borax Pentahydrate, Dissolution Kinetics, Heterogeneous reaction Introduction Boron is one of the most important mineral resources of Turkey (Davies et al., 1991). Turkey possesses 72% of the world’s boron reserves. -

Group 13 Chelates in Phosphate Dealkylation

University of Kentucky UKnowledge University of Kentucky Doctoral Dissertations Graduate School 2006 GROUP 13 CHELATES IN PHOSPHATE DEALKYLATION Amitabha Mitra University of Kentucky, [email protected] Right click to open a feedback form in a new tab to let us know how this document benefits ou.y Recommended Citation Mitra, Amitabha, "GROUP 13 CHELATES IN PHOSPHATE DEALKYLATION" (2006). University of Kentucky Doctoral Dissertations. 293. https://uknowledge.uky.edu/gradschool_diss/293 This Dissertation is brought to you for free and open access by the Graduate School at UKnowledge. It has been accepted for inclusion in University of Kentucky Doctoral Dissertations by an authorized administrator of UKnowledge. For more information, please contact [email protected]. ABSTRACT OF DISSERTATION Amitabha Mitra The Graduate School University of Kentucky 2006 GROUP 13 CHELATES IN PHOSPHATE DEALKYLATION ____________________________ ABSTRACT OF DISSERTATION ____________________________ A dissertation submitted in partial fulfillment of the requirements for the degree of Doctor of Philosophy in the College of Arts and Science at The University of Kentucky By Amitabha Mitra Lexington, Kentucky Director: Dr. David A. Atwood, Professor of Chemistry Lexington, Kentucky Copyright © Amitabha Mitra 2006 ABSTRACT OF DISSERTATION GROUP 13 CHELATES IN PHOSPHATE DEALKYLATION A series of mononuclear boron halides of the type LBX2 (LH = N-phenyl-3,5-di-t- butylsalicylaldimine, X = Cl (2), Br (3)) and LBX ( LH2 = N-(2-hydroxyphenyl)-3,5-di-t- butylsalicylaldimine, X = Cl (7), Br (8); LH2 = N-(2-hydroxyethyl)-3,5-di-t- butylsalicylaldimine, X = Cl (9), Br (10); LH2= N-(3-hydroxypropyl)-3,5-di-t- butylsalicylaldimine, X = Cl (11), Br (12)) were synthesized from their borate precursors LB(OMe)2 (1) (LH = N-phenyl-3,5-di-t-butylsalicylaldimine ) and LB(OMe) (LH2 = N- (2-hydroxyphenyl)-3,5-di-t-butylsalicylaldimine (4), N-(2-hydroxyethyl)-3,5-di-t- butylsalicylaldimine (5), N-(3-hydroxypropyl)-3,5-di-t-butylsalicylaldimine (6)).