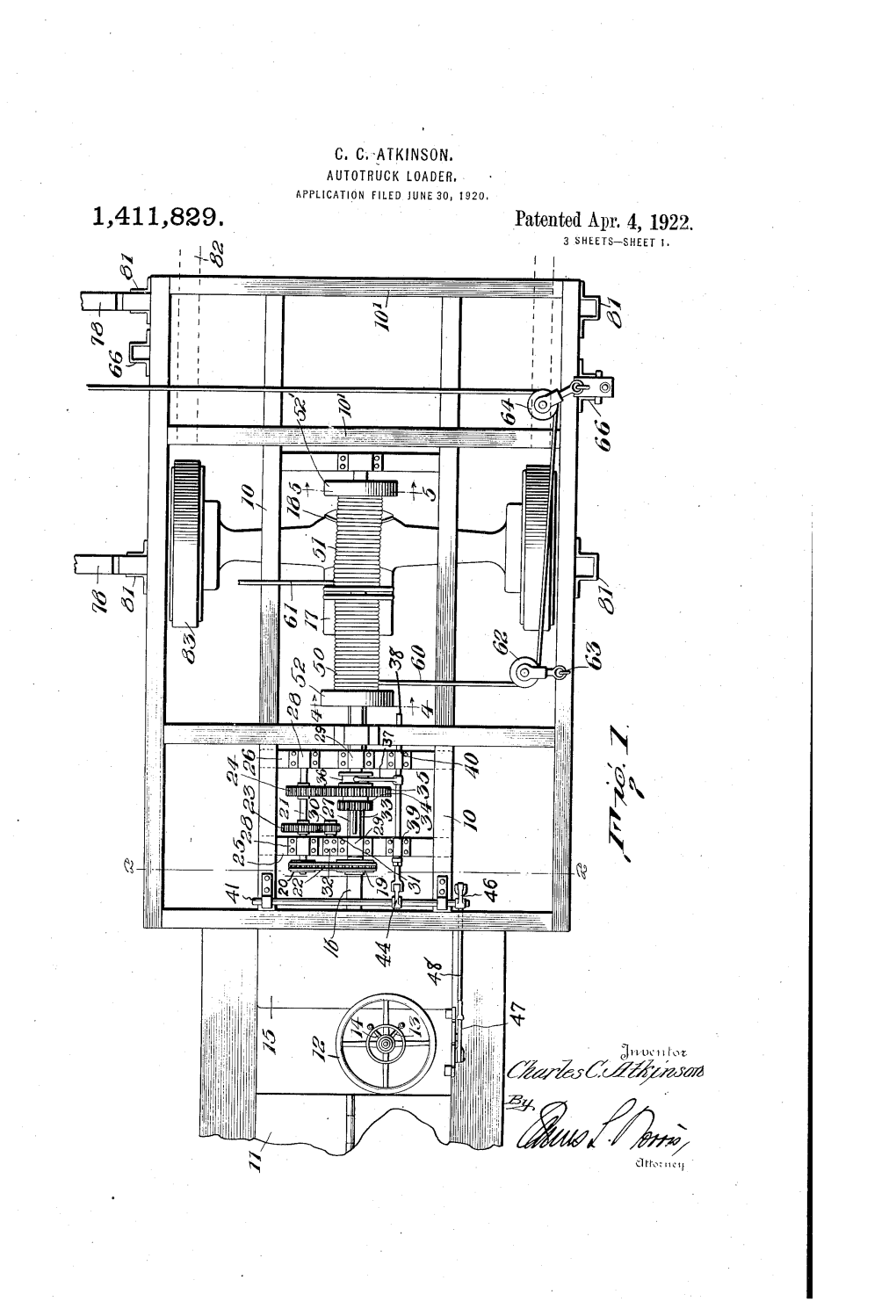

'Patented Apr. 4, 1922

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Alshire Records Discography

Alshire Discography by David Edwards, Mike Callahan & Patrice Eyries © 2018 by Mike Callahan Alshire International Records Discography Alshire was located at P.O. Box 7107, Burbank, CA 91505 (Street address: 2818 West Pico Boulevard, Los Angeles, CA 90006). Founded by Al Sherman in 1964, who bought the Somerset catalog from Dick L. Miller. Arlen, Grit and Oscar were subsidiaries. Alshire was a grocery store rack budget label whose main staple was the “101 Strings Orchestra,” which was several different orchestras over the years, more of a franchise than a single organization. Alshire M/S 3000 Series: M/S 3001 –“Oh Yeah!” A Polka Party – Coal Diggers with Happy Tony [1967] Reissue of Somerset SF 30100. Oh Yeah!/Don't Throw Beer Bottles At The Band/Yak To Na Wojence (Fortunes Of War)/Piwo Polka (Beer Polka)/Wanda And Stash/Moja Marish (My Mary)/Zosia (Sophie)/Ragman Polka/From Ungvara/Disc Jocky Polka/Nie Puki Jashiu (Don't Knock Johnny) Alshire M/ST 5000 Series M/ST 5000 - Stephen Foster - 101 Strings [1964] Beautiful Dreamer/Camptown Races/Jeannie With The Light Brown Hair/Oh Susanna/Old Folks At Home/Steamboat 'Round The Bend/My Old Kentucky Home/Ring Ring De Bango/Come, Where My Love Lies Dreaming/Tribute To Foster Medley/Old Black Joe M/ST 5001 - Victor Herbert - 101 Strings [1964] Ah! Sweet Mystery Of Life/Kiss Me Again/March Of The Toys, Toyland/Indian Summer/Gypsy Love Song/Red Mill Overture/Because You're You/Moonbeams/Every Day Is Ladies' Day To Me/In Old New York/Isle Of Our Dreams M/S 5002 - John Philip Sousa, George M. -

Sonman Shaft Coal Company Explosion of 1944 ....See Inside for Details Contents

Sonman Shaft Coal Company Explosion of 1944 ....see inside for details Contents Holmes Meeting, Western Kentucky Chapter ................................................................................ 3 Certificate of Safety Award ............................................................................................................ 4 Kentucky Chapter Updates............................................................................................................ 7 Story of Siltix Mine Explosion ........................................................................................................ 8 Sonman Shaft Coal Company Explosion .....................................................................................11 Safety Ideas................................................................................................................................. 18 JAHSA Event Schedule ............................................................................................................... 24 National Land Reclamation Award .............................................................................................. 25 Accident Prevention Alert ............................................................................................................ 26 The Mine Safety and Health Administration and Joseph A. Holmes Safety Association Bulletin contains safety articles on a variety of subjects: fatal accident abstracts, studies, posters, and other health and safety-related topics. This information is provided free of charge -

Immersion Into Noise

Immersion Into Noise Critical Climate Change Series Editors: Tom Cohen and Claire Colebrook The era of climate change involves the mutation of systems beyond 20th century anthropomorphic models and has stood, until recent- ly, outside representation or address. Understood in a broad and critical sense, climate change concerns material agencies that im- pact on biomass and energy, erased borders and microbial inven- tion, geological and nanographic time, and extinction events. The possibility of extinction has always been a latent figure in textual production and archives; but the current sense of depletion, decay, mutation and exhaustion calls for new modes of address, new styles of publishing and authoring, and new formats and speeds of distri- bution. As the pressures and re-alignments of this re-arrangement occur, so must the critical languages and conceptual templates, po- litical premises and definitions of ‘life.’ There is a particular need to publish in timely fashion experimental monographs that redefine the boundaries of disciplinary fields, rhetorical invasions, the in- terface of conceptual and scientific languages, and geomorphic and geopolitical interventions. Critical Climate Change is oriented, in this general manner, toward the epistemo-political mutations that correspond to the temporalities of terrestrial mutation. Immersion Into Noise Joseph Nechvatal OPEN HUMANITIES PRESS An imprint of MPublishing – University of Michigan Library, Ann Arbor, 2011 First edition published by Open Humanities Press 2011 Freely available online at http://hdl.handle.net/2027/spo.9618970.0001.001 Copyright © 2011 Joseph Nechvatal This is an open access book, licensed under the Creative Commons By Attribution Share Alike license. Under this license, authors allow anyone to download, reuse, reprint, modify, distribute, and/or copy this book so long as the authors and source are cited and resulting derivative works are licensed under the same or similar license. -

Scripting and Consuming Black Bodies in Hip Hop Music and Pimp Movies

SCRIPTING AND CONSUMING BLACK BODIES IN HIP HOP MUSIC AND PIMP MOVIES Ronald L Jackson II and Sakile K. Camara ... Much of the assault on the soulfulness of African American people has come from a White patriarchal, capitalist-dominated music industry, which essentially uses, with their consent and collusion, Black bodies and voices to be messengers of doom and death. Gangsta rap lets us know Black life is worth nothing, that love does not exist among us, that no education for critical consciousness can save us if we are marked for death, that women's bodies are objects, to be used and discard ed. The tragedy is not that this music exists, that it makes a lot of money, but that there is no countercultural message that is equally powerful, that can capture the hearts and imaginations of young Black folks who want to live, and live soulfully) Feminist film critics maintain that the dominant look in cinema is, historically, a gendered gaze. More precisely, this viewpoint argues that the dominant visual and narrative conventions of filmmaking generally fix "women as image" and "men as bearer of the image." I would like to suggest that Hollywood cinema also frames a highly particularized racial gaze-that is, a representational system that posi tions Blacks as image and Whites as bearer of the image.2 Black bodies have become commodities in the mass media marketplace, particu larly within Hip Hop music and Black film. Within the epigraph above, both hooks and Watkins explain the debilitating effects that accompany pathologized fixations on race and gender in Black popular culture. -

Johnstown, Pennsylvania and Vicinity

DEPARTMENT OF THE INTERIOR UNITED STATES GEOLOGICAL SURVEY GEORGE OTIS SMITH, DIRECTOR BULLETIN 447 MINERAL RESOURCES j . ' OF JOHNSTOWN, PENNSYLVANIA AND VICINITY BY W. C. PHALEN AND LAWRENCE MARTIN SURVEYED IN COOPERATION WITH THE TOPOGRAPHIC AND GEOLOGIC SURVEY COMMISSION OF PENNSYLVANIA WASHINGTON GOVERNMENT PRINTING OFFICE 1911 CONTENTS. Introduction.............................................................. 9 Geography............... ; .................................................. 9 Location.............................................................. 9 Commercial geography................................................... 9 Topography............................................................... 10 Relief...........................................................:.... 10 Surveys......... V.................................................... 11 Triangulation................................. fi. .................. 11 Spirit leveling.................................................... 13 Stratigraphy.............................................................. 14 General statement.................................................... 14 Quaternary system..................................................... 15 Recent river deposits (alluvium).................................... 15 Pleistocene deposits............................................... 15 Carboniferous system. r ............................................... 16 Pennsylvanian series ............................................... 16 Conemaugh formation......................................... -

The Fetishization of Firearms in African-American Folklore and Culture

THE FETISHIZATION OF FIREARMS IN AFRICAN-AMERICAN FOLKLORE AND CULTURE A Dissertation Presented to The Faculty of the Graduate School University of Missouri-Columbia In Partial Fulfillment of the Requirements for the Degree Doctor of Philosophy by RAYMOND MELTON JAVON SU8MMERVILLE Dr. Anand Prahlad, Dissertation Supervisor DECEMBER 2016 © Copyright by Raymond Melton Javon Summerville 2016 All Rights Reserved The undersigned, appointed by the dean of the Graduate School, have examined the dissertation entitled: The Fetishization of Firearms in African-American Folklore and Culture presented by Raymond Summerville, a candidate for the degree of doctor of philosophy, and hereby certify that, in their opinion, it is worthy of acceptance. Professor Anand Prahlad Professor Karen Piper Professor Joanna Hearne Professor Richard Callahan For my mother, Mrs. Sheila Bernice Almond Summerville September 24, 1956—March 1, 2016 ACKNOWLEDGEMENTS I would like to thank my parents, Melton and (the late) Sheila Summerville for instilling in me their work ethic and strong values. All of my friends, immediate and extended family who have volunteered their generous support over the years. I would especially like to thank my advisor Dr. Anand Prahlad for all of his creative insights, constructive feedback, and guidance. He has been an exceptional role model who has encouraged me to continue to strive to reach my personal and professional goals. I would like to thank Dr. Lawless for her valued teachings and for supporting my initial interest in folklore studies. I would also like to thank all of my committee members, Dr. Hearne, Dr. Callahan, and Dr. Piper. Their continued support has been vital. -

"Now I Ain't Sayin' She's a Gold Digger": African American Femininities in Rap Music Lyrics Jennifer M

Florida State University Libraries Electronic Theses, Treatises and Dissertations The Graduate School 2008 "Now I Ain't Sayin' She's a Gold Digger": African American Femininities in Rap Music Lyrics Jennifer M. Pemberton Follow this and additional works at the FSU Digital Library. For more information, please contact [email protected] FLORIDA STATE UNIVERSITY COLLEGE OF SOCIAL SCIENCES “NOW I AIN’T SAYIN’ SHE’S A GOLD DIGGER”: AFRICAN AMERICAN FEMININITIES IN RAP MUSIC LYRICS By Jennifer M. Pemberton A Dissertation submitted to the Department of Sociology in partial fulfillment of the requirements for the degree of Doctor of Philosophy Degree Awarded: Spring Semester, 2008 The members of the Committee approve the dissertation of Jennifer M. Pemberton defended on March 18, 2008. ______________________________ Patricia Yancey Martin Professor Directing Dissertation ______________________________ Dennis Moore Outside Committee Member ______________________________ Jill Quadagno Committee Member ______________________________ Irene Padavic Committee Member Approved: ___________________________________ Irene Padavic, Chair, Department of Sociology ___________________________________ David Rasmussen, Dean, College of Social Sciences The Office of Graduate Studies has verified and approved the above named committee members. ii For my mother, Debra Gore, whose tireless and often thankless dedication to the primary education of children who many in our society have already written off inspires me in ways that she will never know. Thank you for teaching me the importance of education, dedication, and compassion. For my father, Jeffrey Pemberton, whose long and difficult struggle with an unforgiving and cruel disease has helped me to overcome fear of uncertainty and pain. Thank you for instilling in me strength, courage, resilience, and fortitude. -

Composite Material Advances in the Golf Industry

COMPOSITE MATERIAL ADVANCES IN THE GOLF INDUSTRY Jerome S. Berg Manager of Technical Service, True Temper Sports Society of Manufacturing Engineers-Board Advisor Representing the Recreation Industry SUMMARY: The popularity of carbon fiber composites as a primary structure for components in sporting goods appeared to gain momentum in the late 1980s and early 1990s. Particularly in the golf industry, these materials offered lighter weight, a variety of design options not possible with steel, and a high tech image to a rather affluent market. The sporting goods consumer desires equipment which represents the latest technology and is more expensive than his competitor’s. Sporting goods companies are searching for the next advanced material that will allow them to gain another niche in the marketplace which will command a higher price and margin. Successfully implementing these new technologies with the associated research and development requires partnerships among the sporting goods industries, the material vendors, and the academic community. Several product development efforts including metal matrix materials, robust resin systems, and high modulus carbon fibers are discussed. KEYWORDS: sporting goods, golf, metal matrix, composites INTRODUCTION Background and Historical Perspective Advanced materials and new processing technology has created the phenomenon of high-end sporting and recreational equipment for which sports enthusiasts are willing to pay a premium. It is not uncommon to find someone who is willing to pay $2500 for a cutting-edge bicycle made from advanced materials or $500 for a golf club driver. In fact, many of the dilemmas in introducing expensive composite materials faced by the aerospace markets are actually opportunities in the sports market, where a higher material price and material prestige is often a marketing advantage. -

Beanie Sigel Albums Free Download

Beanie sigel albums free download Continue Also known as B. Siegel, Beanie, Beanie Mac, Beanie S., Beanie Segal, Beanie Seagel, Beanie Segal, Beanie Seigal, Beanie Seigel, Beanie Siegal, Beanie Siegel, Beanie Siegle, Beanie Sigel Production Team, BeanieSigel, Beannie, Beans, Beenie Beenie, Beenie Seigel, Beenie Seigel, Beenie Siegal, Beenie Siegle, Beenie Sigel, Bennie Sigel, Bennie Sigel Listen to this album and over 60 million songs with unlimited streaming plans. 1 month free, then $14.99/month Page 2 You are currently listening to samples. Listen to more than 60 million songs with an unlimited streaming plan. Listen to this album and over 60 million songs with unlimited streaming plans. 1 month free, then $14.99/month Page 3 You are currently listening to samples. Listen to more than 60 million songs with an unlimited streaming plan. Listen to this album and over 60 million songs with unlimited streaming plans. 1 month free, then $14.99/month Page 4 You are currently listening to samples. Listen to more than 60 million songs with an unlimited streaming plan. Listen to this album and over 60 million songs with unlimited streaming plans. 1 month free, then $14.99/month is a discography of Beanie Sigel, an American rapper. Albums Studio Albums List of Studio Albums, with Selected Chart Positions, Sales Figures and Title Certification Album Details Peak Chart Position Sales Certificates US 2000 Label: Roc-A-Fella, Def Jam Formats: CD, LP, cassette, digital download 5 2 1 USA: 695,000 RIAA: Gold: June 26, 2001 Label: Roc-A-Fella, Def Jam Formats: CD, LP, cassette, digital download 5 1 USA: 585,000 RIAA: Gold B. -

Governor Maintenance

Best Practice Update: GOVERNOR MAINTENANCE ALL Power Labs Technical Bulletin: #TB79500006 Release Date: July 2016 SUBJECT: Governor Throttle Cleaning & Maintenance Pro cedure. Availability of Governor Manifold Upgrade Kit (UGK) Part # 87700017 A Models: PP20 Symptom: Governor’s throttle plate gets stuck shut, so engine won’t start. Also, poor performance and/or low or varying power, and “hunting” (i.e. rising and falling of engine RPM/frequency) from “crunchy,” unsmooth throttle motion. Cause: Tar and soot building up in governor throttle butterfly shaft and bearings preventing smooth and free movement. Governor throttle be eaned y un & checked eaned e If the Actions: must cl after ever r or cl befor starting. following procedure is strictly adhered to on new governors, bearings should remain free. Procedure: Clean and lubricate the throttle shaft, throttle butterfly plate and throat thoroughly immediately after every shutdown. NOTE: Cleaning is much easier when the dirt is fresh and parts are warm. If the normal tar deposits are not cleaned following a run, they can thicken as they cool and may glue the throttle closed which can keep engine from starting. If you wait to clean, it will take more solvent and effort to get it clean. You will need rubber gloves, a squirt bottle of solvent, rags or paper towels, a long rod or screwdriver, automotive grease (white lithium, axle etc.) and 2.5 mm hex key. NOTE: If you do not already have a quick- release sani clamps, you should install the Governor Upgrade Kit (UGK APL # 877-00017 A) to make governor removal easier. -

The Politics of Shaft: Positioning a Popular Cultural Icon in 1971, 2000 and 2019

Open Journal of Political Science, 2021, 11, 419-438 https://www.scirp.org/journal/ojps ISSN Online: 2164-0513 ISSN Print: 2164-0505 The Politics of Shaft: Positioning a Popular Cultural Icon in 1971, 2000 and 2019 Magnus Dahlstedt1, Peter Ehrström2 1Department of Culture and Society, Linköping University, Norrköping, Sweden 2Regional Science, Faculty of Education and Welfare Studies, Åbo Akademi University, Vaasa, Finland How to cite this paper: Dahlstedt, M., & Abstract Ehrström, P. (2021). The Politics of Shaft: Po- sitioning a Popular Cultural Icon in 1971, This article focuses on how popular culture relates to both society and poli- 2000 and 2019. Open Journal of Political Sci- tics, as a barometer of the present. In a sense, popular culture both mirrors ence, 11, 419-438. https://doi.org/10.4236/ojps.2021.113029 and articulates specific ways of understanding society, the present. In this ar- ticle, we will investigate one specific expression of popular culture, the Afri- Received: May 10, 2021 can American action movie hero Shaft, and how this character appears in Accepted: July 4, 2021 Published: July 7, 2021 different shapes, in different times and contexts. The aim of the article is to examine how the character Shaft appears in three movies, from 1971, 2000 Copyright © 2021 by author(s) and and 2019. This examination draws attention to how three different shapes of Scientific Research Publishing Inc. Shaft materialise, with different values attributed to the character of Shaft. This work is licensed under the Creative Commons Attribution International Specific focus is put on the socio-political expressions of the day and the lo- License (CC BY 4.0). -

Materials for Aircraft Engines

ASEN 5063 Aircraft Propulsion Final Report 2015 Materials for Aircraft Engines TAKEHIRO OKURA Contents 1. Overview ............................................................................................................................................................... 2 2. Fan Section ............................................................................................................................................................ 3 2.1. Fan Blade ...................................................................................................................................................... 3 2.2. Fan Case ........................................................................................................................................................ 4 3. Compressor Section ............................................................................................................................................... 5 4. Combustor Section ................................................................................................................................................ 5 5. Turbine Section...................................................................................................................................................... 6 5.1. Turbine Blade ............................................................................................................................................... 6 5.2. Ni-based superalloys ....................................................................................................................................